Professional Documents

Culture Documents

Service Schedules: Routine Maintenance

Uploaded by

Daniel AguirreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Schedules: Routine Maintenance

Uploaded by

Daniel AguirreCopyright:

Available Formats

Routine Maintenance

Service Schedules

Service Schedules

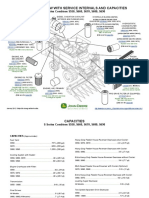

Introduction How to Use the Service Schedules

T3-036_3 T3-012_4

!MWARNING In the example shown, A shows all service requirements to

be carried out every 10 hours and B shows the

Maintenance must be done only by suitably qualified requirements to be carried out every 500 hours.

and competent persons.

Important: Services should be carried out at either the

Before doing any maintenance make sure the machine hourly interval or calendar interval, whichever occurs first.

is safe, it should be correctly parked on level ground. Refer to Calendar Equivalents.

To prevent anyone starting the engine, remove the Important: The intervals given in the schedules must not

starter key. Disconnect the battery when you are not be exceeded. If the machine is operated under severe

using electrical power. If you do not take these conditions (high temperature, dust, water, etc.), shorten

precautions you could be killed or injured. the intervals.

8-3-1-1

A badly maintained machine is a danger to the operator

and the people working around him. Make sure that the

regular maintenance and lubrication jobs listed in the

service schedules are done to keep the machine in a safe

and efficient working condition.

Apart from the daily jobs, the schedules are based on

machine running hours. Keep a regular check on the

hourmeter readings to correctly gauge service intervals.

When there is no hourmeter fitted, use the calendar

equivalents to determine the service intervals. Refer to

Calendar Equivalents. Do not use a machine which is

due for a service. Make sure any defects found during the

regular maintenance checks are rectified immediately.

795390-1

Calendar Equivalents

T3-037

Every 10 Hours = Daily

Every 50 Hours = Weekly

Every 500 Hours = Six Months

Every 1000 Hours = Yearly

Every 2000 Hours = 2 Years

Every 8000 Hours = 8 Years

111 9831-0150-2 111

Routine Maintenance

Service Schedules

Pre-start Cold Checks, Service Points

and Fluid Levels

Note: More frequent checks of engine components than

the engine manufacturer recommends do not invalidate

emissions warranty.

Table 10. Engine

Operation 10 50 100(1) 500 1000 2000

Oil - Level and condition Check

Coolant - Level Check

Air intake piping(2) Check

Cooling fan(2) Check

Crankcase breather tubes Check

Drive belts(2) Check

Fuel sedimenter/Water seperator Drain

Charge air cooler and piping(3) Clean/Check

Air cleaned restriction meter Check

Air cleaner primary/outer element(4) Change

Air cleaner secondary/inner element(10) Change

Fuel system for leaks and contamination Check

Fuel sedimenters/water separators Drain

Fuel filter cum water separator (10 micron) Change

Fuel filter element (2 micron) Change

Fuel filter three layer element (2 micron) Change

Radiator and hoses(2)(5) Clean/Check

Radiator pressure cap (6) Check

Oil and filter(7) Change

Coolant - Strength and condition Check

Drive belt - Condition(2) Check

Drive belts Replace

Automatic belt tensioner Check

Compressor discharge lines (8) Clean

Coolant Change

Crankcase breather element(8) Change

Vibration damper Check

Engine - Steam clean Clean

Air filter elements(9) Change

Overhead-set (10) Check/Adjust

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

(2) Check for wear, damage and security, replace if necessary.

112 9831-0150-2 112

Routine Maintenance

Service Schedules

(3) Check for cracks, holes and other damage.

(4) Change the outer element more frequently in dusty operating environments.

(5) Check every 250 hours.

(6) Make sure the cap is the correct type, either normal duty (15 psi) or light duty (7 psi).

(7) In arduous conditions change the oil and filter after every 250 hours or three months (whichever comes first).

