Professional Documents

Culture Documents

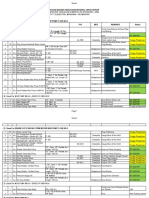

Materials Requirement For Stamping: S.no Machine Name Materials Name Spec's Qty Remark

Uploaded by

Sathish PSK0 ratings0% found this document useful (0 votes)

5 views4 pagesThe document provides a list of 20 materials required for various stamping machines. It includes the machine name, material name, specifications, quantity, and any remarks for each item. The materials include sensors, filters, couplings, pins, blocks, bearings, relays, silencers, breathers, seal kits, o-rings, and guides needed to address issues like oil leakages on machines like the 1250T/630T, 250T, 400T, 110T, and others. Quantities range from 1 to 20 pieces per item.

Original Description:

Original Title

Spares Required 2021-2022

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a list of 20 materials required for various stamping machines. It includes the machine name, material name, specifications, quantity, and any remarks for each item. The materials include sensors, filters, couplings, pins, blocks, bearings, relays, silencers, breathers, seal kits, o-rings, and guides needed to address issues like oil leakages on machines like the 1250T/630T, 250T, 400T, 110T, and others. Quantities range from 1 to 20 pieces per item.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views4 pagesMaterials Requirement For Stamping: S.no Machine Name Materials Name Spec's Qty Remark

Uploaded by

Sathish PSKThe document provides a list of 20 materials required for various stamping machines. It includes the machine name, material name, specifications, quantity, and any remarks for each item. The materials include sensors, filters, couplings, pins, blocks, bearings, relays, silencers, breathers, seal kits, o-rings, and guides needed to address issues like oil leakages on machines like the 1250T/630T, 250T, 400T, 110T, and others. Quantities range from 1 to 20 pieces per item.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Materials requirement for stamping

S.no Machine Name Materials Name Spec's Qty Remark

1 1250/630 T 2D sensor PR08-2DN 20 no's

2 1250/630 T 3D sensor PR12-4DN 20no's

255x255

Panel cooling air filter with 6 no's

3 250 T ,400 T ,110T mm,116.5x116.

cover ,6no's

5 mm

Power pack filter for clutch already

4 630 T 4 no's

/brake and lub tank also purchased

Spider coupling for de- as per coupling

5 400T mech 2 no's

coiler power pack photos

6 1250T/630T Proximity sensor PRDCM 12 8DN 8 no's

7 110 T Clutch brocket pin as per drawing 2 no's

8 110 T Clutch rectangular block as per drawing 2 no's

as per sample

9 110T sprical plain push bearing 2 no's

and drawing

10 110 T /conventional Clutch brocket pin as per drawing 2 no's

11 63 T B conventional Clutch brocket pin as per sample 2 no's

as per sample

12 110T /conventional sprical plain push bearing 2 no's

and drawing

13 250 T /400 T Honeywell relay as per sample 20no's

14 General DCV silencer 1/4" -brass 5no's

15 General DCV silencer 1/8" -brass 5no's

16 General DCV silencer 3/8" -brass 5no's

17 400 T Mech Hol breather size 1" 1no

Piston seal,290

OD x 260 ID

x19,

Polyurethane,

Hardness 93-95

Seal kit and Oring kit for pit

18 400 T Mech Shore-A,WP- 2 no's

man oil leakages issue

400

bar,W.temp : -

40°C to +100°C

,W.medium:

Oil.

O-ring Ø6.99

Seal kit and Oring kit for pit Sec .x275 ID

19 400 T Mech 4no's

man oil leakages issue (Hardness 90-

92 Shore A )

Pistton Guide

Seal kit and Oring kit for pit ring ,2.5 Thk x

20 400 T Mech 2no's

man oil leakages issue 9.5 Width x 911

LG

You might also like

- PRESSURE VESSELS REQUISITIONDocument2 pagesPRESSURE VESSELS REQUISITIONibrahimNo ratings yet

- Engine Room Stores - (Returns, Different and Not Received Items)Document6 pagesEngine Room Stores - (Returns, Different and Not Received Items)tharindu hasarangaNo ratings yet

- Dual Discharge Unit CoolersDocument2 pagesDual Discharge Unit CoolersClarence JarlosNo ratings yet

- Kumwell Code No - REVISI.Document1 pageKumwell Code No - REVISI.Ahmad ZulkarnaenNo ratings yet

- Fluid Power Tee SealsDocument2 pagesFluid Power Tee Sealsmetall 4uNo ratings yet

- Himachal Pardesh State Electricity Board LTDDocument7 pagesHimachal Pardesh State Electricity Board LTDaayush70755No ratings yet

- MTOCO001008Document8 pagesMTOCO001008Mohamed Rizk100% (1)

- SUPERTYFON AT 150-200 With Valve Unit TV 784Document6 pagesSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshNo ratings yet

- Sing Te International Enterprise CO.,LTD - LTD.: CatalogDocument64 pagesSing Te International Enterprise CO.,LTD - LTD.: CatalogMauricio OjedaNo ratings yet

