Professional Documents

Culture Documents

Experimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine Aggregate

Uploaded by

SruthiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine Aggregate

Uploaded by

SruthiCopyright:

Available Formats

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

International Journal of Advanced Research in Biology Engineering Science and Technology (IJARBEST) Vol. 2,

Issue 3, March 2016

EXPERIMENTAL STUDY ON WASTE GLASS AS A PARTIAL

REPLACING MATERIAL IN CONCRETE FOR FINE AGGREGATE

D.Elavarasan1, Dr.G.Dhanalakshmi2

UG Scholar1,Prof & Head2, Department of Civil Engineering, Oxford Engineering college.

Abstract- Concrete industry is one of the consumers of natural resources due to which

sustainability of concrete industry is under threat. In this paper, the issues of economic concern are

addressed by the use of waste glass as partial replacement of fine aggregates in concrete. Fine

aggregates were replaced by waste glass powder as 0%, 10%, 20%, and 30% and by weight for M-20

mix. The concrete specimens were tested for compressive strength, splitting tensile strength at the 7 th

and 28th days of age and the results obtained were compared with those of normal concrete. The results

conclude the permissibility of using waste glass powder as partial replacement of fine aggregates up to

30% by weigh for particle size of range 0-1.18mm. In during phase-II, their flexural strength and

durability study is being carried out.

Keywords- Cement (OPC), Fine aggregate, Waste Glass Powder, Coarse aggregate.

I. INTRODUCTION It hardens and attains strength from chemical reaction

with the water known as hydration. The grade 53

In order to make concrete industry sustainable, the use ordinary Portland cement is used for this research

of waste materials in place of natural resources is one work. B. Fine Aggregate

of the best approaches. In India, 0.7% of total urban

Normal dry river sand is used as a fine aggregate, the

waste enervated comprises of glass. UK produces

sand passing through IS 4.75mm sieve with fineness

over three million tons of waste glass annually. Waste

modulus of 3.36 and specific gravity of 2.67 is used

glass is crushed into specified sizes for use as

as a fine aggregate.

aggregate in various applications such as water

filtration, grit plastering, sand cover for sport turf and C. Coarse Aggregate

sand replacement inconcrete. Concrete is most widely Gravel of 20mm size is used as a coarse aggregate

used man made construction material and its demand which have impact value of 36.6% and crushing value

is increasing day by day. The use of river sand as fine of 33.5%. D. Waste Glass

aggregate leads to exploitation of natural resources, Glass is widely used in our lives through

lowering of water table, sinking of bridge piers and manufactured products such as soda lime glass,

erosion of river bed. If fine aggregate is replaced by bottles and glassware. Glass is an ideal material for

waste glass by specific percentage and in specific size recycling. The use of recycled glass helps in energy

range, it will decrease fine aggregate content and saving. The increasing awareness of glass recycling

thereby reducing the ill effects of river dredging and speeds up inspections on the use of waste glass with

thus making concrete manufacturing industry different forms in various fields.

sustainable.

Preparation of Glass Powder

Glass powder is prepared by crushing the waste

II. MATERIAL USED glasses using Los Angeles abrasion testing machine

which is similar to ball mill.

A. Cement

Cement is a binding material that sets and hardens

independently, and can bind other materials together.

116 All Rights Reserved © 2016

IJARBEST

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

Specific

International Journal of Advanced Research in Biology Engineering Sciencegravity 2.67

and Technology (IJARBEST) 2.65

Vol. 2,

Issue 3, March 2016 Fine modulus 3.36 3.65

C. Property of Coarse aggregate The property of

the coarse aggregate is tabulated below,

Table III - Properties of Coarse aggregate

Property Value

Specific gravity 2.78

Water absorption 1.5%

a) Crushing of waste glasses

Fineness modulus 4.39

IV. TEST ON FRESH CONCRETE

A. Slump cone test on fresh concrete Slump

cone test is conducted on the fresh concrete , the

workability of the different mixes having 0%, 10%,

20% & 30% of waste glass powder is observed and it

b) Glass Powder in Sieves is compared with the workability of the conventional

Fig.1-Waste Glass Powder concrete mix. The results are tabulated below,

Table IV – Slump Cone test on fresh concrete

III. MATERIAL PROPERTIES Waste Glass powder

A. Property of Cement Slump value in (mm)

in (%)

