Professional Documents

Culture Documents

OPC UA SuccessStory WaterTreatment ZWAV v1

OPC UA SuccessStory WaterTreatment ZWAV v1

Uploaded by

Luitz CruzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OPC UA SuccessStory WaterTreatment ZWAV v1

OPC UA SuccessStory WaterTreatment ZWAV v1

Uploaded by

Luitz CruzCopyright:

Available Formats

Success Story V1.

0-en

Branch

Water Treatment

W W W.O P C F O U N DAT I O N .O R G

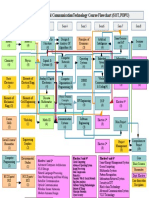

Intelligent Water Management with OPC UA Enabled Smart Devices

M2M Communication Based on PLCopen OPC UA Client Function Blocks

SCADA Elevated Reservoir

ed reservoirs, etc.) distributed over 1,400 km² and covering 40 cities with

Requests for 240,000 people.

process values

and state Due to problems at group1

chang

changes supplier of freshwater has

changed to group 2 Real objects (e.g. pumps) were modeled in the TwinCAT IEC 61131-3

Requests for

process values

6 7 PLC software from Beckhoff Automation as complex objects with

and state

changes

Closed interactive possibilities; thanks to the OPC UA server integrated in the

User Group

Us

Level reached! controller, these objects are automatically available to the outside world

Quality problems

as complex data structures for semantic interoperability. The result is

2 Stopped pumping

in freshwater! 5

decentralized intelligence that makes decisions independently and can

transmit information to neighboring systems. In addition, it can query

Please take overr

1 filling of elevated

reservoir 2 equipment status and values for its own process in order to ensure

trouble-free process cycles.

Waterworks 1 Pumping Plant 1 Pumping Plant 2 Waterworks 2

With the standardized PLCopen function blocks, the devices indepen-

Decentralized, independently acting embedded controllers can form an dently initiate communication from the PLC to other process devices

intelligent network for the control of potable water and wastewater plants. such as OPC UA clients, while at the same time being able to respond to

OPC UA is the ideal technology to establish secure and standardized their requests or to requests from higher-level systems (SCADA, MES,

M2M interaction at these plants. ERP) as OPC UA servers.

The movement toward the 4th industrial revolution, or Industry 4.0, is The devices are connected by wireless routers: a physical interruption of

gaining momentum in a wide range of industries, and water treatment the connection does not lead to a loss of information, since information is

can now be counted as an application example. If we regard some of the automatically buffered in the OPC UA server for a time and can be

Industry 4.0 initiative’s basic concepts, such as platform and vendor-in- retrieved as soon as the connection has been restored – a very important

dependent communication, data security, standardization, decentralized property in which a great deal of proprietary engineering effort was

intelligence and engineering, then a technology for M2M (Machine- invested beforehand. The authentication, signing, and encryption secu-

to-Machine) or IoT (Internet of Things) applications is already available rity mechanisms integrated in OPC UA were used in addition to a closed

in the OPC Unified Architecture (OPC UA). mobile radio group to ensure the integrity of this partly-sensitive data.

OPC UA is used for M2M communication between plants for the intelli- The vendor-independent interoperability standard OPC UA opens up the

gent networking of decentralized, independently acting, very small em- possibility for end users to subordinate the selection of a target platform

bedded controllers. For example, an application with the Joint Water and for the required technology in order to avoid using proprietary products

Wastewater Authority, Vogtland (ZWAV) has around 300 potable water or devices that don’t meet the needs of the application.

plants and 300 wastewater plants (pumping plants, waterworks, elevat-

Testimonial: Licensing Costs Reduced by 90%

The replacement of a proprietary solu- For the engineering part, better stan- The considerable potential for business

tion with a combined OPC UA client/ dardization results in: management optimization is more than

server solution in small, but powerful • Efficient engineering worth putting together existing and new

embedded controllers provided ZWAV • Cost reductions technologies.

with savings on the initial licensing costs • Reuse of technology/equipment

of more than 90 % per device. Minimiz- • Improved transparency

ing service assignments in the field • Increased availability Silvio Merz, Divisional Manager

results in significant additional savings • Increased choice of providers Electrical/Process Technology

Joint Water and Wastewater Authority,

for maintaining several hundred water • Higher interoperability

Vogtland

facilities within an area of 1,400 km². www.zwav.de

OPC UA-Enabled Smart Devices

LTE / UMTS /

GPRS-EDGE

A remarkable increase in efficiency, cost reductions and quality im-

Server Client provements can be observed using the IEC 61131-3 PLC in engineering.