(8) To be done by your local JCB Dealer.

(9) A change is dependant on the Air Cleaner Restrictor. Change the secondary element every other time the primary

element is changed.

(10) Every 5000 hour or four years.

113 9831-0150-2 113

Routine Maintenance

Service Schedules

Table 11. Transmission and Axles

Operation 10 50 100(1) 500 1000 2000

Transmission oil - level Check

Tyres - pressures and condition Check

Wheel nut - security Check

Driveshaft, universal joints and rear axle pivot Grease(2)

Transmission mounts security Check

Axle breathers(3) Clean/Check

Axle mount and driveshaft - security Check

Bevel ring gear - deflection plunger Check

Transmission oil (4) Change

Transmission filter (5) Change

Axle and hub oil Check

Axle and hub oil Change

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

(2) Grease more frequently when the machine is operated in arduous conditions.

(3) Replace if necessary

(4) At every oil change, it is recommended to carry out AEB calibration i.e. automatic filling procedure for clutch using

AEB Calibration tool.

(5) At every oil change, transmission filter must be changed.

Table 12. Hydraulics

Operation 10 50 100(1) 500 1000 2000

Oil level Check

Hydraulic tank breather Check

Oil Sample

Oil filter Change

Hoses, rams and pipe-work - Damage Check

Oil and hydraulic tank breather Change

Suction strainers (x2) Clean

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 13. Brakes

Operation 10 50 100(1) 500 1000 2000

Park brake - Operation Check

Foot brake - Operation Check

114 9831-0150-2 114

Routine Maintenance

Service Schedules

Operation 10 50 100(1) 500 1000 2000

Brake wear (2) Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

(2) Check every 1500 hours.

Table 14. Electrics

Operation 10 50 100(1) 500 1000 2000

Instrument panel - Operation Check

Battery - Electrolyte level (If applicable) Check

Battery terminals - Condition and tightness Check

Battery - Charge and condition Check

Wiring - Chaffing and routing Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 15. Bodywork and Cab

Operation 10 50 100(1) 500 1000 2000

Machine Condition - General Check

Autolube reservoir level (Option) (2) Check

Window washer fluid - Level Check

Seat/Seat belt - Condition and security Check

Check the machine for leaks (For example engine oil and Check

hydraulic fluid)

All pivot-pins, loader arms, centre pivot, rear axle pivots, Grease(3)

steer rams and the Quickhitch locking-pins (Option)

Autolube reservoir filler filter (Option) Change

Hinges Lubricate

Cab heater intake filter(s) Clean(4)

ROPS/FOPS Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

(2) Top-up as necessary.

(3) Grease more frequently when operating in arduous conditions.

(4) Clean more frequently when the machine is operated in a dusty operating environment.

Table 16. Lifting Equipment

Operation 10 50 100(1) 500 1000 2000

Fit for purpose test(2) Complete

115 9831-0150-2 115

Routine Maintenance

Service Schedules

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

(2) This may be required every six months or at least annually in some countries to meet and comply with legislation

and for insurance purposes.

116 9831-0150-2 116

Routine Maintenance

Service Schedules

Functional Test and Final Inspection

Table 17. Engine

Operation 10 50 100(1) 500 1000 2000

Exhaust system - Security Check

Air inlet system - Security Check

Idle speed Check

Torque converter - Stall speed Check

Maximum no load speed Check

Throttle system Check

Exhaust smoke Check

Combined stall speed Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 18. Transmission, Axles and Steering

Operation 10 50 100(1) 500 1000 2000

Transmission - Operation Check

Forward/reverse/speed range - Operation Check

Neutral start - Operation Check

Steering - Operation Check

Oil cooler and pipe-work Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 19. Hydraulics

