Professional Documents

Culture Documents

Operating Instructions en Ja Ko ZH CN: Printed: 07.07.2013 - Doc-Nr: PUB / 5137805 / 000 / 00

Uploaded by

MiguelAngelCedanoBurrolaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operating Instructions en Ja Ko ZH CN: Printed: 07.07.2013 - Doc-Nr: PUB / 5137805 / 000 / 00

Uploaded by

MiguelAngelCedanoBurrolaCopyright:

Available Formats

PS 35

Operating instructions en

ja

ko

zh

cn

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

1

4 6 2 1 7

5 3 3

2

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

38 112

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

ORIGINAL OPERATING INSTRUCTIONS

PS 35 ferrodetector

It is essential that the operating instructions

1 These numbers refer to the corresponding illustra- en

tions. The illustrations can be found on the fold-out cover

are read before the tool is operated for the pages. Keep these pages open while studying the oper-

first time. ating instructions.

In these operating instructions, the designation “the tool”

Always keep these operating instructions to- always refers to the PS 35 Ferrodetector.

gether with the tool.

Parts, operating controls and indicators 1

Ensure that the operating instructions are

with the tool when it is given to other persons.

@ On/off button

; Scan and settings button

Contents Page

= Arrow buttons for navigating in menus

1 General information 1 % Status LEDs (red / green)

2 Description 2 & Marking opening

3 Technical data 5 ( Display

4 Safety instructions 6 ) Battery compartment

5 Before use 7

6 Operation 7

7 Care and maintenance 9

8 Troubleshooting 10

9 Disposal 10

10 Manufacturer’s warranty 11

11 FCC statement (applicable in US) / ICES

statement (applicable in Canada) 11

12 EC declaration of conformity (original) 12

1 General information

1.1 Safety notices and their meaning 1.2 Explanation of the pictograms and other

DANGER information

Draws attention to imminent danger that will lead to Warning signs

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

General

warning

CAUTION

Draws attention to a potentially dangerous situation that Symbols

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful informa-

tion. Read the Return waste

operating material for

instructions recycling.

before use.

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

Location of identification data on the tool to it when making an enquiry to your Hilti representative

The type designation and serial number can be found on or service department.

the type identification plate on the tool. Make a note of

this data in your operating instructions and always refer Type:

Serial no.:

en

2 Description

2.1 Use of the product as directed

The Hilti PS 35 Ferrodetector is designed to detect ferrous metals (steel rebars), non-ferrous metals (copper and

aluminium) and to measure the depth of concrete cover.

The tool is not suitable for locating the position of tensioning cables.

The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or when used

not as directed.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

Take the influences of the surrounding area into account. Do not use the tool or appliance where there is a risk of fire

or explosion.

Modification of the tool is not permissible.

2.2 Display

The measurements, settings and tool status are shown in the display.

2.3 Display illumination

The display illumination switches on automatically in conditions of low ambient light.

2.4 Display

Areas of the display Status area

1 @

2 ; Detection area

Shows the two areas of the display.

2.5 Standard settings in the status area

Standard status area The standard detection mode is set automatically when the tool is

switched on. In this mode, ferrous metals and non-ferrous metals

(copper and aluminium) can be detected. Limited depth scan is switched

off.

2.6 Status indicator

Status area Ferrous metal detection is act-

ive

@

Non-ferrous metal detection is

1 2 3 4 5

active

;

= Limited depth scan is active

Selected depth measurement

range (in mm or inches)

%

& Battery status

Shows which status is active

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

2.7 Detection zone

Detection display @ Signal strength indicator

Depth measurement in mm or

; inches en

1 2

Shows the area in the detection zone

2.8 Menus

Menus 1 Status area, shows the current

menu settings

@

Status: 0 is “Off” and I is “On”.

The symbol on the white back-

;

ground is active.

2 0 I

Display shown when navigating through the menus.

2.9 Symbols in the display

Ferrous metal active (left)

inactive (right)

0 I 0 I

Non-ferrous metal active (left)

inactive (right)

0 I 0 I

Measuring units inches active (left)

inch mm mm active (right)

inch mm inch mm

Limited depth scan (mm) active (left)

inactive (right)

0 25 50 75 0 25 50 75

Limited depth scan (inches) active (left)

inactive (right)

0 1 2 3 0 1 2 3

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

Audible signal active (left)

inactive (right)

0 I 0 I

en User training active (left)

? ? inactive (right)

0 I 0 I

2.10 Warnings and error symbols in the display

Error message Contact Hilti service

Temperature warning Inadmissible operating range

Electromagnetic interference Too much interference from the surroundings

Calibration warning Calibration is required

2.11 Battery condition indicator

Number of segments shown Charge status in %

3 = 100 % capacity

2 =80 % capacity

1 = 50 % capacity

0 = 20 % capacity

Battery symbol blinks = fully discharged

2.12 Items supplied as standard

1 Tool

1 Hand strap

4 Batteries

1 Operating instructions

1 Manufacturer’s certificate

1 Soft pouch

2 Markers

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

3 Technical data

Right of technical changes reserved.