The prerequisite here is:

TwinCAT • an object-oriented approach

PLC

ERP MES HMI

IEC 61131-3

C T R L • Transplant intelligence into the PLC

• Control system or a local visualization is handled simply as

I/O Hardware: an “image” on the PLC

Sensor / Actuator

Advantage: No requirements to manage multiple configurations or

Diagram: TwinCAT OPC UA Client (PLCopen-based) and TwinCAT OPC UA Server are

scaling – or the associated errors. Also, out of the cooperation of the

integrated into one of the smallest Beckhoff controllers, a CX9020 Embedded PC.

OPC Foundation and PLCopen, a similarly high impact can be

Real objects (e.g. pumps) were modeled in the IEC 61131-3 PLC as achieved on the PLC. Through structuring and modularization, data

complex objects with interactive possibilities; thanks to the OPC UA serv- structures or their elements for Data Access, Alarms & Conditions

er integrated in the controller, these objects are automatically available to or Historical Access, are prepared once in an object-oriented manner

the outside world as complex data structures for semantic in the PLC source code. This can save users significant amounts of

interoperability. programming time.

About ZWAV (Joint Water and Wasterwater Authority), Vogtland

The purpose of the Joint Water and Wastewater Authority, Vogtland (ZWAV) is an association of 40 cities in the Vogtland region of

Germany where communities work together to fulfill the responsibilities of water supply and sanitation, which were transferred to the

www.zwav.de

municipalities by law. The ZWAV is responsible for an area of 1,400 km² - covering 40 cities with 240,000 people.

About Beckhoff

Beckhoff implements open automation systems based on PC Control technology. The product range covers Industrial PCs, Industrial Motherboards,

I/O and Fieldbus Components, Drive Technology, and automation software. These innovative products can be used as separate components or

integrated into a complete and seamless control system in all industries. The Beckhoff “New Automation Technology” philosophy represents universal

and open control and automation solutions that are used worldwide in a wide variety of different applications, ranging from CNC-controlled machine

tools to intelligent building automation.

About PLCopen

PLCopen, as an organization active in industrial control, creates higher efficiency in application software development www.plcopen.org

and lowers system lifecycle costs. One of the core activities of PLCopen is focused around IEC 61131-3, the only

global standard for industrial controls programming. The results of the collaboation between PLCopen and OPC-

Foundation include:

- mapping of IEC 61131-3 into the OPC UA namespace in order to provide semantic interoperability

- PLCopen OPC UA client function blocks which enable controllers to initiate OPC UA-based communication

About OPC Unified Architecture (OPC UA)

OPC UA is the interoperability standard for multi-vendor, multi-platform data exchange that is secure and reliable from

small sensors up to IT Enterprise level systems. This technology provides open connectivity across multiple products,

regardless of hardware platform or software operating system. OPC UA (the IEC 62541 standard) includes automated

discovery, security by design, data encryption, and exceptionally powerful information modeling.

You might also like

- Ziv Iec61850Document44 pagesZiv Iec61850vzssz0% (1)

- Process Control WWTP2Document5 pagesProcess Control WWTP2Arima KouseiNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Outline: Csci 136 Computer Architecture IIDocument22 pagesOutline: Csci 136 Computer Architecture IIKamran AmeerNo ratings yet

- Website Design Proposal DentistDocument8 pagesWebsite Design Proposal DentistNamanNo ratings yet

- Test-Bank (1-2-3-5-6-8) PDFDocument12 pagesTest-Bank (1-2-3-5-6-8) PDFAhmed E EsmailNo ratings yet

- Pakscan CatalogueDocument32 pagesPakscan CatalogueragulNo ratings yet

- Allen Bradley Plant Wide Process ControlDocument2 pagesAllen Bradley Plant Wide Process ControlEric DunnNo ratings yet

- RTU560 EnglishDocument16 pagesRTU560 EnglishrhomadonaNo ratings yet

- Rtu560 Datasheet Deabb125506Document16 pagesRtu560 Datasheet Deabb125506alejogomez200No ratings yet

- Cumberland Waste Water Treatment Station SolutionDocument2 pagesCumberland Waste Water Treatment Station Solutionasdsd dsdaNo ratings yet

- Wireless Well Completions ScandOil December 2017Document3 pagesWireless Well Completions ScandOil December 2017RaamNo ratings yet