Operation 10 50 100(1) 500 1000 2000

Piston rods and gland seals Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

117 9831-0150-2 117

Routine Maintenance

Service Schedules

Table 20. Electrics

Operation 10 50 100(1) 500 1000 2000

Gauges and warning lights Check

Wiper motors Check

Cab switches - Operation Check

Horn Check

Heater (Option) Check

Reverse alarm (Option) Check

Lights and indicators (Option) Check

Proximity sensor - Operation Check

Starter motor and alternator - Connections Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 21. Bodywork and Cab

Operation 10 50 100(1) 500 1000 2000

Air conditioning (Option) Check

Tool kit and operator manual Check

Paintwork - Condition Check

Doors and hinges Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

Table 22. Attachments

Operation 10 50 100(1) 500 1000 2000

Attachment - Condition and operation Check

(1) First 100 Hours Service only, to be completed by your JCB Dealer.

118 9831-0150-2 118

Routine Maintenance

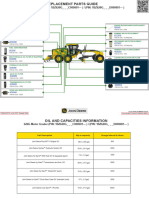

Fluids, Lubricants and Capacities

Fluids, Lubricants and Capacities

Specifications

JCB recommend that you use the JCB lubricants shown as they have been verified by JCB for use on JCB machines.

However, you could use other lubricants that are equivalent to the JCB standards and quality or offer the same machine

component protection.

Table 23.

Item Capacity Fluid/Lubricant JCB Part

(Litres) Number

Fuel System 310 Diesel, Refer to K Fuels ( T 120)

Fuel Additive (1) 90ml per 80 FAST Exocet X01236D 4005/0801

litres of fuel

Engine - Oil 28 Engine Oil CI 4+ (-10 to 50ºC) 4001/3200

Cold Climate (-20ºC+) 10W40 4001/2000

Engine - Coolant 37 JCB Antifreeze HP Coolant 229/01233

JIS K2234 class II (Non Aminic) 4006/1115

4006/1110

Transmission(2) 38 UTTO oil (JCB gear oil HP Plus) 4000/2200

JCB rear axle oil 4000/4600

JCB HP Universal ATF 4000/2300

ZF TE-MIL 06, 11, 12, 14

API-GL-3 SAE 10W30

Cold Climate (JCB EP gear oil plus) 4000/4200

API-GL-4 SAE 10W30

Axles 70 UTTO oil (JCB gear oil HP Plus) 4000/2200

JCB rear axle oil

JCB HP Universal ATF

ZF TE-MIL 06, 11, 12, 14

API-GL-3 SAE 10W30

Hydraulic System(3) 180 HVI Hydraulic Oil 229/00024

Cold climate grade 32 4002/1000

Grease Points JCB Special HP Grease(4) 4003/2000

Lithium complex NLGI 2 4003/2017

Auto Greasing System (Option) JCB special HP Grease 4003/2000

(1) Fuel additive must be added in fuel for cold climate region machines (below -20ºC)

(2) The figure shown is the total capacity of the system. Use the maximum and the minimum marks on the dipstick when

you fill the system.

(3) The total capacity of the hydraulic system depends on the equipment being used. Fill the system with all of the rams

closed and monitor the level in the sight gauge.

(4) If JCB Special MPL Grease is used for normal greasing, all of the 100 hour greasing operations must be done at ten

(10) hour intervals.

Note: No warranty liability will be accepted for engine equivalent) have been used at any stage.

failures where unacceptable fuel grades (or their

119 9831-0150-2 119

Routine Maintenance

Fluids, Lubricants and Capacities

Anti-Corrosion Additives If you use any other brand of antifreeze:

!MWARNING – Ensure that the antifreeze complies with International

Specification ASTM D6210.

Antifreeze can be harmful. Obey the manufacturer's – Always read and understand the manufacturer's

instructions when handling full strength or diluted instructions.

antifreeze. – Ensure that a corrosion inhibitor is included. Serious

7-3-4-4_1 damage to the cooling system can occur if corrosion

inhibitors are not used.