The property of the cement and GGBS is tabulated

below, 0% 65

Table I – Property of cement 10% 68

Property Value 20% 73

Initial setting time 30 minutes 30% 60

Final setting time 9 hours

B. Compaction factor test on fresh concrete

Specific gravity 3.11 Compaction factor test is conducted on the fresh

concrete, the workability of the different mixes

Consistency 30%

having 0%, 10%, 20% & 30% of waste glass powder

is observed and it is compared with the workability of

B. Property of Fine aggregate and waste glass the conventional concrete mix. The results are

powder tabulated below,

The property of the Fine aggregate and Waste glass

powder is tabulated below,

Table II - Properties of Fine Aggregate

Property River Waste glass

sand powder

117 All Rights Reserved © 2016

IJARBEST

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

International Journal of Advanced Research in Biology Engineering Science and Technology (IJARBEST) Vol. 2,

Issue 3, March 2016

in (%) 10% 3 3

Waste Glass powder Compaction factor 20%

30% 33 33

0% 0.83

A. Compressive Strength Test Determination of

10% 0.85 compressive strength of the concrete is an important

parameter. For each, set nine standard cubes were

20% 0.88 casted to determine 7th and 28th days compressive

strength after curing and also nine number of control

30% 0.82 cubes are casted to know the original strength of the

concrete. The cube size is 150X150X150mm as per

Table V- Compaction factor test on fresh concrete the IS 10262 –1982 the 7th and 28th days

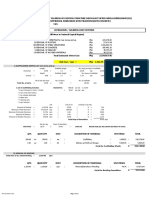

IV. MIX PROPORTION

compressive strength value are given the Table VII.

In the project work, the mix proportion for Strength

Table VII - 7th & 28th days Compressive Strength

of concrete of M20 grade are carried out according to

IS:10262-1982. The detailed mix design is presented Value

in the appendix. The mix proportion obtained and the Waste

quantity of materials required for one cubic meter of glass Cube Compressive strength

concrete is presented in Table V. powder in (N/mm2)

Table V- Mix Proportion of Waste Glass Powder (%)

7 days 28days

Quantity of 0% 14.66 30.33

Materials / m Mix

Materials 3 10% 15.87 31.33

of Proportion

Concrete 20% 15.32 31.00

Cement 383.2 Kg/m3 1 30% 14.3 29.66

Fine Aggregate

654 Kg/m3 1.71 B. Split Tensile Strength Test

(waste glass)

20 mm It is very difficult to directly measure the tensile

Coarse 1162 Kg/m3 3.1 strength of concrete; therefore the splitting tensile

aggregate test, an indirect method, was adopted. To determine

the split tensile strength the cylinders were cast. The

Water 191.6 Litres -

size of the cylinder is 150mm of diameter and 300mm

W/C Ratio 0.5 0.5 of length. The cylinder are cured properly and tested

on 7th and 28th day. Control concrete cylinder

specimen is also cured and tested as per IS

V. TESTING OF SPECIMENS specification. Combinations of test results are

Totally 24 cubes and 24 cylinders were prepared for compared with control concrete specimens.

the 7th & 28th day testing with 0%, 10%, 20%&30%

constant replacement of fine aggregate by Waste

glass powder

Table VI – Specimens where,

Waste glass No.of Cubes No.of

powder Cylinders P is the maximum load on the cylinder (N)

0% 3 3 L is the length of cylinder (mm)

118 All Rights Reserved © 2016

IJARBEST

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

International Journal of Advanced Research in Biology Engineering Science and Technology (IJARBEST) Vol. 2,

Issue 3, March 2016

D is the diameter of cylinder (mm)

Compresssive strength N/mm2)

35

30.33 31.33 31 29.66

th th 30

Table VIII - 7 & 28 days Split Tensile Strength

25

(

Value

20

Waste glass Tensile strength in (N/mm2) 14.66 15.87 15.32 14.3 7 days

powder in (%) 15

7 days 28 days 10 28 days

0% 1.85 2.30 5

0

10% 2.23 2.52 0% 10% 20% 30%

Waste glass in (%)

20% 2.54 3.21

Fig.2- Variation of Compressive Strength of cubes

30% 2.35 3.10

Fig.3 - Variation of Tensile Strength of Cylinders

VI. RESULTS AND DISCUSSIONS From the above findings, the following conclusions

The results and discussions about the various tests are may be made out of the study:

as follows, While using waste glass as fine aggregate

replacement, 7th days and 28th days

compressive strength is found to marginally

increase up to 10% replacement level.

