Professional Documents

Culture Documents

Cad Cam & Automation

Uploaded by

Almas 1710Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cad Cam & Automation

Uploaded by

Almas 1710Copyright:

Available Formats

CAD CAM and

Automation

Semester VII - Mechanical Engineering

(Savitribai Phule Pune University) (SPPU)

ge

Strictly as per the New Credit System Syllabus (2015 Course)

Savitribai Phule Pune University w.e.f. academic year 2018-2019

io eld

ic ow

R. B. Patil

n

bl kn

M.E. (Mech) (Design Engg.)

at

Professor,

Pu ch

Department of Mechanical Engineering,

Army Institute of Technology, Pune.

Te

Maharashtra.

Unit IV contributed by :

Pankaj Dorlikar

M.Tech ( Design)

Assistant Professor,

Department of Mechanical Engineering,

Army Institute of Technology, Pune

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

CAD CAM and Automation

R.B. Patil

Semester VII – Mechanical Engineering (Savitribai Phule Pune University) (SPPU)

Copyright © by Author. All rights reserved. No part of this publication may be reproduced, copied, or stored in a

retrieval system, distributed or transmitted in any form or by any means, including photocopy, recording, or other

electronic or mechanical methods, without the prior written permission of the publisher.

This book is sold subject to the condition that it shall not, by the way of trade or otherwise, be lent, resold, hired out, or

otherwise circulated without the publisher’s prior written consent in any form of binding or cover other than which it is

published and without a similar condition including this condition being imposed on the subsequent purchaser and

ge

without limiting the rights under copyright reserved above.

io eld

First Printed in India : February 2007 (Pune University)

First Edition : July 2018

Second Revised Edition : June 2019 (TechKnowledge Publications)

ic ow

n

bl kn

This edition is for sale in India, Bangladesh, Bhutan, Maldives, Nepal, Pakistan, Sri Lanka and designated countries in

South-East Asia. Sale and purchase of this book outside of these countries is unauthorized by the publisher.

at

Pu ch

Te

ISBN 978-93-89233-82-7

Published by

TechKnowledge Publications

Head Office : B/5, First floor, Maniratna Complex, Taware Colony, Aranyeshwar Corner,

Pune - 411 009. Maharashtra State, India

Ph : 91-20-24221234, 91-20-24225678.

Email : info@techknowledgebooks.com,

Website : www.techknowledgebooks.com

[402042] (FID : PO62) (Old Book Code : PO288A) (New Book Code : PO62A)

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

We dedicate this Publication soulfully and wholeheartedly,

in loving memory of our beloved founder director

Late. Shri. Pradeepsheth Lalchandji Lunawat,

who will always be an inspiration, a positive force and strong support

behind us.

ge

io eld

ic ow

n

bl kn

at

Pu ch

Te

Lt. Shri. Pradeepji L. Lunawat

Soulful Tribute and Gratitude for all Your

Sacrifices, Hardwork and 40 years of Strong Vision…….

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

Dedicated To …..

ge

My Daughter

io eld

Neha

ic ow

&

n

Son

bl kn

at

Nikhil

Pu ch

Te

- R. B. Patil

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

Preface

It gives me a great pleasure to present this book on ‘CAD CAM and Automation’. This book has

been written for the first course in ‘CAD CAM and Automation’, especially for the final year students

of mechanical engineering. Though the number of classical books written by reputed international

authors on various tools in CAD/CAM are available, main objective of this book is to bridge the gap

between the reference books written by the renowned international authors and the requirements of

ge

undergraduate students.io eld

The book has been presented in a simple language without compromising the quality of text. The

concepts have been developed from the fundamentals. The main emphasis has been given on

ic ow

explaining the concepts rather than merely providing the information. Every concept is illustrated

n

with the help of number of solved examples which are arranged in the order of increasing degree of

bl kn

difficulty. This book is an outcome of the years of classroom interaction with the students.

at

Pu ch

This book is presented in the loving memory of Late Shri. Pradeepji Lunawat, a source of

inspiration behind ‘TechKnowledge Publications’. He will always be remembered as motivator by a

Te

team of ‘TechKnowledge Publications’.

I would like to express my thanks to Shri. Shital Bhandari, Shri Arunoday Kumar and

Shri Chandroday Kumar of ‘TechKnowledge Publications’ for their efforts in publishing this book.

My thanks are also due to seema Lunawat for ebook and staff of ‘TechKnowledge

Publications’ for their untiring efforts in bringing this book.

Last, but not least, my special thanks go to all my students whose continuous feedback while teaching

this subject is the source of inspiration behind this book.

A feedback, in the form of suggestions and comments, from the readers for further improvement of

this book will be highly appreciated.

- R. B. Patil

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

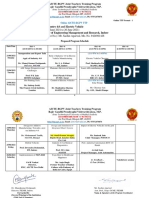

Syllabus

Savitribai Phule Pune University, Pune

Final Year of Mechanical Engineering (2015 Course)

Course Code: 402042 Course Name : AD CAM and Automation

Teaching Scheme : Credits Examination Scheme :

Theory : 03 Hrs Per Week TH : 03 Theory In-Sem : 30 PR : 50

Practical : 02 hrs per week TW : 01 End-Sem : 70 OR : --

TW : 25

Pre-requisites : Engineering Graphics, Engineering Mathematics, Numerical Methods & Optimization, Computer

ge

Aided Machine Drawing, Strength of Materials, Manufacturing Processes

Course Objectives :

io eld

To apply homogeneous transformation matrix for geometrical transformations of 2D/3D CAD entities

To model mathematically analytical and synthetic curves, surfaces

ic ow

To predict performance of simple mechanical components viz. beam, shafts, plates, trusses using FEA (Mathematical and

n

Software treatment)

bl kn

To generate CNC program for appropriate manufacturing techniques viz. turning and milling

To select and apply suitable Rapid Prototyping techniques for engineering applications

at

Pu ch

To study role and components of different Automation strategies.

Course Outcomes :

Te

On completion of the course, students will be able to -

Apply homogeneous transformation matrix for geometrical transformations of 2D CAD entities for basic geometric

transformations.

Use analytical and synthetic curves and surfaces in part modeling.

Do real times analysis of simple mechanical elements like beams, trusses, etc. and comment on safety of engineering

components using analysis software.

Generate CNC program for Turning / Milling and generate tool path using CAM software.

Demonstrate understanding of various rapid manufacturing techniques and develop competency in designing and developing

products using rapid manufacturing technology.

Understand the robot systems and their applications in manufacturing industries.