To provide sufficient corrosion protection, Supplemental

– Ensure that the antifreeze is ethylene glycol based

Coolant Additive (SCA) must be added to the coolant

and does not use Organic Acid Technology (OAT).

mixture. The coolant filter provides the required amount of

SCA, provided the filter is replaced at regular intervals.

Fuels

Coolant Mixtures

Acceptable and Unacceptable Fuels

T3-009_4

Check the strength of the coolant mixture at least once a

Important: No warranty liability will be accepted for engine

year, preferably at the start of the cold period.

failures where unacceptable fuel grades (or their

equivalent) have been used at any stage.

Replace the coolant mixture according to the intervals

shown in the machine's Service Schedule.

Fuel Groups

!MWARNING The major world fuels standards are divided into four

categories. Those that are fully accepted as suitable fuels,

Antifreeze can be harmful. Obey the manufacturer's

those that are acceptable from a "warranty" point of view,

instructions when handling full strength or diluted

but may have undesirable affects on the expected life of

antifreeze.

the engine performance changes from original

7-3-4-4_1

specification, those that will lead to reduce the expected

life, and lastly those that are viewed as unacceptable for

You must dilute full strength antifreeze with clean water

use. (Note: fuels shown on the same line as each other are

before use. Use clean water of no more than a moderate

considered equivalents).

hardness (pH value 8.5). If this cannot be obtained, use

de-ionized water. For further information advice on water

The lists below are not exhaustive of all diesel fuel

hardness, contact your local water authority.

standards encountered in the marketplace. If comment is

required on the suitability of fuel standards not on the list,

The correct concentration of antifreeze protects the engine

requests with, if possible, specification details showing at

against frost damage in winter and provides year round

least the key characteristics described above should be

protection against corrosion.

forwarded to JCB Service for assessment and comment.

As an example, the protection provided by JCB High

Performance Antifreeze and Inhibitor is given below.

50% Concentration (Standard)

Protects against damage down to -40 °C (-39 °F)

60% Concentration (Extreme Conditions Only)

Protects against damage down to -56 °C (-68 °F)

Important: Do not exceed a 60% concentration, as the

freezing protection provided reduces beyond this point.

120 9831-0150-2 120

You might also like

- MarathonWuling Service ManualDocument255 pagesMarathonWuling Service Manualcarlosnochi40% (5)

- Champion 720A With 9150 TransmissionDocument25 pagesChampion 720A With 9150 TransmissionDaniel Aguirre100% (2)

- Case AFX-8010 Service Manual PDFDocument2,688 pagesCase AFX-8010 Service Manual PDFSerhii100% (8)

- Ec PDFDocument2,751 pagesEc PDFDaniel Aguirre100% (1)

- Ec PDFDocument2,751 pagesEc PDFDaniel Aguirre100% (1)

- Ec PDFDocument2,751 pagesEc PDFDaniel Aguirre100% (1)

- Ec PDFDocument2,751 pagesEc PDFDaniel Aguirre100% (1)

- Service Training Manual Transmisión ML260 For JCBDocument84 pagesService Training Manual Transmisión ML260 For JCBDaniel Aguirre100% (1)

- Rt540e-4 Parts Catalog 233136Document559 pagesRt540e-4 Parts Catalog 233136Daniel Aguirre100% (10)

- Nissan Titan Transaxel and TransmissionDocument596 pagesNissan Titan Transaxel and TransmissionDaniel Aguirre100% (3)

- Nissan Titan Transaxel and TransmissionDocument596 pagesNissan Titan Transaxel and TransmissionDaniel Aguirre100% (3)

- Manual de Partes Ç 890.2Document523 pagesManual de Partes Ç 890.2luis melloNo ratings yet

- Filtros Das s550 s660 s670 s680 e s690 John DeereDocument3 pagesFiltros Das s550 s660 s670 s680 e s690 John DeereElthonNo ratings yet

- 345FR ExplodidaDocument51 pages345FR ExplodidaEliomar Maria RibeiroNo ratings yet

