Professional Documents

Culture Documents

Stone Jaw Crusher

Uploaded by

Karin AndersonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stone Jaw Crusher

Uploaded by

Karin AndersonCopyright:

Available Formats

MST Jaw Crusher Highlights

High quality and Reliability

Repairable crusher construction.

Low operating and installation cost

Fast and safe wedge setting adjustment system.

Productivity

Increased stroke for greater capacity.

Large eccentric shaft for greater stroke in the upper chamber.

Large fly wheel provides continuous crushing in toughest applications.

Durability

Stress relieved base frame for higher integrity.

Mild steel fabrication for greatest strength

JAW CRUSHER

Deep pitch gripped jaws for maximum reduction. with minimum weight. MST Series

One year warranty | Quick deliveries | Off the shelf parts | Nationwide distribution | Supplier quality

Single Toggle Jaw Crusher Specifications and Dimensions

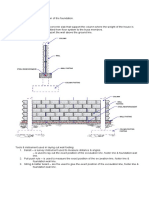

E

I

H

D

F

K

J

C

SIZE A B C D E F G H I J K L

MST 16" X 8" 1355 1050 240 600 210 840 200 1390 1710 1150 400 1020

MST 16" X 12" 1355 1050 240 600 210 840 300 1490 1810 1150 400 1020

MST 20" X 8" 1355 1050 240 600 210 840 200 1390 1710 1260 500 1120

MST 20" X 12" 1355 1050 240 600 210 840 300 1490 1810 1260 500 1120

MST 24" X 8" 1465 1150 300 600 200 900 200 1450 1750 1460 600 1120

MST 24" X 12" 1465 1150 300 600 200 900 300 1550 1850 1460 600 1190

MST L -24" X 20" 1665 1150 300 800 200 1100 500 1805 2105 1460 600 1190

MST 30" X 8" 1495 1150 300 600 250 900 200 1535 2070 1628 750 1340

MST L- 30" X 20" 1695 1150 300 800 250 1100 500 1835 2370 1628 750 1340

MST 36" X 8" 1550 1300 300 600 225 900 200 1700 2020 1890 900 1500

MST L- 36" X 24" 1750 1300 300 800 250 1100 600 2105 2525 1890 900 1550

MST 42" X 8" 1550 1300 300 600 250 900 200 1850 2370 2244 1050 1730

MST L- 42" X 24" 1750 1300 300 800 250 1100 600 2150 2670 2244 1050 1730

MST EL - 42" X 32" 2650 1300 300 1700 250 2000 800 2350 2870 2244 1050 1730 M. R. Engineers Pvt. Limited

MST 48" X 8" 2050 1500 300 1000 250 1300 200 1860 2380 2410 1200 1800 Jampali By Pass Road,

MST L - 48" X 24" 2250 1500 300 1200 250 1500 600 2160 2680 2410 1200 1800 Garvana, At - Rajgangpur,

Dist- Sundergarh - 770017, Orissa

MST EL - 48" X 32" 2750 1500 300 1700 250 2000 800 2350 2870 2410 1200 1800

Tel: +91 9337 140761 / +91 6624 220761

L - LONG TYPE PITMAN / JAW STOCK

Fax: +91 6624 222761 Engineering Future

EL - EXTRA LONG TYPE PITMAN / JAW STOCK

Notice: Any change of Jaw Crusher Specifications shall not be advised additionally. business@mrudyog.com www.mrudyog.com ISO 9001 Registered AN ISO 9001-2008 COMPANY

Page5 Page6 Page1

Crushing Competition Since 1980’s

TECHNICAL DATA

A Single Toggle Jaw Crusher consists of a set of This machine can be used as a granulator as well

vertical jaws, one jaw being fixed and the other as a breaker. In general, jaw crusher is applied as Model Feed Max feed Setting Capacity Power Weight RPM Overall Dimension

being moved back and forth relative to it by a cam primary crusher, in any crushing circuit. It is INCH Opening(mm) size(mm) Adjustment (t/h) (HP) K.W (t) (mm)

or pitman mechanism. The jaws are farther apart generally recommended to use material hardness

