Professional Documents

Culture Documents

Technical & Commercial Contract To Provide Powerstation Management System (Psms

Uploaded by

Alpha AgustinusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical & Commercial Contract To Provide Powerstation Management System (Psms

Uploaded by

Alpha AgustinusCopyright:

Available Formats

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

Technical & Commercial Contract to Provide

PowerStation Management System (PSMS)

for

PT Newmont

Lombok, Indonesia

Ref # PSMS-NEW-0403

April 22, 2003

Operation Technology, Inc.

23692 Birtcher Drive,

Lake Forest, California, USA 92630

Operation Technology, Inc. -1- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

TABLE OF CONTENTS

1 GENERAL...................................................................................................................3

2 PHASE I - PSMS ENGINEERING.............................................................................3

3 PHASE I - SCOPE OF DELIVERABLES.................................................................7

4 PHASE II - PSMS INSTALLATION & INTEGRATION.........................................7

5 PHASE II - SCOPE OF DELIVERABLES..............................................................10

6 PHASE III – LOAD SHEDDING INSTALLATION AND INTEGRATION.........11

7 PHASE III - SCOPE OF DELIVERABLES.............................................................16

8 CLIENT’S RESPONSIBILITIES.............................................................................16

9 USER SUPPORT.......................................................................................................17

10 STANDARDS..........................................................................................................18

11 PROJECT IMPLEMENTATION.............................................................................18

12 CONSIDERATION & PAYMENT SCHEDULE....................................................19

13 PSMS HARDWARE (May be Provided by Client).................................................22

14 LOAD SHEDDING HARDWARE..........................................................................23

15 LIABILITY...............................................................................................................23

Attachment A: Package List and Description

Attachment B: Hardware Specification

Attachment C: Product Description

Attachment D: License Grant & Agreement

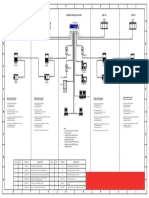

Attachment E: Preliminary Achitecture

ETAP and PowerStation Management System (PSMS) are trademarks of Operation Technology, Inc.

Windows, Windows 2000, Windows XP, and Excel are trademarks of Microsoft Corporation.

2003 Operation Technology, Inc. All rights reserved.

Operation Technology, Inc. -2- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

1 GENERAL

This document presents technical specifications and commercial scope of work for

providing a power management system to PT Newmont, Indonesia hereafter

referred as Client.

ETAP PowerStation Management System (PSMS) offers advanced modules with

the flexibility of several package options. ETAP PSMS provides the following

main features:

i) Advanced monitoring system. The monitoring system will process the data,

reset the alarms, store all parameters and graphically display data on graphic

one-line diagrams in continuous mode.

ii) Real-time simulation capabilities.

iii) System analysis capabilities.

iv) Offline simulation capabilities and Event Playback using archived data.

v) Capability to allow for future system expansion.

vi) Automatic implementation of recommended settings to achieve continuous

optimum system operation.

vii) Operator controlled implementation of recommended settings to achieve

continuous optimum system operation.

viii) Intelligent Load Shedding and Load Preservation.

ix) Continuous scrolling display of data allowing Load Trending.

The proposed system (combination of all three phases) is the PSMS Imperious

package + Intelligent Load Shedding, which will interface with the plant’s

electrical data acquisition/metering system.

The project implementation is broken down into three phases each having

predefined milestones. Phase I covers the engineering associated with preparing

the ETAP PowerStation model for online applications. Phase II covers PSMS

integration for the online model for PSMS with the exception of online control and

load shedding. Phase III covers integration of PSMS for online control and load

shedding.

2 PHASE I - PSMS ENGINEERING

OTI will appoint a “Project Manager” who shall be responsible for its obligations

throughout the project implementation. OTI’s Project Manager will perform or

have others perform the following engineering services.

2.1 Kick-off Meeting

Operation Technology, Inc. -3- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

2.1.1 Kick-off meeting will be arranged to answer questions, request

additional data, and review existing hardware & site design to

coordinate the various aspects of the project. To minimize costs, this

meeting can be held remotely via teleconference, email, Webex, or

other means.

2.2 Data Collection

2.2.1 All existing and available system data should be provided to OTI at

the front-end of the project. This data includes:

The latest ETAP model for the system.

List of metering points and the electrical parameters read from the

field meters along with the set points.

Several sample sets of meter data from along with breaker /

switch status and metering tags in the system for different system

scenarios.

2.2.2 Data collection will be performed by Client. OTI will submit a list of

required data to Client at the start of the project and Client shall be

responsible for collection of all data. All required system data should

be forwarded to OTI at the front-end of the project. The data should

include:

One-line diagrams

Equipment ratings

Protective device models/types

Generators’ governor and exciter models along with their

respective parameters

Generators Load Acceptance and Load rejection test data under

50% and 100% loading

MV motors’ dynamic models along with load slip versus torque

curves

Historical system disturbance records including type and location

of disturbances and their impacts on the system operation.

Other pertinent information describing system apparatus

Existing system study reports

2.2.3 OTI will utilize existing dynamic models for all synchronous

machines. If models are not available, there will be an additional

charge to build the dynamic model(s).

2.2.4 Client will provide all existing and planned relay settings to OTI.

Operation Technology, Inc. -4- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

2.3 System Modeling

2.3.1 Client will provide the system model which will be taken online using

ETAP PSMS in Phase II of the project. The scope of work includes

the 150 kV to 3.3 kV system. The network downstream from that

point would be considered as unmonitored loads. Any additional

modeling below 3.3 kV by OTI would be in the form of lumped

loads. The scope can be expanded at a later date to include detailed

modeling and monitoring of low voltage feeders.

2.3.2 The existing ETAP model will be expanded to include metering

devices, which will interface, with the field meters.

2.4 Visibility Study & Data Acquisition

2.4.1 Review plant metering instruments & locations and suggest any

additional instrumentation that may improve plant monitoring.

2.4.2 Perform a plant visibility study to identify required measurement

points and their optimum location for accurate State and Load

Estimation (SLE) calculations.

2.4.3 A list of all required metering points and required parameters will be

forwarded to the Client upon completion of the visibility studies by

OTI. Client’s representatives shall be assigned to this project for

collection of all required data.

2.5 Evaluation & Validation

2.5.1 Perform model validation studies for steady-state operations.

2.5.2 Power monitoring and control hardware evaluation.

2.5.3 System studies for steady-state operations.

2.5.4 Tag determination and location for steady-state operations.

2.6 Communication Hardware Architecture for PSMS Integration

2.6.1 Based upon the Visibility studies and system evaluation, OTI will

develop a detailed system architecture drawing for the installation of

GE Universal Relays for the purpose of monitoring and load shedding

within PSMS. (Not to exceed 20 GE Universal Relays.)

Operation Technology, Inc. -5- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

2.6.2 OTI will review the plan of action developed by the Client prior to

actions taken to implement replacement of GE SR750 and SR760

Relays with the installation and commissioning of the GE Universal

Relays.

2.6.3 OTI will recommend any changes to the course of action for the

installation and commissioning of the above communication

hardware.