NOTE

All values apply to individual rod-like metal objects positioned at right angles to the direction of movement of the

detector and when the surface of the concrete is flat and smooth with no external interference factors. Detection range

and accuracy is reduced when measurements are taken on brickwork.

en

PS 35

Detection range for locating ferrous metals in concrete >∅ 8 mm (≧ # 3): 5…120 mm (¼ in ...4¾ in)

(individual rebars) ∅ 6…8 mm: 5…100 mm (¼ in ... 4 in)

Detection range for locating non-ferrous metals (copper Diameter Min. 10 mm (½ in), Wall thickness Min. 2 mm

and aluminium pipes) (³/₃₂ in): 5…80 mm (¼ in ...3¹/₈ in)

Depth measurement range for individual rebars >∅ 8 mm (≧ # 3): 5…120 mm (¼...4¾ in)

∅ 6…8 mm: 5…100 mm (¼ ... 4 in)

Accuracy of depth measurement (accurate measure- Depth range 5…60 mm (¼ in ... 2²/₃ in): ±3 mm (±¹/₈ in)

ment mode)* Depth range 60…80 mm (2²/₃ in ... 3¹/₈ in): ±5 mm (±¼

in)

Depth range 80…100 mm (3¹/₈ ... 4 in): ±7 mm (±⁹/₃₂ in)

Depth range 100…120 mm (4 in ... 4³/₄ in): ±11 mm

(±⁷/₁₆ in)

Localization accuracy ±10 mm (±½ in)

Minimum distance between objects Depth range 5…55 mm (¼ in ...2¹/₈ in): 55 mm (2¹/₈ in)

Depth range ≥ 55 mm (2¹/₈ in): Distance/depth factor

>1.5

Power source 4x1.5V (AAA) LR03 alkaline batteries

Battery life at 20 °C 8h

Operating temperature range -15…+50°C (5° F ... 122° F)

Automatic cut-out 5 min

Storage temperature range (dry) -25…+63°C (-13° F ... 145° F)

Relative air humidity 95%

Protection class IP 54 (protection against dust and water spray)

Weight (including batteries) 450 g (1 lb)

Dimensions (L x W x H) 237 mm x 104 mm x 47 mm (9.4 in x 4 in x 2 in)

NOTE

* Applies to concrete with typical aggregate and reinforcement content.

Measuring units Dimensions

mm Millimeters

In Inches

in ¹⁄₈ ¹⁄₈ fraction

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

4 Safety instructions

In addition to the information relevant to safety given 4.2 Proper organization of the workplace

in each of the sections of these operating instructions,

a) Avoid unfavorable body positions when working

the following points must be strictly observed at all on ladders or scaffolding. Make sure you work

times.

from a safe stance and stay in balance at all

en The tool is designed to detect ferrous metals (steel re- times.

bars) and non-ferrous metals (copper and aluminium)

b) When the tool is brought into a warm environment

in concrete, brick, drywall and under plaster surfaces

from very cold conditions, or vice-versa, allow it

in accordance with the information provided in the

to become acclimatized before use.

technical data section.

c) Use the tool only within its specified limits.

d) Observe the accident prevention regulations ap-

4.1 Basic information concerning safety plicable in your country.

a) Do not render safety devices ineffective and do

not remove information and warning notices. 4.3 Electromagnetic compatibility

b) Keep children away from the tool.

Although the tool complies with the strict requirements of

c) Check that the tool functions correctly each time the applicable directives, Hilti cannot entirely rule out the

before use.

possibility of the tool being subject to interference caused

d) Check the display after switching the tool on. The by powerful electromagnetic radiation, leading to incor-

display should show the Hilti logo, the tool model rect operation. Check the accuracy of the tool by taking

designation and version. The tool then carries out a measurements by other means when working under such

brief self-test, after which the standard settings or conditions or if you are unsure. Likewise, Hilti cannot rule

the previously saved settings are displayed. out the possibility of interference with other devices (e.g.

e) Check to ensure that the tool is able to calibrate aircraft navigation equipment). The tool complies with the

itself after switching on. requirements of class A; The possibility of interference

f) Operation of the tool in the proximity of pregnant occurring in a domestic environment cannot be excluded.

women is not permissible.

g) Rapidly changing detection conditions may lead to

4.4 General safety instructions

inaccurate readings.

h) Use the tool only within the specified conditions. a) Check the condition of the tool before use. If the

Do not use the tool on materials containing items tool is found to be damaged, have it repaired at a

such as tensioning cables or stainless steel ob- Hilti service center.

jects. b) The user must check the accuracy of the tool

i) Do not use the tool in the proximity of medical after it has been dropped or subjected to other

instruments and appliances. mechanical stresses.

j) Do not drill at positions where the tool has located c) Although the tool is designed for the harsh con-

an object. ditions of jobsite use, as with other measuring

k) The warnings shown in the display must always instruments it should be treated with care.

be observed. d) Although the tool is protected to prevent entry

l) Do not use the tool for quality control inspections. of dampness, it should be wiped dry each time

m) Do not use the tool in the proximity of sources of before being put away in its transport container.

electromagnetic interference (e.g. electric break- e) Check to ensure that all symbols are visible when

ers in operation). the tool is switched on.

n) Take the influences of the surrounding area into f) Check the accuracy of the tool before using it for

account. Do not use the tool where there is a risk detection or measurement.