- Wgsjt7 Container/Pallet Loader Illustrated Parts List: Weihai Guangtai Airport Equipment Co., LTDDocument294 pagesWgsjt7 Container/Pallet Loader Illustrated Parts List: Weihai Guangtai Airport Equipment Co., LTDHelder CarvalhoNo ratings yet

- CAT Cross ReferenceDocument350 pagesCAT Cross ReferenceOzenildo Ferreira PondeNo ratings yet

- AIB XRHS 836 CD ENDocument27 pagesAIB XRHS 836 CD ENcristianrblr100% (1)

- EMS Vansco - Service Manual SpecificationDocument85 pagesEMS Vansco - Service Manual SpecificationDaniel Aguirre100% (1)

- Reparacion Bujes de Balde YB 1Document4 pagesReparacion Bujes de Balde YB 1Abel Palma AguayoNo ratings yet

- Catalogo Disco Freio e TransmissãoDocument66 pagesCatalogo Disco Freio e Transmissãoandré GuilhermeNo ratings yet

- Bombas TurollaDocument4 pagesBombas TurollaHidroil Neuquen SrlNo ratings yet

- Pá Carregadeira John Deere 444gDocument4 pagesPá Carregadeira John Deere 444gislanmateusfrNo ratings yet

- John Deere 5600 and 5700 Tractors Parts CatalogDocument333 pagesJohn Deere 5600 and 5700 Tractors Parts CatalogDiogoNo ratings yet

- SY35U PART FILTER PERIODICAL SERVICEDocument2 pagesSY35U PART FILTER PERIODICAL SERVICEIman SantosaNo ratings yet

- CE ENG HL630L, 635L AUG2018 Rev.0 WebDocument4 pagesCE ENG HL630L, 635L AUG2018 Rev.0 WebLhsan RajawiNo ratings yet

- LR Lewmar Catalogue 2018 PDFDocument412 pagesLR Lewmar Catalogue 2018 PDFareleemeanNo ratings yet

- Desarmado y Armado Bomba 312cDocument22 pagesDesarmado y Armado Bomba 312cJhon VillamizarNo ratings yet

- 215 Teeth CaterpillarDocument4 pages215 Teeth Caterpillargustavo aliagaNo ratings yet

- Wheel Loader: YT4A2 - 24 KW (48.4 HP) at 2,400 RPM 47 KW (63 HP) at 2,400 RPMDocument2 pagesWheel Loader: YT4A2 - 24 KW (48.4 HP) at 2,400 RPM 47 KW (63 HP) at 2,400 RPMJoao CostaNo ratings yet

- Brosur Sany SY75CDocument2 pagesBrosur Sany SY75Cmbah petruk100% (1)

- Operation and Maintenance Manual: 120M and 12M Motor GradersDocument192 pagesOperation and Maintenance Manual: 120M and 12M Motor GradersAhmed AhmedNo ratings yet

- Massey Ferguson 6245 TRACTORS Service Parts Catalogue Manual (Part Number 1637361)Document16 pagesMassey Ferguson 6245 TRACTORS Service Parts Catalogue Manual (Part Number 1637361)bvk2980022No ratings yet

- Sell heavy equipment specificationsDocument2 pagesSell heavy equipment specificationsMichael BochoridisNo ratings yet

- 4TNV98parts ManualDocument28 pages4TNV98parts ManualsatheeshNo ratings yet

- S6OA00801ZE03 - A3 SizeDocument46 pagesS6OA00801ZE03 - A3 SizesuwardjoNo ratings yet

- 4 WG 160Document21 pages4 WG 160Joao Leno Rodrigues Santos100% (1)

- Parts Catalog for Soil Compactor EngineDocument134 pagesParts Catalog for Soil Compactor EngineIrul Umam100% (1)