While using waste glass as fine aggregate

replacement, 7th days and 28th days Tensile

strength is found to marginally increase up to

3.5 3.21 3.1 20% replacement level.

3

2.52 2.54 3.3% increment in the compressive strength

Tensile strength (N/mm2)

2.5 2.3 2.23 2.35 is found at 10% replacement of fine

2

1.85 7 days aggregate by Waste Glass at 28th days when

1.5

compared to normal concrete.

1

28 days 39.55% increment in the split tensile strength

is found at 20% replacement of fine

0.5

aggregate by Waste Glass at 28th days when

0

compared to normal concrete.

0% 10% 20% 30%

Waste glass in (%) Waste glass can effectively be used as fine

aggregate replacement.

The optimum percentage at which the waste

glass powder is replaced by the fine

aggregate is found to be 10%, beyond which

the strength decreases.

119 All Rights Reserved © 2016

IJARBEST

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

International Journal of Advanced Research in Biology Engineering Science and Technology (IJARBEST) Vol. 2,

Issue 3, March 2016

The optimum replacement level of waste l

glass as fine aggregate is 20% of Tensile

Strength. I

n

VII. REFERENCES v

1. B e

a s

j t

a i

d g

. a

M t

. i

N o

, n

s

C

. I

D n

.

M D

o e

d v

h e

e l

r o

a p

i

“ n

E g

x

p C

e o

r n

i c

m r

e e

n t

t e

a

,

Containing Waste Glass Powder As Pozzolana”

Volume 1, Issue 1, Page 32-37,Oct 10.

2. Khmiri.A, B.Samet &

M.Chaabouni

120 All Rights Reserved © 2016

IJARBEST

ISSN 2395-695X (Print)

ISSN 2395-695X (Online)

International Journal of Advanced Research in Biology Engineering Science and Technology (IJARBEST) Vol. 2,

Issue 3, March 2016

“Assessement Of The Waste Glass Powder

Pozzolanic Activity By Different Methods”,

(IJRRAS), Volume 10, Issue 2, pp: (322-328),

February 2012.

3. Modhera.C.D, M.N. Bajad, A.K. Desai “ A State

of Art Report on Benefits of Using Glass Powder

as a Partial Replacement in

Concrete”, International Journal of

Engineering studies, Vol 4, Issue 1, Pages: (41-

54), (2012).

4. Nithin.V, Mr. M.U.Kiran “Experimental

Investigation on Strength Parameters for

Composite Concrete by Using Waste Glass

Powder, Flyash Aggregate and M-Sand”,

International Journal of Civil and Structural

Engineering Research, Vol. 3, Issue 1, pp:

(407412), Month: April 2015 - September 2015.

5. Priscilla.M, Mr.Pushparaj A Naik “Strength and

Durability Study on Recycled

Aggregate

Concrete Using Glass Powder” , International

Journal of Engineering Trends and Technology

(IJETT) – Volume 11, Issue 5, pp:(259-264),

May 2014.

6. Shruthi.S, S.Chandrakala, G.Narayana “Partial

Replacement Of Cement In Concrete Using

Waste Glass Powder And M-Sand As Fine

Aggregate”, International Journal of Research in

Engineering and Technology, Volume 4, Issue 8,

pp:(133-138), August-2015.

7. Tiwari Darshita, Patel Anoop “Study of Strength

and Workability of Different Grades of Concrete

by Partial Replacement of Fine Aggregate by

Crushed Brick and Recycled Glass Powder”,

International Journal of Science and Research

(IJSR), Volume 3, Issue 6, page 141-145, June

2014.

8. Vanita Aggarwal “Utilisation of Waste Glass

Powder in Concrete”, International Journal of

Innovative Research in Science, Engineering and

Technology, Vol. 3, Issue 7, July 2014.

9. Specification for Coarse and Fine Aggregates

from Natural Sources for Concrete. IS: 3831970,

Bureau of Indian Standards, New Delhi.