of fire or explosion.

o) Use of the tool in the proximity of persons with a 4.5 Electrical safety

cardiac pacemaker is not permissible. a) Keep the batteries out of reach of children.

p) Make sure that the display area can be easily b) Do not allow the batteries to overheat and do not

read (e.g. do not touch the display area with the expose them to fire. The batteries may explode or

fingers, keep the display area clean). release toxic substances.

q) Do not use the tool if it is defective. c) Do not charge the batteries.

r) Always keep the detection area clean. d) Do not solder the batteries into the tool.

s) Always check how the tool is set before using it. e) Do not discharge the batteries by short-circuiting.

t) The accuracy of the tool is influenced by the base This may cause them to overheat and present a risk

material. If the tool is unable to calibrate itself cor- of personal injury (burns).

rectly, small measurement errors may result. f) Do not attempt to open the batteries and do not

u) When the tool is unable to calibrate itself automatic- subject them to excessive mechanical stress.

ally, a warning appears in the display.

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

4.6 Transport

Always remove the batteries before shipping the tool.

5 Before use

2. For accurate results, allow the tool to acclimatize en

itself to the ambient conditions before use if it has

previously been exposed to extreme temperature

fluctuations.

3. Check how the tool is set before using it.

5.1 Inserting the batteries 2

CAUTION 5.3 Switching the tool on / off

Do not use damaged batteries. 1. Switch the tool on by pressing the on/off button.

After switching the tool on, the standard settings are

CAUTION active.

Always replace the complete set of batteries. 2. When the tool is already switched on, press the

on/off button: the tool switches itself off.

DANGER NOTE If the tool is not used or an error message

Do not mix old and new batteries. Do not mix batteries is displayed, it switches itself off automatically after

of different makes or types. five minutes. The tool switches itself off when the

batteries are discharged.

1. Open the battery compartment.

2. Remove the batteries from the packaging and insert

5.4 Settings menu

them in the tool.

NOTE Take care to observe correct polarity (see 1. Switch the tool on.

symbols in battery compartment). 2. Press one of the arrow buttons (right or left) to go to

3. Check to ensure that the battery compartment cover the settings menu.

is closed correctly. 3. Press one of the arrow buttons to move through the

menu and make your selection.

4. Press the scan and settings button to change the

5.2 Checking the tool

settings.

1. Check to ensure that the sensor area is not damp. If 5. After making your selection, the tool will automatic-

necessary, use a cloth to dry the sensor area. ally return to the area display within 5 seconds and

is then ready for operation.

NOTE If no selection is made within 5 seconds, the

tool leaves the settings menu automatically.

6 Operation

2. Switch the tool on by pressing the on/off button.

After carrying out a brief self-test, the tool begins to

calibrate itself automatically. The status LEDs light

green as soon as this has been completed.

6.1 Preparing the tool for use While the tool is calibrating itself, hold it in the air at

least 30 cm (12 in) away from any metal objects and

CAUTION

away from the surface on which you are working.

Always drill at a safe distance from objects you have

3. The first five times the tool is switched on, it runs

detected.

through an animated training program that demon-

strates how it should be used. This training program

1. Before switching the tool on, check that it is not in

can be switched off in the options in the settings

contact with anything and is clear of the working

menus.

surface or metal objects.

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

6.2 Working with the tool imum when the tool is positioned over the center of

Check that the tool makes full contact with the surface the object.

you wish to scan. In the meantime, the depth measurement is shown

Use the tool only on smooth surfaces. in the display.

If the tool is moved further until it is past the ferrous

Bring the tool slowly and carefully into contact with the

metal, the status LEDs light green and the signal

surface to be scanned.

en Do not move the tool at a speed greater than 20 cm/s (9

strength indicator shows a decreasing value.

To obtain an exact indication of the position of the

in/s).

object, the tool must be moved back in the opposite

6.2.1 Sweep scan method direction until the status LEDs light red and the

signal strength indicator shows the maximum value.

Use the marking pen supplied to mark the position

of the ferrous metal object through the marking

opening in the tool.

If the loudspeaker has been activated, a constant

audible signal is emitted so long as the tool is

positioned over the ferrous metal object.

When the tool approaches a non-ferrous metal ob-

ject (copper, aluminium), the “non-ferrous metal”

symbol begins to blink, the status LEDs light red

and the amplitude of the signal strength indicator

rises and reaches its maximum when the tool is

positioned over the center of the object.

If the tool is moved further until it is past the non-

ferrous metal object, the status LEDs light green and

In order to achieve best results, the tool should be used

the signal strength indicator shows a decreasing

with a sweeping motion (extended horizontal and vertical

value.

movements over the object). The series of illustrations

show the sweep method in use. When the tool is switched To obtain an exact indication of the position of the

on for the first time, it displays an animated training object, the tool must be moved back in the opposite

program that shows how the tool should be used to scan direction until the status LEDs again light red and

a surface. the signal strength indicator shows the maximum

value.

Use the marking pen supplied to mark the position

6.3 Locating objects in standard mode of the non-ferrous metal object through the marking

opening in the tool.

If the loudspeaker has been activated, a constant

audible signal is emitted so long as the tool is

positioned over the non-ferrous metal object.