Course Contents

Unit 1 : Computer Graphics

Transformations (2D & 3D) : Introduction, Formulation, Translation, Shear, Rotation, Scaling and reflection,

Homogeneous representation, Concatenated transformation, Mapping of geometric models, Inverse transformations,

Introduction to 3D transformation (Theory + Numerical treatment only for 2D – Max 3 vertices)

Projections : Orthographic, Isometric, Perspective projections (Only theory) (Refer chapter 1)

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

Unit 2 : Geometric Modeling

Curves – Introduction, Analytical curves (Line, circle, ellipse, parabola, hyperbola), Synthetic curves (Hermite Cubic

Spline, Bezier, B-Spline Curve) [Numerical on Line, Circle, Ellipse, Hermite Cubic Spline, Bezier] Surfaces –

Introduction, Surface representation, Analytic surfaces, Synthetic Surfaces, Hermite bicubic, Bezier, B-Spline, Coons

patch surface, Applications in freeform surfaces [only Theory]

Solids - Introduction, Geometry and Topology, Solid Representation, Boundary Representation,

Euler's equation, Constructive Solid Geometry (CSG), Boolean operation for CSG [only Theory] (Refer chapter 2)

Unit 3 : Finite Element Analysis (FEA)

Introduction : Brief History of FEM, Finite Element Terminology (nodes, elements, domain, continuum, Degrees of

freedom, loads and constraints), General FEM procedure, Applications of FEM in various fields, meshing, p and h

formulation, Advantages and disadvantages of FEM [Only theory]

One Dimensional Problem: Finite element modeling, coordinate and linear shape function, Assembly of Global

ge

Stiffness Matrix and Load Vector, Properties of Stiffness Matrix, Finite Element Equations, Temperature Effects.

[Theory + Numerical – composite shaft, spring elements in series and parallel]

io eld

Trusses : Introduction, 2D Trusses, Assembly of Global Stiffness Matrix [Numerical limited to 4X4 matrix]

(Refer chapter 3)

ic ow

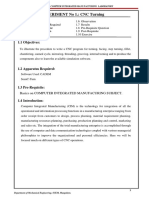

Unit 4 : Computer Aided Manufacturing (CAM)

n

Introduction to Computer Aided Manufacturing (CAM), Coordinate system, Working principal of CNC Lathe, Turning

bl kn

Centers, Milling Machine, Steps in developing CNC part program, Tool and geometric compensations, subroutine and

Do loop using canned cycle. [Only theory – 2 hrs]

at

CNC Lathe part programming (FANUC) : Linear and circular interpolation, Canned cycles for facing, threading,

Pu ch

grooving, etc. [Theory + Program]

CNC Milling part programming (FANUC): Linear and circular interpolation, Pocketing, contouring and drilling cycles.

Te

[Theory + Program] (Refer chapter 4)

Unit 5 : Advanced Manufacturing Method

Product Life Cycle: Introduction, Need, Components/Elements of PLM, Collaborative Engineering.

[Only theory]

Rapid Prototyping : Introduction, classification of RP Processes (SLA, LOM, SLS, FDM, 3D printing), Working

principle, features, models & specification of process, application, advantages and disadvantages, Rapid Tooling and

STL format, Concept of 4D Rapid Prototyping. [Only theory] (Refer chapter 5)

Unit 6 : Automation

Automation : Introduction, Automation strategies, Types of Automation - Hard and Soft Automation, Flexible

Manufacturing System – Types, Advantages, Limitations, AGVs and AS/RS [Only theory]

Group Technology: Introduction, Coding Methods, Concepts of Computer Integrated Manufacturing (CIM) and

Computer Aided Process Planning (CAPP), Variant & Generative methods of CAPP, advantages of CAPP. [Only

theory]

Robotics: RIA definition of Robot, Laws of robotics, Classification of robots, robot anatomy, Point to point and

continuous path robotic systems, Joints, End Effectors, Grippers - Mechanical, Magnetic and Pneumatic, Applications.

[Only theory] (Refer chapter 6)

(New Book Code : PO62A)

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1 Table of Contents

UNIT I UNIT II

Chapter 1 : Computer Graphics 1-1 to 1-55 Chapter 2 : Geometric Modeling 2-1 to 2-67

Syllabus : Transformations (2D & 3D) : Introduction,

Syllabus : Curves : Introduction, Analytical curves (Line,

Formulation, Translation, Shear, Rotation, Scaling and reflection,

circle, ellipse, parabola, hyperbola), Synthetic curves

Homogeneous representation, Concatenated transformation,

(Hermite Cubic Spline, Bezier, B-Spline Curve)

Mapping of geometric models, Inverse transformations,

[Numerical on Line, Circle, Ellipse, Hermite Cubic Spline,

Introduction to 3D transformation (Theory + Numerical treatment

Bezier]

only for 2D – Max 3 vertices)

Surfaces : Introduction, Surface representation, Analytic

Projections : Orthographic, Isometric, Perspective projections

surfaces, Synthetic Surfaces, Hermite bicubic, Bezier, B-

(Only theory)

Spline, Coons patch surface, Applications in freeform

1.1 Introduction to CAD/CAM ............................................ 1-2 surfaces [only Theory]

1.2 Computer Graphics .................................................... 1-2 Solids ; Introduction, Geometry and Topology, Solid

1.3 Two-Dimensional Geometric Transformations ............. 1-2 Representation, Boundary Representation, Euler's

1.3.1 Translation ................................................................. 1-3 equation, Constructive Solid Geometry (CSG), Boolean

operation for CSG [only Theory]

1.3.2 Rotation ...................................................................... 1-3

ge

1.3.3 Scaling ....................................................................... 1-4 2.1 Introduction ................................................................. 2-2

1.3.4 Reflection ................................................................... 1-4 2.1.1 Representation of Curves ............................................ 2-2

1.3.5

io eld

Shear ......................................................................... 1-6 2.1.2 Comparison between Non-Parametric and

1.3.6 Concatenated (Composite) Transformations ............... 1-7 Parametric Curves ...................................................... 2-2

1.4 Two-Dimensional Geometric Transformations using 2.2 Non-Parametric Representation .................................. 2-2

Homogenous Coordinates ........................................... 1-8

ic ow

2.2.1 Forms (Types) of Non-Parametric Representation ..... 2-2

1.4.1 Translation ................................................................. 1-9 2.2.2 Limitations of Non-Parametric Representation of

1.4.2 Rotation ...................................................................... 1-9 Curves ........................................................................ 2-3

n

1.4.3 Scaling ....................................................................... 1-9 2.3 Parametric Representation .......................................... 2-3

bl kn

1.4.4 Reflection ................................................................... 1-9 2.3.1 Advantages of Parametric Representation of

1.4.5 Shear ....................................................................... 1-10 Curves ........................................................................ 2-5

at

Pu ch

1.5 Two-Dimensional Inverse Transformations ................ 1-10 2.4 Types of Curves .......................................................... 2-6

1.5.1 Inverse Translation ................................................... 1-10 2.4.1 Comparison between Analytic and

1.5.2 Inverse Rotation ....................................................... 1-11 Synthetic Curves ........................................................ 2-6

Te

1.5.3 Inverse Scaling ......................................................... 1-11 2.5 Analytic Curves ........................................................... 2-6

1.5.4 Inverse Reflection ..................................................... 1-11 2.6 Lines ........................................................................... 2-6

1.6 Three-Dimensional Geometric Transformations ........ 1-40 2.6.1 Line Connecting Two End Points ................................ 2-6

1.6.1 Translation ............................................................... 1-40 2.6.2 Line Starting From Given Point, of Given Length

and Direction .............................................................. 2-7

1.6.2 Rotation .................................................................... 1-40

2.7 Circles ....................................................................... 2-13

1.6.3 Scaling ..................................................................... 1-41

2.7.1 Parametric Equation of Circle ................................... 2-13

1.6.4 Reflection ................................................................. 1-41

2.7.2 Parametric Equation of Circle by Recursive

1.7 Coordinate Systems .................................................. 1-43

Method ..................................................................... 2-13

1.8 Mapping of Geometric Models ................................... 1-44

2.7.3 Determination of Center and Radius of Circle

1.8.1 Comparison between Geometric Transformation

from End Points of Diameter .................................... 2-14

and Geometric Mapping ........................................... 1-44

2.8 Circular Arcs.............................................................. 2-14

1.9 Two-Dimensional Geometric Mappings ..................... 1-45

2.9 Ellipses ..................................................................... 2-19

1.9.1 Geometric Mapping of Graphics Element ................. 1-45

2.9.1 Parametric Equation of Ellipse ................................. 2-20

1.9.2 Translational Mapping .............................................. 1-45

2.9.2 Parametric Equation of Ellipse by Recursive

1.9.3 Rotational Mapping................................................... 1-46

Method ..................................................................... 2-20

1.9.4 General Mapping ....................................................... 1-46

2.9.3 Parametric Equation of Inclined Ellipse .................... 2-20

1.10 Projections of Geometric Models ............................... 1-49

2.10 Parabolas .................................................................. 2-21

1.11 Types of Projections .................................................. 1-49

2.10.1 Parametric Equation of Parabola .............................. 2-21

1.11.1 Parallel Projections ................................................... 1-49

2.10.2 Parametric Equation of Parabola by Recursive

1.11.2 Perspective Projections ............................................. 1-50 Method ..................................................................... 2-21

1.12 Transformations for Orthographic Projections ........... 1-50 2.10.3 Parametric Equation of Inclined Parabola ................. 2-21

1.13 Transformations for Isometric Projections ................ 1-52 2.11 Hyperbolas ................................................................ 2-22

2.12 Synthetic Curves ....................................................... 2-22

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 2 Table of Contents

2.12.1 Continuity Conditions ................................................ 2-22 One Dimensional Problem : Finite element modeling,

2.12.2 Approaches of Generation of Synthetic Curves ......... 2-24 coordinate and linear shape function, Assembly of Global

2.13 Types of Synthetic Curves ......................................... 2-24 Stiffness Matrix and Load Vector, Properties of Stiffness Matrix,

Finite Element Equations, Temperature Effects. [Theory +

2.14 Hermite Cubic Splines .............................................. 2-24

Numerical – composite shaft, spring elements in series and

2.15 Bezier Curves ........................................................... 2-33

parallel]

2.16 B-Spline Curves ....................................................... 2-37 Trusses : Introduction, 2D Trusses, Assembly of Global

2.17 Comparison between Hermite Cubic Spline Stiffness Matrix [Numerical limited to 4 4 matrix]

Curve, Bezier Curve and B-Spline Curve .................. 2-38

3.1 Introduction to Finite Element Analysis ........................ 3-2

2.18 Introduction to Modeling ............................................ 2-39

3.2 Boundary Conditions and Types of Boundary

2.19 Geometric Modeling .................................................. 2-39 Conditions ................................................................... 3-3

2.20 Methods of Geometric Modeling ................................ 2-39 3.3 Approximate Numerical Methods ................................. 3-4

2.21 Wire-Frame Modeling ................................................ 2-39 3.3.1 Rayleigh-Ritz Method ................................................. 3-4

2.21.1 Types of Wire-Frame Modeling ................................ 2-40 3.3.2 Galerkin Method ......................................................... 3-7

2.21.2 Advantages of Wire-Frame Modeling ....................... 2-40 3.4 Forces, Displacements, Strains and Stresses

2.21.3 Limitations of Wire-Frame Modeling ......................... 2-40 in Body ...................................................................... 3-10

ge

2.22 Surface Modeling ...................................................... 2-40 3.5 Relationships between Forces, Displacements,

2.22.1 Advantages of Surface Modeling .............................. 2-41 and Stresses ............................................................ 3-11

2.22.2 Limitations of Surface Modeling ................................ 2-41 3.5.1 Strain - Displacement Relationship ........................... 3-12

io eld 3.5.2 Stress - Strain Relationship ...................................... 3-14

2.22.3 Representation of Surfaces ...................................... 2-42

2.23 Types of Surface Entities........................................... 2-43 3.5.3 Stress - Strain Relationship for One-Dimensional

2.23.1 Analytic Surfaces ...................................................... 2-43 Problems .................................................................. 3-16

ic ow

2.23.2 Synthetic Surfaces .................................................... 2-44 3.5.4 Stress - Strain Relationship for Two-Dimensional

Problems .................................................................. 3-16

2.24 Solid Modeling ........................................................... 2-45

3.6 Coordinate Systems Used in FEA ............................. 3-18

n

2.24.1 Comparison between Wire Frame Modeling

and Solid Modeling ................................................... 2-46 3.7 Natural Coordinates and Shape Functions for

bl kn

Two Noded One-Dimensional Element ...................... 3-19

2.24.2 Geometry and Topology ........................................... 2-46

3.7.1 Relationship between Local and Natural

2.24.3 Advantages of Solid Modeling .................................. 2-47

at

Coordinates ............................................................. 3-19

Pu ch

2.24.4 Limitations of Solid Modeling .................................... 2-47

3.7.2 Shape Functions .................................................... 3-19

2.24.5 Solid Entities (Primitives) .......................................... 2-47

3.7.3 Property at any Point within Element ........................ 3-20

2.24.6 Mathematical Representation of Solid Entities

Te

3.8 Basic Steps in Finite Element Analysis...................... 3-23

(Primitives) and their Surfaces .................................. 2-48

3.9 Analysis of Steps in Finite Element Method............... 3-26

2.25 Methods of Solid Modeling ........................................ 2-49

3.9.1 Discretization (Meshing) of Body .............................. 3-26

2.25.1 Constructive Solid Geometry (CSG or C-REP) ......... 2-49

3.9.2 Types of Finite Elements .......................................... 3-26

2.25.2 Boundary Representation (B-REP) ............................ 2-51

3.9.3 Element Load Vector for One Dimensional

2.25.3 Sweeping ................................................................. 2-55

Element .................................................................... 3-29