121 All Rights Reserved © 2016

IJARBEST

You might also like

- JSWAS A2 - en PDFDocument88 pagesJSWAS A2 - en PDFSintflut75% (4)

- R2-MCGM SP Schedule of Rates 2018-R2Document28 pagesR2-MCGM SP Schedule of Rates 2018-R2Deepanshu GargNo ratings yet

- Experimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine AggregateDocument6 pagesExperimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine AggregateSruthi100% (1)

- Document 2 dAAb 10052016Document5 pagesDocument 2 dAAb 10052016SruthiNo ratings yet

- Study On Partial Replacement of Cement WDocument6 pagesStudy On Partial Replacement of Cement Wpastor.flores111No ratings yet

- Effect of Mineral Admixtures On The Properties of Sintered Fly Ash Aggregate ConcreteDocument6 pagesEffect of Mineral Admixtures On The Properties of Sintered Fly Ash Aggregate ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Glass Powder As Fine Aggregate in High Strength ConcreteDocument3 pagesGlass Powder As Fine Aggregate in High Strength ConcreteBhagwatNo ratings yet

- Improving The Performance of Bituminous Concrete Mix by Waste PlasticDocument6 pagesImproving The Performance of Bituminous Concrete Mix by Waste PlasticAfi KhanNo ratings yet

- Reuse of Ceramic Waste As Aggregate in Concrete PDFDocument5 pagesReuse of Ceramic Waste As Aggregate in Concrete PDFprotenelllyNo ratings yet

- Experimental Research On Strength Properties of Concrete (M60) Partially Fine Aggregate Replaced With Waste Crushed GlassDocument5 pagesExperimental Research On Strength Properties of Concrete (M60) Partially Fine Aggregate Replaced With Waste Crushed GlassZim DausNo ratings yet

- Flexural Behaviour of Recycled Waste Glass Fine Aggregate Concrete BeamsDocument7 pagesFlexural Behaviour of Recycled Waste Glass Fine Aggregate Concrete BeamsSocheata channNo ratings yet

- Document 2 QLMJ 13032016Document4 pagesDocument 2 QLMJ 13032016koppolusrinivasuluNo ratings yet

- Stabilization of Concrete Using Rubber Tyre Waste: January 2018Document8 pagesStabilization of Concrete Using Rubber Tyre Waste: January 2018Suno AliNo ratings yet

- Partial Replacement of Aggregates by Burnt Brick Bats and Lateritic Fines in Concrete - An Experimental InvestigationDocument10 pagesPartial Replacement of Aggregates by Burnt Brick Bats and Lateritic Fines in Concrete - An Experimental InvestigationIRJMETS JOURNALNo ratings yet

- Ground Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteDocument8 pagesGround Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteIJRASETPublicationsNo ratings yet

- An Experimental Investigation On Concrete Paver Block by Using PVC Plastic MaterialDocument6 pagesAn Experimental Investigation On Concrete Paver Block by Using PVC Plastic MaterialGUGANATHAN ANo ratings yet

- Study On M-Sand As A Partial Replacement of Fine Aggregate in ConcreteDocument4 pagesStudy On M-Sand As A Partial Replacement of Fine Aggregate in ConcretehgbhNo ratings yet

- Analysis of Mix Design of Concrete Using Ceramic WasteDocument6 pagesAnalysis of Mix Design of Concrete Using Ceramic WasteEditor IJAERDNo ratings yet

- Partial Replacement of Sand With Sawdust in ConcreteDocument4 pagesPartial Replacement of Sand With Sawdust in Concrete18TPCV008 DONA RENJITHNo ratings yet

- Zaouai IRECEDocument5 pagesZaouai IRECEismail douidiNo ratings yet

- Study of Partial Replacement of Fine Aggregate by Using Quarry DustDocument8 pagesStudy of Partial Replacement of Fine Aggregate by Using Quarry DustramakrishnaNo ratings yet

- Durability Study of Concrete Using Foundry Waste SandDocument4 pagesDurability Study of Concrete Using Foundry Waste SandEditor IJTSRDNo ratings yet

- Effects of Using Rice Straw and Cotton Stalk Ashes On The Properties of Lightweight Self-Compacting ConcreteDocument12 pagesEffects of Using Rice Straw and Cotton Stalk Ashes On The Properties of Lightweight Self-Compacting Concreteprincessxena.sta.rosaNo ratings yet

- Mechanical Properties of Concrete Incorporating Wfs and WCTDocument7 pagesMechanical Properties of Concrete Incorporating Wfs and WCTShobiHassanNo ratings yet

- Experimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Document11 pagesExperimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Shilpa ShiNo ratings yet

- Study On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementDocument6 pagesStudy On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementIJRASETPublicationsNo ratings yet

- Effect of Use of Silica Sand As Fine Material in Concrete: Related PapersDocument7 pagesEffect of Use of Silica Sand As Fine Material in Concrete: Related Papersshivanand hippargaNo ratings yet

- Effect of Use of Silica Sand As Fine Material in Concrete: Related PapersDocument7 pagesEffect of Use of Silica Sand As Fine Material in Concrete: Related Papersshivanand hippargaNo ratings yet

- IJETR033435Document6 pagesIJETR033435erpublicationNo ratings yet

- Comparative Analysis of River SandDocument5 pagesComparative Analysis of River SandMatt T100% (1)

- Glassfiber PDFDocument8 pagesGlassfiber PDFsuresh nenavathNo ratings yet

- M0509083087 PDFDocument5 pagesM0509083087 PDFMr PolashNo ratings yet

- Comparative Analysis of River & Crushed Sand in Concrete: I J I R S E TDocument5 pagesComparative Analysis of River & Crushed Sand in Concrete: I J I R S E TBasit PatelNo ratings yet

- Review On Use of Waste Marble Powder As Partial Replacement in Concrete MixDocument4 pagesReview On Use of Waste Marble Powder As Partial Replacement in Concrete MixYu Paing HanNo ratings yet

- Sanju SeminorDocument13 pagesSanju SeminorRashmi RuchikaNo ratings yet

- Effect of Fly Ash As A Partial Substitute For Cement On The Splitting Tensile Strength of Concrete Using Recycled Fine AggregateDocument5 pagesEffect of Fly Ash As A Partial Substitute For Cement On The Splitting Tensile Strength of Concrete Using Recycled Fine AggregateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Glass Powder PropertiesDocument7 pagesGlass Powder PropertiesMR. ESHAN GHARPURENo ratings yet

- Effect of Fly Ash As A Partial Substitute For Cementon The Splitting Tensile Strength of Concrete Using Recycled Fine AggregateDocument5 pagesEffect of Fly Ash As A Partial Substitute For Cementon The Splitting Tensile Strength of Concrete Using Recycled Fine AggregateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Prediction of Strength Parameters For Cellular Light Weight Concrete by Using Fly Ash As Partial Replacement of CementDocument5 pagesPrediction of Strength Parameters For Cellular Light Weight Concrete by Using Fly Ash As Partial Replacement of CementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Reuse of Plastic Waste in Paver BlocksDocument3 pagesReuse of Plastic Waste in Paver BlocksMehran Amin BattNo ratings yet

- Experimental Study On Partial Replacement of Cement by Red Mud IJERTCONV3IS04064Document4 pagesExperimental Study On Partial Replacement of Cement by Red Mud IJERTCONV3IS04064Taimoor NasserNo ratings yet

- Experimental Study of Bituminous Concrete Containg Plastic Waste MaterialDocument9 pagesExperimental Study of Bituminous Concrete Containg Plastic Waste MaterialCivil StructureNo ratings yet

- GLASSDocument6 pagesGLASSMR. ESHAN GHARPURENo ratings yet

- Applications of Green Materials For The Preparation of Ecofriendly Bricks and PaversDocument5 pagesApplications of Green Materials For The Preparation of Ecofriendly Bricks and PaversMauricio David Ruiz OdarNo ratings yet

- The International Journal of Science & TechnoledgeDocument7 pagesThe International Journal of Science & TechnoledgescegtsNo ratings yet

- Irjet V6i6166Document6 pagesIrjet V6i6166shivanand hippargaNo ratings yet

- Strength Aspects of Concrete by Partially Replacing Cement by GGBS and Coarse Aggregate by Waste Ceramic Tiles PDFDocument5 pagesStrength Aspects of Concrete by Partially Replacing Cement by GGBS and Coarse Aggregate by Waste Ceramic Tiles PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialsDocument5 pagesBitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialsIJAERS JOURNALNo ratings yet

- An Experimental Investigation On Steel Fiber Reinforced Concrete With Partial Replacement of Natural Sand by M-SandDocument7 pagesAn Experimental Investigation On Steel Fiber Reinforced Concrete With Partial Replacement of Natural Sand by M-SandAnonymous kw8Yrp0R5rNo ratings yet

- Research PaperDocument3 pagesResearch Paperpablo narag0% (1)

- Experimental Studies On Concrete For The Partial Replacement of Cement by Egg Shell Powder and GGBSDocument7 pagesExperimental Studies On Concrete For The Partial Replacement of Cement by Egg Shell Powder and GGBSAnonymous kw8Yrp0R5rNo ratings yet