Range (mm)

at the top than at the bottom, forming a tapered above 4 in Mohr's hardness. Soft material tends to Jaw Stock

chute so that the material is crushed progressively generate more fines. In this case use a variable Jaw Stock (Pitman) designed to handle severe crushing 16 X8 400 X 200 < 150 25 - 40 10/12 30/ 22.5 4.5 350 1355 X 1710 X 1150

smaller and smaller as it travels downward until it pulley to restrict rpm of the machine. Single Toggle conditions. It can be removed from the frame as an 16 X 12 400X 300 < 250 50 - 100 15 - 20 30/22.5 4.5 325 1355 X 1810 X 1150

is small enough to escape from the bottom jaw crushers are constructed of heavy duty assembly. Mild steel fabrication and precision machined 20 X 8 500 X 200 < 150 25 - 40 13-16 35/26 5 350 1355 X 1710 X 1260

opening. The movement of the jaw can be quite fabricated plate frames with reinforcing ribs for greatest strength with minimum weight. It achieves

its movement through the eccentric machining of the 20 X 12 500 X 300 < 250 50 - 75 20-25 35/26 5 325 1355 X 1810 X 1260

small, since complete crushing is not performed in throughout. The crushers components are of high

one stroke. The inertia required to crush the strength design to accept high power draw. flywheel shaft. 24 X 8 600 X 200 < 150 25 - 40 20-25 40/30 6.3 350 1465 X 1750 X 1460

material is provided by a weighted flywheel that Manganese steel is used for both fixed and 24 X 12 600 X 300 < 250 50 - 100 30-40 40/30 6.5 325 1465 X 1850 X 1460

moves a shaft creating an eccentric motion that movable jaw faces. L 24 X 20 600 X 500 < 400 100 - 200 35-60 40/30 7 300/325 1665 X 2105 X 1460

causes the closing of the gap. Jaw Wedge 30 X 8 750 X 200 < 150 25 - 40 25-30 50/37.5 7 350 1495 X 2070 X 1628

L 30 X 20 750 X 500 < 400 100 -200 40-70 50/37.5 10 300/325 1695 X 2370 X 1628

36 X 8 900 X 200 < 150 25 - 40 30-40 60/45.0 9.5 350 1550 X 2020 X 1890

Fly Wheel Bearing Housings Jaw stock Bearing L 36 X 24 900 X 600 < 500 100 - 200 80-120 60/45.0 13 300/325 1750 X 2525 X 1890

Made of Solid Cast Iron Grade 20 driven Made of Graded Cast Steel IS:1030. Removable 42 X 8 1050 X 200 < 150 25 - 40 40-50 80/60 12 350 1550 X 2370 X 2244

Side Plates by V- Belt or Flat Belts. Extra large bearing housings make servicing easier and guard L 42 X 24 1050 X 600 < 500 100 - 200 85-130 100/75 17 300 1750 X 2670 X 2244

It helps to protect the Crusher Body diameter, counter weight to balance the against contamination. Long life Bearing Housing Eccentric Shaft

eccentric load of the machine and heavy EL 42 X 32 1050 X 800 < 700 150 - 250 200-300 100/75 23 275/300 2650 X 2870 X 2244

made of high-strength manganese and less maintenance. Massive, oversized, heat-treated shaft forged of special

steel Grade - III. split hub flywheels for smooth operation 48 X 8 1200 X 200 < 150 25 - 40 45-60 100/75 17 350 2050 X 2380 X 2410

alloy to provide an exceptionally large eccentric throw

even in tough conditions which helps to L 48 X 24 1200 X 600 < 500 100 - 200 100-150 120/90 20 300 2250 X 2680 X 2410

and to handle overloads and hard materials. It is also

reduce power consumption.

ultrasonically tested. EL 48 X 32 1200 X 800 < 700 150 - 250 250-350 120/90 25 275/300 2750 X 2870 X 2410

Main Frame

Extra Heavy duty, welded by sophisticated welding L - LONG TYPE PITMAN / JAW STOCK

techniques, thermally stress relieved, high strength EL - EXTRA LONG TYPE PITMAN / JAW STOCK

steel frame withstands the constant pressures of Toggle Bearing Notice: Any change of Jaw Crusher technical data shall not be advised additionally.

crushing. Body is ribbed by thick plates to give Our heavy duty, premium quality, grease

adequate strength. Repairable crusher construction. lubricated self aligned spherical roller bearings

offer substantially more bearing life and feature

true rolling motion and ability to carry severe

Fixed Jaw / Swing Jaw radial and thrust loads.

These jaw plates move regularly and crush

the input materials to required fineness.