- 620G Motor Grader (PIN - 1BZ620G - C000001-) (PIN - 1BZ620G - D000001-) Replacement Parts GuideDocument5 pages620G Motor Grader (PIN - 1BZ620G - C000001-) (PIN - 1BZ620G - D000001-) Replacement Parts GuideFagner Pires de SáNo ratings yet

- Manual Peças D50Document382 pagesManual Peças D50weslleyNo ratings yet

- Axle Partsbook enDocument36 pagesAxle Partsbook enALPEL ALBISNo ratings yet

- Parts Manual CA150DDocument253 pagesParts Manual CA150DJosé JuárezNo ratings yet

- 8345R 8370R 8400R Replacement Parts GuideDocument3 pages8345R 8370R 8400R Replacement Parts GuideOleksandr YermolenkoNo ratings yet

- لباداتDocument2 pagesلباداتم. عثمان التميمي100% (1)

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBADocument3 pages216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBAubaldo caraballoNo ratings yet

- Parts CatalogDocument318 pagesParts Cataloggabriel santos100% (1)

- AFA Electronic Parts Catalog PDFDocument90 pagesAFA Electronic Parts Catalog PDFYew Lim100% (1)

- Torque Converter and Transmission Parts ListDocument58 pagesTorque Converter and Transmission Parts ListJose De Moura CamaraNo ratings yet

- Swing Machines: 2154D 2454D 2954D 3754DDocument44 pagesSwing Machines: 2154D 2454D 2954D 3754DDenis BarbozaNo ratings yet

- CTP Engine BearingsDocument4 pagesCTP Engine BearingsmkNo ratings yet

- Adubadeira Massey Fergunson MF 2013Document48 pagesAdubadeira Massey Fergunson MF 2013Fazendas VilelaNo ratings yet

- RAMMER - Tools BrochureDocument10 pagesRAMMER - Tools BrochurefernandoalvesvnbNo ratings yet

- A Great Business Decision: Hydraulic Excavator Wheeled Loading ShovelDocument5 pagesA Great Business Decision: Hydraulic Excavator Wheeled Loading ShovelandrewgeorgecherianNo ratings yet

- Filtros MaquinasDocument34 pagesFiltros MaquinasAndres AlfonzoNo ratings yet

- PM-102 CalibrationsDocument44 pagesPM-102 CalibrationsДмитрий100% (1)

- Capacidades 312 PDFDocument2 pagesCapacidades 312 PDFFelipe MancillaNo ratings yet

- JOST Hubodometer PDFDocument1 pageJOST Hubodometer PDFfdpc1987No ratings yet

- Caterpillar Cat 216B SKID STEER LOADER (Prefix RLL) Service Repair Manual (RLL00001-06799)Document26 pagesCaterpillar Cat 216B SKID STEER LOADER (Prefix RLL) Service Repair Manual (RLL00001-06799)rpoy9396615100% (1)

- Parts List for Drive Shaft AssemblyDocument1 pageParts List for Drive Shaft AssemblyrogerioNo ratings yet

- Cartuchos CAT Com Suas Galonagens PDFDocument11 pagesCartuchos CAT Com Suas Galonagens PDFpaimporcateNo ratings yet

- Gb5 Fb80 Parts Catalog v5.2 ColorDocument96 pagesGb5 Fb80 Parts Catalog v5.2 ColorAnatoliy RozenbljumNo ratings yet

- Get PDFAttachmentDocument3 pagesGet PDFAttachmentGégé di TPNo ratings yet

- 5 Cruces Cat-FuturaDocument1 page5 Cruces Cat-Futurakarijoseph02No ratings yet

- UNSPSC Codes - V7.0.901Document13 pagesUNSPSC Codes - V7.0.901vipinchawlaNo ratings yet

- Dynapac Compaction Equipment AB Technical ManualDocument254 pagesDynapac Compaction Equipment AB Technical ManualFelipe Douglas da Silva100% (1)