2.25.4 Parametric (Analytical) Solid Modeling .................... 2-56

3.9.4 Global Load Vector ................................................... 3-31

2.25.5 Primitive Instancing .................................................. 2-56

3.9.5 Global Nodal Displacement Vector ........................... 3-31

2.25.6 Feature Based Modeling............................................ 2-57

3.9.6 Node Numbering and Element Connectivity ............. 3-32

2.25.7 Constraint Based Modeling ....................................... 2-61

3.9.7 Element Stiffness Matrix (Element Force-Nodal

2.25.8 Comparison of Constructive Solid Geometry

Displacement Relationship) for 1-D Element by

(C-Rep) Approach and Boundary Representation

Direct Stiffness Method ........................................... 3-32

(B-Rep) Approach .................................................... 2-62

3.9.8 Global Stiffness Matrix .............................................. 3-34

2.26 Solid Manipulations ................................................... 2-63

3.9.9 Global Force-Nodal Displacement Relationship

2.27 Applications of Solid Modeling ................................... 2-64

for One Dimensional Body ........................................ 3-34

UNIT III 3.9.10 Properties of Global Stiffness Matrix ........................ 3-39

3.9.11 Methods of Solving Force - Stiffness - Nodal

Chapter 3 : Finite Element Analysis 3-1 to 3-180 Displacement Equations (Treatment of Specified

Boundary Conditions) ............................................... 3-39

Syllabus : Introduction : Brief History of FEM, Finite Element

3.9.12 Element Strain - Nodal Displacement Relationship

Terminology (nodes, elements, domain, continuum, Degrees of

for 1-D Element ........................................................ 3-41

freedom, loads and constraints), General FEM procedure,

3.9.13 Element Stress - Nodal Displacement Relationship

Applications of FEM in various fields, meshing, p and h

for 1-D Element ........................................................ 3-42

formulation, Advantages and disadvantages of FEM [Only theory]

3.10 Temperature Effects ................................................ 3-120

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 3 Table of Contents

3.11 Quadratic Shape Functions ..................................... 3-135 4.10 Applications of CNC Machine Tools .......................... 4-16

3.11.1 Relationship between Local and Natural 4.11 Systems of NC/CNC Machine Tools .......................... 4-16

Coordinates ............................................................ 3-135 4.11.1 Structure .................................................................. 4-17

3.11.2 Quadratic Shape Functions .................................... 3-135 4.11.2 Spindle and Feed Drives .......................................... 4-17

3.11.3 Properly at any Point Within Element ..................... 3-136 4.11.3 Actuator Support Bearings ....................................... 4-17

3.12 Problem Solving by Finite Element Analysis 4.11.4 Feedback Systems ................................................... 4-18

Packages ................................................................ 3-137 4.11.5 Automatic Tool Changers ......................................... 4-18

3.13 Introduction to Two-Dimensional Trusses ................ 3-138 4.11.6 Tooling ..................................................................... 4-19

3.14 Coordinate Systems and Transformation Matrix ...... 3-138 4.11.7 Material Handling Systems ....................................... 4-19

3.14.1 Relation between Local Coordinates and Global 4.11.8 Pallet Changer Systems ........................................... 4-20

Coordinates ........................................................... 3-139

4.11.9 Lubrication System ................................................... 4-21

3.14.2 Relation between Local Nodal Displacement and

4.11.10 Coolant System ........................................................ 4-21

Global Nodal Displacement .................................... 3-140

4.12 DNC Machine Tools .................................................. 4-21

3.14.3 Relation between local load vector and global

load vector .............................................................. 3-140 4.12.1 Basic Elements of DNC Machine Tool System ......... 4-22

4.12.2 Functions of DNC Machine Tool System .................. 4-22

3.15 Element Stiffness Matrix in Global Coordinate

ge

System ................................................................... 3-140 4.12.3 Advantages of DNC Machine Tools .......................... 4-22

4.12.4 Limitations of DNC Machine Tools ........................... 4-23

3.16 Element Stress Calculations ................................... 3-142

4.13 Adaptive Control (AC) System ................................... 4-23

3.17 Mesh Refinement .................................................... 3-179

io eld 4.13.1 Advantages of Adaptive Control (AC) Systems ........ 4-23

UNIT IV 4.13.2 Types of Adaptive Control (AC) Systems ................. 4-23

4.14 Introduction to Part Programming .............................. 4-24

Chapter 4 : Computer Aided Manufacturing 4-1 to 4-127

4.14.1 Steps in Part Programming ....................................... 4-24

ic ow

Syllabus : Introduction to Computer Aided Manufacturing 4.15 Coordinate Systems used in Manual Part

(CAM), Coordinate system, Working principal of CNC Lathe, Programming............................................................. 4-25

n

Turning Centers, Milling Machine, Steps in developing CNC part 4.16 Format of Manual Part Programming ........................ 4-25

bl kn

program, Tool and geometric compensations, subroutine and Do 4.16.1 Types of Formats of Block in Manual Part

loop using canned cycle. [Only theory – 2 hrs] Programming ............................................................ 4-26

CNC Lathe part programming (FANUC) : Linear and circular 4.17 Manual Part Programming for Turning

at

Pu ch

Applications : Turning Center .................................... 4-26

interpolation, Canned cycles for facing, threading, grooving, etc.

[Theory + Program] 4.17.1 Coordinate System (Axes Designation Conventions)

Used in Turing Center .............................................. 4-26

CNC Milling part programming (FANUC) : Linear and circular

Te

4.17.2 Zero Points and Reference Points ............................ 4-27

interpolation, Pocketing, contouring and drilling cycles. [Theory +

4.17.3 Cutting Process Parameter Selection for Turning

Program]

Applications .............................................................. 4-28

4.1 NC Machine Tools ....................................................... 4-2 4.17.4 G-Codes (Preparatory Functions) used in

4.1.1 Elements of NC Machine Tool System ....................... 4-2 Turning Center ......................................................... 4-29

4.2 Classification of NC (Numerical Control) Machine 4.17.5 M Codes (Miscellaneous Functions) used in

Tool Systems .............................................................. 4-3 Turning Center ......................................................... 4-35

4.2.1 According to Control Loop Feedback Systems ........... 4-4 4.17.6 Programming Types used in Turing Applications ...... 4-36

4.2.2 According to Type of Tool Motion Control ................... 4-4 4.17.7 Subprogram (Subroutines) ....................................... 4-37

4.2.3 According to Programming Methods ........................... 4-6 4.17.8 Macros ..................................................................... 4-37

4.3 Advantages of NC Machine Tools ............................... 4-8 4.17.9 Canned Cycles ......................................................... 4-37

4.4 Limitations of NC Machine Tools ................................. 4-8 4.17.10 General Structure of Turning Part Program .............. 4-39

4.5 Applications of NC Machine Tools ............................... 4-9 4.18 Manual Part Programming for Milling Applications

