Professional Documents

Culture Documents

2.8c Risk Assessment Rev.02 - Blank

Uploaded by

Shafie ZubierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.8c Risk Assessment Rev.02 - Blank

Uploaded by

Shafie ZubierCopyright:

Available Formats

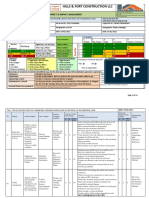

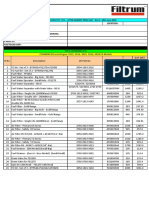

RISK ASSESSMENT AND ANALYSIS/قييم توـحليل لاـمخاطر

تــ

RA Number:قييم لاـمخاطر

رقم تــASKEC/800/380Kv-04 DEPARMENT / AREA: لاـمنطقـة/ اـالدارة: EHVPD - COA

WORKPLACE / TASK / ACTIVITY / PROCESS NAME: لاـمعـدة/ لاـعمليـة/ لاـمهمة/ لاـموقعـ

RA TEAM (NAMES):ريق لاـتقييم

اسمءاـ فــ DATE:9/29/2019: اتاريخ

1.SAFETY OFFICER: Kamala Kannan, Daya Singh NEXT REVIEW DATE / 9/29/2020: اـاـدم ريخ مراجـعـة لق

اـتــ

2.ENGINEER: Faisal Mohd, Sethu 380 KV OHTL Shutdown / Modification Works in Existing Temporary Ckt 9019 to 9050 A & B APPROVED BY MANAGER / SUPERVISOR:اعتمد من قـبل

to Establish Ckt's 9019 to 9089 A & B and 9050 to 9089 A & B

3.SUPERVISOR: Jamshed, Dwarika Prasad & Elangoven SIGNATURE:لاـتوقيعـ

RISK ASSESSMENT

HAZARD IDENTIFICATION/حديد لاـمخاطر

تــ CONTROL/وـسائـل لاـتحكم RISK REDUCTION ACTION PLAN/تقييم لاـمخاطر

خـطـة لاـعمل ل ـ

تقييم المخاطر

R

C C

L L i

o i o i s

n R n

s k a s k k

Workplace/ Activity/ Process/ Equipment/ e e Controls

Item # Risk Issue (Possible Incident) (What can go e

l

n

(Improve Existing Controls/ Implement new controls) واـسيطـرة

ل لاـتحكم

e

l R

Follow up By Whom (Name) &

Implemented (Yes

الـرقم materials / لاـمعـدات/موقعـ لاـعمل ظـمهمة لاـعمل Hazards اـالخطـار wrong) (Accident/ Ill health to person, fire or Existing Controls وـسائـل لاـتحكم لاـمتوفرة q i k اـالضافية q i a

By When (Date) لاـمهمة لاـمعنية

/ No)/ تــ لاـتنفيذ

هل م

لاـمتسلسل لاـمواد property loss) / لاـمخاطر لاـمحتملة/ u i u لاـتاريخ/تنفيذ

بــ

لاـ الـ/نـعم

h h n

e o n e o k

n g n

c o c o i

e d e d n

g

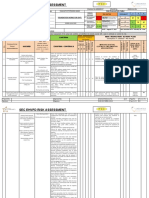

a) Permit to work system must be followed.

f) Obtain permit from concerned external

b) Ensure ground level is even and good condition to Faisal Muhammed

authority/ies before starting the activity.