- Catálogo de Peças 6075 Tier 3Document88 pagesCatálogo de Peças 6075 Tier 3posvendasdf5No ratings yet

- NB Parts ConstructionDocument196 pagesNB Parts ConstructionAgus YulfizarNo ratings yet

- Diagramas Caterpillar KENR7039 - 02Document2 pagesDiagramas Caterpillar KENR7039 - 02jorge antonio guillenNo ratings yet

- PIX V-Belts CatalogueDocument21 pagesPIX V-Belts CataloguemarranNo ratings yet

- Rear 3-Point Hitch Removal StepsDocument4 pagesRear 3-Point Hitch Removal Stepsjosh1419No ratings yet

- Cummins NTA855 Engine PartsDocument2 pagesCummins NTA855 Engine PartsIbrahim YunusNo ratings yet

- Hangcha 5 7TN1 PDFDocument2 pagesHangcha 5 7TN1 PDFTiagoNo ratings yet

- Massey Ferguson 4708 TRACTOR (ECO4 TIER 2) (E5090001 - 99999999) Service Parts Catalogue Manual (Part Number 6246200)Document16 pagesMassey Ferguson 4708 TRACTOR (ECO4 TIER 2) (E5090001 - 99999999) Service Parts Catalogue Manual (Part Number 6246200)bvk2980022No ratings yet

- Planos HidráulicosDocument1 pagePlanos HidráulicosDaniel AguirreNo ratings yet

- Conexión Pneumática Fastrac 3220Document1 pageConexión Pneumática Fastrac 3220Daniel AguirreNo ratings yet

- Parker GP0130 (Valvula Poporcional LC1)Document2 pagesParker GP0130 (Valvula Poporcional LC1)Daniel AguirreNo ratings yet

- Clam Shovel PWM Control (By Joystick and Aux ECU)Document13 pagesClam Shovel PWM Control (By Joystick and Aux ECU)Daniel AguirreNo ratings yet

- Planos Eléctricos 455Document13 pagesPlanos Eléctricos 455Daniel Aguirre50% (2)

- Data Sheet 68749835 Electronic Throttle BodyDocument3 pagesData Sheet 68749835 Electronic Throttle BodyDaniel AguirreNo ratings yet

- Controlador de Bomba de Inyección Delphi DP210Document80 pagesControlador de Bomba de Inyección Delphi DP210Daniel Aguirre100% (1)

- 2019 North American Customer Training CatalogDocument30 pages2019 North American Customer Training CatalogTatak Bay AhmedNo ratings yet

- Geely FC PDFDocument419 pagesGeely FC PDF801400100% (2)

- Champion 720A With 9150 Transmission Hydraulic ShematicDocument12 pagesChampion 720A With 9150 Transmission Hydraulic ShematicDaniel Aguirre100% (2)

- Nissan Titan Power Control SystemDocument98 pagesNissan Titan Power Control SystemDaniel Aguirre100% (2)

- Transmission - Service Manual (Sección Transmisión)Document1 pageTransmission - Service Manual (Sección Transmisión)Daniel AguirreNo ratings yet

- Nissan Note Power Control SystemDocument106 pagesNissan Note Power Control SystemDaniel Aguirre100% (1)

- RN (P Rnill Tirnrn : G1Jill ( Ooill (Document54 pagesRN (P Rnill Tirnrn : G1Jill ( Ooill (Carlos Andres Vargas100% (1)

- Power Supply, Ground and Circuit ElementsDocument183 pagesPower Supply, Ground and Circuit ElementsDaniel Aguirre0% (1)

- Woodward Coil CommanderDocument2 pagesWoodward Coil CommanderDaniel AguirreNo ratings yet

- Nissan Frontier Service Manual Heater and Aire ConditionatedDocument53 pagesNissan Frontier Service Manual Heater and Aire ConditionatedDaniel AguirreNo ratings yet