6.4 Locating objects consisting solely of ferrous

metal

1. Switch the tool on and hold it at least 30 cm (12

in) away from any metal objects and away from the

surface on which you are working.

The tool activates standard mode after completing 1. Switch the tool on.

automatic calibration. Activate the ferrous metals detection mode in the

The depth measurement units (mm or in) are shown menus and deactivate the non-ferrous metals de-

in the display and the status LEDs light green. tection mode.

The tool is ready to be used for locating objects. 2. The limited depth scan mode may be activated if

2. Carefully bring the tool into contact with the surface desired.

to be scanned and then begin to move it sideways. 3. Then follow the steps described in the section “Loc-

NOTE Deactivate the limited depth scan setting ating objects in standard mode” (for ferrous metals).

if you wish to detect ferrous metal without depth

limitation.

When the tool approaches a ferrous metal object (a

rebar), the “ferrous metal” symbol begins to blink,

the status LEDs light red and the amplitude of the

signal strength indicator rises and reaches its max-

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

6.5 Locating objects consisting solely of 2. Carefully bring the tool into contact with the surface

non-ferrous metal to be scanned and then begin to move it slowly

sideways.

When the tool approaches a rebar, the “ferrous

metal” symbol begins to blink, the status LEDs light

red and the amplitude of the signal strength indic-

ator rises and reaches maximum when the tool is

positioned over the center of the rebar. If the tool

en

1. Switch the tool on. is moved further until it is past the rebar, the status

Activate the non-ferrous metal detection mode in the LEDs light green and the signal strength indicator

menus and deactivate the ferrous metal detection shows a decreasing value. To obtain an exact indic-

mode. ation of the position of the rebar, the tool must be

The limited depth scan mode is deactivated auto- moved back in the opposite direction until the status

matically. LEDs again light red and the signal strength indicator

2. Follow the steps described in the section “Locating shows the maximum value. When the tool is in the

objects in standard mode” (for non-ferrous metal). area where maximum signal strength is indicated,

the initial depth measurement is displayed.

6.6 Precise rebar depth measurement. 3. At this point, press the “scan” button and the precise

NOTE depth measurement will then be displayed within

The precise depth measurement mode can be used only two to three seconds.

with reinforcing bars in concrete.

6.7 Limited depth scan

NOTE

This measurement mode allows rebars to be located

within a specified depth range.

NOTE

When using the tool in this mode, the preset depth must

take a clearance distance from the rebar into account.

1. Switch the tool on.

2. In the settings menu, select “ferrous metals” and set

the desired depth scan range in which you wish to

locate the rebars. If necessary, you can deactivate

the non-ferrous metals localization function.

1. Switch the tool on. 3. Press the “scan” button to select the desired max-

Activate the ferrous metals detection mode in the imum depth range (25, 50 or 75 mm; 1, 2 or 3

menus and deactivate the non-ferrous metals de- in).

tection mode. 4. Use the tool as described in the section “Detecting

objects in standard mode” for ferrous metals. In this

scanning mode, only objects located at a depth less

than the preset measuring depth will be detected.

The last setting is memorized by the tool.

7 Care and maintenance

7.1 Cleaning and drying cleaned and dried (at maximum 40°C / 104°F). Repack

1. Use only a clean, soft cloth for cleaning. If necessary, the equipment only once it is completely dry.

moisten the cloth slightly with pure alcohol or a little Check the accuracy of the equipment before it is used

water. after a long period of storage or transportation.

NOTE Do not use any other liquids as these may Remove the batteries from the tool before storing it for a

damage the plastic components. long period. Leaking batteries may damage the tool.

2. The temperature limits for storage of your equipment

must be observed, especially in winter / summer. 7.3 Transport

Use the Hilti toolbox or packaging of equivalent quality for

7.2 Storage transporting or shipping your equipment. Make sure that

the tool is held securely in place inside the Hilti toolbox

Remove the tool from its case if it has become wet.

The tool, its carrying case and accessories should be

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

or equivalent packaging during transport. Store the tool The calibration service provides confirmation that the

safely. tool is in conformance, on the day it is tested, with the

CAUTION specifications given in the operating instructions.

Always remove the batteries before shipping the tool. The tool will be readjusted if deviations from the man-

ufacturer’s specification are found. After checking and

7.4 Hilti calibration service adjustment, a calibration sticker applied to the tool and

en We recommend that the tool is checked by the Hilti cal-

a calibration certificate provide written verification that

the tool operates in accordance with the manufacturer’s

ibration service at regular intervals in order to verify its

specification.

reliability in accordance with standards and legal require-

ments. Calibration certificates are always required by companies

certified according to ISO 900x.

Use can be made of the Hilti calibration service at any

time, but checking at least once a year is recommended. Your local Hilti Center or representative will be pleased

to provide further information.

8 Troubleshooting

Fault Possible cause Remedy

The tool can’t be switched on. The battery is exhausted. Replace the battery.

The battery is inserted the wrong way Insert the battery correctly.

round (incorrect polarity).

The battery compartment is not Close the battery compartment.

closed.

The tool can’t calibrate itself. The tool is too close to metal objects. Switch the tool off and then hold it

at least 30 cm (12 in) away from any

metal objects and away from the sur-

face on which you are working before

switching it on again.