- 72 - Operation and Maintenance of Hydro Equipment HP&D's Issue 6 2021Document8 pages72 - Operation and Maintenance of Hydro Equipment HP&D's Issue 6 2021rotimi olalekan fataiNo ratings yet

- Automatic Filling Management System For Industries Saubhagya Tandon, Shreya Srivastava, Sandeep Pal Srji Vol 3 Issue 2 Year 2014Document6 pagesAutomatic Filling Management System For Industries Saubhagya Tandon, Shreya Srivastava, Sandeep Pal Srji Vol 3 Issue 2 Year 2014Dr. Krishna N. SharmaNo ratings yet

- 90 NetDocument4 pages90 Nettuan nguyen duyNo ratings yet

- Kandoo - A Framework For Efficient and Scalable Offloading of Control ApplicationsDocument6 pagesKandoo - A Framework For Efficient and Scalable Offloading of Control Applicationsdvc.290603No ratings yet

- Boiler Application Using Wireless Bridge Between PLC and ScadaDocument6 pagesBoiler Application Using Wireless Bridge Between PLC and ScadaDhaval MehtaNo ratings yet

- A Water Pumping Control System With A Programmable Logic Controller (PLC) PDFDocument8 pagesA Water Pumping Control System With A Programmable Logic Controller (PLC) PDFsunnyday32No ratings yet

- Beckhoff - Waster and Clean Water Process Solution r4Document32 pagesBeckhoff - Waster and Clean Water Process Solution r4Romi AntonNo ratings yet

- Studi Penerapan Metode Island OperationDocument8 pagesStudi Penerapan Metode Island OperationSyarifah FebriaNo ratings yet

- Scad ADocument31 pagesScad AnareshkattaNo ratings yet

- SCADADocument8 pagesSCADAAkash KallattiNo ratings yet

- Ahmadzakihamidi 2018Document7 pagesAhmadzakihamidi 2018JOSE GREGORIO DAVILA HERNANDEZNo ratings yet

- Flygt MultismartDocument2 pagesFlygt MultismartspurscoukNo ratings yet

- Utility of SCADA in Power Generation and Distribution SystemDocument6 pagesUtility of SCADA in Power Generation and Distribution SystemUrekMazinoNo ratings yet

- Pocket Folder - Contents (PDF) - Added 4-3-20Document22 pagesPocket Folder - Contents (PDF) - Added 4-3-20Dereck SeckmanNo ratings yet

- S210e PDFDocument8 pagesS210e PDFOlid Antonio Castillo PalmerosNo ratings yet

- LanzDocument5 pagesLanzAhmed AlsalamiNo ratings yet

- Edp Distribution Automation (R) Evolution: Cired Cired Cired CiredDocument4 pagesEdp Distribution Automation (R) Evolution: Cired Cired Cired CiredkotiniNo ratings yet

- Using Standard Protocols For Scada Master-Station and Remote Terminal Units (Rtus)Document7 pagesUsing Standard Protocols For Scada Master-Station and Remote Terminal Units (Rtus)SGQNo ratings yet

- Network Monitoring - I2o - 10 - 2017Document4 pagesNetwork Monitoring - I2o - 10 - 2017Annie De WildeNo ratings yet

- Rotork Actuators With Profibus: Case StudyDocument5 pagesRotork Actuators With Profibus: Case StudympicaNo ratings yet

- Lecture 9 - SCADA SystemsDocument53 pagesLecture 9 - SCADA SystemsDebabrata Adak.No ratings yet

- Rotork Actuators With Profibus: ClientDocument2 pagesRotork Actuators With Profibus: ClientadamsNo ratings yet

- Implementing A State of The Art Automation Control, Scada and Information System Into An Existing Manually Operated 20 MGD WWTP Below Budget, On Schedule and Without Process InterruptionDocument14 pagesImplementing A State of The Art Automation Control, Scada and Information System Into An Existing Manually Operated 20 MGD WWTP Below Budget, On Schedule and Without Process Interruptionengineer_CINo ratings yet

- CS0060005 Data Transmission From Wind Farm To Distribution Center Using SYNC2101 v1.02.072017 1Document2 pagesCS0060005 Data Transmission From Wind Farm To Distribution Center Using SYNC2101 v1.02.072017 1RuchirNo ratings yet

- Openflows Sewerops Connect Edition: Operational Decision Support Software For Wastewater ConveyanceDocument2 pagesOpenflows Sewerops Connect Edition: Operational Decision Support Software For Wastewater ConveyanceJuan Carlos GutiérrezNo ratings yet