- Galvanic CorrosionDocument5 pagesGalvanic Corrosionsatheez3251No ratings yet

- Ch15 Differential Momentum BalanceDocument20 pagesCh15 Differential Momentum Balance89kkNo ratings yet

- The PersonalityDocument7 pagesThe PersonalityMeris dawatiNo ratings yet

- EagleBurgmann BT-ARP ENDocument4 pagesEagleBurgmann BT-ARP ENMarin PintarićNo ratings yet

- Teaching Strategies in The New NormalDocument19 pagesTeaching Strategies in The New NormalEloisa Canlas - Quizon67% (3)

- Samuel Mendez, "Health Equity Rituals: A Case For The Ritual View of Communication in An Era of Precision Medicine"Document227 pagesSamuel Mendez, "Health Equity Rituals: A Case For The Ritual View of Communication in An Era of Precision Medicine"MIT Comparative Media Studies/WritingNo ratings yet

- Fif-12 Om Eng Eaj23x102Document13 pagesFif-12 Om Eng Eaj23x102Schefer FabianNo ratings yet

- University of Delhi Third Admission List - Bachelor of Education (B.Ed.)-2021Document8 pagesUniversity of Delhi Third Admission List - Bachelor of Education (B.Ed.)-2021FERA Future electronics and research administrationNo ratings yet

- Presentation 5 1Document76 pagesPresentation 5 1Anshul SinghNo ratings yet

- Benevolent Assimilation Proclamation AnalysisDocument4 pagesBenevolent Assimilation Proclamation AnalysishgjfjeuyhdhNo ratings yet

- Simplified Coil DesignDocument6 pagesSimplified Coil DesignNestor Alberto EscalaNo ratings yet

- Mil PRF 23699FDocument20 pagesMil PRF 23699FalejandroNo ratings yet

- Autochief® C20: Engine Control and Monitoring For General ElectricDocument2 pagesAutochief® C20: Engine Control and Monitoring For General ElectricВадим ГаранNo ratings yet

- Lesson Plan Nº1Document7 pagesLesson Plan Nº1Veronica OrpiNo ratings yet

- Activity No.1 in GED 103Document2 pagesActivity No.1 in GED 103Kenneth HerreraNo ratings yet

- 12th Maths - English Medium PDF DownloadDocument38 pages12th Maths - English Medium PDF DownloadSupriya ReshmaNo ratings yet

- Os8 - XCVR 8.7r3 RevaDocument85 pagesOs8 - XCVR 8.7r3 RevaDouglas SantosNo ratings yet

- Cegep Linear Algebra ProblemsDocument92 pagesCegep Linear Algebra Problemsham.karimNo ratings yet

- Jallikattu: Are Caste and Gender the Real Bulls to TameDocument67 pagesJallikattu: Are Caste and Gender the Real Bulls to TameMALLIKA NAGLENo ratings yet

- 8D Form - LongDocument6 pages8D Form - LongmaofireNo ratings yet

- REHAU 20UFH InstallationDocument84 pagesREHAU 20UFH InstallationngrigoreNo ratings yet

- Quick Start Guide - QualiPoc AndroidDocument24 pagesQuick Start Guide - QualiPoc AndroidDmitekNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- Free Fall ExperimentDocument31 pagesFree Fall ExperimentLeerzejPuntoNo ratings yet

- Rizal's Works Inspire Filipino PrideDocument2 pagesRizal's Works Inspire Filipino PrideItzLian SanchezNo ratings yet

- Distributed Oracle EAM - A White PaperDocument38 pagesDistributed Oracle EAM - A White PaperrpgudlaNo ratings yet

- Assignment 7Document1 pageAssignment 7sujit kcNo ratings yet

- OPM - Assignment 2Document12 pagesOPM - Assignment 2Nima IraniNo ratings yet

- Guidelines For Synopsis & Dissertation-DefenseDocument10 pagesGuidelines For Synopsis & Dissertation-DefenseRajni KumariNo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet