Professional Documents

Culture Documents

RISKMAN

Uploaded by

Jam Kaii0 ratings0% found this document useful (0 votes)

9 views3 pagesManaging Process Inspection and Verification of Deliveries

RECEIVING AND STORING OF DELIVERIES

All delivered items must be inspected to ensure they meet quality standards and the establishment's needs. Inspections check for damage, quality, use by date, and discrepancies against the order. Safe food handling requires inspecting deliveries, vehicles, and driver practices; ensuring a receiver is available; and checking temperatures, packaging, and storing deliveries promptly according to food type and temperature requirements. Proper storage practices minimize theft and spoilage, including labeling, recording, and conducting regular stock takes of food and supplies.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentManaging Process Inspection and Verification of Deliveries

RECEIVING AND STORING OF DELIVERIES

All delivered items must be inspected to ensure they meet quality standards and the establishment's needs. Inspections check for damage, quality, use by date, and discrepancies against the order. Safe food handling requires inspecting deliveries, vehicles, and driver practices; ensuring a receiver is available; and checking temperatures, packaging, and storing deliveries promptly according to food type and temperature requirements. Proper storage practices minimize theft and spoilage, including labeling, recording, and conducting regular stock takes of food and supplies.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesRISKMAN

Uploaded by

Jam KaiiManaging Process Inspection and Verification of Deliveries

RECEIVING AND STORING OF DELIVERIES

All delivered items must be inspected to ensure they meet quality standards and the establishment's needs. Inspections check for damage, quality, use by date, and discrepancies against the order. Safe food handling requires inspecting deliveries, vehicles, and driver practices; ensuring a receiver is available; and checking temperatures, packaging, and storing deliveries promptly according to food type and temperature requirements. Proper storage practices minimize theft and spoilage, including labeling, recording, and conducting regular stock takes of food and supplies.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

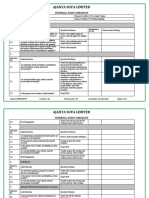

Managing Process Inspection and Verification of Deliveries

RECEIVING AND STORING OF DELIVERIES

Inspection and Verification

Food Handling All delivered items must be checked to ensure that the products

It refers to any activities that involve handling of food products meet the standard quality and needs of the establishment.

which includes from preparation to displaying of the food. 1. Damage and Breakage

Safe food handling techniques are used to control the safety of food 2. Quality

and this covers the processes from receiving of food into the o Intended Use

premises down to waste disposal. o Cost Price

o House Standard & Customer Expectation

Receiving of Delivery o Urgency of Need

This is where the food handling starts as soon as the raw materials 3. Use by date

arrived on the premises of the establishment in which each o Avoid Spoilage

procured products were meticulously checked and verified in 4. Discrepancy

accordance with the specs on their purchase order. o Based on the order

Checking is needed to ensure that;

Right Receiver Safe Food Handling Requirements in Relation to Food Receipt

Right Specification

Quantity as per order 1. Inspect the Deliveries Physically

Food condition upon arrival Free from visible contamination

Common Supplies No rodents or any pests

Food Check the use-by date

Beverage 2. Inspect the Vehicles

Tools and Equipment Check whether the carrier is clean and appropriate for any food

Cleaning Materials and Chemicals related deliveries.

Linens 3. Check the Practices of the Driver

Stationery Items Personal Hygiene

Segregate the food item based on its categories

4. Availability of the Receiver

Deliveries should not be left unattended at this raises the possibility

of contamination as well as potential theft.

5. Temperature

The food should be delivered on the proper temperature as based Check the temperature daily

on the food and safety plan using a calibrated thermometer Do not overcrowd

6. Check the Packaging Separate the raw to ready to eat goods

Check the label, name of the manufacturer or supplier Frozen Goods Storage Practices

7. Store At least -15 C or below

Store all the deliveries as soon as possible. Thawed item must never be refrozen

Storing Supplies Freezer door should be kept closed

Storing Freezer should be defrosted regularly

It refers to safekeeping of the food supplies and materials needed in

accordance with the temperature and its type

Storing Supplies

The storage areas must meet the general requirements that hold for

the processing area to ensure that the space can be cleaned.

Pilferage

A good storage practices also minimize the possible theft incident

within the kitchen

Storing Practices that minimize the Pilferage Incident Stock take

Lock Also known as physical inventory. It refers to counting of the

Prohibition of Bags available stocks in the storage.

Proper Receiving and Storage Procedures

Spot check on garbage bins Stocktaking Sheet

Stockman should label and record the item as soon as the item was placed

on the food storage which includes;

Name of the item

Date when it was placed in the storage

Time

Name of the Relevant Person

Date of Expiry

Dry Goods Storage

It is a non-refrigerated storage where canned and dried foods are

kept.

