Professional Documents

Culture Documents

Substation Automation Operator Software

Uploaded by

Alpha AgustinusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Substation Automation Operator Software

Uploaded by

Alpha AgustinusCopyright:

Available Formats

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

3. SUBSTATION AUTOMATION OPERATOR SOFTWARE

The Substation Automation concept integrates various power system Intelligent Electronic

Devices (IEDs), local/remote Human Machine Interfaces (HMI), remote SCADA

communications, and virtually any other component into a single coordinated

environment. Device-level, substation-level as well as enterprise-level integration

provides seamless access to monitoring and control functions for a system to operate

efficiently and productively. Different departments such as engineering, operations, and

maintenance can all gain access to the information that is required for their functions with

adequate security so as not to jeopardize the integrity of the system. Overall system

flexibility, usability, and security establish an easy-to-use, expandable system that will

provide a foundation for future growth and maintainability.

3.1 OPERATING SYSTEM

The substation host computer operates using the Windows NT operating system. All

programs and functions adhere to the look, feel, and operation of the system. Windows

NT has demonstrated itself to be a stable software platform and has a clear growth path for

the future. Based on this open platform, numerous off the shelf software applications such

as spreadsheets, databases, and communications packages are easily integrated into the

system. No modifications or additions are made to the operating system.

3.2 HUMAN MACHINE INTERFACE (HMI)

The Human Machine Interface (HMI) – typically based on WONDERWARE HMI

software, provides a graphical user interface between users and the automation system as

well as data logging, alarming, reporting, trending, and control functions for the system.

Configuration of the HMI can be performed either offline or dynamically online (including

remote upgrade). Standard display formats are used so that a common look and feel will

result regardless of the IED integrated into the system. Note that customization of screens

to meet specific user requirements is easily accommodated with the WONDERWARE

HMI. Some of the “standard” screens include:

1. Logon Window

2. Main Menu

3. Substation One-Line Diagram

4. Annunciator

5. Alarm History

6. Standard device control and display “Wizards”

7. System Architecture diagram

8. On-line System Documentation

3. GESA Operator Software 3-1

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

Basic control of the system is effected through the use of “check before operate” command

sequences as implemented through the HMI. Automatic control of various aspects of the

system can be effected through the use of “scripts” – software commands that can take

action based on the state of other measured variables. For example, if a measured

temperature on a transformer was above a user defined threshold, a “script” could be

executed to turn on the cooling fans on the transformer and/or issue an over-temperature

alarm. See section 3.6 for screen examples.

3.3 IED DRIVER SOFTWARE

Substation Automation supports three primary IED driver / physical interface options,

namely:

MMS over TCP/IP or ISO over Ethernet

Modbus (either on RS-232/485 or on TCP/IP over Ethernet)

MMS is the foundational language of the Electric Power Research’s Utility

Communication Architecture (UCA). MMS provides a common set of services among

devices of different manufacturers all connected on a common LAN. In addition to a

common language, MMS provides a self description mechanism that allows a remote

host / client to query the IED and request a description of all variables defined in the IED.

Many of the common variable names have been compiled in a common data dictionary

known as the Generic Object Model for Substation and Field Equipment (GOMSFE).

Standard variable (or object) names allow for the creation of standard object viewers and

standard SCADA point definitions. MMS will be used to communicate with the Universal

Relays.

In the future, MMS could be used to interface the substation LAN with Utility SCADA

and Loadshedding Power Distribution desired SCADA protocol through the GE-Harris

D20.

ModBus and DNP3 is the language spoken by most UR relays. The Modbus driver

provided in this system can communicate with any UR relay that speaks Modbus and

provide pre-configured access to present values, control actions, Sequence of Events, and

Waveform capture. For communicating with those Modbus devices not pre-configured

driver, a “user configurable” Modbus driver is provided.