OTI’s scope of involvement with the installation and commissioning of the GE

Universal Relays is purely on a recommendation and review basis. OTI assumes no

liability, directly or otherwise, for the actual installation and implementation of the

process. The scope of the proposal estimates the need for fourteen GE Universal

Relays, with a not to exceed of twenty GE Universal Relays.

2.7 Transient Stability and Load Shedding Studies

2.7.1 Transient Stability analysis will be performed to investigate the

stability limits of a power system before, during and after system

changes and disturbances. The program models dynamic

characteristics of a power system, implements the user-defined events

and actions, solves the system network equation and machine

differential equations interactively to find out system and machine

responses in time domain. From these responses, it is possible to

determine the system transient behavior, make stability assessment,

find protective device settings, and apply the necessary remedy or

enhancement to improve the system stability.

2.7.2 Results of the Transient Stability analysis will enable OTI to clearly

outline the load shedding hardware requirements. Based on OTI’s

recommendation, the client will install and commission the necessary

load shedding hardware. OTI will provide an option at the end of this

proposal to provide turnkey installation and commissioning of the

load shedding hardware.

2.7.3 Preliminary load shedding study will be performed along with the

stability studies per the following:

Evaluate system protection scheme settings

Evaluate plant historical disturbance records

Identification and validation of system parameters.

Design system transient stability limit study cases

Perform transient stability limit assessment based on the study

results

Run study cases to verify and fine tune the optimal and

achievable stability limits

Operation Technology, Inc. -6- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

Perform strategic load-shedding schedule protection design

Evaluate and recommend load-shedding hardware

implementation scheme

3 PHASE I - SCOPE OF DELIVERABLES

3.1 Client will receive an updated ETAP model of the system per the

Engineering Services mentioned in Section 2 of this proposal.

3.2 Client will receive a recommendation from OTI for additional hardware

needed to perform system monitoring and load shedding.

4 PHASE II - PSMS INSTALLATION & INTEGRATION

Phase II may begin prior to the completion of Phase I, relying upon the completion

of the at least the data collection and visibility study milestones in Phase I.

4.1 Purchase PSMS Imperious (except Online Control)

4.1.1 PSMS Server Software

500 Tag Interface

500 Bus Simulation Capabilities

PC-Based, Windows 2000

OPC Interface

Client-Server Architecture

Multi-Console Capability

User Access Management

ODBC Format

4.1.2 PSMS Consoles

One Primary Console

4.1.3 Advanced Monitoring

Base Modules

Continuous Real-Time Monitoring

On Demand Data Retrieval

State Estimator and Load Distributor

Data Reconciliation and Consistency Check

Bad Data Detection and Correction

Alarm Management and Processing

Energy Cost Monitoring

4.1.4 Real-Time Simulator

Operation Technology, Inc. -7- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

Load Flow

Short Circuit

Motor Starting

Harmonic Analysis

Transient Stability

4.1.5 Event Playback

Sequence of Event Recorder (Seconds-based)

Playback Server

Playback Historian

4.2 PSMS Server and Console Hardware

4.2.1 Client has the option of purchasing the hardware for PSMS Server

and Console locally or OTI can provide the hardware (PCs) to Client.

If Client chooses to use existing PC’s for PSMS Server and Console,

they should meet the PSMS minimum hardware requirements (See

Attachment B). The PSMS Server needs to be delivered to OTI in

California for use in the Factory Acceptance Test.

4.3 Data Collection

4.3.1 Client will provide OTI will several sample sets of real-time data for

validation of the online PSMS model.

4.4 Tag Database Creation

4.4.1 Compile a tag cross-reference list that references the field device tag

names and characteristics to those used by PSMS. This tag database

would be created and used for online model validation.

4.5 Model Validation

4.5.1 OTI will validate the model for online operation. Online model

validation is the most important part of this phase. The validation

process involves comparing the metered data provided by Client with

the State Estimation results. Discrepancies are usually found in the

two results indicating inaccuracies of the offline model with respect

to the real system. One benefit of Phase II is to obtain a more accurate

model of the system, which Client can utilize for online applications

as well as accurate offline studies. Any deviations found during this

study would be listed and this list would be provided to Client for

field verification.

Operation Technology, Inc. -8- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

4.5.2 OTI will modify meter locations in the ETAP model based upon the

results of the above validation.

4.6 Factory Acceptance Test

4.6.1 Conduct a one-day Factory Acceptance Test (FAT) in OTI’s,

California R&D office. This test is done for the purpose of

establishing that the design and functional operation of the complete

system conforms to the specified requirements.

4.7 PSMS interface

4.7.1 Communication interface to PSMS Server/Console(s) will be via

OLE for Process Control (OPC) protocol. An OPC Server will be

used to communicate with the monitoring and control equipment.

Communication to the select hardware to perform load shedding will

be done in phase III of this project.

4.8 Install and Setup PSMS

4.8.1 OTI will install and commission, the PSMS Server, PSMS Console,

Playback Server, OPC Server, Watch windows and real-time

simulation at the site. The installation and commissioning will be

used as an opportunity to train site staff on the setup of PSMS.

4.8.2 Engineering assistance for the system integration phase of the project

will include installation, setup and configuration of PSMS only. One

five-day trip to the site is required by one OTI engineer to perform

PSMS installation and integration.

4.8.3 Deliver PSMS User Guide to the plant that describes the operation of

PSMS.

4.9 Site Acceptance Test (SAT), PSMS Imperious except Online Control

4.9.1 A five-day trip to the site by one OTI engineer is required to perform

SAT. The PSMS Site Acceptance Test will be conducted at the

Client facility to validate the PSMS model with real time data and

verify connectivity to all assigned tags via the input tag table. PSMS

will be confirmed on the primary console, and tested for functionality

based on SAT guideline. The SAT is designed to determine the

accuracy of the PSMS performance.

Operation Technology, Inc. -9- Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

4.9.2 Upon a successful SAT, the Client’s Project Manager shall “sign off”

on the SAT results and the project shall move into the initial period of

Maintenance Contract Services as described in PSMS License Grant

& Agreement.

4.9.3 However, if any the above SAT does not pass OTI Project Manager

may request a “retest”. For the subsequent test(s), OTI’s Project

Manager is not required to be present at the plant site. The Project

Managers shall decide collectively to base the subsequent test upon

either the same plant operating data from the previous SAT or new

real time plant operating data.

4.9.4 The SAT shall include a checklist for the Client’s Project Manager to

sign that indicates that interface screens meet the original scope

specifications and that PSMS shall perform all purchased functions

described within the users’ manuals.

4.9.5 OTI will prepare the necessary test procedures. Columns shall be

provided so that the nominated testers can formally sign that the test

is complete and satisfactory.

4.10 Training

OTI provides one five-day on-site Introductory Training course on PSMS: A

maximum of 10 engineers/operators will attend the training course. Training

materials are included in the price. The customer is responsible for providing

a computer for each student to use during the training. All travel expenses

incurred by OTI in the performance of the training, such as the cost for air

tickets, travel days, local transportation, lodging, and expenses shall be

reimbursed at actual cost and will be invoiced per occurrence.