The tool displays an electro- The tool is too close to electromag- Keep the tool away from sources of

magnetic interference warning. netic interference. electromagnetic interference.

The tool displays a temperature The temperature is too high or too Observe the operating temperature

warning. low. range (technical data).

No indication when positioned The ferrous / non-ferrous metal mode Activate the desired detection mode.

over an object. is not active.

9 Disposal

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must be

correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking

back old tools or appliances for recycling. Ask Hilti Customer Service or your Hilti representative for further information.

10

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

For EC countries only

Do not dispose of electronic measuring tools or appliances together with household waste.

In observance of the European Directive on waste electrical and electronic equipment and its imple-

mentation in accordance with national law, electric tools and batteries that have reached the end of their

life must be collected separately and returned to an environmentally compatible recycling facility.

en

10 Manufacturer’s warranty

Hilti warrants that the tool supplied is free of defects in Additional claims are excluded, unless stringent na-

material and workmanship. This warranty is valid so long tional rules prohibit such exclusion. In particular, Hilti

as the tool is operated and handled correctly, cleaned is not obligated for direct, indirect, incidental or con-

and serviced properly and in accordance with the Hilti sequential damages, losses or expenses in connec-

Operating Instructions, and the technical system is main- tion with, or by reason of, the use of, or inability to

tained. This means that only original Hilti consumables, use the tool for any purpose. Implied warranties of

components and spare parts may be used in the tool. merchantability or fitness for a particular purpose are

specifically excluded.

This warranty provides the free-of-charge repair or re-

placement of defective parts only over the entire lifespan For repair or replacement, send the tool or related parts

of the tool. Parts requiring repair or replacement as a immediately upon discovery of the defect to the address

result of normal wear and tear are not covered by this of the local Hilti marketing organization provided.

warranty.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

11 FCC statement (applicable in US) / ICES statement (applicable in Canada)

This device complies with section 15 of the FCC stand- NOTE

ards and fulfills the IC requirements in accordance with Changes or modifications not expressly approved by Hilti

ICES-003 for class B. could void the user’s authority to operate the equipment.

Operation is subject to the following two conditions:

PS 35 01

1. This device may not cause interference not in compli- Hilti=trademark of Hilti Corp., Schaan, LI Made in Malaysia

ance with the standards.

This device complies with part 15 of the FCC Rules. Operation is subject to the condition that this device does not cause

harmful interference. This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la classe B

est conforme à la norme NMB-003 du Canada.

Power: 6V/160 mA

2. This device must accept any interference received, in- Item No.: Serialnumber:

cluding interference that may cause undesired operation.

402292

11

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

12 EC declaration of conformity (original)

Designation: Ferrodetector Technical documentation filed at:

Type: PS 35 Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Year of design: 2009

Hiltistrasse 6

en We declare, on our sole responsibility, that this product 86916 Kaufering

complies with the following directives and standards: Deutschland

2011/65/EU, 2006/95/EC, 2004/108/EC, EN ISO 12100.

Hilti Corporation, Feldkircherstrasse 100,

FL‑9494 Schaan

Paolo Luccini Matthias Gillner

Head of BA Quality and Process Man- Executive Vice President

agement

Business Area Electric Tools & Ac- Business Area Electric

cessories Tools & Accessories

01/2012 01/2012

12

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

Hilti Corporation

LI-9494 Schaan

Tel.: +423 / 234 21 11

Fax:+423 / 234 29 65

www.hilti.com

*409101*

409101

Hilti = registered trademark of Hilti Corp., Schaan

W 3655 | 0313 | 10-Pos. 2 | 1

Printed in Germany © 2013

Right of technical and programme changes reserved S. E. & O. 409101 / A3

Printed: 07.07.2013 | Doc-Nr: PUB / 5137805 / 000 / 00

You might also like

- Condensed Intro To Tesla Transformers - Eric DollardDocument59 pagesCondensed Intro To Tesla Transformers - Eric Dollard~ScaLaR~100% (4)

- Xomox-HPBF Double Offset PDFDocument24 pagesXomox-HPBF Double Offset PDFPinak VadherNo ratings yet

- Wiki Korean BookDocument33 pagesWiki Korean Bookneonstar100% (1)

- IGCSE Chemistry Section 2 Lesson 1Document66 pagesIGCSE Chemistry Section 2 Lesson 1Antonia Putri Sri Nova YolandhaNo ratings yet

- 745 Multi-Tree-Handling Device Operator's Manual: WarningDocument18 pages745 Multi-Tree-Handling Device Operator's Manual: WarningЕвгений МакаровNo ratings yet

- Drypix 6000 12eDocument501 pagesDrypix 6000 12eraj_meditech100% (1)

- 7 Forms of Corrosion IDocument39 pages7 Forms of Corrosion IJesus De la RosaNo ratings yet

- Furniture Production Materials - 2Document9 pagesFurniture Production Materials - 2Pitz Shady ShinNo ratings yet

- Cast OlinDocument24 pagesCast OlinAnonymous CZHJN2EU0U100% (1)