Dry Goods Storage Practices Stocktaking sheet includes;

Fly and Vermin Proof Date

Well Ventilated and Lighted Section to be counted

Do not Overstocked Who has conducted

Clean and sanitize before reuse and refill Product column

Unit column

Refrigerated Goods Storage Practices Unit cost Column

Must be at 5 Degree Celsius Stock Value

Quantity

You might also like

- Name of Licensed Premises: - License No.: - Check by (Name)Document7 pagesName of Licensed Premises: - License No.: - Check by (Name)atherNo ratings yet

- MAN - The Triune God - Geoffrey HodsonDocument29 pagesMAN - The Triune God - Geoffrey HodsonmichaelcadNo ratings yet

- Tallarn-0 5Document2 pagesTallarn-0 5Mardness1302No ratings yet

- Lesson 2 Risk Management As Applied To Safety, SecurityDocument30 pagesLesson 2 Risk Management As Applied To Safety, SecurityMarlon AndayaNo ratings yet

- Sop - Kitchen DepartmentDocument11 pagesSop - Kitchen DepartmentChef Chef100% (3)

- Radiation Monitoring InstrumentsDocument107 pagesRadiation Monitoring InstrumentsCristina ȚărnăNo ratings yet

- Chief Technology Officer or IT Director or IT ManagerDocument4 pagesChief Technology Officer or IT Director or IT Managerapi-77407532No ratings yet

- Writing Food Safety PlanDocument17 pagesWriting Food Safety PlanAleksandar Pavlovski0% (1)

- Module 2 - Material HandlingDocument26 pagesModule 2 - Material HandlingJaisree AnandNo ratings yet

- The Food Production FlowDocument120 pagesThe Food Production FlowTrisha RachoNo ratings yet

- Quail Farming Made Easy: A DIY Handbook for Starting Your Own Quail FarmFrom EverandQuail Farming Made Easy: A DIY Handbook for Starting Your Own Quail FarmNo ratings yet

- JFCDocument2 pagesJFCMaria roxanne HernandezNo ratings yet

- Receiving Deliveries Standard Operating Procedures: Revised 3/2020 1Document2 pagesReceiving Deliveries Standard Operating Procedures: Revised 3/2020 1Marichelle PaloNo ratings yet

- Writing A Food Safety Plan PDFDocument17 pagesWriting A Food Safety Plan PDFFitri RamadhaniNo ratings yet

- Week 5 Risk MGTDocument10 pagesWeek 5 Risk MGTjudezaNo ratings yet

- Food Product Flow: Objective: in This Chapter The Student Will Able ToDocument15 pagesFood Product Flow: Objective: in This Chapter The Student Will Able ToRosiee Salazar TejadaNo ratings yet

- Art AppreciationDocument6 pagesArt AppreciationJam KaiiNo ratings yet

- SOP Receiving-DeliveriesDocument2 pagesSOP Receiving-DeliveriesErdinan SetiawanNo ratings yet

- SITXFSA002 PowerPoint Slides V1.1Document110 pagesSITXFSA002 PowerPoint Slides V1.1Stacy Parker100% (1)

- Purchasing, Receiving, Handling and Storage of Meat GuidlinesDocument16 pagesPurchasing, Receiving, Handling and Storage of Meat Guidlinesthei riosNo ratings yet

- Food Product FlowDocument55 pagesFood Product FlowAli Nah100% (1)

- Food Safety PlanDocument3 pagesFood Safety Plansafety officer100% (2)

- Receiving DeliveriesDocument3 pagesReceiving DeliveriesklutgringNo ratings yet

- SITHKOP005 Coordinate Cooking OperationDocument7 pagesSITHKOP005 Coordinate Cooking Operationbijay rai100% (3)

- SITHKOP005 Coordinate Cooking OperationDocument8 pagesSITHKOP005 Coordinate Cooking OperationBaljeet SinghNo ratings yet

- Orca Share Media1676505355563 7031773118863093717Document42 pagesOrca Share Media1676505355563 7031773118863093717Charls Aron ReyesNo ratings yet

- Letter of RecommendationDocument1 pageLetter of RecommendationIsaac Kocherla100% (1)

- Fifo PolicyDocument2 pagesFifo PolicySatya TripathiNo ratings yet

- IDOC As Web ServiceDocument40 pagesIDOC As Web ServiceUmesh Nanjaiah100% (2)