Deep pitch gripped jaws for maximum

reduction. The jaw-faces are fully Wedge Block

reversible. All the Jaw Plates are cast with

high strength manganese steel Grade- III Springs

enriched with Chromium. 300

Toggle Plate

It is a safety system designed to shear

protecting crusher components if non-

250

crushable object is introduced to

Toggle Block crusher. 35

200 45

Output Size (mm)

It is supported by adjustable screws and allows

Toggle Bearing horizontal setting of the toggle block. It is used 60

They protect the wearing of the toggle block and the for fine adjustment of the closed side settings.

100

lever Assembly. These Toggle Bearings are cast in 150

Tension Rod special grade steel. 150

Without the tension rod & spring the bottom of the pitman 200

would just flop around as its not connected to the toggle plate,

rather just resting against it in the toggle bearing. The tension 100 250

Springs

rod system tensions the pitman to the toggle plate. 300

50

0

Used in a Wide Range of Applications Heavy Duty Design Delivers Heavy Duty Production 0 25 50 75 100

1.Aggregate The proven MST series jaw crushers are designed to crush It all comes down to delivering the most tons of material, the most technology, this crusher delivers high production, infinite setting Percentage Output (%)

2.Mining (Surface and Underground) efficiently all, even hardest rock and recycle materials. MST series cost effectively. Built to deliver a low cost per ton, the M. R. adjustment and large feed opening. This crusher is engineered to

3.Recycling (Concrete, Asphalt and others) jaw crushers are suitable for any demanding crushing application Engineers Single Toggle (MST Series) Jaw Crusher is designed for handle hard rock, ores and demolition concrete for the quarrying,

4.Industrial (Slag, Anodes and others) both stationary and mobile processes. exceptionally heavy and continuous applications. Utilizing the latest mining and recycling industries.

Page2 Page3 Page4

You might also like

- Commissioning Procedure For HVAC SYSTEM (QP) 24-02Document48 pagesCommissioning Procedure For HVAC SYSTEM (QP) 24-02Congson Jeff89% (18)

- RX 60 30 Still ManualDocument6 pagesRX 60 30 Still ManualDavid Klachuk50% (2)

- Still NGT4Document6 pagesStill NGT4Ali Biomy100% (1)

- YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesYL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- Mk5 Series Single Toggle Jaw Crushers: Manufactured in The UKDocument2 pagesMk5 Series Single Toggle Jaw Crushers: Manufactured in The UKJhunior Contreras NeyraNo ratings yet

- Series 5 Specification SheetDocument2 pagesSeries 5 Specification Sheetjuanchooo50xdNo ratings yet

- Neco Hubless CI Pipe Price List 2022Document1 pageNeco Hubless CI Pipe Price List 2022Kevin MaldeNo ratings yet

- Impact CrusherDocument2 pagesImpact CrusherAhmed El-sheshtawyNo ratings yet

- Amafilter Cricketfilter For Wet Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Wet Cake Discharge 20210414virus40No ratings yet

- Base Hinged Masts Technical Data PDFDocument1 pageBase Hinged Masts Technical Data PDFgarpheetNo ratings yet

- Covers Whip SockDocument1 pageCovers Whip SockMichaël AlbaneseNo ratings yet

- Competitor Comparation - 1265Document2 pagesCompetitor Comparation - 1265cribytritNo ratings yet

- R T MV: SeriesDocument4 pagesR T MV: SeriesAhmed El-sheshtawyNo ratings yet

- NEW Gelen Catalog-EnglishDocument40 pagesNEW Gelen Catalog-Englishsam saminNo ratings yet

- WC67K EngDocument8 pagesWC67K Engclaudio ponceNo ratings yet

- Material HandlingDocument36 pagesMaterial HandlingvishnusankarNo ratings yet

- Competitor Comparation - 1060Document2 pagesCompetitor Comparation - 1060cribytritNo ratings yet

- Schiavi Enc Met Page097Document1 pageSchiavi Enc Met Page097Adel AdelNo ratings yet

- Amafilter Cricketfilter For Dry Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Dry Cake Discharge 20210414virus40No ratings yet

- Belt Cleaner: Head PulleyDocument7 pagesBelt Cleaner: Head PulleyAgung Pandega PutraNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- Cricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Document2 pagesCricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Dwi Agus DermawanNo ratings yet