- 12ClassicsI - OKp20 Elisabeth RochatDocument20 pages12ClassicsI - OKp20 Elisabeth Rochatpenfo100% (1)

- As 103090 LS-9000 Um 15623GB WW GB 2110 2Document454 pagesAs 103090 LS-9000 Um 15623GB WW GB 2110 2Michelle Kozmik JirakNo ratings yet

- KWE 5000 LM - FVS 3201 Manual PDFDocument328 pagesKWE 5000 LM - FVS 3201 Manual PDFdennis haryanto100% (1)

- Users Guide PD 42 en Operating Instruction PUB 5140894 000Document25 pagesUsers Guide PD 42 en Operating Instruction PUB 5140894 000siboNo ratings yet

- Operating-Instruction-DAG-450-S-02-Operating-Instruction-PUB-5069463-000Document54 pagesOperating-Instruction-DAG-450-S-02-Operating-Instruction-PUB-5069463-000elieraffoul98No ratings yet

- User's Manual: Insulation Resistance TesterDocument60 pagesUser's Manual: Insulation Resistance TesterNui DirekNo ratings yet

- User's Manual: Insulation Resistance TesterDocument60 pagesUser's Manual: Insulation Resistance TesterconglxNo ratings yet

- qqwDocument32 pagesqqwhabtamubedassaNo ratings yet

- PNOZ E3 1p ENDocument30 pagesPNOZ E3 1p ENJose Gabriel Aguirre AndradeNo ratings yet

- SIW 18T-A: Operating Instructions en Mode D'emploi FR Manual de Instrucciones Es Manual de Instruções PTDocument27 pagesSIW 18T-A: Operating Instructions en Mode D'emploi FR Manual de Instrucciones Es Manual de Instruções PTAHMADNo ratings yet

- Hilti SFD 2-ADocument25 pagesHilti SFD 2-AMitchell DanielsNo ratings yet

- PNOZ E1vp EN PDFDocument37 pagesPNOZ E1vp EN PDFDaniel Oswaldo LozanNo ratings yet

- Pilz Pnoz - User ManualDocument26 pagesPilz Pnoz - User ManualWellington MatosNo ratings yet

- HILTI - TE 7 Rotary HammerDocument18 pagesHILTI - TE 7 Rotary HammerSasidharan Kattisseril GovindanNo ratings yet

- X1 Boost User Manual 614.00392.016368679644974218947218417Document24 pagesX1 Boost User Manual 614.00392.016368679644974218947218417John Alfred VillaNo ratings yet

- CR06 Hybrid Recorder Instruction ManualDocument111 pagesCR06 Hybrid Recorder Instruction ManualStancu BranNo ratings yet

- Pnoz Xv3.1: Safety RelaysDocument36 pagesPnoz Xv3.1: Safety RelaysAlekseyNo ratings yet

- Thyssen Brake Control BSV1Document25 pagesThyssen Brake Control BSV1Tecwyn WebsterNo ratings yet

- M - 614.00754.00 X1 Mini G3.1 ManualDocument25 pagesM - 614.00754.00 X1 Mini G3.1 ManualThinh LeNo ratings yet

- Manual Balanca Shimadzu Auw220DDocument117 pagesManual Balanca Shimadzu Auw220DmrenaultNo ratings yet

- iGX440U: Werkstatt-Handbuch Manual de Taller Shop Manual Manuel D' AtelierDocument10 pagesiGX440U: Werkstatt-Handbuch Manual de Taller Shop Manual Manuel D' AtelierAlbertoNo ratings yet

- Philips HeartStart MRX - User TrainingDocument142 pagesPhilips HeartStart MRX - User TrainingΒαγγέλης ΛυράκηςNo ratings yet

- ValueJet 1614 SM Rev 1.4Document444 pagesValueJet 1614 SM Rev 1.4totooosNo ratings yet

- PNOZ X2.1: Safety RelaysDocument18 pagesPNOZ X2.1: Safety RelaysgustavoNo ratings yet

- PNOZ X2 1 Operat Man 1003354-EN-07 PDFDocument18 pagesPNOZ X2 1 Operat Man 1003354-EN-07 PDFmuaadhNo ratings yet

- Pa 726233Document9 pagesPa 726233Zanthii SantiagoNo ratings yet

- X1 Mini Manual With CTDocument22 pagesX1 Mini Manual With CTEmanuel BarrosNo ratings yet

- PNOZ s4.1: Safety RelaysDocument32 pagesPNOZ s4.1: Safety Relayschao wangNo ratings yet

- Vegawave 63Document36 pagesVegawave 63TranQuocThinhNo ratings yet

- X3!4!10kw User ManualDocument24 pagesX3!4!10kw User Manualpitr134No ratings yet

- شاشة سيمنس أجهزة الأشعة و التنظير الإيرانية PDFDocument104 pagesشاشة سيمنس أجهزة الأشعة و التنظير الإيرانية PDFmohammed hakimNo ratings yet

- M6847 MH8517 UserGuide v1 2Document16 pagesM6847 MH8517 UserGuide v1 2Shan AhmadNo ratings yet

- Pnoz X4: Safety RelaysDocument33 pagesPnoz X4: Safety RelaysJosito HNNo ratings yet