- ACE3600 Remote Terminal Unit: The Next Generation of High-Performance ControlDocument6 pagesACE3600 Remote Terminal Unit: The Next Generation of High-Performance ControlСергейNo ratings yet

- Qingliu 2006Document4 pagesQingliu 2006ikhwanNo ratings yet

- Application of Scada in Modeling of Power Distribution Systems and Induction MotorDocument6 pagesApplication of Scada in Modeling of Power Distribution Systems and Induction MotorYamuna ShivprasadNo ratings yet

- Servelec Kingfisher RTUDocument4 pagesServelec Kingfisher RTURyan TayNo ratings yet

- Cajun P220: Gigabit SwitchesDocument4 pagesCajun P220: Gigabit SwitchesEdgar F. Espinoza SilverioNo ratings yet

- HP Switching and Routing Technologies: Web-Based Training Course CompanionDocument102 pagesHP Switching and Routing Technologies: Web-Based Training Course CompanionivanovNo ratings yet

- Guri Dam: Ingenuity and EnergyDocument5 pagesGuri Dam: Ingenuity and EnergyEmmnauel VieiraNo ratings yet

- Ovation Scada Communication Server en 67362Document5 pagesOvation Scada Communication Server en 67362sinakal nakalNo ratings yet

- Introduction To Programmable ControllersDocument6 pagesIntroduction To Programmable Controllersfaysal_superiorNo ratings yet

- Control System 3Document36 pagesControl System 3RajeevSangamNo ratings yet

- New, Manufacturer-Independent IO-Link Interface For The Intelligent Process AutomationDocument7 pagesNew, Manufacturer-Independent IO-Link Interface For The Intelligent Process AutomationVanbeverNo ratings yet

- Remote Plant Monitoring Using Wireless Technology: TechnicalDocument4 pagesRemote Plant Monitoring Using Wireless Technology: TechnicalGull KhanNo ratings yet

- PAC8000 RTU: Intelligent PlatformsDocument8 pagesPAC8000 RTU: Intelligent PlatformsAnindaNo ratings yet

- Wastewater Treatment Plant SCADA ApplicationDocument6 pagesWastewater Treatment Plant SCADA ApplicationDaniel Elmer Parado SosaNo ratings yet

- NasbyG 2021 SCADA-terminology OWWA2021 Apr19toMay5-2021 Slides PDFDocument29 pagesNasbyG 2021 SCADA-terminology OWWA2021 Apr19toMay5-2021 Slides PDFAhmed Essam El-DinNo ratings yet

- Scada: S.Anbu Kaviraj & M. Mahendhiran Government College of Engineering Tirunelveli-627007Document7 pagesScada: S.Anbu Kaviraj & M. Mahendhiran Government College of Engineering Tirunelveli-627007Dinesh DinuNo ratings yet

- Mobile Control Station (Oct - Dec 02)Document4 pagesMobile Control Station (Oct - Dec 02)santhoshNo ratings yet

- Data Centre Monitoring and Management: e BookDocument14 pagesData Centre Monitoring and Management: e BookAnonymous GI3MMOCftCNo ratings yet

- Using Smart Triggers For Improved User Performance in 802.11 Wireless NetworksDocument14 pagesUsing Smart Triggers For Improved User Performance in 802.11 Wireless NetworksAmol Mukund KhireNo ratings yet

- Scada in Water SecurityDocument5 pagesScada in Water SecurityBharadwaj SanthoshNo ratings yet

- Rotork Innovation Assists Automation in The Water Industry: Also InsideDocument20 pagesRotork Innovation Assists Automation in The Water Industry: Also InsideIñaki EseberriNo ratings yet

- Auto Recloser Nulec U27 SchneiderDocument12 pagesAuto Recloser Nulec U27 SchneiderJordan CentenoNo ratings yet

- RT - SCADA - FY2019 - v5Document18 pagesRT - SCADA - FY2019 - v5Mas Ahmad Safwan Masbah100% (1)

- Why Go Digital White Paper GEA-32016Document5 pagesWhy Go Digital White Paper GEA-32016Fabio ThomazNo ratings yet

- 2017 MasterThesisAbstractYoutubeVideosLuisCruzRGDocument1 page2017 MasterThesisAbstractYoutubeVideosLuisCruzRGLuitz CruzNo ratings yet

- OPC UA SuccessStory WaterTreatment ZWAV v1Document2 pagesOPC UA SuccessStory WaterTreatment ZWAV v1Luitz CruzNo ratings yet