4.6 CNC Machine Tools .................................................... 4-9 Machining Center ...................................................... 4-76

4.6.1 Elements of CNC Machine Tool System ..................... 4-9 4.18.1 Coordinate System (Axis Designation Conventions

4.7 Classification of CNC (Computer Numerical Control) used) in CNC Machining Center ............................... 4-76

Machine Tool Systems .............................................. 4-10 4.18.2 Zero Points and Reference Points ............................ 4-76

4.7.1 According to Control Loop Feedback Systems ......... 4-11 4.18.3 Cutting Process Parameter Selection for Milling

4.7.2 According to Type of Tool Motion Control ................. 4-11 Applications .............................................................. 4-77

4.7.3 According to Programming Methods ......................... 4-13 4.18.4 G-Codes (Preparatory Functions) used

in Machining Center .................................................. 4-79

4.7.4 According to Type of Controllers .............................. 4-14

4.18.5 M-Codes (Common Miscellaneous Functions)

4.7.5 According to Axis and Type of Operations ................ 4-15

used in Machining Center ......................................... 4-88

4.8 Advantages (Features) of CNC Machine Tools .......... 4-15

4.18.6 General Structure of Milling Part Program ................ 4-89

4.9 Limitations of CNC Machine Tools ............................ 4-16

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 4 Table of Contents

UNIT V UNIT VI

Chapter 5 : Advanced Manufacturing Method 5-1 to 5-27 Chapter 6 : Automation 6-1 to 6-57

Syllabus : Product Life Cycle : Introduction, Need,

Components/Elements of PLM, Collaborative Engineering. [Only Syllabus : Automation : Introduction, Automation Strategies,

theory] Types of Automation - Hard and Soft Automation, Flexible

Rapid Prototyping : Introduction, Classification of RP Manufacturing System – Types, Advantages, Limitations, AGVs

Processes (SLA, LOM, SLS, FDM, 3D printing), Working and AS/RS [Only theory]

Principle, Features, Models & Specification of Process, Group Technology : Introduction, Coding Methods, Concepts of

Application, Advantages and Disadvantages, Rapid Tooling and Computer Integrated Manufacturing (CIM) and Computer Aided

STL format, Concept of 4D Rapid Prototyping. [Only theory] Process Planning (CAPP), Variant & Generative Methods of

CAPP, advantages of CAPP. [Only theory]

5.1 Introduction to Rapid Prototyping................................. 5-2

Robotics : RIA Definition of Robot, Laws of Robotics,

5.2 Categories of Manufacturing Processes ...................... 5-2

Classification of Robots, Robot Anatomy, Point to Point and

5.3 Basic Steps in Rapid Prototyping Process ................... 5-2 Continuous Path Robotic Systems, Joints, End Effectors,

5.4 Benefits (Advantages) of Rapid Prototyping ................ 5-5 Grippers - Mechanical, Magnetic and Pneumatic, Applications.

ge

5.4.1 Direct Benefits of Rapid Prototyping ........................... 5-5 [Only theory]

5.4.2 Indirect Benefits of Rapid Prototyping ......................... 5-5

6.1 Introduction to Automation........................................... 6-2

5.5 Limitations of Rapid Prototyping .................................. 5-5

io eld

5.6 Classification of Rapid Prototyping Systems 6.1.1 Need for Automation .................................................. 6-2

(Techniques) .............................................................. 5-5 6.2 Types of Automation ................................................... 6-3

5.6.1 Liquid-Based Rapid Prototyping Systems ................... 5-6 6.2.1 Comparison of Types of Automation Systems ............. 6-4

ic ow

5.6.2 Solid-Based Rapid Prototyping Systems .................... 5-6

6.3 Advantages and Limitations of Automation.................. 6-4

5.6.3 Powder-Based Rapid Prototyping Systems ................ 5-6

6.3.1 Advantages of Automation ......................................... 6-4

n

5.7 Liquid Based Rapid Prototyping Systems .................... 5-6

6.3.2 Limitations of Automation ........................................... 6-5

bl kn

5.7.1 Stereolithography (SLA) Process ................................ 5-6

5.8 Solid Based Rapid Prototyping Systems ..................... 5-8 6.4 Migration to Automation............................................... 6-6

at

5.8.1 Fused Deposition Modelling (FDM).............................. 5-8 6.4.1 Advantages of Migration to Automation ...................... 6-7

Pu ch

5.8.2 Laminated Object Manufacturing (LOM) .................... 5-11 6.5 Strategies in Automation ............................................. 6-7

5.9 Powder Based Rapid Prototyping Systems ............... 5-13

6.6 Stages of Automation .................................................. 6-8

Te

5.9.1 Selective Laser Sintering (SLS) ................................. 5-13

6.7 Machining Centers ..................................................... 6-9

5.9.2 Three Dimensional (3D) Printing................................ 5-16

6.8 Flexible Manufacturing Systems (FMS) ..................... 6-10

5.9.3 Comparison between Stereolithography (SLA)

Process, Selective Laser Sintering (SLS) 6.8.1 Elements (Components) of Flexible Manufacturing

Process and 3D-Printing Process ............................. 5-18 System (FMS) ........................................................... 6-10

5.10 Applications of Rapid Prototyping .............................. 5-19 6.9 Types of Flexible Manufacturing Systems ................. 6-11

5.11 Rapid Tooling ........................................................... 5-21

6.9.1 Classification of FMS Based on Number

5.11.1 Classification of Rapid Tooling ................................ 5-21 of Machines .............................................................. 6-12

5.12 STL Format .............................................................. 5-22

6.9.2 Classification of FMS Based on Flexibility

5.12.1 Advantages of STL File Format ................................ 5-22

of System ................................................................. 6-13

5.12.2 Disadvantages of STL File Format ........................... 5-23

6.9.3 Classification of FMS Based on Type of Layout ....... 6-13

5.12.3 Problems of STL File Format .................................... 5-23

5.13 4D Rapid Prototyping (4D Printing) ............................ 5-23 6.10 Advantages, Limitations and Applications of

Flexible Manufacturing Systems ............................... 6-14

5.14 Introduction to Product Lifecycle Management

(PLM) ........................................................................ 5-24 6.10.1 Advantages of Flexible Manufacturing Systems ....... 6-14

5.14.1 Need of Product Lifecycle Management ................... 5-24 6.10.2 Limitations of Flexible Manufacturing Systems ......... 6-15

5.14.2 Product Lifecycle Management ................................ 5-25 6.10.3 Applications of Flexible Manufacturing Systems ....... 6-15

5.14.3 Phases (Stages) of Product Lifecycle 6.11 Computer Integrated Manufacturing (CIM) ................ 6-15

Management (PLM) .................................................. 5-25 6.11.1 Four Islands of Automation of CIM