Equipment / vehicle / Trailer Electrocution, major injury of placed vehicle/trailer. g) Ensure all safety documents, calibration certificate (Electrical Engg)

Moving /Placed near energized human being, fatality, Toppling, c) Ensure sufficient clearance is available to move near 2 2 4 and TUV of equipments must be available and valid. 2 1 2 Sethu K

Equipment damage. energized lines. (More than 10 meter) (Electrical Engg)

line, Un even ground level d) Ensure proper grounding provided. h) Provide appropriate training to drivers and Daya Sankar

e) Ensure proper operation and good condition of the operators. (HSE Officer)

i) Conduct daily tool box talk before start the activity.

equipment before usage.

e) Vehicle inspection must be done before start. Faisal Muhammed

Mobilization of materials tools and a) Unauthorized driving strictly prohibited. f) Vehicle speed should not exceed 20km/hr. in site. (Electrical Engg)

1 Vehicle Movement - Major/Minor Injury of person, b) Traffic rules must be followed. g) Signal man must be provided inside the site till the Sethu K

equipments. Men struck with Vehicle, Vehicle fatality, Vehicle damage 2 3 6 2 2 4

c) Do not drive in poor visibility. equipment enters in site, positioned and egress from (Electrical Engg)

accident.

d) All passengers on boards to be fasten the seat belts. site/location. Daya Sankar

h) Ensure availability of first aid box and first aider. (HSE Officer)

Severe weather condition - Heat rash, Heat cramps, Heat d) Stop the work when wind exceeds 20 miles per Faisal Muhammed

High temperature, a) Work to be stopped during poor visibility, Sand hour.

stroke, Excess sweating, De (Electrical Engg)

High Humidity, Hydration, Major injury / Fatality storm and Rain etc. e) Necessary refreshments, cold drinks, ORS, Glucose Sethu K

High wind intensity/dusty wind / due to fall from height, Eye b) Provide cold water in every 30 minutes. 3 2 6 etc. to be provided at the site in hot season. 3 1 3 (Electrical Engg)

Sand storm, c) Use full sleeves to cover the body. Use layer of f) Provide respiratory protection dust mask.

Rain – Slippery condition injury, Lungs or respiratory Injury, clothes. g) Emergency vehicle must be available at site. Daya Sankar

Minor/Major Personal injury h) Provide rest shelter. (HSE Officer)

a) Obtain permit to work before starting the activity.

d) Provide manual and mechanical handling training

b) All PPEs and tools must be inspected before use on to all.

Manual and mechanical handling of Cut, Abrasion, Fracture, Material daily basis.

2 Slip, Trip, fall from the same level. 2 2 4 e) Conduct daily TBT before start the activity. 2 1 2

material tools and equipments. damage. c) Use proper and adequate PPEs like hand gloves,

safety shoes, helmet, high visibility jacket, goggles and f) Ensure the availability of first aid box and first

overall. aider.

Lack of supervision, Using sub a) Regular inspection & maintenance of equipment to e) Ensure use of proper tools and equipment as per

standerd equpment/tools (not the approved work schedule.

ensure its safe working condition.

registered/ not inspected by third Major injury, Fatal Accident, f) Do not use tools with blunt edge.

3 Condition of equipment/tools party maintenance not done etc), Material Damage, cut injury, b) Ensure operator checks / inspection prior to use. 4 3 12 g) Proper storage, maintenance & regular 4 1 4

Equpment/ tools operate or used Physical injury to the person. c) Follow manufacturer instructions for maintenance inspections. d) only color coded tools/equipment

of equipment.

by unskilled / untrained d) Use of proper PPE shoyld be used at workplace

technician/ worker

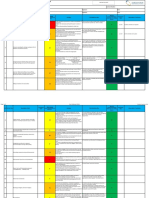

a) Deploy only trained & competent operators

Major Injury, Fatal Accident, for equipment operation.

Incompetent /

Unauthorized Operation, Working Material Damage Personnel b)Follow manufacturer instructions for operating the e). Ensure the thired party certification of all tools

Equipment operation Injury, equipment

near live lines. and equipment/s.

4 (tenstioner/puller, crane, showel, Asset Damage, c) Proper Tool box talks to be conducted prior to start 3 4 12 3 2 6

Bypassing the Approved f). Follow the RA and JSP.

winch machine etc.) procedures. Equipment Damage, of work g). Ensure competent supervision.

d) Use Proper tools , safety harness and PPE ( Safety

Shoes, insulating (rubber) gloves, Safety Helmet,

Voltage tester etc)

i) Obtain external permit from the concern authority

before start the work.

a)Follow PTW Syustem. j) Ensure proper grounding on both side identified

b) Avoid working if lightning threat is suspected. adjacent tower’s circuit/s.

Electrocution (Fatality/injury) c) Work area shall be clearly identified before start of k) Presence of competent person (Permit/ LOA

Fire /Explosion work. holder) must require while installing or removing the

Flashes d) Work with proper safety clearance distance and

Major Injury, fatal Accident, grounding.

Station tripping sufficient grounding. 3 3 9 3 2 6

material damage l) Competent person must ensure the voltage

Damage to the equipment and e) Ensure Competent Supervision all the time. absence before installing the grounding.

properties, Fall of tools Height f) Use proper PPE. m) Adequate equipment (VAV) shall be used to

Phobia g) Ensure the availabily of first aid box and fire ensure the voltage absence before installing the

5 Working on towers near Live lines extinguisher at site. grounding.

h) Conduct daily tool box talk before start the work. n) Ensure availability of first Aider and ambulance at

working location.

i) Tools must be secured with rope to a j)

Medical examination of work height workers must be

done prior to mobilzation

a) Proper grounding of conductors. e) Conduct daily tool box talk before start the work.

f) Ensure only trained and skilled workmen are

b) Equipments should be grounded.

Electric shock, Major Injury, fatal deployed.

Induction currents Accident, material damage c) Adequate vertical & horizontal safety clearance 2 2 4 g) Ensure the voltage absence by using Voltage 2 1 2

should be maintained. absence ameter before proceding for grounding of

d) Use proper PPE.

conductors.

d) Obtain external permit from the concern authority

before start the work.

e) Adequate vertical & horizontal safety clearance +

a) Proper earthing of conductors

Modification Works near existing Working near energized lines Electrocution Major injury, b) Nearby structures with proper earthing additional distance for safety shouldbe maintained

6 5 3 15 as per standard. 5 2 10

Live OHTL Induction current fatal accident, Material damage c) Use proper PPE ( Safety Shoes, insulating (rubber)

for 13.8kV - 1.0 Meter

gloves, Safety Helmet, Voltage tester etc) for 33kV - 1.0 Meter

for 132kV - 1.5 Meter

for 380kV - 5.0 Meter

a) Use Safety harness with double lanyard with f) All Lifting Gears like Pulley, Slings, Rope and

properly hooked while working above 1.8 mtr height. Insulator Assembly Should be Inspected before

b) Waist pouch for carrying bolt, nuts and hand tools Work.

Removing & Lack of supervison must be available with line men during working above g) Color Coding of T & P Should be Verified

alternation Approved procedure not followed Major Injury 1.8 mtr height. h) Work Should be executed by Experienced

7 4 3 12 4 2 8

of existing Using uninspected lifting gears, ,fatal accident, material damage c) Do not throw up / throw down the materials / Foreman.

structure/line at height tools or lifting belts tools. i) Adequate and damage free guy ropes to be used,

d) Ensure availability of Emergency vehicle @ Site. tied properly.

e) Mechanical lifting Equipment’s like shovel must be j) Smooth (without jerk) lifting must be ensured.

inspected before start of work. k) Competency of the Operator should be verified.

a) Proper Platform should be used for pressing of

conductor.

b) Use of appropriate PPE's like full body harness, fall

Descending / Ascending towers in arrestor, helmet and shoes. h) Spacer Trolley Load Should within the SWL

poor Weather conditions, c) Do not throw up / throw down the materials / tools. i) During clipping and jumpering, nobody should

Uncertified/Lack of experience of stand below the working zone.

Conductor & OPGW Major Injury d) All the arrangement should be prepared under

Lineman or fitters, Lack of j) Retractable fall arrester and safety Harness must

8 clipping, spacering competent supervison, ,fatal, material skilled foreman. 4 3 12 be used by the line man during jumpering work. 4 2 8

and jumpering Approved procedure not followed, damage e) Proper Housekeeping should be done before start

of work.

Using uninspected lifting gears,

tools or lifting belts. f) No Technician should stand under the Tower.

g) Adequate and damage free guy ropes to be used,

tied properly.

Page 1 of 1 Rev.2 [08-April-2019] Projects Business Unit

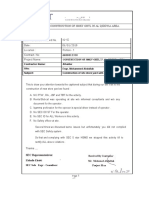

RA Prepared by : RA Accepted by : RA Approved by SEC / Safety Rep: RA Aprroved by SEC-HV&EHVPD:

Name & Sign Name & Sign Name & Sign Name & Sign

Desgination Desgination Desgination Desgination

Date Date Date Date

You might also like

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- Risk Assessment and Analysis for 380KV DC OHTL Qiddiya Area WorkDocument4 pagesRisk Assessment and Analysis for 380KV DC OHTL Qiddiya Area WorkshafieNo ratings yet

- Royal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesDocument2 pagesRoyal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesLenaj Ebron100% (3)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SCAFFOLDING WORKDocument2 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SCAFFOLDING WORKNav100% (1)

- Risk assessment and analysis for construction of new substationDocument234 pagesRisk assessment and analysis for construction of new substationShafie ZubierNo ratings yet

- RISK ASSESSMENT OF RACKING OUT CIRCUIT BREAKERDocument4 pagesRISK ASSESSMENT OF RACKING OUT CIRCUIT BREAKERRais BurondkarNo ratings yet

- Electrical Safety SWPDocument12 pagesElectrical Safety SWPRavikant PandeyNo ratings yet

- 003 Material HandlingpdfDocument4 pages003 Material Handlingpdfghada gattouchNo ratings yet

- Risk Assessment DrivingDocument3 pagesRisk Assessment Drivingghada gattouch100% (2)

- ABC-SFOP-36 Fall Protection PlanDocument25 pagesABC-SFOP-36 Fall Protection PlanShafie ZubierNo ratings yet

- 002 Excavation & TrenchingpdfDocument3 pages002 Excavation & Trenchingpdfghada gattouch100% (1)

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- GEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment CheckDocument3 pagesGEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment Checkacanbasri1980No ratings yet

- OHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEDocument21 pagesOHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEmohammed tofiqNo ratings yet

- Ehs Risk Register / Assessment: Name of The Project Reference No Activities CoveredDocument7 pagesEhs Risk Register / Assessment: Name of The Project Reference No Activities CoveredNirajan MarwaitNo ratings yet

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiNo ratings yet

- Risk Assessment AnalysisDocument7 pagesRisk Assessment Analysiskamranshamoo1No ratings yet

- Ra09 Lifting ActivitiesDocument4 pagesRa09 Lifting Activitiesluatdolphin100% (1)

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationDocument2 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationYasHie PwincsZaNo ratings yet

- Hazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantDocument6 pagesHazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantShariq KhanNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument16 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- N16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSDocument5 pagesN16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSAntaryami Singh GoondiNo ratings yet

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- RiskAssessment For Precast Foundation and Road MarkingDocument13 pagesRiskAssessment For Precast Foundation and Road MarkingAneessh KumarNo ratings yet

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDocument4 pagesHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaNo ratings yet

- COVID-19 Risk Assesment For NCCCLDocument3 pagesCOVID-19 Risk Assesment For NCCCLmohit100% (2)

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- 02-RA For Panel InstallationDocument5 pages02-RA For Panel Installation287100% (1)

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman AlqaysiNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Accident Incident Report FormDocument3 pagesAccident Incident Report FormTuan NguyenNo ratings yet

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- UG RA 004 - Test Pit Manual ExcavationDocument5 pagesUG RA 004 - Test Pit Manual ExcavationshamshuddinNo ratings yet