- Product Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCDocument9 pagesProduct Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCJosé Isaac Chávez HuamánNo ratings yet

- Engine Service Parts for Land Rover Defender and Discovery 1Document14 pagesEngine Service Parts for Land Rover Defender and Discovery 1Billy FoxNo ratings yet

- Stainless steel putty knife, sandpaper, epoxy, cylinders & moreDocument2 pagesStainless steel putty knife, sandpaper, epoxy, cylinders & moreFrancisCarloTadenaNo ratings yet

- Rite Touch™ Electric Kit & Replacement PartsDocument1 pageRite Touch™ Electric Kit & Replacement PartsJose Luis DominguezNo ratings yet

- List of Critical Spares & Consumables Final Updated On 01.12.2021Document2 pagesList of Critical Spares & Consumables Final Updated On 01.12.2021suraj rawatNo ratings yet

- Atuadores Quifer Séries KP e KMDocument14 pagesAtuadores Quifer Séries KP e KMAdriano SilvaNo ratings yet

- Supplies & Solutions: For Every IndustryDocument2 pagesSupplies & Solutions: For Every IndustryranjithNo ratings yet

- TFP1540 02 2017Document6 pagesTFP1540 02 2017Rashel HasanNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- ICp PerkinDocument4 pagesICp PerkinLeila EspinosaNo ratings yet

- 3月份电气备件计划Electrical - Spare - Parts - Program - for - july kilnDocument6 pages3月份电气备件计划Electrical - Spare - Parts - Program - for - july kilnbewenet abayNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- Stringing T&P Reqd For A606 765 KV Dc-ZebraDocument3 pagesStringing T&P Reqd For A606 765 KV Dc-Zebraprithvirajd20No ratings yet

- Electronic PartsDocument65 pagesElectronic PartswaggcasNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- ASCO - Fluid Valves OCT06Document2 pagesASCO - Fluid Valves OCT06safinditNo ratings yet

- CC - HC - Open GrilDocument2 pagesCC - HC - Open GrilDiego Antonio Alonso PinedaNo ratings yet

- Evaluasi Teknis SP SHALE SHAKERDocument13 pagesEvaluasi Teknis SP SHALE SHAKEREraldo RiverNo ratings yet

- Dear Sir,: Remal Al-Rafedain (Rar) For General Contracting LTDDocument2 pagesDear Sir,: Remal Al-Rafedain (Rar) For General Contracting LTDRa'ad HaniNo ratings yet

- Ficha Tecnica - HP-2402Document10 pagesFicha Tecnica - HP-2402Benjamin MillerNo ratings yet

- B.O.M - 130 & 139Document6 pagesB.O.M - 130 & 139er_paramjeetgillNo ratings yet

- Datasheet, Technical Data Performer Scroll Compressor, SM185-4Document8 pagesDatasheet, Technical Data Performer Scroll Compressor, SM185-4Sebastian OctavianoNo ratings yet

- Lampira RQ1revDocument5 pagesLampira RQ1revZulkepri ManaluNo ratings yet

- Marc and Jenssen Industrial CorporationDocument12 pagesMarc and Jenssen Industrial CorporationAdrian Bien SaturnoNo ratings yet

- Uttern D62 - 2016 Parts CatalogueDocument64 pagesUttern D62 - 2016 Parts CatalogueSimenNo ratings yet

- UntitledDocument8 pagesUntitledTomas MalyNo ratings yet

- Pump CatalogAC PowerDocument8 pagesPump CatalogAC Powernadir belaghitNo ratings yet

- Consumable WsDocument7 pagesConsumable WsBahtiar SetiawanNo ratings yet

- Tilting Machine Hose DetailsDocument15 pagesTilting Machine Hose Detailssiruslara6491No ratings yet

- Cek Piso, Dempul Dan NylonDocument13 pagesCek Piso, Dempul Dan NylonAl MusyafirinNo ratings yet

- FPB Nitrile U-CupsDocument2 pagesFPB Nitrile U-CupsNCvetarskyNo ratings yet

- Parthenon PedalPCBDocument6 pagesParthenon PedalPCBnghtlghtNo ratings yet

- Mewp TL SeriesDocument54 pagesMewp TL SeriesEmanuel FuenzalidaNo ratings yet

- Pump, Tandem - MountingDocument2 pagesPump, Tandem - MountingJESUSNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument10 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionJennifer SalamancaNo ratings yet

- MTZ36-4VM - Danfoss CompressorDocument3 pagesMTZ36-4VM - Danfoss CompressorAnca SterianNo ratings yet

- Specification Sheet: Centrifuge For Petrol and Mineral OilsDocument3 pagesSpecification Sheet: Centrifuge For Petrol and Mineral Oilsh8pb8jzyhgNo ratings yet

- DS5404 Standard US ENDocument4 pagesDS5404 Standard US ENkicsnerNo ratings yet

- SZ185Document9 pagesSZ185TÁ CURRUTNo ratings yet

- Commercial Unit CoolersDocument2 pagesCommercial Unit CoolersClarence JarlosNo ratings yet