3. GESA Operator Software 3-2

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

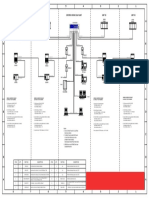

Figure 3A: Host Computer Software Architecture

3.4 LOGIC ENGINE

Basic control logic for the system can be implemented through the powerful scripting

language that is part of the Wonderware HMI package and through FlexLogic in the UR

relays. The language allows for mathematical manipulation of data, including a complete

library of mathematical functions, and the ability to test and take action for various

conditions.

3.5 SYSTEM APPLICATION SOFTWARE

3.5.1 MONITORING

Metering/IED Status

Values are continuously polled from the IED and loaded into the dynamic database of the

host computer. The actual values polled are IED specific. Typical polled values include

amps, volts, watts, vars etc. Device status values include processor error, memory,

EEPROM and other detectable hardware errors.

3. GESA Operator Software 3-3

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

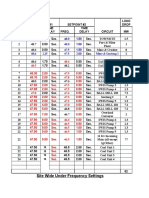

Figure 3B: UR’s Metering Values Screen

Sequence of Events (SOE)

IED captured events include a broad range of change of state occurrences including

pickup, trips, contact operations, alarms, setting changes, and self-test status for each IED

as available. The events are stored in daily files on the system hard disk with multi-year

storage capability. Events are reportable based on a number of user-definable sort

parameters such as time, date, and device type. The user can create custom defined

queries on the captured events.

Figure 3C: UR’s Events Logging Screen

3. GESA Operator Software 3-4

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

Equipment Status/Diagnostics

The Substation Automation maintains a database of the real-time status of each connected

IED (self-test failures, outputs protection off, etc.) as available. These and other system

events are entered in the historical logger. System events include errors from the data

server, user configured alarms, battery, or breaker monitor and program diagnostics.

Data Logging/Archiving

The Substation Automation uses the HMI database for historical data that provides for

easy off-line analysis. Each trend chart can display up to eight variables. User defined

traces can be generated using built-in mathematical functions operating on any

combination of dynamic database variables. Data can be automatically archived on a user-

defined basis and retrieved for future viewing.

Alarm Annunciation

Systems alarms are user definable and automatically logged in the system log file. These

alarms can also be used to light windows in a digital annunciator panel with

acknowledgment capability.

Figure 3D: Example of an Alarm Annunciation Screen

Data Logging

In addition to the standard screens listed above, the Wonderware HMI provides a powerful

data logger that is completely user configurable. Variables such as Volt, Amps, Watts,

Vars, Transformer Temperature, Feeder Loading, etc. can be trended and logged to both

local and remote databases. User defined traces can be generated using built-in

3. GESA Operator Software 3-5

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

mathematical functions operating on any combination of dynamic database variables.

Trend times are set by the user and both present and historical data can be viewed.

Oscillography Viewing

The Substation Automation can automatically retrieve oscillography and fault reports

created by the IEDs connected to the system. Data is maintained on the hard disk of the

substation automation system where it can be accessed and viewed locally or remotely.

Oscillography/fault report access of third party IEDs can be accessed using the third party

access software operating in a virtual terminal mode.

The Power Management system optionally proposes implementation of a Universal

COMTRADE viewer program. The viewer would be able to simultaneously open and

display up to 16 COMTRADE files and automatically time-synchronize data from

multiple relays. In this program, the user would be able to add, subtract, multiply, and

divide waveforms and well as operate on waveforms with complex trigonometric

functions. Additionally, the user could perform Fourier analysis of the captured data files

in support of Power Quality analysis.

2.5.3 CONTROL

Supervisory Operation

The system has supervisory control of breaker trip & close, LTC raise & lower,

block/unblock/pause reclosing and capacitor bank switching. Additionally, if suitable

communication is available, supervisory control may be extended to downstream reclosers,

line switches, and capacitor banks.

