Professional Documents

Culture Documents

Combining Distributed Synchronized High Frequency Measurements

Uploaded by

Ira CervoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combining Distributed Synchronized High Frequency Measurements

Uploaded by

Ira CervoCopyright:

Available Formats

25th International Conference on Electricity Distribution Madrid, 3-6 June 2019

Paper n° 1058

COMBINING DISTRIBUTED SYNCHRONIZED HIGH FREQUENCY MEASUREMENTS

WITH A CONTROL SYSTEM FOR SMART LOW VOLTAGE GRIDS

Gerwin HOOGSTEEN Marco E. T. GERARDS Johann L. HURINK

University of Twente – Netherlands University of Twente – Netherlands University of Twente – Netherlands

g.hoogsteen@utwente.nl m.e.t.gerards@utwente.nl j.l.hurink@utwente.nl

Gerard J. M. SMIT Omar MANSOUR Dennis BIJWAARD

University of Twente – Netherlands Smart State Technology – Netherlands Smart State Technology – Netherlands

g.j.m.smit@utwente.nl mansour@smartstatetechnology.nl dennis@smartstatetechnology.nl

concepts [3], implemented in DEMKit [4], with the open

ABSTRACT platform and LV-Sensors from Smart State Technology

This paper presents a real-time monitoring and control (SST) [5]. An overview of this system is given in the next

section. The following sections present initial integration

system for low voltage grids built with Smart State tests and performance evaluation of running DEMKit

Technology’s (SST) LV-Sensors and their open platform software on the SST open platform hardware. Furthermore

together with the TRIANA energy management an evaluation of the integrated control system itself is

methodology. This platform uses synchronized real-time presented. At the end we draw conclusions and present

measurement data from various locations in the grid. The future work to improve the solution.

presented control system uses this real-time data to resolve

deviations in power consumption from a given planning. SYSTEM OVERVIEW

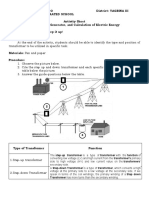

Based on this solution, necessary actions can be taken to The envisioned EMS combines optimized plannings of

avoid grid overloading and enhance the Quality of Service flexibility with real-time measurements from the LV-

(QoS) to customers. The control system, implemented Sensors. A newly developed control mechanism combines

using DEMKit, runs on the SST LV-Sensors modules. both information streams to control attached devices. An

Initial integration tests show that the solution works stable overview of this system is depicted in Figure 1, which will

and resolves prediction errors to ensure QoS. be explained in this section.

INTRODUCTION Smart State Technogy LV-Sensors

The energy transition brings various challenges to low- The used SST LV-Sensors provide high frequency

voltage (LV) distribution grids, such as an increased risk measurement data at a sampling rate of up to 128 KHz.

of over/under voltage and grid overloading. With the Two flavours of the LV-Sensors are available, one for

ongoing electrification, this stress on the LV grid is currents and one for voltages. Multiple sensor nodes can

expected to increase. Especially in the Netherlands, which be deployed in a grid, where the common system

aims to phase out the usage of natural gas rapidly, the architecture consists of a time beacon, voltage sensors,

expected shift to electric based space heating using heat current sensors and data aggregation. The measurement

pumps will have a significant effect on the load in these samples are synchronized in time using the GPS time

LV networks. Furthermore, with the integration of electric beacon which broadcasts GPS pulse per second (PPS)

mobility, more service interruptions are expected as shown information to LV-Sensors distributed throughout the grid

in [1]. Upgrading existing LV networks to cope with these using a 5.8 GHz analogue transmitter. A schematic

developments is not an economically appealing solution. overview of a possible setup is shown in Figure 2.

Instead, we aim for a low-cost solution based on modular

real-time measurement units targeted for LV grids, such as

presented in [2]. An energy management system (EMS)

runs on top of such modules and controls flexibility offered

by end-users to perform peak shaving, and thereby avoids

grid overloading and service interruptions. Possible forms

of flexibility are delaying the charging of electric vehicles

(EV) or preheating rooms.