(Elements of CIM) .................................................... 6-16

5.14.4 Benefits of Using Product Lifecycle Management ..... 5-26

6.11.2 Computer Hardware Layout of CIM .......................... 6-17

5.15 Elements (Components) of PLM................................ 5-26

6.11.3 Benefits of CIM ......................................................... 6-18

5.16 Collaborative Engineering.......................................... 5-27

6.12 Automated Guided VEHICLES (AGV) ....................... 6-19

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 5 Table of Contents

6.12.1 Types of Automated Guided Vehicles (AGVs) .......... 6-19 6.23.3 Design of Grippers ................................................... 6-38

6.12.2 Advantages (Benefits) of Automated Guided 6.24 Manipulators .............................................................. 6-41

Vehicles ................................................................... 6-20

6.25 Actuators (Drives) for Robots ................................... 6-41

6.12.3 Limitations of Automated Guided Vehicles ............... 6-20

6.25.1 Mechanical Actuators ............................................... 6-42

6.13 Automated Storage and Retrieval System

6.25.2 Hydraulic Actuators .................................................. 6-44

(AS/RS) ..................................................................... 6-20

6.25.3 Pneumatic Actuators ................................................ 6-44

6.13.1 Components of Automated Storage and Retrieval

System (AS/RS) ....................................................... 6-21 6.25.4 Electric Actuators ..................................................... 6-44

6.13.2 Advantages of Automated Storage and Retrieval 6.25.5 Comparison of Electric, Hydraulic and Pneumatic

System ..................................................................... 6-22 Actuators ................................................................. 6-44

6.13.3 Limitations of Automated Storage and Retrieval 6.26 Robot Controllers ...................................................... 6-46

System ..................................................................... 6-22 6.27 Robot Sensors .......................................................... 6-46

6.14 Group Technology .................................................... 6-22 6.27.1 Types of Sensors ...................................................... 6-47

6.14.1 Part Family ............................................................... 6-23

ge

6.28 Types of Robots ....................................................... 6-48

6.14.2 Machine Cells ........................................................... 6-24 6.28.1 Non-Servo-Controlled Robots ................................... 6-48

6.15 Methods of Grouping Parts Into Part Families ........... 6-25 6.28.2 Servo-Controlled Robots .......................................... 6-49

io eld

6.15.1 Visual Inspection ...................................................... 6-25 6.29 Types of Basic Configurations of Robot..................... 6-49

6.15.2 Composite Part Method ............................................ 6-25 6.29.1 Cartesian Configuration Robots ................................ 6-50

ic ow

6.15.3 Production Flow Analysis (PFA) ................................ 6-25 6.29.2 Cylindrical Configuration Robots............................... 6-50

6.15.4 Parts Classification and Coding ................................. 6-26 6.29.3 Spherical (Polar) Configuration Robots..................... 6-50

n

6.16 Advantages and Limitations of Group 6.29.4 Articulated (Jointed-Arm) Configuration Robots ........ 6-51

bl kn

Technology ................................................................ 6-27

6.30 Suitability of Robots................................................... 6-51

6.16.1 Advantages of Group Technology ............................ 6-27

6.31 Applications of Robots in Manufacturing Industry ...... 6-52

at

Pu ch

6.16.2 Limitations of Group Technology .............................. 6-28

6.31.1 Machine Loading and Unloading .............................. 6-52

6.17 Computer Aided Process Planning (CAPP) ............... 6-28

6.31.2 Material Handling ..................................................... 6-52

Te

6.17.1 Types of Computer Aided Process Planning

6.31.3 Welding ................................................................... 6-53

(CAPP) ..................................................................... 6-28

6.31.4 Spray Painting .......................................................... 6-53

6.17.2 Advantages of Computer Aided Process Planning ... 6-29

6.31.5 Machining Operations ............................................... 6-53

6.18 Introduction to Industrial Robot)................................. 6-30

6.31.6 Assembly ................................................................. 6-53

6.18.1 RIA Definition of Robot ............................................. 6-30

6.31.7 Inspection ................................................................. 6-53

6.18.2 Generations of Robots .............................................. 6-30

6.32 Applications of Robots in Other Areas ....................... 6-54

6.18.3 Advantages of Robots .............................................. 6-30

6.33 Methods of Robot Programming ............................... 6-54

6.18.4 Limitations of Robots ................................................ 6-30

6.33.1 Mechanical Programming ......................................... 6-54

6.19 Basic Components (Anatomy) of Robot..................... 6-30

6.33.2 Lead through (Teach through) Programming ............ 6-54

6.20 Types of Robot Joints ............................................... 6-32

6.33.3 Textual Language Programming ............................... 6-55

6.21 Degrees of Freedom of Robot ................................... 6-32

6.33.4 Textual Robot Programming Languages ................... 6-55

6.21.1 Degrees of Freedom of Arm ..................................... 6-33

6.34 Parameters in Robot Specifications and Selection

6.21.2 Degrees of Freedom of End Effector (Wrist).............. 6-33

of Robot ................................................................... 6-56

6.22 End Effectors of Robot ............................................. 6-33

6.34.1 Typical Specifications of Robot ................................ 6-57

6.23 Grippers .................................................................... 6-34

Solved University Question Papers of

6.23.1 Types of Grippers ..................................................... 6-34 Aug. 18 (In Sem) and Dec. 2018(End Sem)

6.23.2 Factors to be considered in Selection of Grippers .......................................................................A-1 to A-28

(End Effectors) .......................................................... 6-37

Powered by TCPDF (www.tcpdf.org)

1

UNIT I

Chapter

Computer Graphics

SYLLABUS

ge

Transformations (2D & 3D) : Introduction, Formulation, Translation, Shear, Rotation,

io eld

Scaling and Reflection, Homogeneous Representation, Concatenated Transformation,

Mapping of Geometric Models, Inverse Transformations, Introduction to 3D Transformation

ic ow

(Theory + Numerical Treatment only for 2D – Max 3 Vertices)

Projections : Orthographic, Isometric, Perspective Projections (Only Theory)

n

bl kn

at

TOPICS

Pu ch

Te

1.8 Mapping of Geometric Models

1.1 Introduction to CAD/CAM

1.9 Two-Dimensional Geometric Mappings

1.2 Computer Graphics

1.10 Projections of Geometric Models

1.3 Two-Dimensional Geometric Transformations

1.11 Types of Projections

1.4 Two-Dimensional Geometric Transformations Using

Homogenous Coordinates 1.12 Transformations for Orthographic Projections

1.5 Two-Dimensional Inverse Transformations 1.13 Transformations for Isometric Projections

1.6 Three-Dimensional Geometric Transformations

1.7 Coordinate Systems

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-2 Computer Graphics

1.1 INTRODUCTION TO CAD/CAM (iii) CNC machining ; (iv) Computational fluid dynamics;

(v) Simulation ; (vi) Animation, etc.