- CC - WSS - Open GrilDocument17 pagesCC - WSS - Open GrilDiego Antonio Alonso PinedaNo ratings yet

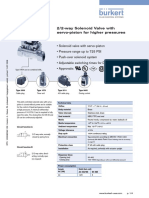

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- Rev MR TATA 1 MGDocument6 pagesRev MR TATA 1 MGSurajNo ratings yet

- Section Detail Drawing and Part List for Turbo SifterDocument4 pagesSection Detail Drawing and Part List for Turbo SiftertrungNo ratings yet

- Description: - Butterfly Valve DN 32 - 900Document8 pagesDescription: - Butterfly Valve DN 32 - 900thehuy015No ratings yet

- Norgren Push-In FittingsDocument9 pagesNorgren Push-In Fittingsalex.lenagroNo ratings yet

- Parker 3 Way SolenoidDocument8 pagesParker 3 Way SolenoidFlavius DumitrescuNo ratings yet

- EL - 4156 (MRL - 6P-Auto) G+5 FinalDocument12 pagesEL - 4156 (MRL - 6P-Auto) G+5 FinaljayakumarNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

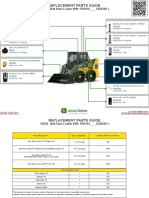

- 312GR Skid Steer Loader PIN 1T0312G G366358 Replacement Parts GuideDocument3 pages312GR Skid Steer Loader PIN 1T0312G G366358 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- Esp Module 4Document34 pagesEsp Module 4ELLEN B.SINAHONNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Ahmed KhedrNo ratings yet

- Science 10 - Q1 - W5 - D2Document1 pageScience 10 - Q1 - W5 - D2zenaida a academiaNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Swapnil Pratap SinghNo ratings yet

- Techspec XS enDocument2 pagesTechspec XS enpesumasinadNo ratings yet

- Q12 KeyDocument3 pagesQ12 KeyMuhammad AbdullahNo ratings yet

- pc102 - Final ProjectW13 - Ramon GutierrezDocument10 pagespc102 - Final ProjectW13 - Ramon GutierrezEJ LacdaoNo ratings yet

- A Geometric Method For Kinematics of Delta Robot and Its Path Tracking Control PDFDocument6 pagesA Geometric Method For Kinematics of Delta Robot and Its Path Tracking Control PDFJameszouqunNo ratings yet

- السيرة الذاتيةDocument1 pageالسيرة الذاتيةYounesNo ratings yet

- File 5119 PDFDocument5 pagesFile 5119 PDFIsabele LavadoNo ratings yet

- Nitro2 User Manual v2.24 PDFDocument29 pagesNitro2 User Manual v2.24 PDFReifesxd ProNo ratings yet

- Datasheet - CI 7432Document5 pagesDatasheet - CI 7432Alexandre NettoNo ratings yet

- This Study Resource WasDocument6 pagesThis Study Resource WasRian RorresNo ratings yet

- Dual-band patch antenna for 5G applicationsDocument3 pagesDual-band patch antenna for 5G applicationsHarini VemulaNo ratings yet

- 78ac PDFDocument7 pages78ac PDFvhgiaoNo ratings yet

- Microwave Engineering FundamentalsDocument24 pagesMicrowave Engineering Fundamentalsjm m100% (1)

- ConclusionDocument1 pageConclusionSAVITHRINo ratings yet

- Kick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. KlefDocument13 pagesKick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. Klefavula43No ratings yet

- Catwalk Walk Base Plate Grouting 1Document30 pagesCatwalk Walk Base Plate Grouting 1MdShahbazAhmedNo ratings yet

- Modern Control Systems Linear Approximation Laplace TransformDocument3 pagesModern Control Systems Linear Approximation Laplace TransformramNo ratings yet

- Plan Test Strategy for Flight Search WebsiteDocument13 pagesPlan Test Strategy for Flight Search WebsiteНаталья ПримаNo ratings yet

- PLC Ladder Examples 2021Document18 pagesPLC Ladder Examples 2021JosephNo ratings yet

- Liftking Forklift PDIDocument1 pageLiftking Forklift PDIManual ForkliftNo ratings yet

- (GR No. 15574) Smith, Bell & Co Vs NatividadDocument18 pages(GR No. 15574) Smith, Bell & Co Vs Natividadshopee onlineNo ratings yet

- 20NCT2 1784 SampleDocument12 pages20NCT2 1784 Samplekimjohn dejesusNo ratings yet

- SA-10/20 User ManualDocument31 pagesSA-10/20 User ManualJorgeLuis Anaya NúñezNo ratings yet

- Philippines Customs Law and ProceduresDocument70 pagesPhilippines Customs Law and ProceduresRojusandino Acevedo Ylagan50% (2)

- Mitchell Board of Education June 26 Meeting AgendaDocument33 pagesMitchell Board of Education June 26 Meeting AgendainforumdocsNo ratings yet

- Optimize School Distribution With MappingDocument5 pagesOptimize School Distribution With MappingRolyn ManansalaNo ratings yet