In this work we propose a sophisticated EMS that handles

high frequency measurement data from various locations

in an LV grid. Such an EMS must balance local energy

production and consumption, and at the same time uses

real-time measurements to maintain power quality and

resolve overloading problems. We develop such a system

within the Open Real Time Development Platform for Figure 1: Overview of the proposed system for ORTEP

Smart Grids (ORTEP) project, by combining the TRIANA

CIRED 2019 1/5

25th International Conference on Electricity Distribution Madrid, 3-6 June 2019

Paper n° 1058

generic device classes and optimization algorithms. A

scenario is a composition of multiple individual modelling

components. With the modular setup, it is possible to

easily create a scenario and compare various control and

optimization algorithms. Furthermore, components that

model the behaviour of virtual devices can be replaced by

components that interact with their real world counterpart.

This way, it is possible to perform hardware-in-the-loop

(HIL) simulations or deploy demonstrators with the

DEMKit software for validation. The main goal of this

paper is to show the results of running DEMKit simulation

scenarios in real life and to find bottlenecks in this

Figure 2: Example of multiple LV-Sensors in an LV network approach.

Each LV-Sensor incorporates an ARM-based low-power Combining LV-Sensors and DEMKit

embedded system running Linux. Currently, the LV- In this paper we use the TRIANA energy management

Sensors make use of an embedded Orange Pi embedded methodology [3]. This methodology employs a model

computer with and ARM processor. Although multiple predictive control (MPC) approach by based on

variants are possible, we restrict the evaluation to an predictions of the energy profile and possible flexibility.

Orange Pi Zero with an Allwinner H2 Quadcore SoC and The predictions are used as input for a mathematical

256MB of RAM. Connected to the Orange Pi is a shield optimization framework to create a near optimal planning

that contains an advanced multichannel ADC (with for usage of flexibility for e.g. the next day. Such a

simultaneous sampling capability up to 128KHz), a planning often uses discrete time intervals of 15 minutes.

digitally programmable clock oscillator, a micro- Real-time measurements from the LV-Sensors are used to

controller, and the PPS transceiver circuitry. The voltage take proper control actions, given the planning and the

sensors have a measurement range of 600V (230V current state of the grid.

nominal) and make use of signal transformers, while the

current sensors use of split-core CTs and have a For planning, the Profile Steering approach [4] is used. It

measurement range up to 600A. optimizes the energy profile using a predefined desired

energy profile with minimum and maximum bounds (e.g.

Next to the provided hardware, the LV-Sensors also congestion limits) as target. In an iterative fashion, it

provide an open platform, which allows third parties to updates device profiles to minimize the Euclidean distance

directly access real-time measurement data from the LV- between the desired profile and the planned profile.

Sensors, both locally and remotely. A major part of the Furthermore, tailor made device optimization algorithms,

LV-Sensors open platform concept is the DSP-framework. see e.g. [6], are used to create a planning for each

The DSP framework ensures that data, measurements and individual device. The use of MPC allows the control

signal events can easily be exchanged between various system to make informed decisions concerning short- and

sensors and aggregation units distributed throughout the long-term objectives and available flexibility. Thereby it

grid, as well as between various algorithms. For efficient avoids greedy use of flexibility, which potentially leads to

communication, the open platform makes use of two larger problems in the future. An example is discharging a

libraries: Zero Messaging Queue (ZMQ), and the battery too greedily now, which may result in an empty

structured binary format CBOR. Users of the system can battery that cannot resolve severe overloading problem in

run their applications directly on the hardware platform. the future. Such a situation would result in a reduced

This results in low-cost sensors suitable for LV wide area Quality of Service (QoS) to end-users by either performing

monitoring with synchrophasor based measurements and load-shedding or a service interruption.

calculations suitable for e.g. remote monitoring, (dynamic)

state estimation, and congestion management. Such a situation is what our solution aims to prevent.

However, as predictions are never completely accurate, a

DEMKit mechanism to deal with prediction errors is required.