- Trio Impact Horizontal Crushers BrochureDocument3 pagesTrio Impact Horizontal Crushers BrochureOliver CabanillasNo ratings yet

- Competitor Comparation - 1055Document2 pagesCompetitor Comparation - 1055cribytritNo ratings yet

- Effective Control: Spring BuffersDocument3 pagesEffective Control: Spring Buffersakın ersözNo ratings yet

- Civil DrawingDocument2 pagesCivil DrawingsaifulNo ratings yet

- Casing PropertiesDocument1 pageCasing Propertiesamin peyvandNo ratings yet

- STD STR Tulangan: Berat BesiDocument17 pagesSTD STR Tulangan: Berat Besialfian militanNo ratings yet

- Sevak Price ListDocument14 pagesSevak Price ListPentagon LeadNo ratings yet

- Pinbush - Tyre Coupling 2014Document4 pagesPinbush - Tyre Coupling 2014Priyam NandwanaNo ratings yet

- Wittur Range of Systems: Machine Roomless EfficiencyDocument16 pagesWittur Range of Systems: Machine Roomless EfficiencyLe Huynh LongNo ratings yet

- Erke Catalog enDocument52 pagesErke Catalog enKarbonKale100% (1)

- Universal Joint Drawing - 1Document2 pagesUniversal Joint Drawing - 1patelchiragisNo ratings yet

- NEW E4043 ComparisonDocument8 pagesNEW E4043 Comparisonrajeshwar devarajanNo ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- Drilling Workover Rig: Ts-SinotaiDocument12 pagesDrilling Workover Rig: Ts-SinotaiRobertoVitorianoNo ratings yet

- Clutch Disc Thai AsahiDocument8 pagesClutch Disc Thai AsahiVipuchit SirikhemapornNo ratings yet

- CNC Glass Cutting TableDocument6 pagesCNC Glass Cutting TableMarcel PiersonNo ratings yet

- Technical Parameters For DD Seriese Guide Rod Diesel Pile HammerDocument1 pageTechnical Parameters For DD Seriese Guide Rod Diesel Pile HammerMuqorobinNo ratings yet

- CARBON STEEL 150#-300#: Rating Unit KDocument4 pagesCARBON STEEL 150#-300#: Rating Unit KMarizta Perdani PutriNo ratings yet

- Davi - BARCODE - MCP Angle RollDocument8 pagesDavi - BARCODE - MCP Angle Rollبازرگانی راهیان کار و دانشNo ratings yet

- Sintex MRP PRICE LISTDocument3 pagesSintex MRP PRICE LISTPratik Choksi0% (1)

- Inova Cardan Joints Series JCDocument2 pagesInova Cardan Joints Series JCSympatyagaNo ratings yet

- Techson Brochure SEP NEWDocument15 pagesTechson Brochure SEP NEWKamal SharmaNo ratings yet

- MC Injection Spec2023Document1 pageMC Injection Spec2023anandan777No ratings yet

- Jaw CrusherDocument20 pagesJaw CrusherEzaz Ahmed SkNo ratings yet

- Utility Project UrgentDocument1 pageUtility Project Urgentshivamdubey12No ratings yet

- Model Jaw Vertical ConeDocument4 pagesModel Jaw Vertical ConerianNo ratings yet

- Wykrawarka Ramienna Atom G999-BroszuraDocument4 pagesWykrawarka Ramienna Atom G999-BroszuraSeba O.No ratings yet

- Brosur Genset Sariling PerkinsDocument2 pagesBrosur Genset Sariling PerkinsJoko SutrisnoNo ratings yet

- CFT Lea038.e2Document2 pagesCFT Lea038.e2Asifur RahmanNo ratings yet

- Shield Vibration Isolaion Product SheetDocument19 pagesShield Vibration Isolaion Product SheetVikin WangNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- WENLEN - Roscadas Catalogo WR2F - WEB WLDocument2 pagesWENLEN - Roscadas Catalogo WR2F - WEB WLnf seccoNo ratings yet

- MKD EnglischDocument2 pagesMKD Englischriver karimNo ratings yet

- Lay Out Taso Gudang PLB 13-03-2024Document2 pagesLay Out Taso Gudang PLB 13-03-2024ferikomangNo ratings yet

- 21 Vav With Sound AttenuatorDocument2 pages21 Vav With Sound AttenuatorSlam HassanNo ratings yet