5 PHASE II - SCOPE OF DELIVERABLES

OTI will provide and deliver the following hardware, software and documentation,

contingent upon Client executing the standard Software License & Services

Agreement for PSMS.

5.1 One PSMS Server and One Console software. (Includes Playback Server)

5.2 One OPC server software.

5.3 Engineering Services per Section 4 of this proposal.

5.4 One PSMS User Guide / Operating Manual.

5.5 PSMS Onsite Training

Operation Technology, Inc. - 10 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

5.6 If applicable (optional as part of the order), OTI will provide One PSMS

Server PC and One PSMS Console PC’s with hardware requirements

matching Attachment B.

6 PHASE III – LOAD SHEDDING INSTALLATION AND INTEGRATION

6.1 Load Preservation System

The proposed dynamic Load Preservation System through PSMS allows for

optimum load shedding. This system is a combination of PSMS logic and

IED (PLC or UR Relay) programming where PSMS will download a

dynamic load shed priority list to the IED’s. This scheme considers a non-

traditional approach where a strategically devised load shedding is

determined using PSMS. The major advantage of this scheme is that it goes

beyond the classical load shedding schemes (such as using relay frequency or

breaker interlock) by prolonging the system CCT (critical clearing time), thus

improving the system stability margins with minimal load rejection. This is

achieved by constructing a Stability Knowledge Base (SKB) for the system

for various operating configurations and loading/ generation conditions.

Based on the SKB and Load Priority Tables (LPT) along with the on-line

parameters collected from the system (as defined by the Visibility study),

PSMS reacts in a fraction of the time than the conventional method of using

frequency relays. This is achieved since PSMS anticipates the system

reaction to a given disturbance (location, magnitude etc.) based on the SKB

and initiate the appropriate actions way before a frequency relay even detects

a change (df/dt).

This scheme requires transient system analysis on the system model to be

performed for all applicable (operating) configuration and loading/generation

conditions including any plant specific set up prior to implementation. The

other conventional methods (frequency relay) are used with this scheme as a

back up protection.

6.2 Load Shedding System

A Load Shedding Scheme can be implemented to monitor the status of the

plant such that on tripping of a power source, the lower priority loads can be

immediately shed. The priorities can be simple or complex depending upon

the decision of the plant operation departments.

To generate the appropriate sequences including islanding and load

balancing/shedding, the collected data from the IED’s shall be modeled in the

PSMS Server and transferred to various consoles- Monitoring, Simulator and

Supervisory Control / Advisory Control for its respective functions. The

Supervisory Control / Advisory Control shall be engineered for various

operations through its Stability Knowledge Base (SKB). These operations

will be inferred from past history of the system, results from Transient

Operation Technology, Inc. - 11 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

Stability runs at various scenarios in the system and then take all the

necessary information and produce load shedding / islanding sequences based

on current status of equipment.

For Dynamic Load Shedding, a Load Priority Table (LPT) will be built in the

SKB, which will dynamically be changing, based on the system changes and

type of disturbance recorded. These sequence tables will be created

continuously and available on the nodes where the corresponding equipment

is located. These sequences will be kept armed. The initiation of the

sequences will take place only when the initiating point of the sequence is

actuated through a hardwired signal.

6.3 Stability Knowledge Base (SKB)

In order to develop any load shedding system, the system stability margins

should be defined. This requires a comprehensive transient stability study of

the system for various operating condition and configuration. The purpose of

these studies is to determine CCT (critical clearing time) for disturbances

throughout the electrical power system. Based on these studies further

analysis is made as to the method to prolong the system CCT, thus improving

the system stability margins with minimal load rejection. This is done by

constructing a Stability Knowledge Base (SKB) for the system for various

operating configurations and loading/ generation conditions. The steps

required to perform the studies are as follows:

Model the power system in PSMS including dynamic model of

generators and loads.

Identify and validate the system parameters

Design transient stability study cases

Evaluate the system protection scheme settings

Evaluate the plant historical disturbance records

Define stability margin constraints

Run study cases to verify and fine tune the optimal and achievable

stability limits

Perform transient stability limit assessment based on the study results

Run hundreds of cases for various operating scenarios to develop the

SKB

Design strategic load shedding protection scheme on the result.

Test and verify various operating scenarios with the developed load

shedding scheme

Compile the SKB.

6.4 Load Priority Tables (LPTs)

LPTs are stored in the IED. These tables define the priority of a load from

the Process point of view based on the location and magnitude of the

Operation Technology, Inc. - 12 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

disturbance, available generation and loading as well as the status

(configuration of Protective Devices (PDs)) of the electrical power system.

Multiple tables are allowed and will be available at the IED level in the

“active” mode.

PSMS updates the LPTs based on the changes in system. The tables are

rearranged to optimize the number and the total kW to be shed.

PSMS updates the IEDs and splits the table among the regional locations, the

table may be sorted in order of geographical location.

Tables are sorted in the order of priority. The structure of the tables will be

established based on the system requirements

6.5 State Tables

PSMS monitors the state of the system based on the collected data. The

number of state tables is based on the possible configuration of the system

such as Normal, Islanded, Generator ON/OFF, etc. PSMS monitors the

status of the PDs and determines which LPT is appropriate for each specified

location of the system.

6.6 Arm List

PSMS develops the arm lists and downloads them to the local IEDs.

Given the current state of the facility is in and possible states the facility can

transition to, PSMS will calculate various scenarios for each state.

Each Local IED receives a multiple LPT based on the updated state.

When the transition of state occurs, IED will initiate the load shedding based

on the last update from PSMS. PSMS continuously check the status of the

system to optimize the amount of load shed throughout the system.

6.7 Purchase of Online Control and Load Shedding System

6.7.1 On-Line Control

Remote Control of Switching Devices

Remote Control of On-Line Compensation Equipment (if

applicable)

6.7.2 Intelligent Load Shedding

Dynamic Load Priority Table

Operation Technology, Inc. - 13 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

User Defined “Teaching” of Neural Network

Automatic "Training" of Neural Network

User-Defined Load Priority Tables (LPT)

Load Shedding Scheme Redundancy with Backup

Contingencies

Display ILS Tables at Any Time Instant

Simulate Various Disturbances & Display Results

Simulate & Test ILS Recommendations

Advanced Adaptive Learning Algorithm

6.8 Install and Setup PSMS Online Control and Load Shedding

6.8.1 OTI will install and commission, the PSMS Online Control and Load

Shedding system.

6.8.2 Engineering assistance for the system integration phase of the project

will include installation, setup and configuration of PSMS. One five-

day trip to the site is required by one OTI engineer to perform PSMS

Online Control and Load Shedding installation and integration.

6.8.3 If Client changes the metering hardware that PSMS was connected to

in Phase II, a change order from OTI is necessary for the additional

work that is required to reconnect the communication interface to

PSMS in Phase III.

6.9 Load Shedding Validation

6.9.1 The purpose of Load shedding is to protect electrical distribution

system from total failure or blackout against instability linked to

sudden large load changes such as a loss of power generators.

Additional Transient Stabilities studies will be performed to

determine optimal load shedding system capabilities.

Recommendations will be made based on those studies for proper

settings for control and switching equipment to maximize load

preservation for the system and minimize the load shedding of critical

applications.