Prediction errors occur in both the time domain (e.g. a

To implement an EMS on top of the open platform LV- cloud passing by later, affecting PV production) and the

Sensors, we use the DEMKit simulation and energy domain (e.g. total produced energy is lower than

demonstration toolkit developed at the University of predicted). In [4] it is shown that an event-driven variant

Twente [4]. DEMKit provides a software platform with the of Profile Steering is able to adequately deal with

necessary tools for researchers to develop and validate new prediction errors from both domains. This method

optimization algorithms and control mechanisms for the continuously incorporates updated predictions and

smart grid. The software is written in Python3 to benefit performs partial re-planning to keep the overall power

from object oriented programming, while being flexible to profile as close as possible to the original planned profiles.

rapidly create prototypes of new control concepts. The Profile Steering algorithms form the green right hand

block of TRIANA in Figure 1.

A library with components is provided with DEMKit to

allow the creation of such smart grid scenarios. These The LV-Sensors open platform aggregates data from

components include grid assets (cables and transformers), multiple sensors in the grid. All incoming samples are

CIRED 2019 2/5

25th International Conference on Electricity Distribution Madrid, 3-6 June 2019

Paper n° 1058

𝑡𝑎𝑟𝑔𝑒𝑡

synchronized and optionally signal processing is 𝑃𝑡𝑐𝑜𝑛𝑡𝑟𝑜𝑙 = 𝑃𝑡 − 𝑃𝑡𝑚𝑒𝑎𝑠𝑢𝑟𝑒𝑑 + 𝑃𝑡−1

𝑐𝑜𝑛𝑡𝑟𝑜𝑙

performed. The resulting output samples are streamed via

ZMQ to the TRIANA methodology. Here, the setpoint for the controlled power (𝑃𝑡𝑐𝑜𝑛𝑡𝑟𝑜𝑙 ) in

time interval t depends on the current target (the result

The left hand TRIANA block in Figure 1 concerns the from the offline optimization) and measured value from

online control algorithm. As events in the smart grid play the sensors. This gives the difference that must be added

on much smaller time scales than the 15 minute interval 𝑐𝑜𝑛𝑡𝑟𝑜𝑙

to the previous control action 𝑃𝑡−1 .

planning, we use an online control concept similar to [7].

The control mechanism continuously tries to minimize the CPU Memory Samples Samples

error between the planned power consumption and the Case [%] [%] in total /second

measured power consumption by updating the power NoComm 40-50 9.3 170856 47.46

output of a controllable asset. On the longer time-scale, the Comm 100 9.4 152677 42.41

event-based Profile Steering algorithm makes sure that

Table 1: Results of the control-loop performance evaluation

sensible trade-offs are made to keep the operation of the

grid within bounds for the longer term. On the other hand,

Profiling of the tests (Table 1) shows that the system is

if the asset has insufficient flexibility to resolve dangerous

highly capable of performing this test. Without control to

situations, the controller does as much as it can and

an external system (NoComm), it is able to process 47.46

immediately signals other controllers for assistance. Such

samples per second on average out of the maximum

a signal could be used to e.g. perform load-shedding as a

achievable 50.00. The load on the CPU is around 40-50%

last resort to prevent e.g. overloading.

and memory utilisation is around 9.3%. When sending

control signals to a second system via an HTTP REST API

EXPERIMENT 1: INTEGRATION TESTS (Comm), the CPU load increases to 100%. This also results

Within the ORTEP project, we further develop the to a slight decrease in handled samples. The RMSE with

capabilities of DEMKit to operate in demonstration respect to the target is calculated to be 30.96 W. Figure 3

projects. Among those developments is the addition of also shows that the system is capable of responding

ZMQ interfaces for distributed optimization across quickly to rapid power consumption changes by providing

multiple control nodes. Furthermore, for the online control a smooth overall power profile in general.

mechanism we use the real-time measurements from the 40

LV-Sensors as input. Hereby, the distribution of SST LV- 30

Sensors in a grid matches the decentralized architecture of

the Profile Steering approach. 20

Power [W]

10

Test 1: control-loop performance 0

The first step to real deployment of such a system is the -10

ability to receive the measurement data in the control -20

system itself. As the data must be processed at a high rate,

we developed a new component for the DEMKit software, -30

which runs in a separate process. This in contrast to other -40

components that run synchronized with the discrete time 0 5 10 15 20 25 30 35 40 45 50 55

intervals used in simulations. This component reads the Time [minutes]

data signal from the LV-Sensors by subscribing to the Percentile 95 Percentile 5 Mean

ZMQ channels defined in the open platform specification.