Custom Solutions

Additional system capabilities are available on a custom system solution basis. Some

typical custom solutions include:

Input Exclusivity

Output Interlock Coordination

Automatic Voltage Regulation (Through Load Tap Changer or Cap. Bank)

Automatic Multi-line Transfer and Recovery (Automated Substation

Sequencing)

Automatic Load-shed and Restoration

Transformer Thermal Curve (Hot Spot) Calculation

3. GESA Operator Software 3-6

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

Multi-level Security Access

Each function available from host computer can be protected with various levels of

security. Typical levels include view, set, control, and master/administrative. Only those

function for which the user has a predetermined access right will be displayed. All

security access is logged into a report listing the users that have accessed the host

computer.

3.5.3 ANALYSIS

System performance evaluation

The host can provide its own health report which includes average CPU utilization, disk

space availability and communication error rate. In particular if any of these categories

exceed user-defined thresholds, a system health check alarm can be issued.

Historical Data Storage

The host creates and archives multiple historical data based on selections of the various

present value captured in the present value polls. The user can select the variables to

capture, capture times, and archiving interval. Historical data can be recalled for viewing

locally or remotely.

3.6 ENTERPRISE DATA REPOSITORY (Optional)

The WONDERWARE software provides an option to automatically perform data

archiving functions at both a local and remote level. This section describes the options and

capabilities available.

Local Repository - On-Line Database

The Wonderware HMI utilizes two different on-line databases: one for configuration data,

and one for run-time data values.

The configuration database is manipulated through the extensive use of user-friendly

dialog boxes with easy-to-use navigation and editing features built into the interface. Two

update mechanisms are provided for updating the run-time configuration of the

WONDERWARE system: batch update and dynamic update. Batch update requires that

the run-time WONDERWARE project be stopped in order to update the configuration all

at one time.

Dynamic update will allow updates to the run-time configuration to occur on a

transactional basis. Dynamic configuration changes are made immediately to the run-time

3. GESA Operator Software 3-7

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

system as soon as the configuration change is confirmed. Configuration changes to

WONDERWARE may be made locally or remotely through the inherent capability of

Windows NT shared drives.

The run-time value database is a memory resident database of active values that may be

accessed for graphical screens or external data requests. WONDERWARE is based upon a

client-server architecture design and as such, the server side of the WONDERWARE

product can be used at the substation host computer to gather data, log data, and serve

requests for data, without the need for the client graphical interface to be present. As such,

WONDERWARE HMI will be provided at the substations that require local repository

capability. The graphical client screens will be offered as an option.

Historical Information Subsystem (HIS)

An ODBC interface is used by WONDERWARE when logging data to an historical

database. Databases supported include Microsoft Access Database Files, Microsoft SQL

Server database, and Oracle database.

Possible information that can be logged directly includes alarms, events, and point data.

Additional capability is available through the application of WONDERWARE’s Basic

Control Engine (BCE) which provides a Visual Basic for Applications based programming

extension to both the server and client sides of WONDERWARE. Through the BCE,

additional data logging capabilities can be implemented for applications such as incident

processing. The BCE allows a great deal of flexibility and capability in providing support

for functions that may not be an inherent feature of the base WONDERWARE package.

Remote Corporate Repository

A WONDERWARE enterprise server can be provided to support the concept of a

corporate data repository. This server will communicate with the individual substation

WONDERWARE systems and gather run-time value data on an exception or periodic

basis. These run-time values can be made available to the corporate WAN users through

two mechanisms: WebGateway, and ODBC database.

WONDERWARE provides the ability to serve HTML-based WEB pages for viewing with

Microsoft Explorer or Netscape Navigator. The web document uses standard HTML

format containing textual WONDERWARE data values as well as bitmap or ActiveX

graphics. The WebGateway interface can be provided as a “view-only” interface thus

offering widespread access to substation information without compromising operational

security.

The WONDERWARE enterprise server can also perform historical data logging (similar

to the local substation computers) to populate an ODBC compliant database with values

for subsequent retrieval and analysis.