- Line Proven Solution: Press BrakesDocument2 pagesLine Proven Solution: Press BrakesSarath KumarNo ratings yet

- 20 SpecialDocument1 page20 SpecialVarun SalianNo ratings yet

- Nozzle LoadingDocument3 pagesNozzle Loadingtranhonghakd5533No ratings yet

- Syntron VibratorsDocument48 pagesSyntron VibratorsKarin AndersonNo ratings yet

- Tel MovilDocument91 pagesTel MovillandagoNo ratings yet

- Terex Jaques Torrent ScreensDocument16 pagesTerex Jaques Torrent ScreensKarin AndersonNo ratings yet

- U&m - VBP 500-800-900-1200-1500 - Atex - enDocument66 pagesU&m - VBP 500-800-900-1200-1500 - Atex - enKarin AndersonNo ratings yet

- Linear Vibration Feeder: Gordon H. Y. Wong Date Submitted 4/24/08Document51 pagesLinear Vibration Feeder: Gordon H. Y. Wong Date Submitted 4/24/08Saran CoolNo ratings yet

- Installation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsDocument8 pagesInstallation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsKarin AndersonNo ratings yet

- Syntron VibratorsDocument48 pagesSyntron VibratorsKarin AndersonNo ratings yet

- Installation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsDocument8 pagesInstallation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsKarin AndersonNo ratings yet

- Unit 5 - 1 - Operation Maintenance and Monitoring of FSTPs - DavidMRobbinsDocument39 pagesUnit 5 - 1 - Operation Maintenance and Monitoring of FSTPs - DavidMRobbinsKarin AndersonNo ratings yet

- SMI ImpactorDocument12 pagesSMI ImpactorKarin Anderson100% (1)

- Cutter-Crusher Rammer RC 6: Operation and Maintenance OMRC6ENG.903Document56 pagesCutter-Crusher Rammer RC 6: Operation and Maintenance OMRC6ENG.903Karin AndersonNo ratings yet

- Operations and Maintenance GuideDocument321 pagesOperations and Maintenance GuideNatrajiNo ratings yet

- The - Role - of - Vibration - Monitoring - Schaeffler (UK) - (2009) PDFDocument20 pagesThe - Role - of - Vibration - Monitoring - Schaeffler (UK) - (2009) PDFjuanarcos_778612No ratings yet

- Serivce ManualDocument300 pagesSerivce ManualJeevan M Jeeva100% (2)

- SMI ImpactorDocument12 pagesSMI ImpactorKarin Anderson100% (1)

- Proto J94020 CatalogDocument44 pagesProto J94020 CatalogKarin AndersonNo ratings yet

- JOEST SouthAfrica Broschure 2016 09 WebDocument8 pagesJOEST SouthAfrica Broschure 2016 09 WebKarin AndersonNo ratings yet

- 03greatwesternfc19 PDFDocument44 pages03greatwesternfc19 PDFEmanuel RigueroNo ratings yet

- Operation & Maintenance Manual: 24 Series BioclereDocument69 pagesOperation & Maintenance Manual: 24 Series BioclereKarin AndersonNo ratings yet

- Omp Appendix C - Standard Operating ProceduresDocument120 pagesOmp Appendix C - Standard Operating ProceduresKarin AndersonNo ratings yet

- Operation & Maintenance Best Practice O&MBestPracticesDocument169 pagesOperation & Maintenance Best Practice O&MBestPracticesevrimkNo ratings yet

- Guideline Management Crushing and Screening Feb10 1Document10 pagesGuideline Management Crushing and Screening Feb10 1Karin AndersonNo ratings yet

- Component Replacement Labor: For Crushing EquipmentDocument2 pagesComponent Replacement Labor: For Crushing EquipmentKarin AndersonNo ratings yet

- UP6 11-22kw - 80448418Document156 pagesUP6 11-22kw - 80448418cesar gNo ratings yet

- RaptorOverviewBrochure 2013 Email PDFDocument16 pagesRaptorOverviewBrochure 2013 Email PDFtincho_0026No ratings yet

- Conceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsDocument221 pagesConceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsestramilsolutionNo ratings yet

- BC1515 Operator-1Document76 pagesBC1515 Operator-1Karin AndersonNo ratings yet

- Serivce ManualDocument300 pagesSerivce ManualJeevan M Jeeva100% (2)