The online control process steers a controllable asset as Figure 3: Resulting mean total power and 5th and 95th percentile

quickly as possible to match the planned power value. deviation from target

To test the integration, we realized the execution of the We note that the test software is written in Python3 scripts,

algorithm directly on the LV-Sensors hardware. For this which allows for fast deployment of the concept, but

test, we did not have a controllable asset available, so we leaves room for performance improvement using compiled

used a modelled battery within the DEMKit simulation code instead. Furthermore, it is likely that assets are also

environment instead. The controller received real limited in the rate at which they accept control signals.

measurement data from an external SST LV-Sensors

module in the grid. In this test we evaluated the amount of Test 2: Prediction and control algorithms performance

samples the system is able to process within an hour using The second test is to run the optimization and control

the online algorithm on the system. Furthermore we algorithms of a typical household on the LV-Sensors

evaluated how fast new control actions can be executed. hardware. With this test we evaluate whether the hardware

The simple method just reads data and calculates the is powerful enough to serve as a Home Energy

control action. In an extended version of the test we sent a Management System (HEMS). A simulation scenario of a

control signal back to an external system (in our case a household is loaded in DEMKit to run on the LV-Sensor

home automation platform) to check the rate at which hardware. This scenario includes all components of a

external systems can be controlled through an HTTP future smart household and corresponding optimization

REST API. The used control rule for this test is a simple algorithms to investigate whether the hardware is able to

feed-back loop: provide the required computation power. As setup, the

CIRED 2019 3/5

25th International Conference on Electricity Distribution Madrid, 3-6 June 2019

Paper n° 1058

standard single-house scenario of DEMKit is used, which interval lengths of 1s and provide the computation power

includes the following components: for a smooth user experience.

• a static uncontrollable load,

• a PV panel setup, EXPERIMENT 2: DEMONSTRATOR SETUP

• a controllable washing machine,

• a controllable dishwasher, Next to integrating DEMKit with the LV-Sensors, it is also

important to validate that the envisioned control

• battery storage system,

mechanism operates stable. The algorithms are backed by

• electric vehicle, mathematical proofs and are extensively tested in various

• thermal model with a heat pump. case studies [4, 6]. However, these have not been tested in

The simulation step-size is set to 60 seconds and one week a practical setting where more prediction errors may occur

(7 days) is simulated. compared to synthetic data used in the aforementioned

case studies. Furthermore, when deploying the system as a

Test 2 Test 3 HEMS, users also interact with the system. Hence, to

CPU usage 100 % 38 % validate the system in a realistic environment, we have set

Memory usage 10.1-10.7 % 16.4-17.0 % up DEMKit as a demonstrator in a pilot household. Within

Model training 9.8 s 10182.9 s this scenario all components of the proposed EMS are

Controllers 44.1 s 35.3 s deployed.

Device sim. 157.4 s 227.4 s

Writing output 1332.3 s 3630.0 s For this demonstration setup, a scenario was created in

Table 2: System load and time spent in different functions during DEMKit, such that it can be used to validate it before real

test 2 and test 3 deployment. The scenario contains the following

components:

The profiling results (Table 2, Test 2) show that the • uncontrollable load with historical data,

hardware platform is capable of acting as a HEMS. The • PV setup with historical power and weather data,

single-threaded simulation requires between 10.1% and • a virtual battery,

10.7% of memory and takes in total 1544 seconds to • a controllable (deferrable) washing machine.

complete. This leaves enough computation time for the

real-time control loop and to deliver a smooth user Furthermore, multiple scenarios are created to evaluate the

experience. The statistics also reveal that most time (1332 added value of the proposed solution with online-control

seconds, 86%) is spent in storing data. The pure control using LV-Sensors measurements. These are:

algorithms require only 44 seconds (3%). In comparison, ORTEP Control (OC): The system as presented in the

the same test requires approximately 50 seconds in total on paper with real-time measurements and online control.

a desktop with an Intel Core i7 3770. Greedy Control (GC): No optimization used, only a

greedy control strategy for the battery.