3. GESA Operator Software 3-8

Guna Elektro SCADA AND LOADSHEDDING POWER DISTRIBUTION

NEWMONT

These two approaches to supporting the corporate repository concept allows for both an

isolated data server layer (thus eliminating the need for general users to access the

substation computer system directly) as well as a scaleable solution for expanding the

system as the need arises.

3. GESA Operator Software 3-9

You might also like

- SCADA in POWER DISTRIBUTION SYSTEMSDocument10 pagesSCADA in POWER DISTRIBUTION SYSTEMSrohinibhaskar0% (1)

- UCCNC Software Installation and User's GuideDocument93 pagesUCCNC Software Installation and User's GuideDanny PetoNo ratings yet

- Windows 8 Case StudyDocument11 pagesWindows 8 Case StudyAnna CampanatiNo ratings yet

- SCADA-WorldView Applications GuideDocument4 pagesSCADA-WorldView Applications GuideMichael June AgitoNo ratings yet

- Scada in Power Distribution SystemsDocument10 pagesScada in Power Distribution SystemsMike AjayiNo ratings yet

- Inteliigent Remote BillingDocument49 pagesInteliigent Remote BillingSTAR E WORLDNo ratings yet

- Application of SCADA in PSDocument5 pagesApplication of SCADA in PSupparahalNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) : July 2017Document24 pagesSupervisory Control and Data Acquisition (SCADA) : July 2017Royal Ritesh SharmaNo ratings yet

- Remote Monitoring and Control of Generator Sets in Diosdado Macapagal International Airport Using SCADA and PLCDocument9 pagesRemote Monitoring and Control of Generator Sets in Diosdado Macapagal International Airport Using SCADA and PLCromer88No ratings yet

- Control System: Types of Industrial Control SystemsDocument19 pagesControl System: Types of Industrial Control SystemsAdnan Nawaz100% (2)

- Topic 3 SCADA Systems Software and Protocols 1696390569Document44 pagesTopic 3 SCADA Systems Software and Protocols 1696390569aliabdallah20232023No ratings yet

- Scada ReportDocument26 pagesScada Reportkiswah computers100% (1)

- SCADA - WikipediaDocument66 pagesSCADA - WikipediaMazen Al-mahbashiNo ratings yet

- SCADA - Topic - 3 - Updated (SCADA Software and Protocols)Document44 pagesSCADA - Topic - 3 - Updated (SCADA Software and Protocols)Fazil MəmmədliNo ratings yet

- Advanced Industrial Automation and Building Automation Lecture on SCADA Block DiagramDocument9 pagesAdvanced Industrial Automation and Building Automation Lecture on SCADA Block DiagramsharonNo ratings yet

- ARTIGO - Substation Automation System - ARUN, LATESHDocument5 pagesARTIGO - Substation Automation System - ARUN, LATESHALEXANDRE SALES BRAZ JUNIORNo ratings yet

- Supervisory Control and Data Acquisition (SCADA)Document16 pagesSupervisory Control and Data Acquisition (SCADA)محمد العراقيNo ratings yet

- IasalumnoDocument36 pagesIasalumnoFernando Leyva VegaNo ratings yet

- Max DnaDocument17 pagesMax DnaAdil ButtNo ratings yet

- Miimetiq Brochure enDocument10 pagesMiimetiq Brochure enDario Tejero VillenaNo ratings yet

- SCADA Applications in Power SystemsDocument5 pagesSCADA Applications in Power SystemsTeju NookalaNo ratings yet

- SMS Based Hardware Controlling System A PDFDocument7 pagesSMS Based Hardware Controlling System A PDFsebeshotNo ratings yet

- Gea-S1252c Controlst Fact SheetDocument2 pagesGea-S1252c Controlst Fact Sheetimant197812gmail.comNo ratings yet

- Introduction to Process Control SystemsDocument59 pagesIntroduction to Process Control SystemsUdit Upreti100% (1)

- Research Paper On ScadaDocument7 pagesResearch Paper On ScadamkmanojdevilNo ratings yet