- Fluke 3 Jumper Test MethodDocument5 pagesFluke 3 Jumper Test MethodLuitz CruzNo ratings yet

- Agent-Based Optimisation of Logistics and Production PlanningDocument14 pagesAgent-Based Optimisation of Logistics and Production PlanningLuitz CruzNo ratings yet

- سارق الكلاب - مكتبة المغامراتDocument80 pagesسارق الكلاب - مكتبة المغامراتnabila nabilaNo ratings yet

- Dr. HENG, Chun Huat Teaching Assistant Dr. BA MyintDocument7 pagesDr. HENG, Chun Huat Teaching Assistant Dr. BA MyintNixNo ratings yet

- 103-Huawei OceanStor Distributed Storage V1.2Document42 pages103-Huawei OceanStor Distributed Storage V1.2Juan Francisco AriasNo ratings yet

- Wang 2021Document26 pagesWang 2021Dhruv PatelNo ratings yet

- Prn256m8v69ag8gkf 15eDocument12 pagesPrn256m8v69ag8gkf 15eArif YuliantoNo ratings yet

- Yuhua Secondary School 2022 WA3 Mock Paper For HBL Secondary 1Document5 pagesYuhua Secondary School 2022 WA3 Mock Paper For HBL Secondary 1nithiyaashreepsivakumarNo ratings yet

- Brosur Tomy MDX-310 - Refrigerated Centrifuge For Life ScienceDocument3 pagesBrosur Tomy MDX-310 - Refrigerated Centrifuge For Life ScienceMamik ShofiaNo ratings yet

- Curve Fitting: Origin Provides Full Control of The Fitting ProcessDocument2 pagesCurve Fitting: Origin Provides Full Control of The Fitting ProcessFabiana AzevedoNo ratings yet

- Bilal Shaikh CV For Information Security Consultants (Qatar)Document5 pagesBilal Shaikh CV For Information Security Consultants (Qatar)Kiran ModiNo ratings yet

- Pallet Strategy-PutawayDocument9 pagesPallet Strategy-PutawayEKTA Simaria (US)No ratings yet

- Shivaji University KolhapurDocument8 pagesShivaji University KolhapurPallavi PatilNo ratings yet

- Lista Precios202103Document6 pagesLista Precios202103Juankar ApoloNo ratings yet

- B Tech ICT Course Flow ChartDocument1 pageB Tech ICT Course Flow ChartPUBG IS OUR LIFENo ratings yet

- Python DATA VISUALIZATIONDocument31 pagesPython DATA VISUALIZATIONkoteswari kasireddyNo ratings yet

- A Novel Clustering Approach and Adaptive SVMDocument16 pagesA Novel Clustering Approach and Adaptive SVMIraqi.Germany groupNo ratings yet

- Microprocessors and MicrocontrollersDocument86 pagesMicroprocessors and MicrocontrollersbrightmoreNo ratings yet

- Final Year Project Proposal-1Document10 pagesFinal Year Project Proposal-1monaNo ratings yet

- Gen Math PDF Lesson 1Document18 pagesGen Math PDF Lesson 1Olivera John ReyNo ratings yet

- Pag-Aalay NG Puso (Minsan Lamang) (Lyrics and Chords)Document3 pagesPag-Aalay NG Puso (Minsan Lamang) (Lyrics and Chords)Frances LeticiaNo ratings yet

- Nortel Baystack 5510 ManualDocument140 pagesNortel Baystack 5510 ManualGregNo ratings yet

- A Project Submitted in Partial Fulfilment of The Requirements For The Award of The Degree OF Bachelor of Computer ApplicationDocument33 pagesA Project Submitted in Partial Fulfilment of The Requirements For The Award of The Degree OF Bachelor of Computer ApplicationNikhil BajajNo ratings yet

- CodeDocument3 pagesCodeTranNguyenBaoKhangNo ratings yet

- Car Number Plate Detection Using MATLAB and Image ProcessingDocument29 pagesCar Number Plate Detection Using MATLAB and Image Processingحسان فضل الشعيبيNo ratings yet

- Pnc12extreme Pga Eng WebDocument2 pagesPnc12extreme Pga Eng Webnikhil chobeyNo ratings yet

- PRN 2Document8 pagesPRN 2abcdeg2No ratings yet

- INSY 5339 - Data Mining Exam #2 ReviewDocument1 pageINSY 5339 - Data Mining Exam #2 ReviewLaluMohan KcNo ratings yet

- Consuming RESTful API - GuideDocument8 pagesConsuming RESTful API - GuideRenato SantosNo ratings yet