Test 3: Optimization algorithms performance No Control (NB): Business as usual without a battery

The third integration test is similar to the second test. This To test the system in real, with the different scenarios in

test focusses on a use-case with real historical data to parallel, we use a micro-server (Intel Celeron J4105 with

evaluate the required computation time to train the models 8GB of RAM) to avoid processing power bottlenecks for

used for predictions on the LV-Sensors hardware. this test. The simulation scenario is copied to the target

Furthermore, this test is used to validate whether system and only minimal effort was required to convert the

algorithms run fast enough to provide a seamless user- simulation scenario into a real demonstration by replacing

experience. For this we run the system for 10 hours using a few components in the scenario and adjusting some

an interval length of 10 seconds. This scenario consists of DEMKit parameters. This shows that the simulation

the following components: scenario can be transferred to the real test-bed easily. One

• prediction algorithms for the uncontrollable load drawback of this approach is that DEMKit is still mostly

using historical data, single-threaded at this moment. Therefore, we reduced the

• model training and prediction algorithms for the control action speed by using discrete time intervals of 10

power production of a solar panel, seconds to provide computing time for the (re-)planning

• optimization of a battery. algorithms.

The results of running the system for 10 hours are provided To monitor its operation, the control system connected to

in Table 2 (Test 3). From these results it is immediately a home automation system (Home Assistant). This

clear that the algorithms to train the models using historical automation system allows us to control a non-smart

data are the main bottleneck. This is explained by the washing machine using a controllable switch between its

heavy interaction with an external database and the fact power cord and the wall socket. For this, the power supply

that the code of these algorithms have not been optimized to the washing machine is cut off as soon as its starts its

yet. However, they can easily run in a separate thread. The program. An interface is created in Home Assistant to set

control and device interfacing code only require modest a deadline for the washing machine, such that the

processing time (35.3 and 227.4 seconds respectively), optimization algorithm can find the optimal start time that

which is less than 1% of the discrete time interval length respects the user comfort constraints. When this optimized

of 10 seconds on average. Hence, enough processing time is reached, the control system toggles the switch to

power is left to run the synchronized parts of DEMKit at power the machine, which then continues its operation.

CIRED 2019 4/5

25th International Conference on Electricity Distribution Madrid, 3-6 June 2019

Paper n° 1058

Demonstrator setup results of further electrification. For the implementation of the

Figure 4 shows the overall resulting profile of the three control mechanism, we used the DEMKit simulation and

tested scenarios during the 18th and 19th of December 2018. demonstration toolkit. The integration tests show that the

As can be expected, OC results in the flattest profile, LV-Sensors hardware delivers the required computational

followed by GC. The lack of predictive control with GC performance for the proposed solution. Furthermore, the

results in an empty battery and hence a power peak, around total solution is capable of processing the real-time

8:00 on the first day and 20:00 on the second. The measurements adequately. A live test of the proposed

predictive control of the proposed solution (OC) prevents control algorithm shows that the system runs stable and

this by leaving approximately 1kWh of energy left in the adapts the control setpoints adequately to prevent peaks in

battery to be able to shave this peak. As a result, the GC the power usage. Furthermore deploying a DEMKit

strategy results in the same high peaks as NB since it scenario in reality, as well as integrating it with and onto

cannot deliver flexibility when it matters. These worst- the SST LV-Sensors open platform, did not cause major

case power values for the three cases are given in Table 3. hurdles.