- Final Report - Ali Akhtar and YasirDocument21 pagesFinal Report - Ali Akhtar and YasirAliNo ratings yet

- ELUTIONS - ControlMaestro - Suite Overview - EUDocument12 pagesELUTIONS - ControlMaestro - Suite Overview - EUSadegh AkbariNo ratings yet

- SCADADocument26 pagesSCADADr-Amit Kumar SinghNo ratings yet

- Chapter - 6 - Scada IntroductionDocument5 pagesChapter - 6 - Scada IntroductionMathavaraja JeyaramanNo ratings yet

- Experion Scada PinDocument7 pagesExperion Scada PinKhalid AliNo ratings yet

- Substation Automation SystemDocument5 pagesSubstation Automation Systembinode0% (1)

- Power System Automation: Eminar EportDocument16 pagesPower System Automation: Eminar EportAnurajNo ratings yet

- Scada PaperDocument6 pagesScada PaperhafizgNo ratings yet

- Online Ship Control System Using SCADADocument5 pagesOnline Ship Control System Using SCADAPradeep SinghNo ratings yet

- SCADA PaperDocument15 pagesSCADA Paperprashantbgpatel1No ratings yet

- SCADA - Beginner - S GuideDocument58 pagesSCADA - Beginner - S GuidescribddderNo ratings yet

- Iaa Unit 04Document19 pagesIaa Unit 04SurajNo ratings yet

- Iaa Unit 04Document19 pagesIaa Unit 04SurajNo ratings yet

- SCADA System Overview: Data Acquisition, Components and FeaturesDocument34 pagesSCADA System Overview: Data Acquisition, Components and FeaturesVikrant OkeNo ratings yet

- Building Management System SpecificationDocument41 pagesBuilding Management System SpecificationHareendralal A.G.No ratings yet

- SCADA - Wikipedia, The Free EncyclopediaDocument9 pagesSCADA - Wikipedia, The Free EncyclopediaDayanand Gowda KrNo ratings yet

- What is SCADA? The Ultimate GuideDocument10 pagesWhat is SCADA? The Ultimate GuidefasihNo ratings yet

- Final PaperDocument9 pagesFinal PaperAshish GhodkeNo ratings yet

- Architecture of A Fault Diagnosis Expert System For Power Plants ProtectionDocument5 pagesArchitecture of A Fault Diagnosis Expert System For Power Plants Protectionserg6007No ratings yet

- Systems Concepts: SCADA Is TheDocument5 pagesSystems Concepts: SCADA Is ThePHPNo ratings yet

- Systems Concepts: SCADA Is TheDocument5 pagesSystems Concepts: SCADA Is TheAfrNo ratings yet

- Systems Concepts: SCADA Is TheDocument5 pagesSystems Concepts: SCADA Is TheAfrNo ratings yet

- SCADADocument5 pagesSCADAapi-3765150100% (1)

- Systems Concepts: SCADA Is TheDocument5 pagesSystems Concepts: SCADA Is TheAfrNo ratings yet

- Distributed Control System (DCS) : Information Technology Institute Intake32 - MechatronicsDocument9 pagesDistributed Control System (DCS) : Information Technology Institute Intake32 - Mechatronicshonesty88No ratings yet

- Node Commander User Manual (8500-0038)Document121 pagesNode Commander User Manual (8500-0038)Tuba Eroglu AzakNo ratings yet

- Smarthmi (Human Machine Interface)Document8 pagesSmarthmi (Human Machine Interface)Hung Cuong PhamNo ratings yet

- Max DNADocument17 pagesMax DNAderby_mnit3785100% (3)

- Automated Substation Monitoring System Requirements & EvaluationDocument11 pagesAutomated Substation Monitoring System Requirements & Evaluationpvenky_kkdNo ratings yet

- Erl Scada BrochureDocument12 pagesErl Scada BrochureBehzadNo ratings yet

- DCS System Layout and Its Different PartsDocument6 pagesDCS System Layout and Its Different PartsVraja Kisori100% (1)