6.9.2 OTI will validate the model for Online Control and Load Shedding

operation. Load Shedding validation is the most important part of this

phase. The validation process involves comparing the metered data

provided by Client with the State Estimation and Load Shedding

study results. Discrepancies are usually found in the two results

indicating inaccuracies of the offline model with respect to the real

system. Any deviations found during this study would be listed and

this list would be provided to Client for field verification.

Operation Technology, Inc. - 14 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

6.9.3 Modifications to meter relay locations may be required based upon

the results of the above validation.

6.10 Site Acceptance Test (SAT), PSMS Online Control and Load Shedding

6.10.1 A five-day trip to the site by one OTI engineer is required to perform

SAT. The PSMS Site Acceptance Test will be conducted at the

Client facility to validate the PSMS connectivity to all assigned

hardware.

6.10.2 Upon a successful SAT, the Client’s Project Manager shall “sign off”

on the SAT results and the project shall move into the initial period of

Maintenance Contract Services as described in PSMS License Grant

& Agreement.

6.10.3 However, if any the above SAT does not pass OTI Project Manager

may request a “retest”. For the subsequent test(s), OTI’s Project

Manager is not required to be present at the plant site. The Project

Managers shall decide collectively to base the subsequent test upon

either the same plant operating data from the previous SAT or new

real time plant operating data.

6.10.4 The SAT shall include a checklist for the Client’s Project Manager to

sign that indicates that interface screens meet the original scope

specifications and that PSMS Load Shedding shall perform all

purchased functions described within the users’ manuals.

6.10.5 OTI will prepare the necessary test procedures. Columns shall be

provided so that the nominated testers can formally sign that the test

is complete and satisfactory.

6.11 SAT Final Review

6.11.1 A SAT Final Review will be conducted for PSMS Server software,

the input tag table, and the system model in accordance with the SAT

results. A five-day trip to the site by one OTI engineer is required for

the final review to resolve any open issues with the SAT.

7 PHASE III - SCOPE OF DELIVERABLES

7.1 PSMS Load Shedding software.

7.2 Engineering Services per Section 6 of this proposal.

Operation Technology, Inc. - 15 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

8 CLIENT’S RESPONSIBILITIES

OTI requests that the Client appoint respective Project Managers who shall be

responsible for their obligations throughout the project implementation.

Implementation of PSMS requires that the Client to provide the following

information and assistance at their expense.

8.1 Project Management

Client will provide coordination between OTI and Client staff and/or any

other subcontractors.

8.2 Data Collection

All existing and available system data should be provided to OTI at the front-

end of the project. These data should include:

8.2.1 Existing ETAP Model for the selected portion of the system.

8.2.2 Equipment ratings.

8.2.3 All Plant & equipment descriptions.

8.2.4 All Plant operating data such as expected predominant plant operation

mode(s), i.e. base load, part load, etc.

8.2.5 All reference data and other pertinent information describing system

apparatus.

8.2.6 List of metering points and the electrical parameters read from the

field meters along with the set points.

8.3 Tag Configuration

Complete tag list, presented as an Excel spreadsheet (predefined format),

with specification of engineering units, zero and calibration span (in

engineering unit) displayed in engineering units, and description of the

instrument saved.

8.4 Required Measured Data

All applicable measured data for each equipment component to be made

available and accessible throughout the project. Various set of “Real-time”

data from Pegasus and DCS along with breaker / switch status and metering

tags in the system for different system conditions.

8.5 Hardware Compliance

Operation Technology, Inc. - 16 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

OTI requests to approve of all hardware and software specifications for the

PSMS prior to its purchase. The Client should ensure that PSMS Server and

Console hardware meet the minimum PC hardware as well as operating

system requirements per Attachment B.

8.6 Software Security

OTI requests restricted use of the PSMS Computer by non-OTI personnel

until they have received formal PSMS training, e.g. no changing of

passwords during the PSMS installation, turnoff the modem, disconnecting

the telephone line, loading other software programs, changing computer

configurations, etc.

8.7 Physical Security

Client will be responsible for any materials, which OTI may deliver or have

delivered to the plant.

8.8 Metering Hardware

Client will be responsible for purchasing and installing any additional

hardware required for setting up PSMS that is not specifically stated in the

above proposal.

9 USER SUPPORT

9.1 OTI will provide software support via telephone, e-mail and fax, at no

additional charge, during the initial twelve months following the SAT. Client

will receive all upgrades that are released for PSMS system during the

maintenance period at no additional charge. Follow-up user support and

program upgrades will be provided at 15% of the prevailing published price

annually. Client may elect to pre-pay maintenance for up to five years at the

time of the PSMS purchase at the prices published in the proposal.

10 STANDARDS

10.1 The user manuals, other documentation, computer screens, training and other

interfaces shall be presented in English. The units of measure shall be in

English or as requested by the Client. OTI reserves the right to change or

modify the proposed computer hardware and software, other than the PSMS

software.

Operation Technology, Inc. - 17 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

11 PROJECT IMPLEMENTATION

11.1 OTI proposes to start work on Phase I and Phase II simultaneously, as

requested, upon receipt of Client’s Purchase Order and Client’s execution of

PSMS Software License and Services Agreements. OTI will begin work on

Phase III upon receipt of Client’s Purchase Order and any addendums to the

PSMS Software License and Services Agreements as necessitated by the

selection of third party services, software, and hardware (if any.)

11.2 Duration for completing Phase I of the project will be less than five months.

Completion of Phase II is expected to occur concurrently with the completion

of Phase I. A detailed plan of action is laid out in the updated Microsoft

Project file created by the Client, which is associated with this project. Note

that several milestones, including data collection and validation, need to be

completed prior to working on portions of Phase II. Completion of Phase III

is less than three months after the successful commissioning of the load

shedding hardware, the completion of the SAT of Phase II, and the execution

of the purchase order for Phase III. Note that project completion dates will be

affected if there is a slippage in delivery of the required system data as

specified in this proposal.

11.3 Each party shall identify a Project Manager within two weeks of OTI’s

authorization to proceed with the project. The respective Project Managers

shall be totally responsible for their companies’ activities from initiating the

project through conducting SAT. The Project Managers shall develop and

concur on a detailed project schedule. OTI shall assign a Project Manager

and a Project Engineer for this project.

11.4 OTI proposes a total of seven trips to visit the Client’s site and one client trip

to visit OTI’s R&D office. Estimated average trip duration is seven days

each, which includes two travel days per round trip. The objectives of these

trips are to:

11.4.1 Perform the visibility study (Phase I)

11.4.2 Conduct the FAT at OTI (Phase II)

11.4.3 Installation and commissioning of PSMS Imperious except Online

Control (Phase II)

11.4.4 Perform the Phase II SAT and train the plant staff (Phase II)

11.4.5 Installation and commissioning of PSMS Online Control and Load

Shedding (Phase III)

Operation Technology, Inc. - 18 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

11.4.6 Perform the Phase III SAT (Phase III)

11.4.7 Perform the SAT Review (Phase III)

11.5 OTI reserves the right to modify the number and duration of trips to satisfy

Client’s requirements. OTI shall rely upon conference calls with the Client

periodically to review the project’s status.