3000

OC GC NB

Some aspects remain to be researched and implemented

2000 for a full deployment of the presented system. Firstly, we

Power [W]

1000

need to extend the DEMKit software with multi-threading

capabilities. The current, simulation oriented, single-

0 threaded implementation hinders the user experience as

-1000 interaction is blocked during the optimization process. The

-2000

challenge here is to implement a solution that works well

in both simulations and real-world deployment to

00:00

04:00

08:00

12:00

16:00

20:00

00:00

04:00

08:00

12:00

16:00

20:00

00:00

minimize the time-to-deployment and ensures feedback

Time [hours] from demonstrators is available for future simulations. For

the offline planning, including the expected accuracy of

Figure 4: Final power consumption for three scenarios the predictions is considered to increase the robustness of

the resulting planning. Finally, the real-time control loop

OC GC NB may be extended with some filtering algorithm to avoid

Max. power [W] 122 2352 2555 that short term phenomena affect the online-control system

Min. power [W] -132 -1 -1590 in a negative way.

Table 3: Worst case power consumption

ACKNOWLEDGMENTS

Looking at the control actions used with OC (Figure 5), it

is clear that, despite forecasting errors in the PV The authors thank Dutch national program TKI iDeego

production, the control mechanism is able to closely (project ORTEP) and RVO for their support.

follow the day-ahead planning (planning). Most notable is

the event-based adaption of the planning around 13:00 on REFERENCES

the first day. At this point new weather predictions [1] G. Hoogsteen, A. Molderink, J.L. Hurink, G.J.M.

indicated a lower irradiation forecast. This results in a Smit, B. Kootstra and F. Schuring, 2017, "Charging

higher intra-day planning (realization) with a higher target electric vehicles, baking pizzas, and melting a fuse in

power. As a result, the control system makes sure that Lochem", Proceedings CIRED conference, vol. 2017,

enough energy is stored to perform peak-shaving during 1629-1633

the evening peak the next day. The measured profile (with [2] O. Mansour, F. Baldinger, T. Jansen, 2011,

virtual battery) matches the intra-day planning accurately. “Challenges in smart distribution grids”, Proceedings

CIRED conference, vol. 2011

200 Measured Realization Planning [3] A. Molderink, V. Bakker, M.G.C. Bosman, J. L.

Hurink and G.J.M. Smit, 2010, "Management and

Power [W]

100 Control of Domestic Smart Grid Technology," IEEE

0 Transactions on Smart Grid, vol. 1, no. 2, 109-119

-100 [4] G. Hoogsteen, 2017, “A cyber-physical systems

-200 perspective on decentralized energy management”,

PhD dissertation, University of Twente

00:00

04:00

08:00

12:00

16:00

20:00

00:00

04:00

08:00

12:00

16:00

20:00

00:00

[5] O. Mansour and D. Bijwaard, 2018,

Time [hours] www.smartstatetechnology.nl

Figure 5: Control actions with the OC case [6] T. van der Klauw, 2017, “Decentralized energy

management with profile steering: resource allocation

problems in energy management”, PhD dissertation,

CONCLUSIONS AND OUTLOOK University of Twente

In this paper we presented a smart distributed monitoring [7] M.H.H. Schoot Uiterkamp, M.E.T. Gerards and J.L.

solution based on the SST LV-Sensors open platform. Hurink, 2018. “Fill-level prediction in online valley-

Connected to this platform is the TRIANA methodology filling algorithms for electric vehicle charging”, IEEE

for smart grids. The presented approach safeguards the Innovative Smart Grid Technologies, vol 2018, 1-6

operation of future low-voltage grids to guarantee a high

quality of service to end-users while mitigating the effects

CIRED 2019 5/5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual de Partes PL003 PDFDocument1,249 pagesManual de Partes PL003 PDFPablo Terán Salazar75% (4)

- Reliability & Maintainability Manual of TBEA Shenyang Transformer ProductsDocument67 pagesReliability & Maintainability Manual of TBEA Shenyang Transformer ProductsHeptolNo ratings yet

- S9Document191 pagesS9Félix Enríquez100% (1)

- 02 - Lecture - Outline KINEMATICS IN ONE DIMENSIONDocument126 pages02 - Lecture - Outline KINEMATICS IN ONE DIMENSIONIra CervoNo ratings yet

- 03 - Lecture - Outline VECTORS AND COORDINATES SYSTEMSDocument65 pages03 - Lecture - Outline VECTORS AND COORDINATES SYSTEMSIra CervoNo ratings yet

- 04 - Lecture - Outline KINEMATICS IN TWO DIMENSIONTIONDocument126 pages04 - Lecture - Outline KINEMATICS IN TWO DIMENSIONTIONIra CervoNo ratings yet

- 01 - Lecture - Outline CONCEPTS OF MOTIONDocument94 pages01 - Lecture - Outline CONCEPTS OF MOTIONIra CervoNo ratings yet

- 05 - Lecture - Outline FORCE AND MOTIONDocument99 pages05 - Lecture - Outline FORCE AND MOTIONIra CervoNo ratings yet

- Orange PiDocument28 pagesOrange PiIra CervoNo ratings yet

- Energy Resources and SystemsDocument8 pagesEnergy Resources and SystemsIra CervoNo ratings yet

- Butterworth Spiral Filter For Image Processing With Edge EnhancementDocument3 pagesButterworth Spiral Filter For Image Processing With Edge EnhancementIra CervoNo ratings yet

- Abdel G Awad 2016Document15 pagesAbdel G Awad 2016Ira CervoNo ratings yet

- Asynchronous (Cervo Ramboyong)Document16 pagesAsynchronous (Cervo Ramboyong)Ira CervoNo ratings yet

- Performance Analysis of Coded SSB-QPSK Radio Channels: in MobileDocument6 pagesPerformance Analysis of Coded SSB-QPSK Radio Channels: in MobileIra CervoNo ratings yet

- 10.1007@978 981 32 9453 0Document237 pages10.1007@978 981 32 9453 0Ira CervoNo ratings yet

- Malik 2020Document22 pagesMalik 2020Ira CervoNo ratings yet

- Removal of High Frequency Noise From ECG Signal Using Digital IIR Butterworth FilterDocument4 pagesRemoval of High Frequency Noise From ECG Signal Using Digital IIR Butterworth FilterIra CervoNo ratings yet

- Communication Aids and Strategies Using Tool of Technology: Cervo - Hucamis - MuerongDocument27 pagesCommunication Aids and Strategies Using Tool of Technology: Cervo - Hucamis - MuerongIra CervoNo ratings yet

- Chebyshev Filters: The Chebyshev and Butterworth ResponsesDocument10 pagesChebyshev Filters: The Chebyshev and Butterworth ResponsesIra CervoNo ratings yet

- Butterworth Pattern Based Simultaneous Damping and Tracking Controller Designs For Nanopositioning SystemsDocument6 pagesButterworth Pattern Based Simultaneous Damping and Tracking Controller Designs For Nanopositioning SystemsIra CervoNo ratings yet

- Application of Butterworth Filter in Display of Radar Target TrackDocument3 pagesApplication of Butterworth Filter in Display of Radar Target TrackIra CervoNo ratings yet

- Color Image Sharpening Using DST-Based Matrix Low-Pass Butterworth FiltersDocument2 pagesColor Image Sharpening Using DST-Based Matrix Low-Pass Butterworth FiltersIra CervoNo ratings yet

- Experiment No.1: Introduction To Lti Representation and Transfer Function ModelDocument7 pagesExperiment No.1: Introduction To Lti Representation and Transfer Function ModelIra CervoNo ratings yet

- Business ModelDocument39 pagesBusiness ModelIra CervoNo ratings yet

- A Novel Modulator: Nakul Birla', Nishit Gautam2, Jasmeen Patel3, Pavithra Balaji4Document4 pagesA Novel Modulator: Nakul Birla', Nishit Gautam2, Jasmeen Patel3, Pavithra Balaji4Ira CervoNo ratings yet

- ABB Trafo ServiceDocument12 pagesABB Trafo ServicemohamedfathyaliNo ratings yet