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Next-Generation switching OS configuration and management: Troubleshooting NX-OS in Enterprise EnvironmentsFrom EverandNext-Generation switching OS configuration and management: Troubleshooting NX-OS in Enterprise EnvironmentsNo ratings yet

- Young Davidson Gold Mine Power Quality Case Study CSDocument2 pagesYoung Davidson Gold Mine Power Quality Case Study CSAlpha AgustinusNo ratings yet

- Subject: Underfrequency Load Shedding Program: I. Electrical System DynamicsDocument7 pagesSubject: Underfrequency Load Shedding Program: I. Electrical System DynamicsAlpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument2 pagesScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Attachment A - Package List and DescriptionDocument4 pagesAttachment A - Package List and DescriptionAlpha AgustinusNo ratings yet

- PT Newmont Power Management System in LombokDocument24 pagesPT Newmont Power Management System in LombokAlpha AgustinusNo ratings yet

- LOAD SHED Under Frequency - Rev1Document1 pageLOAD SHED Under Frequency - Rev1Alpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument2 pagesScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Utility SCADA and Load Shedding Power Distribution System for NewmontDocument12 pagesUtility SCADA and Load Shedding Power Distribution System for NewmontAlpha AgustinusNo ratings yet

- Unit 51 Unit 52 Control Room Coal Plant Unit 53 Unit 54: 50-SW-SCAD01Document1 pageUnit 51 Unit 52 Control Room Coal Plant Unit 53 Unit 54: 50-SW-SCAD01Alpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument1 pageScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Note 4: Item Qty. Part No. Description Item Qty. Part No. DescriptionDocument1 pageNote 4: Item Qty. Part No. Description Item Qty. Part No. DescriptionAlpha AgustinusNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsAlpha AgustinusNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsAlpha AgustinusNo ratings yet

- Hardware ComponentsDocument6 pagesHardware ComponentsAlpha AgustinusNo ratings yet

- Eaton MV Withdrawable Vacuum Fused Contactor Trucks - : Built For Extreme!Document3 pagesEaton MV Withdrawable Vacuum Fused Contactor Trucks - : Built For Extreme!Alpha AgustinusNo ratings yet

- Binter Only Operating On Tuesday For Month of August ONLY: KAS 2017 Summer Schedule - From June 2nd OnwardsDocument1 pageBinter Only Operating On Tuesday For Month of August ONLY: KAS 2017 Summer Schedule - From June 2nd OnwardsAlpha AgustinusNo ratings yet

- 2 Core Multimode: Detail DRW: 80-94L-SCAD01 Detail DRW: 10-94L-SCAD01Document1 page2 Core Multimode: Detail DRW: 80-94L-SCAD01 Detail DRW: 10-94L-SCAD01Alpha AgustinusNo ratings yet

- (/coresight/) Ad Hoc Display 331SWB1508: Alpha AgustinusDocument1 page(/coresight/) Ad Hoc Display 331SWB1508: Alpha AgustinusAlpha AgustinusNo ratings yet

- 03 TT - High ResistanceDocument3 pages03 TT - High ResistanceStephen BridgesNo ratings yet

- 03 TT - High ResistanceDocument3 pages03 TT - High ResistanceStephen BridgesNo ratings yet

- 22 Vesda VLC Tds A4 Ie LoresDocument2 pages22 Vesda VLC Tds A4 Ie LoresEduard AlzateNo ratings yet

- Siemens - Harmonics in Power Systems, Causes Effects and Control (2013)Document24 pagesSiemens - Harmonics in Power Systems, Causes Effects and Control (2013)micaNo ratings yet

- Shanghai Liquid Resistance Starter GuideDocument15 pagesShanghai Liquid Resistance Starter GuideAlpha AgustinusNo ratings yet

- Introduction To Cyanide Gold Mining: Orcr Usepa July 2012Document14 pagesIntroduction To Cyanide Gold Mining: Orcr Usepa July 2012Tingwe PoulNo ratings yet