- V5i4 Ijertv5is040932Document3 pagesV5i4 Ijertv5is040932qwerty qwertyNo ratings yet

- Partial Replacement of Fine Aggregates in Concrete by Ceramic Powder and Ggbs PowderDocument4 pagesPartial Replacement of Fine Aggregates in Concrete by Ceramic Powder and Ggbs PowderRaphael VarelaNo ratings yet

- Experimental Investigation of Silica Fume Based Concrete of M25 GradeDocument7 pagesExperimental Investigation of Silica Fume Based Concrete of M25 GradeIJRASETPublicationsNo ratings yet

- Comparative Study On The Effects of Steel Slag Aggregate Over Blended Cement ConcreteDocument12 pagesComparative Study On The Effects of Steel Slag Aggregate Over Blended Cement ConcreteIJRASETPublicationsNo ratings yet

- Experimental Study On Concrete by Replacement of Fine Aggregate With Copper Slag, GGBS and M - SandDocument4 pagesExperimental Study On Concrete by Replacement of Fine Aggregate With Copper Slag, GGBS and M - SandInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Use of Glass Wastes As Fine Aggregate in Concrete: January 2012Document4 pagesUse of Glass Wastes As Fine Aggregate in Concrete: January 2012Yuri ValenciaNo ratings yet

- Irjet V6i421Document4 pagesIrjet V6i421Merk GetNo ratings yet

- Studies On Strength and Durability of Concrete Made With Manufactured SandDocument5 pagesStudies On Strength and Durability of Concrete Made With Manufactured SandEditor IJTSRDNo ratings yet

- Irjet V3i720Document6 pagesIrjet V3i720SHARAN PATILNo ratings yet

- Eco-Efficient Concretes Use of Ceramic Powder As A Partial Replacement of CementDocument4 pagesEco-Efficient Concretes Use of Ceramic Powder As A Partial Replacement of CementDipali DewanganNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Report LitratureDocument1 pageReport LitratureSruthiNo ratings yet

- S.N O TitleDocument1 pageS.N O TitleSruthiNo ratings yet

- Manual ConcreteTechDocument72 pagesManual ConcreteTechDharmaraaj RajalinggamNo ratings yet

- TransportationEngineeringLabmanual PDFDocument68 pagesTransportationEngineeringLabmanual PDFkumar animireddiNo ratings yet

- Manual ConcreteTechDocument72 pagesManual ConcreteTechDharmaraaj RajalinggamNo ratings yet

- Incorporation of Waste Glass As A Partial Replacement of Fine Aggregate in ConcreteDocument11 pagesIncorporation of Waste Glass As A Partial Replacement of Fine Aggregate in ConcreteSruthiNo ratings yet

- A Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteDocument5 pagesA Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteSruthiNo ratings yet

- Incorporation of Waste Glass Powder As Partial Replacement of Fine Aggregate in Cement ConcreteDocument8 pagesIncorporation of Waste Glass Powder As Partial Replacement of Fine Aggregate in Cement ConcreteSruthiNo ratings yet

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 pagesPartial Replacement of Fine Aggregates by Using Waste GlassSruthiNo ratings yet

- Irjet V3i3105Document4 pagesIrjet V3i3105SruthiNo ratings yet

- A Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteDocument5 pagesA Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteSruthiNo ratings yet

- Irjet V3i3105Document4 pagesIrjet V3i3105SruthiNo ratings yet

- Manual ConcreteTechDocument72 pagesManual ConcreteTechDharmaraaj RajalinggamNo ratings yet

- ThesisDocument5 pagesThesisJenny ValderramaNo ratings yet

- For RESEARCH 1 PDFDocument7 pagesFor RESEARCH 1 PDFronnie oraleNo ratings yet

- Recycled Glass As A Partial Replacement For Fine Aggregate in Structural Concrete - Effects On Compressive StrengthDocument7 pagesRecycled Glass As A Partial Replacement For Fine Aggregate in Structural Concrete - Effects On Compressive StrengthSruthiNo ratings yet

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 pagesPartial Replacement of Fine Aggregates by Using Waste GlassSruthiNo ratings yet

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 pagesPartial Replacement of Fine Aggregates by Using Waste GlassSruthiNo ratings yet

- For RESEARCH 1 PDFDocument7 pagesFor RESEARCH 1 PDFronnie oraleNo ratings yet

- Recycled Glass As A Partial Replacement For Fine Aggregate in Structural Concrete - Effects On Compressive StrengthDocument7 pagesRecycled Glass As A Partial Replacement For Fine Aggregate in Structural Concrete - Effects On Compressive StrengthSruthiNo ratings yet

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 pagesPartial Replacement of Fine Aggregates by Using Waste GlassSruthiNo ratings yet

- Partial Replacement of Fine Aggregates by Using Waste GlassDocument6 pagesPartial Replacement of Fine Aggregates by Using Waste GlassSruthiNo ratings yet

- Kleemann DesignsDocument78 pagesKleemann DesignsptmetromediaNo ratings yet

- ch38Document6 pagesch38Zouhair BoukriNo ratings yet

- Architecture Vernacular Terms 4Document2 pagesArchitecture Vernacular Terms 4Christian James TuazonNo ratings yet

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- PRESENTATION - Belzona Cold BondingDocument37 pagesPRESENTATION - Belzona Cold BondingNathachai LeewathanakijNo ratings yet

- Ethylene Vinyl Acetate WikipediaDocument4 pagesEthylene Vinyl Acetate WikipediaxiaoboshiNo ratings yet

- Hexply 8552: Mid-Toughened, High Strength, Damage-Resistant, Structural Epoxy MatrixDocument6 pagesHexply 8552: Mid-Toughened, High Strength, Damage-Resistant, Structural Epoxy MatrixshaxahNo ratings yet

- Perbandingan Harga Pipa Dan SRDocument6 pagesPerbandingan Harga Pipa Dan SRRahma FauziahNo ratings yet

- Abe Construction Chemicals Diy Epidermix 396Document2 pagesAbe Construction Chemicals Diy Epidermix 396abstickleNo ratings yet

- 2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Document17 pages2014 - 68 - EU Pressure Equipment - Summary List of Harmonised Standards - Generated On 10.02.2021Bilel MahjoubNo ratings yet

- Sheet Metal DesignDocument13 pagesSheet Metal Designsivakumar subramanianNo ratings yet

- List of Accredited BP (2015)Document9 pagesList of Accredited BP (2015)Jayson MalaaNo ratings yet

- 02 205 FWHS Foam Water Hydrant Station R1Document2 pages02 205 FWHS Foam Water Hydrant Station R1jajakaNo ratings yet

- Analysis of Tapping Process in Three Types of Cast Iron PDFDocument8 pagesAnalysis of Tapping Process in Three Types of Cast Iron PDFFlorin MilasNo ratings yet

- Defects On & in SlabsDocument26 pagesDefects On & in Slabsfoush bashaNo ratings yet

- Sheet Metal Tools PDFDocument13 pagesSheet Metal Tools PDFANDERSON LIMA DA SILVANo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Duplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojDocument7 pagesDuplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojAyyappanSubramanianNo ratings yet

- NDP-80 Data SheetDocument9 pagesNDP-80 Data SheetSarah PerezNo ratings yet

- Subject Lecturer: Ban Ahmed Khaleel: Experiment No. (1) : "Determination of Slump of Fresh Concrete"Document4 pagesSubject Lecturer: Ban Ahmed Khaleel: Experiment No. (1) : "Determination of Slump of Fresh Concrete"AL SniperNo ratings yet

- Welding TechnologyDocument218 pagesWelding Technologywbl_200789% (9)

- Two Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransDocument21 pagesTwo Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransJohn Michael TalanNo ratings yet

- Properties of Crumb Rubber Concrete Paving Blocks With SBR LatexDocument7 pagesProperties of Crumb Rubber Concrete Paving Blocks With SBR LatexTung-Chai LingNo ratings yet

- API 5l Practice Questions Doc r2Document4 pagesAPI 5l Practice Questions Doc r2Anonymous SLI4aGNo ratings yet

- Sikafloor 21 Purcem LP - Pds enDocument6 pagesSikafloor 21 Purcem LP - Pds enWahidCesarRNo ratings yet

- Case Studies Catalogue: Lik HungDocument22 pagesCase Studies Catalogue: Lik HungE DaeNo ratings yet

- Pipe Inspection, Testing & MarkingDocument12 pagesPipe Inspection, Testing & MarkingRamalingam PrabhakaranNo ratings yet

- CatalogoDocument7 pagesCatalogoHECTOR IGNACIO HIDALGO MARAMBIONo ratings yet