- Pnoz S5: Safety RelaysDocument38 pagesPnoz S5: Safety RelaysDumebiNo ratings yet

- Wa0008Document331 pagesWa0008Yos BirNo ratings yet

- Wax Dispensers Operator Guide A81610200 - 01-1-20Document19 pagesWax Dispensers Operator Guide A81610200 - 01-1-20matroodghaNo ratings yet

- AS3 Quick Start Manual E6582070 001Document68 pagesAS3 Quick Start Manual E6582070 001Erland CuariteNo ratings yet

- Sentron 7kg9661 UsDocument292 pagesSentron 7kg9661 UsSimpalean NicolaeNo ratings yet

- Ba NF30 en 04 069206Document28 pagesBa NF30 en 04 069206April WoodsNo ratings yet

- PNOZ s3 Operat Man 21395-EN-12Document27 pagesPNOZ s3 Operat Man 21395-EN-12Jose Jesus Canche UcNo ratings yet

- Pnoz S4: Safety RelaysDocument36 pagesPnoz S4: Safety RelaysPratik TapadiaNo ratings yet

- Safety Relays: Operating Manual-18436-EN-06Document28 pagesSafety Relays: Operating Manual-18436-EN-06Domingos FranciscoNo ratings yet

- Pnoz X4: Safety RelaysDocument33 pagesPnoz X4: Safety RelaysNiteshNo ratings yet

- 86515-01,03,05,07,09,11 ManualDocument19 pages86515-01,03,05,07,09,11 ManualCristián UrbinaNo ratings yet

- Installation and Operating InstructionsDocument12 pagesInstallation and Operating Instructionsrazali131266No ratings yet

- PNOZ s6 Operat Man 21398-EN-10Document30 pagesPNOZ s6 Operat Man 21398-EN-10antonioNo ratings yet

- 3pdf Manual PDFDocument39 pages3pdf Manual PDFserviciobsasNo ratings yet

- Futaba T3PDF ManualDocument39 pagesFutaba T3PDF ManualLuke PavoneNo ratings yet

- SEPAM 80 Quick Start 51247480FE-09Document36 pagesSEPAM 80 Quick Start 51247480FE-09A. JELLALINo ratings yet

- EN Supplementary Instructions Alignment Device For Radar Sensors VEGAPULS 10 20 30 Series VEGDocument16 pagesEN Supplementary Instructions Alignment Device For Radar Sensors VEGAPULS 10 20 30 Series VEGAgus Dani RamdaniNo ratings yet

- EN VEGAVIB 61 Transistor (NPN PNP)Document36 pagesEN VEGAVIB 61 Transistor (NPN PNP)yoquins22No ratings yet

- EN VEGASWING 61 Relay (DPDT)Document40 pagesEN VEGASWING 61 Relay (DPDT)Fredy TorresNo ratings yet

- Operating Manual (Deh-8350sd) - Eng - Esp - Por PDFDocument104 pagesOperating Manual (Deh-8350sd) - Eng - Esp - Por PDFHenrique BiesdorfNo ratings yet

- FH62C14Manual Beta - InglesDocument136 pagesFH62C14Manual Beta - InglestatianaloredoNo ratings yet

- Operator Dce50-90hmDocument174 pagesOperator Dce50-90hmCao LanNo ratings yet

- P2Hz X3: Safety RelaysDocument17 pagesP2Hz X3: Safety RelaysS.No ratings yet

- Pioneer DEH9350SDDocument104 pagesPioneer DEH9350SDRutch ChintamasNo ratings yet

- Esib 04 CompleteDocument782 pagesEsib 04 CompleteJorge AndradeNo ratings yet

- Electrical MachinesDocument624 pagesElectrical MachinesMiguelAngelCedanoBurrolaNo ratings yet

- Thordarson Transformer Catalog (1942)Document29 pagesThordarson Transformer Catalog (1942)MiguelAngelCedanoBurrolaNo ratings yet

- Ficha TLX 2.5 6.0Document2 pagesFicha TLX 2.5 6.0MiguelAngelCedanoBurrolaNo ratings yet

- Monocrystalline Module: High Customer ValueDocument2 pagesMonocrystalline Module: High Customer ValueMiguelAngelCedanoBurrolaNo ratings yet

- History and Road MapDocument2 pagesHistory and Road MapMiguelAngelCedanoBurrolaNo ratings yet

- Hipro Series: 390-410 WattDocument2 pagesHipro Series: 390-410 WattMiguelAngelCedanoBurrolaNo ratings yet

- Mosfet Battery CahergerDocument1 pageMosfet Battery CahergerMiguelAngelCedanoBurrolaNo ratings yet

- Readme First PDFDocument2 pagesReadme First PDFFelipe Mafioletti SchuartzNo ratings yet

- 144 Layout 340-355W 17.7% 0 +5W: Multicrystalline ModuleDocument2 pages144 Layout 340-355W 17.7% 0 +5W: Multicrystalline ModuleMiguelAngelCedanoBurrolaNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Lagrangian Relaxation Unit Commitment (LRUC) : U SD Su PG C MinimizeDocument11 pagesLagrangian Relaxation Unit Commitment (LRUC) : U SD Su PG C MinimizeMiguelAngelCedanoBurrolaNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Input Formats and Naming ConventionsDocument8 pagesInput Formats and Naming ConventionsMiguelAngelCedanoBurrolaNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Factores Penalizaci N PDFDocument2 pagesFactores Penalizaci N PDFMiguelAngelCedanoBurrolaNo ratings yet