- WWW - MK-Electronic - De: FRU (Field Replaceable Unit) ListDocument7 pagesWWW - MK-Electronic - De: FRU (Field Replaceable Unit) ListCarlos EduardoNo ratings yet

- Bobcat 225: May 2003 Eff. W/serial Number KE582332Document52 pagesBobcat 225: May 2003 Eff. W/serial Number KE582332juan felipe alzate aristizabalNo ratings yet

- E35A27-VBS7 Diode PDFDocument1 pageE35A27-VBS7 Diode PDFNelson antonioNo ratings yet

- Measurement of Inductance by Phasor Diagram Method PhysicsDocument4 pagesMeasurement of Inductance by Phasor Diagram Method PhysicsnileshugemugeNo ratings yet

- Plug Setting Multiplier & Time Setting Multiplier - Electrical4u PDFDocument8 pagesPlug Setting Multiplier & Time Setting Multiplier - Electrical4u PDFNirav ChauhanNo ratings yet

- Spiral CableDocument2 pagesSpiral Cableanju vargheseNo ratings yet

- Shev - Control Units Emb7300Document3 pagesShev - Control Units Emb7300FathyNo ratings yet

- Electric Actuator - Rotork - For DeNox - BOFA, SOFA, OFADocument2 pagesElectric Actuator - Rotork - For DeNox - BOFA, SOFA, OFAA.YOGAGURUNo ratings yet

- 3G-LTE MR ConversionDocument8 pages3G-LTE MR ConversionHamzah AbdulhadiNo ratings yet

- Networks TypesDocument16 pagesNetworks TypesNewton Dannie AbelNo ratings yet

- PathfinderDocument91 pagesPathfinderShashi SagarNo ratings yet

- Zhone Product GuideDocument12 pagesZhone Product GuideSahibzada Fazal E Akbar100% (1)

- BS en 60243232Document30 pagesBS en 60243232RoverNo ratings yet

- TD 62107Document10 pagesTD 62107wtn2013No ratings yet

- Fortis Wind Energy Alize 10kW Wind TurbineDocument2 pagesFortis Wind Energy Alize 10kW Wind TurbineROSMADI BIN ABDULLAHNo ratings yet

- חוברת הפעלה למכונה לגילוף חוטיםDocument22 pagesחוברת הפעלה למכונה לגילוף חוטים208020No ratings yet

- P&ID 335 Comment Marking 220606Document50 pagesP&ID 335 Comment Marking 220606Azhar BudimanNo ratings yet

- 8 Candidate Quiz Buzzer Using 8051 MicrocontrollerDocument33 pages8 Candidate Quiz Buzzer Using 8051 MicrocontrollerVani Sunny100% (3)

- Power Socket Strip PSS300: Instructions For UseDocument16 pagesPower Socket Strip PSS300: Instructions For UseJesus DunoNo ratings yet

- Afe Builtin System Catdat Da6510 76Document18 pagesAfe Builtin System Catdat Da6510 76rmsserviceNo ratings yet

- Omega Manual FrenchDocument23 pagesOmega Manual FrenchmimiscriNo ratings yet

- Activity Sheet Session 9-MORADO, NANETTEDocument4 pagesActivity Sheet Session 9-MORADO, NANETTENanette MoradoNo ratings yet

- Fluido 2 ManualDocument68 pagesFluido 2 ManualEdmar MirandaNo ratings yet

- Schedule of Rate, Both Civil and Mechanical/Electrical With All Corrigendum and Addendum As On 03-Nov-2021Document159 pagesSchedule of Rate, Both Civil and Mechanical/Electrical With All Corrigendum and Addendum As On 03-Nov-2021SK FARIDULNo ratings yet

- Tutorial Arduino Bluetooth 8 Lamp PDFDocument12 pagesTutorial Arduino Bluetooth 8 Lamp PDFZulkarnain ZainalNo ratings yet

- Silicon N Channel MOSFET Tetrode BF 998: FeaturesDocument8 pagesSilicon N Channel MOSFET Tetrode BF 998: FeatureshaNo ratings yet