- Beagle Entertainment System v0.8 User Guide: Andrew HendersonDocument34 pagesBeagle Entertainment System v0.8 User Guide: Andrew HendersonClaudio Andres Uribe FigueroaNo ratings yet

- Concept Notes - Computer Lyst2449Document234 pagesConcept Notes - Computer Lyst2449kasturi31391No ratings yet

- SDM Case StudiesDocument193 pagesSDM Case StudiesmyrmomNo ratings yet

- Home Service Managment SystemDocument45 pagesHome Service Managment Systemnadinidhanu8No ratings yet

- Planning and Designing A Windows Server EnvironmentDocument34 pagesPlanning and Designing A Windows Server EnvironmentSonPhamNo ratings yet

- Computer Components, Software Types, and Number Systems ExplainedDocument3 pagesComputer Components, Software Types, and Number Systems ExplainedOnyebuchi OsitaNo ratings yet

- Nicehash GuiaDocument13 pagesNicehash GuiaEgnis R LopezNo ratings yet

- Kofax Capture Installation GuideDocument142 pagesKofax Capture Installation GuideJuan Carlos S ONo ratings yet

- WebSphere Application Server 8.5 Security HardeningDocument111 pagesWebSphere Application Server 8.5 Security HardeningvelvetvampNo ratings yet

- Developing With CrxdeDocument11 pagesDeveloping With CrxdebuntyneffsarNo ratings yet

- 03 NetNumen U31 Introduction - 40PDocument40 pages03 NetNumen U31 Introduction - 40PjedossousNo ratings yet

- The Ultimate Quizzers Guide To Technology by Vidit BhargavaDocument136 pagesThe Ultimate Quizzers Guide To Technology by Vidit BhargavaRaunak GargNo ratings yet

- Catalog BeckDocument50 pagesCatalog BeckJJGLNo ratings yet

- HAHADocument109 pagesHAHAceejayNo ratings yet

- Disc Stakka Spec SheetDocument1 pageDisc Stakka Spec SheetfostechNo ratings yet

- Chapter 10 AnswersDocument6 pagesChapter 10 AnswersJohn HoltNo ratings yet

- 2.2.4.7 Lab - Install A Linux Virtual MachineDocument3 pages2.2.4.7 Lab - Install A Linux Virtual MachineNAJMNo ratings yet

- Programming Notes ESD2Document100 pagesProgramming Notes ESD2kunal smithNo ratings yet

- Design Principles and Goals: StorageDocument16 pagesDesign Principles and Goals: StorageSri KanthNo ratings yet

- CL Commands IIDocument728 pagesCL Commands IIapi-3800226No ratings yet

- Week 4 QuizDocument5 pagesWeek 4 QuizgengiscanNo ratings yet

- System Administrator ResumeDocument4 pagesSystem Administrator Resumewiznu46No ratings yet

- 1 Malaysia Netbook User ManualDocument24 pages1 Malaysia Netbook User ManualYip AlexNo ratings yet

- Forensic Acquisition and Analysis of VMware Virtual Hard DisksDocument8 pagesForensic Acquisition and Analysis of VMware Virtual Hard DisksKwameOpareNo ratings yet

- Ooad UNIT 5 NotesDocument29 pagesOoad UNIT 5 NotesVidhyaNo ratings yet

- Eset File Security For Linux 7 EnuDocument58 pagesEset File Security For Linux 7 Enudownload wfhNo ratings yet

- COMPUTER STUDIES QUESTION & ANSWERS G8 and 9Document21 pagesCOMPUTER STUDIES QUESTION & ANSWERS G8 and 9Mwape MusondaNo ratings yet

- File Concept Access Methods Directory Structure File System Mounting File Sharing ProtectionDocument30 pagesFile Concept Access Methods Directory Structure File System Mounting File Sharing ProtectionFarooq ShadNo ratings yet