11.6 OTI shall notify Client’s Project Manager three weeks prior to the desired

date to conduct the FAT at OTI’s Lake Forest, CA office. In the event that

the Client’s Project Manager cannot attend the FAT, then OTI’s Project

Manager shall conduct the test as planned, send the results to the Client’s

Project Manager and then have a conference call with the Client’s Project

Manager to discuss the results.

11.7 OTI will notify Client’s Project Manager one month prior to each of the site

trips. The Client’s Project Manager may request a one-time delay up to one

month in initiating the SAT. In the event that the Client’s Project Manager

further desires to delay the initiation of the SAT, then the invoices pursuant

to Paragraphs 12.3.7 shall be paid as if PSMS passed the SAT. Afterwards,

Client may request OTI to initiate the SAT at a mutually convenient date to

the parties.

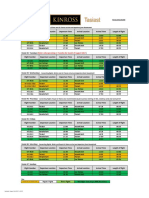

12 CONSIDERATION & PAYMENT SCHEDULE

12.1 Phase I – PSMS Engineering

OTI proposes to provide engineering services based on the scope of

deliverables. Client agrees to pay the price below:

12.1.1 Total Phase I Price (Total of 740 man-hours) $ 82,900

Notes:

The price in 12.1.3 is quoted for a maximum of 740 man- hours of engineering.

Any additional engineering requests will be handled as a change order.

Estimated travel expenses of $3,085 are not included in the above prices.

12.2 Phase II – PSMS Software

OTI proposes to license and install PSMS based on the scope of deliverables.

Client agrees to pay the price below.

12.2.1 PSMS Imperious except Online Control

(500 Tag / 500 Bus) $ 66,600

12.3 Phase II – PSMS Engineering and Training

Operation Technology, Inc. - 19 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

OTI proposes to provide engineering services based on the scope of

deliverables. Client agrees to pay the price below:

12.3.1 Phase II Engineering (Total of 240 man-hours) $ 32,400

12.3.2 Training (Discounted) $ 11,000

12.3.3 Phase II Engineering and Training $ 43,400

Notes:

The price in 12.2.1 is quoted for a maximum of 240 man-hours of engineering.

Any additional engineering request will be handled as a change order.

Estimated travel expenses of $9,260 are not included in the above prices.

12.4 Phase III – PSMS Load Shedding Software

12.4.1 One PSMS Online Control and Load Shedding Software $32,200

12.5 Phase III – PSMS Load Shedding Engineering and Installation

OTI proposes to license and install PSMS based on the scope of deliverables.

Client agrees to pay the price below.

12.5.1 Phase III Engineering (Total of 160 man-hours) $ 21,600

Notes:

The price in 12.5.1 is quoted for a maximum of 160 man-hours of engineering.

Any additional engineering request will be handled as a change order.

Estimated travel expenses of $9,260 are not included in the above prices.

12.6 OTI shall invoice the Client according to the following:

12.6.1 Phase I - 50% of the PSMS Engineering price upon receipt of Client’s

Purchase Order.

Phase I - 50% of the PSMS Engineering price upon delivery of

completed ETAP model and communication hardware

recommendations.

12.6.2 Phase II - 100% of the PSMS Software price upon receipt of Client’s

Purchase Order and executed PSMS Software License and Services

Agreements.

12.6.3 Phase II - 100% of the Hardware price at the time of hardware order

(if applicable).

Operation Technology, Inc. - 20 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

12.6.4 Phase II - 30% of the PSMS Engineering and Training price upon

receipt of Client’s Purchase Order and executed Software License and

Services Agreements.

12.6.5 Phase II - 30% of the PSMS Engineering and Training price upon

submitting the configuration required for the measured and calculated

System tags and an accurate plant state point diagram.

12.6.6 Phase II - 30% of the PSMS Engineering and Training price upon

completion of the installation and commissioning of PSMS.

12.6.7 Phase II - 10% of the PSMS Engineering and Training price upon

successful completion of the PSMS Integration SAT.

12.6.8 Phase III - 100% of the PSMS Software price upon receipt of Client’s

Purchase Order and executed PSMS Software License and Services

Agreements.

12.6.9 Phase III - 100% of the Hardware price at the time of hardware order

(if applicable).

12.6.10 Phase III - 50% of the Load Shedd

Purchase Order and executed Software License and Services

Agreements.

12.6.11 Phase III - 40% of the Load Shedd

installation and commissioning of Load Shedding.

12.6.12 Phase III - 10% of the Load Shedd

completion of the Load Shedding SAT.

12.7 OTI shall invoice the Client per occurrence for its traveling expenses

associated with this project at actual cost based upon written documentation.

Travel expenses shall include the cost for business-class air tickets, local

transportation, lodging and meals.

12.8 Either party may request a Change Order, which reflects an increase or

decrease in the proposed work scope. The parties shall concur in writing as

to the scope of the Change Order and its impact on the project schedule and

prices prior to commencing the work proposed in the Change Order. As an

example, the Client may desire OTI to provide additional PSMS Consoles,

simulation capabilities, and/or engineering that is not envisioned in this

Commercial Proposal’s scope.

Operation Technology, Inc. - 21 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

12.9 OTI shall provide additional services, training, technical support and

engineering consulting at a nominal engineering services rate of $161 per

man-hour, portal-to-portal, plus direct expenses. Travel time shall consist of

eight hours per 24-hour day.

12.10 OTI shall submit its invoices to the Client for direct payment. Invoices are

due and payable in full within 30 days from OTI’s invoice dates. Client is

responsible to pay any taxes and/or customs due on the hardware purchased

and/or the PSMS sale, installation, and/or services. Any additional costs that

OTI may incur to import hardware to the Client’s site or conduct business

within the Client’s country to facilitate the delivery of PSMS shall be paid for

or reimbursed by the Client with its prior approval. A finance charge of

1.5% per month shall apply after the forty days on any unpaid balances.

Invoices are payable in United States currency. The Client shall wire transfer

the funds to the following OTI’s account:

Wells Fargo Bank

Bank Number 121000248

Account Number 692-171580

Operation Technology, Inc.

International Swift BIC: WFBIUS6S

13 PSMS HARDWARE (May be Provided by Client)

PSMS Hardware includes one PSMS Server and one PSMS Console PC. Client has

the option of purchasing the PC’s locally or can request OTI to provide the

appropriate PC’s. If Client should choose to use existing PC’s for PSMS, they should

meet then minimum hardware requirements as mentioned in the Attachment B –

PSMS Hardware Requirements.

13.1 One PSMS Server Hardware…………………………..…….US $ 12,000.00

13.2 One PSMS Console Hardware…………………………..……US $ 7,000.00

13.3 One OPC Server Hardware…………………………..…….....US $ 7,000.00

Server hardware is not configured as redundant. Expect additional costs for

redundant systems. PSMS hardware specification is listed in Previous Attachment-B.

Note that the above hardware price ranges vary based on manufacturer brand and

are subject to change. PSMS Server and Console PCs can be furnished by OTI.