- Risk Assessment FormDocument2 pagesRisk Assessment FormMeng Hwi KorNo ratings yet

- 2.8c Risk Assessment - 005 Light Materials and Equipment Loading - Unloading Rev. July 2019Document9 pages2.8c Risk Assessment - 005 Light Materials and Equipment Loading - Unloading Rev. July 2019Wasim KhanNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- Alec Qa QC AssesmentDocument34 pagesAlec Qa QC AssesmentAbirhamNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- OHS-PR-09-03-F02 HIRA - 020 Lifting of Heavy Equipment Using Crane Rev. 2021Document14 pagesOHS-PR-09-03-F02 HIRA - 020 Lifting of Heavy Equipment Using Crane Rev. 2021bilalgradioshNo ratings yet

- Tower Light Inspection ChecklistDocument1 pageTower Light Inspection ChecklistHabib ur rahmanNo ratings yet

- SEC-EHV-Risk-assesment-form-Rev.-2..Foundation Works For OHTLDocument4 pagesSEC-EHV-Risk-assesment-form-Rev.-2..Foundation Works For OHTLSn AhsanNo ratings yet

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- Risk Assessment For Ceramic & Porcelain Tile WorksDocument6 pagesRisk Assessment For Ceramic & Porcelain Tile WorksFaizan TanveerNo ratings yet

- RISK-REGISTERDocument2 pagesRISK-REGISTERعمرو100% (1)

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- Risk Assessment For Pools Maintenance Al Ain ZooDocument13 pagesRisk Assessment For Pools Maintenance Al Ain Zooطارق رضوان100% (1)

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Hazard Risk Assessment and Control at Godrej Project SiteDocument11 pagesHazard Risk Assessment and Control at Godrej Project SiteRajput AmitNo ratings yet

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDocument5 pages7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasNo ratings yet

- SH-F43 - PTW Format - R02Document2 pagesSH-F43 - PTW Format - R02vini100% (1)

- BackfillingDocument2 pagesBackfillingGyanendra Narayan NayakNo ratings yet

- OHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pagesOHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterShafie ZubierNo ratings yet

- 86p$permit To Height WorkDocument2 pages86p$permit To Height WorkATIKUR RAHMANNo ratings yet

- Incident Investigation ReportDocument2 pagesIncident Investigation Reportsudeesh kumarNo ratings yet

- Vacuum Test Risk AssessmentDocument6 pagesVacuum Test Risk AssessmentJohn Mark Macoy100% (1)

- TABREED Risk Assessment for Road Crossing Piping NetworkDocument6 pagesTABREED Risk Assessment for Road Crossing Piping NetworkAjas Aju100% (1)

- GIS Building Expansion and Reactor Installation HIRADocument8 pagesGIS Building Expansion and Reactor Installation HIRAAbdul Rasheed Mangrio100% (1)

- JHA for Unloading Product from Ship at Port of SalalahDocument4 pagesJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- Self Leveling - Epoxy Work (R-A)Document3 pagesSelf Leveling - Epoxy Work (R-A)anisaanNo ratings yet

- PR-PDC-9029-01 - Rev.00 Scaffolding Work Procedure - FinalDocument64 pagesPR-PDC-9029-01 - Rev.00 Scaffolding Work Procedure - FinalShafie ZubierNo ratings yet

- SEC Reviews Proposed Safety OfficerDocument3 pagesSEC Reviews Proposed Safety OfficerShafie ZubierNo ratings yet

- W 13 Daily, Weekly Observation RegisterDocument424 pagesW 13 Daily, Weekly Observation RegisterShafie ZubierNo ratings yet

- Accident Summary Report - 380kv OHTL, ALHAIDER December 2020Document20 pagesAccident Summary Report - 380kv OHTL, ALHAIDER December 2020Shafie ZubierNo ratings yet