- SCR 32Document6 pagesSCR 32Alan Ivan Gonzalez MerinoNo ratings yet

- Low Cost, Precision IC Temperature Transducer: 8C Max at +258C 8C Max (08C To +708C) 8C To +1058C mA/KDocument9 pagesLow Cost, Precision IC Temperature Transducer: 8C Max at +258C 8C Max (08C To +708C) 8C To +1058C mA/KMiguelAngelCedanoBurrolaNo ratings yet

- Problem A PotenciaDocument9 pagesProblem A PotenciaMiguelAngelCedanoBurrolaNo ratings yet

- V (kV) R (Ω/km) X (Ω/km) Y (S/km)Document2 pagesV (kV) R (Ω/km) X (Ω/km) Y (S/km)MiguelAngelCedanoBurrolaNo ratings yet

- Transistor IRFP350Document7 pagesTransistor IRFP350MiguelAngelCedanoBurrolaNo ratings yet

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- TOPManual V6Document138 pagesTOPManual V6Miguel AcbNo ratings yet

- Power Flow of Abule-EgbaDocument14 pagesPower Flow of Abule-EgbaMiguelAngelCedanoBurrolaNo ratings yet

- Atpdraw User ManualDocument189 pagesAtpdraw User Manualfancpuintel267% (3)

- Electric PowerDocument302 pagesElectric PowerMiguelAngelCedanoBurrolaNo ratings yet

- Cambridge Secondary 1 CheckpointDocument20 pagesCambridge Secondary 1 CheckpointAnisahNo ratings yet

- Cons555 Report Aysegul AkinDocument6 pagesCons555 Report Aysegul AkinAysegul AkınNo ratings yet

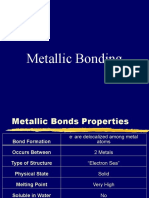

- Metallic BondingDocument16 pagesMetallic Bondingmathvin thummalaNo ratings yet

- Deophantine 6Document169 pagesDeophantine 6Caro Kan LopezNo ratings yet

- Trace Elements in Terrestrial Environments Biogeochemistry, Bioavailability, and Risks of Metals - Domy C. Adriano (Auth.) 2001Document866 pagesTrace Elements in Terrestrial Environments Biogeochemistry, Bioavailability, and Risks of Metals - Domy C. Adriano (Auth.) 2001Alcides Cordova Mateo67% (3)

- Lecture 1 - Introduction To Engineering MaterialsDocument39 pagesLecture 1 - Introduction To Engineering MaterialsGerald Mari QuiachonNo ratings yet

- Clintch Process 1Document25 pagesClintch Process 1yogeshNo ratings yet

- Car Manufacturing ProcessDocument10 pagesCar Manufacturing ProcessNaveed Malik100% (1)

- Mortuary ChamberDocument6 pagesMortuary Chambersaurabh_acmasNo ratings yet

- 21.5 Alloys and Other Metal PropertiesDocument6 pages21.5 Alloys and Other Metal PropertiesSamNo ratings yet

- Review of E-Waste Material Used in Making of ConcreteDocument4 pagesReview of E-Waste Material Used in Making of ConcreteIJSTENo ratings yet

- X Science Tutorials PDFDocument213 pagesX Science Tutorials PDFLushila MinjNo ratings yet

- Lesson 3 Metals and Metal Working Processes: OverviewDocument17 pagesLesson 3 Metals and Metal Working Processes: OverviewNadjer C. AdamNo ratings yet

- Extracting Metals KS3Document9 pagesExtracting Metals KS3Audrey NahuriraNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

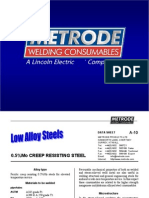

- Metrode ConsumablesDocument309 pagesMetrode Consumablesrodofgod100% (1)

- Chapter 6 ReactivityDocument22 pagesChapter 6 ReactivityEric ChewNo ratings yet

- Paper 6Document92 pagesPaper 6Jamal RidzuanNo ratings yet

- Metals and Non Metals NotesDocument3 pagesMetals and Non Metals NotesVUDATHU SHASHIK MEHERNo ratings yet

- Properties of Metals Mechanical Electrical Thermal Magnetic Chemical Properties PDFDocument8 pagesProperties of Metals Mechanical Electrical Thermal Magnetic Chemical Properties PDFMahesh Daxini ThakkerNo ratings yet

- Me6403 Emm PDFDocument116 pagesMe6403 Emm PDFRAMESHKUMAR.S MCE-LECT/MECHNo ratings yet

- Reactivity Series Homework Worksheet LADocument4 pagesReactivity Series Homework Worksheet LAkevinzhao704No ratings yet

- Synopsis Metals and NonmetalsDocument7 pagesSynopsis Metals and NonmetalsSaumya DhokariyaNo ratings yet

- E1 - en Descaling LiquidDocument1 pageE1 - en Descaling LiquidAbdou AssatarNo ratings yet