CAD/CAM : The entry of computers in the fields of design 1.3 TWO-DIMENSIONAL GEOMETRIC

and manufacturing has led to the emergence of two new areas

TRANSFORMATIONS

known as :

Geometric Transformations :

1. Computer-Aided Design (CAD); and

Geometric transformations change the orientation, size, and

2. Computer-Aided Manufacturing (CAM). shape of the objects in the database as well as on the graphics

image, as shown in Fig. 1.3.1. This alter the coordinate

1. Computer-Aided Design (CAD) : Computer-Aided Design

descriptions of objects.

(CAD) can be defined as the use of computer systems to

assist in the creation, modification, synthesis, analysis,

and/or optimization of a design.

2. Computer-Aided Manufacturing (CAM) : Computer-

Aided Manufacturing (CAM) can be defined as the use of

ge

computer systems to plan, manage, and control the

manufacturing operations through the direct or indirect

io eld

computer interface with the manufacturing machine.

Integration of Design and Manufacturing : Traditionally,

the design and manufacturing have been treated as two

ic ow

distinct and separate activities. However, the CAD/CAM has

led to the greater integration of design and manufacturing.

n

Fig. 1.3.1 : Geometric Transformation

1.2 COMPUTER GRAPHICS

bl kn

Use of Geometric Transformations :

(SPPU - Dec. 13) The geometric transformations are used for the following

at

Pu ch

purposes :

.University Question.

Q. What is computer graphics ? (Dec. 13) (i) In a construction of a model;

(ii) In editing the model using the commands like : translate,

Te

Computer Graphics : Computer graphics deals with the rotate, zoom, mirror, array, etc;

generation, transformation and modification of a two (iii) For obtaining orthographic, isometric and prospective views

dimensional or a three dimensional model of an object using of the model;

a graphics software or an application software or both. (iv) To view the model from different positions; and

(v) In animations.

Generation of Model : The user can generate a model either

Formulation :

with the help of a programming or by using the user friendly

Any two dimensional graphic element (or object) is

application software (like : CATIA, PTC Creo, SOLID constructed out of points. Hence, transformation of any two

works, etc). The latest trend in computer graphics is to use dimensional graphic element essentially means the

the specialized application software rather than using the transformation of all the points of geometric entity.

programming, which is time consuming.

Applications of Computer Graphics :

1. Different fields of application of computer graphics :

(i) Science ; (ii) Engineering,

(iii) Medicine ; (iv) Education;

(v) Entertainment ; (vi) Advertising;

(vii) Business ; (viii) Art, etc.

2. Different areas of applications of computer graphics in

mechanical engineering :

(i) Solid modeling ; (ii) Finite element analysis;

Fig. 1.3.2 : Formulation

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-3 Computer Graphics

Matrix representation of point P (x, y) : Translation matrix : Consider a point P ( x, y ) is translated

{P} = { yx } …(1.3.1)

by a distances tx in X-direction and ty in Y-direction to a new

position P ( x, y ). Therefore,

Matrix representation of transformed point P (x, y) :

x = x + tx

x

{P} = { } y

and y = y + ty

...(1.3.3)

x

{P} = [TR] { } y …(1.3.2)

The above Equations (1.3.3) can be written in matrix form as,

{ xy } + tt

where, [TR] = transformation matrix.

The transformation of point results in the change in the

{ xy } = x

y

...(1.3.4)

position of point in the database as well as on the graphics or { P} = { P } + { T } ...(1.3.5)

image.

Basic Geometric Transformations :

where, { P } = { yx } = original position of the point

{ yx } = new position of the point

ge

The basic geometric transformations used in modelling are : { P } =

t

{ T } = x = translation matrix

ty

io eld

1.3.2 Rotation :

ic ow

n

bl kn

at

Pu ch

Te

The different basic geometric transformations are discussed in

subsequent sections. (a) Rotation of Point

1.3.1 Translation :

(b) Rotation of Line

Fig. 1.3.4 : Rotation of Graphics Element

Rotation : In rotation, the graphics element (or object) is

Fig. 1.3.3 : Translation of Graphics Element

rotated about the origin (Z-axis) by an angle , as shown in

Translation : A translation involves moving the graphics Fig. 1.3.4. For a positive angle, this rotation is in the

element (or object) from one location to another, as shown in counterclockwise direction. The rotation of any graphics

Fig. 1.3.3. The translation of any graphics element is nothing element is the rotation of all the points of that element.

but the translation of all the points of that element.

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-4 Computer Graphics

Rotation Matrix : Consider a point P (x, y) is rotated about

the origin (Z-axis) by an angle ‘’ in counterclockwise

where, [S] = [ S0 S0 ] = scaling matrix

x

y

direction to a new position P (x, y), as shown in

Fig. 1.3.4(a).

Let, r = constant distance of the point from the origin

= original angular position of the point from

the horizontal

From Fig. 1.3.4(a),

x = r cos

...(1.3.6)

and y = r sin

x = r cos ( + )

ge

or x = r cos cos – r sin sin ...(1.3.7)

Fig. 1.3.5 : Scaling of Graphics Element

and y = r sin ( + ) = r sin cos + r cos sin

io eld If the scaling factors Sx and Sy are less than 1, the size of the

or y = r cos sin + r sin cos ...(1.3.8)

element (or object) is reduced and it moves closer to the

Substituting Equations (1.3.6) in Equations (1.3.7) and origin. On the other hand, if the scaling factors Sx and Sy are

(1.3.8),we get,

ic ow

greater than 1, the size of the element (or object) is enlarged

x = x cos – y sin and it moves away from the origin.

n

...(1.3.9) Uniform scaling and differential scaling : If Sx = Sy, the

bl kn

and y = x sin + y cos

scaling is known as uniform scaling, whereas if Sx Sy, the

– sin

{ xy } [ cos ] { xy } scaling is known as differential scaling. By using the

at

= ...(1.3.10)

sin cos

Pu ch

differential scaling, the circle can be converted to ellipse and

or { P } = [ R ] { P } ...(1.3.11) vice versa.

Te

– sin 1.3.4 Reflection :

where, [ R ] = [ cos

sin cos ] = rotation matrix

Reflection : A reflection is the transformation that produces

1.3.3 Scaling :

a mirror image of the graphics element (or object) about any

Scaling : A scaling alters the size of the graphics element (or axis or line. The reflection of any graphics element is the

object). It is used to enlarge or reduce the size of the element, reflection of all the points of that element.

as shown in Fig. 1.3.5. Various commonly used reflections :

The scaling of any graphics element is the scaling of all the

(i) Reflection about X-axis

points of that element.