- Food Repacking SOPDocument4 pagesFood Repacking SOPKayla OcampoNo ratings yet

- Standard Receiving ProceduresDocument2 pagesStandard Receiving ProceduresKimmy BiacoNo ratings yet

- Sitxinv002 Maintain The Quality of Perishable Items: Activity 1ADocument8 pagesSitxinv002 Maintain The Quality of Perishable Items: Activity 1ANancy VermaNo ratings yet

- Dnic Sop Kitchen DepartmentDocument10 pagesDnic Sop Kitchen DepartmentYusak TewalNo ratings yet

- Section 2 - Operational Standards: OS/03: Storage of FoodDocument2 pagesSection 2 - Operational Standards: OS/03: Storage of Foodmuhammed asharudheenNo ratings yet

- Storing Food Safely - FinalDocument1 pageStoring Food Safely - FinalMMNo ratings yet

- Rsfs 2019 Lesson 4Document14 pagesRsfs 2019 Lesson 4RICHARD C. DIZONNo ratings yet

- Pembetulan Peta Minda SlideDocument3 pagesPembetulan Peta Minda SlideNur Husnina ZawawiNo ratings yet

- Midterm and FinalDocument15 pagesMidterm and FinalJane Ednalaga GorospeNo ratings yet

- Lesson 2 - TleDocument59 pagesLesson 2 - Tlesharmaine LabogNo ratings yet

- Participate in Safe Food HandlingDocument23 pagesParticipate in Safe Food HandlingSukhin ChauhanNo ratings yet

- SITXINV002 - Maintain The Quality of Perishable ItemsDocument20 pagesSITXINV002 - Maintain The Quality of Perishable ItemsJyot SoodNo ratings yet

- Food Safety StandardsDocument4 pagesFood Safety StandardssalazarayieNo ratings yet

- SITHKOP005 - Written AssessmentDocument7 pagesSITHKOP005 - Written AssessmentTephieNo ratings yet

- Receiving Safe Food - FinalDocument1 pageReceiving Safe Food - FinalMMNo ratings yet

- Food Purchasing, Receiving and StorageDocument29 pagesFood Purchasing, Receiving and StorageLien Mar GastadorNo ratings yet

- Standard Operational Procedure MaherDocument7 pagesStandard Operational Procedure MaherRiesya RenathaNo ratings yet

- Haccp SOP 2015 TUV-translateDocument69 pagesHaccp SOP 2015 TUV-translatebrurNo ratings yet

- Ohs-Info Sheet No. 4Document11 pagesOhs-Info Sheet No. 4Ferlyn AboyNo ratings yet

- Internal Audit Checklist STORE, PURCHASE - DISPATCHDocument4 pagesInternal Audit Checklist STORE, PURCHASE - DISPATCHRavi BaghelNo ratings yet

- Module Food FlowDocument14 pagesModule Food FlowMark Edrian RodriguezNo ratings yet

- IC09 - TSH Food Safety Manual August 2019Document26 pagesIC09 - TSH Food Safety Manual August 2019j KiizaNo ratings yet

- HRA Audit Feilds or ChecklistDocument3 pagesHRA Audit Feilds or ChecklistJovendra Pratap SinghNo ratings yet

- Reopening Checklist For Food Businesses During COVID-19: Planning and Preparation For Start-UpDocument7 pagesReopening Checklist For Food Businesses During COVID-19: Planning and Preparation For Start-Upkarupukamal100% (1)

- Risk Management Applied To Food Safety, Security and SanitationDocument3 pagesRisk Management Applied To Food Safety, Security and SanitationLea Mae100% (1)

- Food FlowDocument93 pagesFood FlowDilan PreciousNo ratings yet

- Group 2 TveDocument9 pagesGroup 2 TveSHEALA LADERANo ratings yet

- Shelf-Life Study Basic GuideDocument4 pagesShelf-Life Study Basic Guidelysmacinas0401No ratings yet

- DDDDocument2 pagesDDDJheann Flestado SapicoNo ratings yet

- PFS Chap.9Document41 pagesPFS Chap.9Jana JarshiNo ratings yet

- Food FlowDocument15 pagesFood FlowJessa CapangpanganNo ratings yet

- Safe Food Handling Procedures: StandardsDocument14 pagesSafe Food Handling Procedures: StandardsAndy TllNo ratings yet

- Food and Beverage CycleDocument4 pagesFood and Beverage CycleJoseph Louis BautistaNo ratings yet

- Infobite Food PackagingDocument1 pageInfobite Food PackagingMMNo ratings yet

- Food Safety ManualDocument47 pagesFood Safety ManualsalazarayieNo ratings yet

- SITXINV002 Maintain The Quality of Perishable ItemsDocument3 pagesSITXINV002 Maintain The Quality of Perishable ItemsÇrox Rmg PunkNo ratings yet