14 LOAD SHEDDING HARDWARE

OTI shall determine the quantity and type of hardware needed to perform the

necessary load shedding application as part of the Load Shedding Analysis. The cost

Operation Technology, Inc. - 22 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

for load shedding hardware and installation of the hardware is not included in the

above price.

The estimated cost of Load Shedding hardware using General Electric (GE)

Universal Relays to implement Load Shedding, including installation, configuration,

and testing is less than $200,000.00. PLCs or other Universal-Type Relays may be

less expensive, and may be a viable option. This will be determined by the

engineering studies included in Phase I of the above proposal.

The PSMS interface including the tag database and Load State Estimator may need

to be revised if the new load shedding hardware replaces existing monitoring

hardware. In the instance that the 240 hours specified do not provide enough time to

make the validation and necessary changes it may require a service change order. If

a change order is required, the client will be notified prior to spending additional

hours.

The terms and conditions for phase III may be different than Phase I and Phase II

depending upon the vendor [s] selected. In addition the installation of the hardware

may require infrastructure upgrades at the site, which are also not included in this

proposal.

15 LIABILITY

THE TOTAL LIABILITY OF OTI UNDER ANY EVENT OR CIRCUMSTANCE

IS LIMITED TO ONE-HALF OF THE AMOUNT OF THE CONTRACT AS

LISTED IN PARAGRAPH 12.1.1, 12.2.3 AND 12.5.1 OF THIS CONTRACT.

THE CLIENT AGREES THAT OTI AND ITS OFFICERS, EMPLOYEES OR

REPRESENTATIVES SHALL NOT BE LIABLE IN ANY WAY FOR ERRORS

MADE BY THE CLIENT, HIS AGENTS OR EMPLOYEES BY TRANSPOSING

OR RECOPYING OF ENGINEERING DATA, CALCULATION AND

DRAWINGS, WRONG INTERPRETATION OF THE STUDY RESULTS, AND

CHANGES TO THE FINAL RECOMMENDATION OR REPORT.

FURTHERMORE, OFFICERS, EMPLOYEES, REPRESENTATIVES, OR

OTHER AGENTS OF OTI SHALL BE HELD HARMLESS FROM ANY

CLAIMS, INCIDENTAL OR CONSEQUENTIAL DAMAGES, AND SHALL

NOT BE LIABLE FOR ANY COSTS, LOSSES, DELAYS, ASSOCIATED

DAMAGES, OR ANY OTHER CHARGES, WHICH MAY BE THE RESULT OF

SUCH ERRORS.

This confidential proposal remains valid until May 9, 2003. All prices are in US currency

and exclude shipping, handling, taxes, duties, surcharges and other government-specified

amounts. Estimated tax amounts in Indonesia are 6% (hardware, software, and training)

and 6% + 10% (engineering / consulting services) based on the specific type of product /

Operation Technology, Inc. - 23 - Revision 1

PSMS – PT Newmont, Lombok, Indonesia

PSMS – NEW - 0403

service. These amounts may vary depending upon the clients’ relationship with the local

government.

Operation Technology, Inc. - 24 - Revision 1

You might also like

- Electricity Billing System (Akshi, Abdul Kadir, Abhishek Jain) Group - 18Document9 pagesElectricity Billing System (Akshi, Abdul Kadir, Abhishek Jain) Group - 18Realme SubscriberNo ratings yet

- Remote Monitoring-Srs-V1Document13 pagesRemote Monitoring-Srs-V1JeyanthiRanjit100% (1)

- Monitoring Services For Networks-on-Chips: George Kornaros, Ioannis Papaeystathiou, and Dionysios PnevmatikatosDocument32 pagesMonitoring Services For Networks-on-Chips: George Kornaros, Ioannis Papaeystathiou, and Dionysios Pnevmatikatosslinc_a82No ratings yet

- Psoc Notes PDFDocument61 pagesPsoc Notes PDFanon_613151744100% (1)

- Go Mac PapDocument5 pagesGo Mac Papsyedsalman1984No ratings yet

- Verification of Ancillary Services in Large Scale Power SystemDocument40 pagesVerification of Ancillary Services in Large Scale Power SystemPEOCALDUO1No ratings yet

- Challenges and Lessons Learned From Commissioning An IEC 61850-90-5 Based Synchrophasor SystemDocument8 pagesChallenges and Lessons Learned From Commissioning An IEC 61850-90-5 Based Synchrophasor SystemGelareh ShefaeiNo ratings yet

- GE-Challenges and Lessons Learned From The Design and Implementation of An IEC 61850-90-5 Based Synchrophasor System-Georgia Tech Conference (GOOD)Document10 pagesGE-Challenges and Lessons Learned From The Design and Implementation of An IEC 61850-90-5 Based Synchrophasor System-Georgia Tech Conference (GOOD)Gustavo AguayoNo ratings yet

- 00 - CASABLANCA - Supervisor System and Network Specifications - EnG VerDocument18 pages00 - CASABLANCA - Supervisor System and Network Specifications - EnG VerLinh TinhNo ratings yet

- Testing Dynamic Reports: Application NoteDocument17 pagesTesting Dynamic Reports: Application NoteViswanathan NarayananNo ratings yet

- Electrical Power and Energy Systems: Hamze Hajian-HoseinabadiDocument9 pagesElectrical Power and Energy Systems: Hamze Hajian-HoseinabadiRiza SaidNo ratings yet

- Robotics and AutomationDocument130 pagesRobotics and AutomationtycsdepartmentNo ratings yet

- Scada Based Power Control System Using PLC: Mrs Bhavna Pancholi, Damor Mehul ManubhaiDocument3 pagesScada Based Power Control System Using PLC: Mrs Bhavna Pancholi, Damor Mehul ManubhaiYihenew MengistNo ratings yet

- Kezunovic Cigre2005Document11 pagesKezunovic Cigre2005pvenky_kkdNo ratings yet

- Software Requirements SpecificationDocument22 pagesSoftware Requirements SpecificationBala KrishnanNo ratings yet

- UNMS Hardware SpecificationsDocument12 pagesUNMS Hardware SpecificationsChief Engineer PRTINo ratings yet

- Training DocumentDocument101 pagesTraining Documentscada.wupptclNo ratings yet

- Intelligent Decision System For Start-Up Schemes Based On The Power-Grid Integrated Data PlatformDocument5 pagesIntelligent Decision System For Start-Up Schemes Based On The Power-Grid Integrated Data PlatformFrank_TaroNo ratings yet

- SPC-0804.02-60.05 Rev D2 DCS SpecificationDocument31 pagesSPC-0804.02-60.05 Rev D2 DCS SpecificationharmlesdragonNo ratings yet

- CFOT-8ETJS7 - Start-Up Service For Single-PhaseDocument12 pagesCFOT-8ETJS7 - Start-Up Service For Single-PhaseVerdi ChanNo ratings yet

- Architecture of A Fault Diagnosis Expert System For Power Plants ProtectionDocument5 pagesArchitecture of A Fault Diagnosis Expert System For Power Plants Protectionserg6007No ratings yet

- Study of Software Interface For Adaptive Control SystemDocument42 pagesStudy of Software Interface For Adaptive Control SystemLin ChongNo ratings yet