- Contractors' Top Management Contact Details (2022)Document3 pagesContractors' Top Management Contact Details (2022)Shafie ZubierNo ratings yet

- Examiners Report - January 2010 Unit C PDFDocument14 pagesExaminers Report - January 2010 Unit C PDFIrshad AhmedNo ratings yet

- SN Operator/Driver Name Operator/Driver Iqama No Operator/Driver Profession On Iqama Operator/Driver Type of SAG LicenseDocument4 pagesSN Operator/Driver Name Operator/Driver Iqama No Operator/Driver Profession On Iqama Operator/Driver Type of SAG LicenseShafie ZubierNo ratings yet

- 3 Daily, Weekly Observation RegisterDocument424 pages3 Daily, Weekly Observation RegisterShafie ZubierNo ratings yet

- Prequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewDocument9 pagesPrequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewShafie ZubierNo ratings yet

- 5.19.3 Job Safety Practices Rev 02-BlankDocument4 pages5.19.3 Job Safety Practices Rev 02-BlankShafie ZubierNo ratings yet

- MEEDCO Daily Wind Speed RecordDocument1 pageMEEDCO Daily Wind Speed RecordShafie ZubierNo ratings yet

- Plant Facility Safety ObservationsDocument4 pagesPlant Facility Safety ObservationsShafie ZubierNo ratings yet

- Dangers of Oxygen-Deficient Atmospheres: Safetygram 17Document4 pagesDangers of Oxygen-Deficient Atmospheres: Safetygram 17Shafie ZubierNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- SEC 5-STAR FIRE SAFETY REPORTDocument6 pagesSEC 5-STAR FIRE SAFETY REPORTShafie ZubierNo ratings yet

- 5.19.3 Job Safety Practices Rev 02-BlankDocument4 pages5.19.3 Job Safety Practices Rev 02-BlankShafie ZubierNo ratings yet

- HSE Risk Register for Contractor ProjectsDocument3 pagesHSE Risk Register for Contractor ProjectsShafie ZubierNo ratings yet

- Daily wind speed record for 380 Kv OHTL project in RiyadhDocument1 pageDaily wind speed record for 380 Kv OHTL project in RiyadhShafie ZubierNo ratings yet

- 5.19.3 Job Safety Practices Rev 02-BlankDocument4 pages5.19.3 Job Safety Practices Rev 02-BlankShafie ZubierNo ratings yet

- Drilling & Workover Services Department: Coastline Geophysical Saudi Arabia Limited. Man Power DetailsDocument3 pagesDrilling & Workover Services Department: Coastline Geophysical Saudi Arabia Limited. Man Power DetailsShafie ZubierNo ratings yet

- Audit Report (380kv OHTL IN QIDDYIA, ALHAIDER) AUGUST 2020Document8 pagesAudit Report (380kv OHTL IN QIDDYIA, ALHAIDER) AUGUST 2020Shafie ZubierNo ratings yet

- Site Instruction/ Date Lo Ca Tion 1 Contract.: Name: Alhalder Attn: Engr. Mohammed Abdullah Site Yard With MajorDocument2 pagesSite Instruction/ Date Lo Ca Tion 1 Contract.: Name: Alhalder Attn: Engr. Mohammed Abdullah Site Yard With MajorShafie ZubierNo ratings yet

- General Environmental RegulationsDocument198 pagesGeneral Environmental RegulationsShafie ZubierNo ratings yet

- Maintenece Card 2752Document4 pagesMaintenece Card 2752Shafie ZubierNo ratings yet

- Environmental Audit Protocol 2019.. (Updated Protocol 2019)Document56 pagesEnvironmental Audit Protocol 2019.. (Updated Protocol 2019)Shafie ZubierNo ratings yet

- Cgsa Incident Report 2016Document16 pagesCgsa Incident Report 2016shafieNo ratings yet

- Environmental Inspection ChecklistDocument6 pagesEnvironmental Inspection ChecklistShafie Zubier100% (1)