- SG - PMR - 01417 - Kitchen Storage Training Material - Entire Module Not CompletedDocument18 pagesSG - PMR - 01417 - Kitchen Storage Training Material - Entire Module Not CompletedKenn G MunyekiNo ratings yet

- Pe ReviewDocument4 pagesPe ReviewJam KaiiNo ratings yet

- Philippine Pop CultureDocument3 pagesPhilippine Pop CultureJam KaiiNo ratings yet

- Macro Perspective 2Document11 pagesMacro Perspective 2Jam KaiiNo ratings yet

- Math in The Modern WorldDocument7 pagesMath in The Modern WorldJam KaiiNo ratings yet

- Art AppreciationDocument6 pagesArt AppreciationJam KaiiNo ratings yet

- Macro PerspectiveDocument7 pagesMacro PerspectiveJam KaiiNo ratings yet

- Phil. History FinalDocument4 pagesPhil. History FinalJam KaiiNo ratings yet

- Business Partner Application Form: Bintang Arif Kurniawan 08119002384Document1 pageBusiness Partner Application Form: Bintang Arif Kurniawan 08119002384Bintang ArifNo ratings yet

- Aldi and Walmart CaseDocument4 pagesAldi and Walmart CaseJackNo ratings yet

- Lab Guide: Musculoskeletal AssessmentDocument6 pagesLab Guide: Musculoskeletal AssessmentDaisy MellaNo ratings yet

- MIL-H-6875H Heat Treatment of SteelDocument29 pagesMIL-H-6875H Heat Treatment of Steelgoathead61No ratings yet

- Michael Buble - HomeDocument5 pagesMichael Buble - Homepurbaalam0702No ratings yet

- Bi NilamDocument2 pagesBi NilamSANGGERTANA A/P KULANTHAVELU MoeNo ratings yet

- Healthcare SCM in Malaysia - Case StudyDocument10 pagesHealthcare SCM in Malaysia - Case StudyHussain Alam100% (1)

- Nodeep Kaur The Jailed Activist Meena Harris Tweeted AboutDocument11 pagesNodeep Kaur The Jailed Activist Meena Harris Tweeted AboutBIDIFianNo ratings yet

- Brand ImageDocument2 pagesBrand Imagedollys59No ratings yet

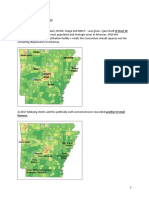

- Arkansas DispensariesDocument6 pagesArkansas DispensariesAdam ByrdNo ratings yet

- CFA Level I - Timetable (August 2021 Exam) (V2)Document1 pageCFA Level I - Timetable (August 2021 Exam) (V2)Via Commerce Sdn BhdNo ratings yet

- Marketing Case StudiesDocument10 pagesMarketing Case StudiesSwati ChamariaNo ratings yet

- DalmaDocument2 pagesDalmaSatish MishraNo ratings yet

- Product Selector Guide Marine Protective Coatings en 196830Document1 pageProduct Selector Guide Marine Protective Coatings en 196830wilberizquierdo1No ratings yet

- Beamray 50R100R Data SheetDocument2 pagesBeamray 50R100R Data Sheethassan elgamriNo ratings yet

- 6 SBMA V RodriguezDocument9 pages6 SBMA V RodriguezLexNo ratings yet

- Assignment Arts Appreciation: Submitted To: Mam Sana Submitted By: Mahnoor Akhter Session: 2018-2022 Semester: 1Document16 pagesAssignment Arts Appreciation: Submitted To: Mam Sana Submitted By: Mahnoor Akhter Session: 2018-2022 Semester: 1Mahnoor AkhterNo ratings yet

- Sharp+Lc c6554u+Difference+Lc 65d64uDocument30 pagesSharp+Lc c6554u+Difference+Lc 65d64uNicholas RileyNo ratings yet

- Solar Brochure February 2023Document24 pagesSolar Brochure February 2023prakistaoNo ratings yet

- NY Mid-Eastern Group - Aug 2010Document3 pagesNY Mid-Eastern Group - Aug 2010CAP History LibraryNo ratings yet

- 6 Pre-Transfusion TestingDocument24 pages6 Pre-Transfusion TestingRhema AyuhNo ratings yet

- Yoga Retreat in India - Short Course - Yoga Treatment - Yoga TherapyDocument1 pageYoga Retreat in India - Short Course - Yoga Treatment - Yoga TherapynaveenNo ratings yet

- FC52Document5 pagesFC52Bassel AlmouieNo ratings yet