- SortingDocument6 pagesSortingParveet KumarNo ratings yet

- Design and Improvement of A Control System For A Wet Mix Plant With Iot ControlDocument7 pagesDesign and Improvement of A Control System For A Wet Mix Plant With Iot ControlWan Barmawi Mhd. RazaqNo ratings yet

- ECE2MksIvyrESys PDFDocument27 pagesECE2MksIvyrESys PDFRithi VishwanathanNo ratings yet

- Design of On-Board Software For An Experimental SatelliteDocument10 pagesDesign of On-Board Software For An Experimental SatelliteAlex ParampampamNo ratings yet

- Technical Specifications and Scope of Work of AMRDocument34 pagesTechnical Specifications and Scope of Work of AMRApurwa PatilNo ratings yet

- Project ObjectiveDocument2 pagesProject ObjectiveWaqar AzeemNo ratings yet

- TM950TRE.40-ENG - POWERLINK Configuration and Diagnostics - V4000 PDFDocument80 pagesTM950TRE.40-ENG - POWERLINK Configuration and Diagnostics - V4000 PDFСергей ШилинNo ratings yet

- MatterDocument47 pagesMatterDevanand T SanthaNo ratings yet

- A Hardware Software WSN Platform Rojas Barrett Issc 2017Document6 pagesA Hardware Software WSN Platform Rojas Barrett Issc 2017ajaz ahmedNo ratings yet

- Road To The Integrated Protective Relaying Fault Information SystemDocument4 pagesRoad To The Integrated Protective Relaying Fault Information SystemproteccionesNo ratings yet

- A Hardware Software WSN Platform Rojas Barrett Issc 2017 PDFDocument6 pagesA Hardware Software WSN Platform Rojas Barrett Issc 2017 PDFRamsha KhanNo ratings yet

- Completions Management System Specification - Rev.0Document45 pagesCompletions Management System Specification - Rev.0Titus100% (1)

- E560 IEC60870-5-104 HostDocument68 pagesE560 IEC60870-5-104 HostT Dung LuNo ratings yet

- UNMS Software SpecificationsDocument41 pagesUNMS Software SpecificationsChief Engineer PRTINo ratings yet

- Relay Maintenance Tech Ref Approved by PCDocument36 pagesRelay Maintenance Tech Ref Approved by PCEduardo777_777No ratings yet

- 5.1 - FMCSDocument19 pages5.1 - FMCSJon100% (1)

- MICROCONTROLLERS AND MICROPROCESSORS SYSTEMS DESIGN - ChapterDocument12 pagesMICROCONTROLLERS AND MICROPROCESSORS SYSTEMS DESIGN - Chapteralice katenjeleNo ratings yet

- FS SAS - ElectricalFacilitiesDesignCriteriaDocument23 pagesFS SAS - ElectricalFacilitiesDesignCriteriaTiurma V SinagaNo ratings yet

- Case Study: Protection Settings Management at City PowerDocument7 pagesCase Study: Protection Settings Management at City PowerMohamed WahidNo ratings yet

- Replacement of Distributed Control System of TG - 4 and Provision of These Parameters On The System Near The Manager Using Networking FacilitiesDocument3 pagesReplacement of Distributed Control System of TG - 4 and Provision of These Parameters On The System Near The Manager Using Networking FacilitiesGunadevan ChandrasekaranNo ratings yet

- Edge Processing and Enterprise Integration Closing The Gap On Sensor NetworksDocument11 pagesEdge Processing and Enterprise Integration Closing The Gap On Sensor NetworksSrioNo ratings yet

- A - PROJECT - REPORT - On - INVENTORY - MANAGEMENT (1) (Repaired)Document17 pagesA - PROJECT - REPORT - On - INVENTORY - MANAGEMENT (1) (Repaired)Aditya SharmaNo ratings yet

- FactoryDocument17 pagesFactorycesar.econocomNo ratings yet

- Facilities and Operations - Modernization Project Office: Brookhaven National LaboratoryDocument23 pagesFacilities and Operations - Modernization Project Office: Brookhaven National LaboratoryAyman SaberNo ratings yet

- Mo Ta DHD OCC - EnglishDocument15 pagesMo Ta DHD OCC - EnglishVu Anh TuanNo ratings yet

- Course FileDocument36 pagesCourse FileElakkiya N.SNo ratings yet

- 5 2marksDocument22 pages5 2marksElakkiya N.SNo ratings yet

- Power System Automation: Eminar EportDocument16 pagesPower System Automation: Eminar EportAnurajNo ratings yet

- PredictiveMaintenance ExcavatorDocument4 pagesPredictiveMaintenance ExcavatorDody Rakhmat RamadhanNo ratings yet

- Design and Development of A Synchrophasor Measurement Unit As Per IEEE Standard C37.118.1 2011 Saeed Hassan Khan 20151112 1Document15 pagesDesign and Development of A Synchrophasor Measurement Unit As Per IEEE Standard C37.118.1 2011 Saeed Hassan Khan 20151112 1Har HarNo ratings yet

- Inteliigent Remote BillingDocument49 pagesInteliigent Remote BillingSTAR E WORLDNo ratings yet

- 34-SAMSS-623 Programmable Controller Based ESD SystemsDocument31 pages34-SAMSS-623 Programmable Controller Based ESD Systemscherif yahyaouiNo ratings yet

- Establishment of A Control Philosophy For The Pebble Bed Modular Reactor FJE Laubscher, HA GrobbelaarDocument6 pagesEstablishment of A Control Philosophy For The Pebble Bed Modular Reactor FJE Laubscher, HA GrobbelaarghostamirNo ratings yet

- Design and Implementation of A UCA-based Substation Control SystemDocument8 pagesDesign and Implementation of A UCA-based Substation Control Systemsupachaik6151No ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Attachment A - Package List and DescriptionDocument4 pagesAttachment A - Package List and DescriptionAlpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument2 pagesScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsAlpha AgustinusNo ratings yet

- LOAD SHED Under Frequency - Rev1Document1 pageLOAD SHED Under Frequency - Rev1Alpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument2 pagesScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Subject: Underfrequency Load Shedding Program: I. Electrical System DynamicsDocument7 pagesSubject: Underfrequency Load Shedding Program: I. Electrical System DynamicsAlpha AgustinusNo ratings yet

- Young Davidson Gold Mine Power Quality Case Study CSDocument2 pagesYoung Davidson Gold Mine Power Quality Case Study CSAlpha AgustinusNo ratings yet

- Substation Automation Operator SoftwareDocument9 pagesSubstation Automation Operator SoftwareAlpha AgustinusNo ratings yet

- Hardware ComponentsDocument6 pagesHardware ComponentsAlpha AgustinusNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsAlpha AgustinusNo ratings yet

- System DescriptionDocument12 pagesSystem DescriptionAlpha AgustinusNo ratings yet

- (/coresight/) Ad Hoc Display 331SWB1508: Alpha AgustinusDocument1 page(/coresight/) Ad Hoc Display 331SWB1508: Alpha AgustinusAlpha AgustinusNo ratings yet

- Scada and Load Shedding Power Distribution: Project ProposalDocument1 pageScada and Load Shedding Power Distribution: Project ProposalAlpha AgustinusNo ratings yet