- BWX 6630 4Document62 pagesBWX 6630 4Karin AndersonNo ratings yet

- Unit 5 - 1 - Operation Maintenance and Monitoring of FSTPs - DavidMRobbinsDocument39 pagesUnit 5 - 1 - Operation Maintenance and Monitoring of FSTPs - DavidMRobbinsKarin AndersonNo ratings yet

- Cavity Wall 1Document48 pagesCavity Wall 1Mahesh RamtekeNo ratings yet

- Landscape Irrigation Products Catalog: The Intelligent Use of WaterDocument196 pagesLandscape Irrigation Products Catalog: The Intelligent Use of WaterCosmin BonghezNo ratings yet

- Method Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsDocument26 pagesMethod Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsIrfan AliNo ratings yet

- A Case History On Design, Construction, and Performance of Stone Column ...Document10 pagesA Case History On Design, Construction, and Performance of Stone Column ...Suthan PooranampillaiNo ratings yet

- Chieftain 400 600 - Rev 3 March 07Document105 pagesChieftain 400 600 - Rev 3 March 07Борис ЯвнийNo ratings yet

- Tev Bipl GitcoDocument86 pagesTev Bipl GitcoVishal RawatNo ratings yet

- Submitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliDocument46 pagesSubmitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliBipinNo ratings yet

- Rynglok AB25 TF100-17Document8 pagesRynglok AB25 TF100-17cesarin2011No ratings yet

- July 2022 Past Board (Similar Questions)Document15 pagesJuly 2022 Past Board (Similar Questions)Harold GarciaNo ratings yet

- 01 The Law and Practice of Delay Claims A Practical Introduction TrainorDocument19 pages01 The Law and Practice of Delay Claims A Practical Introduction TrainorMOHNo ratings yet

- PDS01.01.002-A - Wouter Witzel - EVS InstallationDocument1 pagePDS01.01.002-A - Wouter Witzel - EVS InstallationVilius BukysNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- 77 Talbot Street - NTU Introduction-CompressedDocument30 pages77 Talbot Street - NTU Introduction-CompressedPaoloNo ratings yet

- CPC Prefinal Exam 2020Document2 pagesCPC Prefinal Exam 2020Allyssa OpantoNo ratings yet

- BoQ Extend Ramp Door Pontoon-Blank (1) HindoliDocument3 pagesBoQ Extend Ramp Door Pontoon-Blank (1) HindoliandhyirawanNo ratings yet

- Equivalent StiffnessDocument6 pagesEquivalent Stiffnesssmg_b100% (6)

- Masonry 9Document5 pagesMasonry 9Shaina Freya Grantoza NasolNo ratings yet

- Wet Pilot TypeDocument15 pagesWet Pilot TypeDipanjan ChakrabartiNo ratings yet

- Aqua Snap®Document96 pagesAqua Snap®Jonh RiberosNo ratings yet

- TECHNICAL DATA FUSE LINK TYPE K (15 38 KV) WEBDocument1 pageTECHNICAL DATA FUSE LINK TYPE K (15 38 KV) WEBSantiago EspitiaNo ratings yet

- Container Inspection Manual - Update - 08-2016 ULTIMO 2018 Imagenes A ColorDocument35 pagesContainer Inspection Manual - Update - 08-2016 ULTIMO 2018 Imagenes A ColorImpresora MillantuNo ratings yet

- Cas-White Chemical Resistant and Anti SlipDocument28 pagesCas-White Chemical Resistant and Anti SlipAnonymous llBSa7No ratings yet

- Ebf IbcDocument2 pagesEbf IbcMurat TopbaştekinNo ratings yet

- Philippine Overseas & Domestic Construction Board: Executive Director, PODCBDocument37 pagesPhilippine Overseas & Domestic Construction Board: Executive Director, PODCBZamhyrreNo ratings yet

- Slurryflex SA Hard Wall Mining Hose DatasheetDocument2 pagesSlurryflex SA Hard Wall Mining Hose DatasheetBeaver Process EquipmentNo ratings yet

- Damp ProofingDocument23 pagesDamp ProofingyaredNo ratings yet

- PPR Pipe & Fitting - PolygonDocument9 pagesPPR Pipe & Fitting - PolygonThy YuNo ratings yet

- Permeable Paving-2017Document9 pagesPermeable Paving-2017ZerotheoryNo ratings yet

- SOM-BMT Lab Manual FinalDocument48 pagesSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)