- Working System: Sec Consultant Eng. Shafie Sec Consultant Eng. MohammadDocument1 pageWorking System: Sec Consultant Eng. Shafie Sec Consultant Eng. MohammadShafie ZubierNo ratings yet

- Directional Drilling Short Answer Questions 2016Document7 pagesDirectional Drilling Short Answer Questions 2016AKSHAY SHEKHAWAT0% (2)

- 75 Civil Engineering Interview QuestionsDocument2 pages75 Civil Engineering Interview QuestionsZakir AliNo ratings yet

- Industrial VisitDocument22 pagesIndustrial VisitInvincible GamerNo ratings yet

- Nero Soundtrax ManualDocument54 pagesNero Soundtrax ManualrbNo ratings yet

- Life Cycle AssesmentDocument34 pagesLife Cycle AssesmentMayank Joshi100% (1)

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoNo ratings yet

- Troubleshooting guide for car audio amplifierDocument2 pagesTroubleshooting guide for car audio amplifierDanny Garcia LopezNo ratings yet

- Green Mark Manager 6 May 2019Document1 pageGreen Mark Manager 6 May 2019Haider Tyebally TyeballyNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Location:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDocument23 pagesLocation:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDadasaheb More100% (2)

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)

- Training Video 1 - Installation and Set UpDocument11 pagesTraining Video 1 - Installation and Set UpLengendary PhubrNo ratings yet

- Combine Harvester Instruction Book: Sampo Rosenlew LTD P.O.Box 50 FIN-28101 PORIDocument154 pagesCombine Harvester Instruction Book: Sampo Rosenlew LTD P.O.Box 50 FIN-28101 PORIjamppajoo2No ratings yet

- Study pointers in C with examplesDocument6 pagesStudy pointers in C with examplespremsagarNo ratings yet

- Torre Sauter 4 PosiçõesDocument22 pagesTorre Sauter 4 PosiçõesPaulo Henrique ValérioNo ratings yet

- Field Engineer ResumeDocument3 pagesField Engineer ResumesambhuNo ratings yet

- AR212 - Plumbing Fixtures Materials FittingsDocument6 pagesAR212 - Plumbing Fixtures Materials FittingsLooky RivasNo ratings yet

- Happyfox API ManualDocument28 pagesHappyfox API ManualcadoNo ratings yet

- Quartz Analogue Watches User Manual: Display and FunctionsDocument3 pagesQuartz Analogue Watches User Manual: Display and FunctionsFlorin MihaiNo ratings yet

- GIC Presentation at PSRC 05 14 2014Document48 pagesGIC Presentation at PSRC 05 14 2014frodo frodoNo ratings yet

- APS155CH Installation ManualDocument6 pagesAPS155CH Installation ManualTom GibbsNo ratings yet

- Yogesh Kumar Garg Resume Mechanical EngineerDocument3 pagesYogesh Kumar Garg Resume Mechanical EngineerYogeshGargNo ratings yet

- Conducting Polymers: 22-2-96 by Colin PrattDocument7 pagesConducting Polymers: 22-2-96 by Colin PrattkshitijscribdNo ratings yet

- EGCP-2 Engine Generator Control PackageDocument226 pagesEGCP-2 Engine Generator Control PackageJorge EspinozaNo ratings yet

- A Practical Study For New Design of Essential OilsDocument17 pagesA Practical Study For New Design of Essential OilsEmmanuel PlazaNo ratings yet

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- DMRC Project (Mech)Document33 pagesDMRC Project (Mech)Jyoti Singh100% (3)

- VOIP On Packet Tracer PDFDocument10 pagesVOIP On Packet Tracer PDFHead Bang100% (2)

- Renovate Galvanized SteelDocument1 pageRenovate Galvanized SteelSam SamuelsonNo ratings yet

- Presentation On Gas Power PlantDocument82 pagesPresentation On Gas Power Plantakshay gupta100% (2)