- Unit 51 Unit 52 Control Room Coal Plant Unit 53 Unit 54: 50-SW-SCAD01Document1 pageUnit 51 Unit 52 Control Room Coal Plant Unit 53 Unit 54: 50-SW-SCAD01Alpha AgustinusNo ratings yet

- Note 4: Item Qty. Part No. Description Item Qty. Part No. DescriptionDocument1 pageNote 4: Item Qty. Part No. Description Item Qty. Part No. DescriptionAlpha AgustinusNo ratings yet

- 2 Core Multimode: Detail DRW: 80-94L-SCAD01 Detail DRW: 10-94L-SCAD01Document1 page2 Core Multimode: Detail DRW: 80-94L-SCAD01 Detail DRW: 10-94L-SCAD01Alpha AgustinusNo ratings yet

- Eaton MV Withdrawable Vacuum Fused Contactor Trucks - : Built For Extreme!Document3 pagesEaton MV Withdrawable Vacuum Fused Contactor Trucks - : Built For Extreme!Alpha AgustinusNo ratings yet

- 03 TT - High ResistanceDocument3 pages03 TT - High ResistanceStephen BridgesNo ratings yet

- GZYQ Liquid Soft StarterDocument15 pagesGZYQ Liquid Soft StarterAlpha AgustinusNo ratings yet

- 03 TT - High ResistanceDocument3 pages03 TT - High ResistanceStephen BridgesNo ratings yet

- Binter Only Operating On Tuesday For Month of August ONLY: KAS 2017 Summer Schedule - From June 2nd OnwardsDocument1 pageBinter Only Operating On Tuesday For Month of August ONLY: KAS 2017 Summer Schedule - From June 2nd OnwardsAlpha AgustinusNo ratings yet

- 22 Vesda VLC Tds A4 Ie LoresDocument2 pages22 Vesda VLC Tds A4 Ie LoresEduard AlzateNo ratings yet

- Siemens - Harmonics in Power Systems, Causes Effects and Control (2013)Document24 pagesSiemens - Harmonics in Power Systems, Causes Effects and Control (2013)micaNo ratings yet

- Introduction To Cyanide Gold Mining: Orcr Usepa July 2012Document14 pagesIntroduction To Cyanide Gold Mining: Orcr Usepa July 2012Tingwe PoulNo ratings yet

- Rps Sr. Sec. School Computer Science: Practical FileDocument37 pagesRps Sr. Sec. School Computer Science: Practical FileNikhil DiwanNo ratings yet

- The Many Facts Pointing To Paul Le Roux Being Satoshi Nakamoto - Bitcoin NewsDocument14 pagesThe Many Facts Pointing To Paul Le Roux Being Satoshi Nakamoto - Bitcoin Newsmc.capitao.do.matoNo ratings yet

- Set-Up Software.: Emea1.indd 1 9/30/2010 4:05:45 PMDocument24 pagesSet-Up Software.: Emea1.indd 1 9/30/2010 4:05:45 PMAbizahi Méndez HernándezNo ratings yet

- LNMIIT Shines in Google Summer of Code 2014Document1 pageLNMIIT Shines in Google Summer of Code 2014Arpit KathuriaNo ratings yet

- EV-07B Protocol v1.2 V20200508Document48 pagesEV-07B Protocol v1.2 V20200508John BuckleyNo ratings yet

- AMIGA - Chessmaster 2100 (Fidelity), The ManualDocument7 pagesAMIGA - Chessmaster 2100 (Fidelity), The ManualjajagaborNo ratings yet

- 3PAR Remote Copy With VMware Site Recovery ManagerDocument15 pages3PAR Remote Copy With VMware Site Recovery ManagerYordanka Atanasova StoyanovaNo ratings yet

- Overview of Python and MysqlDocument4 pagesOverview of Python and MysqlAkshayaNo ratings yet

- Lecture 19 - CSS TEXTDocument49 pagesLecture 19 - CSS TEXTTanveer Ahmed HakroNo ratings yet

- Cloud Adoption Framework For Small and Medium-Size Enterprises SMEs in Ethiopia - Birhane WoldegebrealDocument108 pagesCloud Adoption Framework For Small and Medium-Size Enterprises SMEs in Ethiopia - Birhane WoldegebrealMikatechNo ratings yet

- Theory Python QuestionsDocument6 pagesTheory Python QuestionsPurvi ChaurasiaNo ratings yet

- SA-BTT350P SA-BTT750P: Blu-Ray Disc Home Theater Sound SystemDocument149 pagesSA-BTT350P SA-BTT750P: Blu-Ray Disc Home Theater Sound SystemValentin SivrievNo ratings yet

- Sprac 51Document16 pagesSprac 51fabiolmtNo ratings yet

- Red Hat Ceph Storage Hardware Selection GuideDocument23 pagesRed Hat Ceph Storage Hardware Selection GuideVinh HuynhNo ratings yet

- Mobile Banking ServicesDocument11 pagesMobile Banking ServicesDiksha SadanaNo ratings yet

- Relational Databases and SQL: Accounting Information Systems, 9eDocument46 pagesRelational Databases and SQL: Accounting Information Systems, 9eDesiree Ann GamboaNo ratings yet

- 21FL0027 - BDS (Esubmission)Document6 pages21FL0027 - BDS (Esubmission)liam josef lauditNo ratings yet

- Optimal Scheduling of Water Supply ProjectsDocument22 pagesOptimal Scheduling of Water Supply ProjectsCrazyBookWormNo ratings yet

- Persuasive Web Design (Therese Fessenden) PDFDocument237 pagesPersuasive Web Design (Therese Fessenden) PDFAlex TrifanNo ratings yet

- Chen 2020 J. Phys. Conf. Ser. 1684 012007Document7 pagesChen 2020 J. Phys. Conf. Ser. 1684 012007Minhquang NgoNo ratings yet

- Arts 6 Diamond Q1 - 1Document3 pagesArts 6 Diamond Q1 - 1Ralph Fael LucasNo ratings yet

- CCNA 1 Activity 1.2.4.4 AnswersDocument3 pagesCCNA 1 Activity 1.2.4.4 AnswersJordan Segundo60% (5)

- Redline Connect v3.9 RelNotesDocument7 pagesRedline Connect v3.9 RelNotesalex BecerraNo ratings yet

- L-2..Number SystemsDocument63 pagesL-2..Number SystemsSaima Binte IkramNo ratings yet

- 03 Csmath2 DeterminantDocument39 pages03 Csmath2 DeterminantFrancis ObinaNo ratings yet

- Fourier E40 BrochureDocument8 pagesFourier E40 BrochureDeiveegan MNo ratings yet

- Porcupine Excel AssignmentDocument25 pagesPorcupine Excel AssignmentAndrea XiaoNo ratings yet

- Matlab Simulation of Cordic Based Adaptive Filtering For Noise Reduction Using Sensors ArrayDocument6 pagesMatlab Simulation of Cordic Based Adaptive Filtering For Noise Reduction Using Sensors ArrayMohamed GanounNo ratings yet

- Scheme - I Sample Question PaperDocument4 pagesScheme - I Sample Question PaperNaresh KumarNo ratings yet