(ii) Reflection about Y-axis

Scaling Matrix :

(iii) Reflection about origin

Let, Sx = Scaling factors in X-direction

(iv) Reflection about line y = x

Sy = Scaling factors in Y-direction

(v) Reflection about line y = – x

x = x Sx ...(1.3.12)

and y = y Sy (i) Reflection about X-axis :

The above Equation (1.3.12) can be written in matrix form as, Consider a point P (x, y) is reflected about the X-axis to a

new position P (x, y) , as shown in Fig. 1.3.6. Then,

{ xy } = [ S0 S0 ] { xy }

x

y

...(1.3.13) x = x ...(1.3.15)

or { P } = { S } { P } ...(1.3.14) and y = –y

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-5 Computer Graphics

= [ 01 – 01 ] { xy } ...(1.3.16) or { P } = [ My ] { P } ...(1.3.20)

where,

or { P } = [ Mx ] { P } ...(1.3.17)

where, [ My ] = [ – 01 01 ] = reflection matrix about Y-axis

[ Mx ] = [ 01 – 01 ] = reflection matrix about X-axis (iii) Reflection about origin :

ge

io eld

Fig. 1.3.8 : Reflection About Origin

ic ow

Consider a point P (x, y) is reflected about the origin to a new

n

position P ( x, y ), as shown in Fig. 1.3.8. Then,

bl kn

x = –x ...(1.3.21)

and y = –y

at

Pu ch

Fig. 1.3.6 : Reflection About X-axis

(ii) Reflection about Y-axis : { xy } = [ – 01 – 01 ] { xy } ...(1.3.22)

Te

or { P } = [ Mo ] { P } ...(1.3.23)

where,

[ Mo ] = [ – 01 – 01 ] = reflection matrix about origin

(iv) Reflection about line y = x :

Consider a point P (x, y) is reflected about the line y = x to a

new position P (x, y), as shown in Fig. 1.3.9. Then,

x = y

...(1.3.24)

and y = x

Fig. 1.3.7 : Reflection About Y-axis

Consider a point P ( x, y ) is reflected about the Y-axis to a

new position P ( x, y ), as shown in Fig. 1.3.7. Then,

x = –x

…(1.3.18)

and y = y

{ yx } = [ – 01 01 ] { xy } ...(1.3.19)

Fig. 1.3.9 : Reflection About Line y = x

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-6 Computer Graphics

{ xy } = [ 10 10 ] { xy } ...(1.3.25) where, Shx = shear parameter

or { P } = [ Myx ] + { P } ...(1.3.26) { xy } = [ 10 Sh1 ] { xy }

x

...(1.3.31)

where, [ Myx ] = [ 01 10 ] = reflection matrix about line y = x or { P } = [ Shx ] { P } ...(1.3.32)

where,

(v) Reflection about line y = – x :

Consider a point P (x, y) is reflected about the line y = – x to [ Shx ] = [ 10 Sh1 ] = X-direction shear matrix

x

a new position P (x, y), as shown in Fig. 1.3.10. Then,

x = –y

...(1.3.27)

and y = –x

x

{ } y

= [ – 01 – 01 ] { xy } ...(1.3.28)

ge

or { P } = [ My– x ] { P } ...(1.3.29)

where,

io eld

[ My – x ] = [ – 01 – 01 ] = reflection matrix about line y = – x (a) Before Shear (b) After Shear

Fig. 1.3.11 : X-direction Shear of Graphics Element

(ii) Y-direction shear :

ic ow

n

bl kn

at

Pu ch

Te

Fig. 1.3.10 : Reflection About Line y = – x

(a) Before Shear (b) After Shear

1.3.5 Shear : Fig. 1.3.12 : Y-Direction Shear of Graphics Element

Consider a point P (x, y) is subjected to shear in Y-direction

Shear : A shear transformation distorts the shape of the

so as to occupy a new position P (x,y), as shown in Fig. 1.3.12.

graphics element (or object) such that the distorted shape

appears as if the object were composed of internal layers that Then, x = x

had been caused to slide over each other.

and y = y + Shy x …(1.3.33)

Types of shear :

where,

(i) X-direction shear

Shy = shear parameter

(ii) Y-direction shear

{ yx } = [ Sh1 10 ] { xy }

y

...(1.3.34)

(i) X-direction shear :

or { P } = [ Sh y ] { P } ...(1.3.35)

Consider a point P (x, y) is subjected to shear in X-direction

so as to occupy a new position P (x, y), as shown in Fig. 1.3.11. where, [ Sh y ] = [ Sh1 10 ] = Y-direction shear matrix

y

Then,

x = x + Shx y

and y = y ...(1.3.30)

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-7 Computer Graphics

1.3.6 Concatenated (Composite) 1. Translation matrix :

Transformations : tx

{T} = t =

y { 34 } ...(a)

(SPPU - Dec.12, May 16)

2. New position of line :

.University Questions.

{ P } = { P } + { T }

Q. What do you understand by concatenated

transformation ? (Dec. 12)

Q. Write a short note on : concatenated transformation,

{ P } = { 12 } + { 34 } = { 55 } ...(b)

with example. (May 16)

and { Q } = { Q } + { T }

Concatenated (Composite) Transformations :

A concatenated (composite) transformation is the

{ Q } = { 67 } + { 34 } = { 1010 } ...(c)

combination of two or more transformations such as : The coordinates of the end points for a translated line are :

translation, rotation, scaling, and reflection. A single P (5, 5) and Q (10, 10). This transformation is shown in

transformation matrix, known as concatenated

ge

Fig. P. 1.3.1. …Ans.

transformation matrix or composite transformation

matrix, can be obtained

io eld for such combination of

transformations. The combination of transformations into a

single composite transformation improves the performance of

graphics package.

ic ow

The concatenated transformation of any graphics element (or

object) is the concatenated transformation of all the points of

n

that element.

bl kn

Concatenated (Composite) Transformation Matrix :

Consider a point P (x, y) is to be reoriented to a new position

at

Pu ch

P (x, y) by first rotating and then scaling. This concatenated

transformation can be carried out as follows :

Te

{ P } = [ S ] [ R ] { P } ...(1.3.36)

or { P } = [ CT ] { P } ...(1.3.37)

where, [R] = rotation matrix

[S] = scaling matrix

The corresponding concatenated transformation matrix is Fig. P. 1.3.1

given by, Example 1.3.2 :

[ CT ] = [S] [R] ...(1.3.38) A line PQ with end points P (2, 3) and Q (7, 8) is to be

– sin

= [ S0 S0 ] [ cos

x

y sin cos ] rotated about origin by 30 in clockwise direction. Determine

the coordinates of the end points for a rotated line.

S cos – Sx sin

= x

or [ CT ]

Sy sin Sy cos ...(1.3.39) Solution :

Example 1.3.1 : Given : = – 30

A line PQ with end points P(2, 1) and Q(7, 6) is to be moved 1. Rotation matrix :

by 3 units in X-direction and 4 units in Y-direction. Determine

the coordinates of the end points for a translated line.

[R] = [ cossin – sin

cos ]

Solution : = [ cos (– 30)

sin (– 30)

– sin (– 30)

cos (– 30) ]

Given : tx = 3 ; ty = 4. or [R] = [ 0.866 0.5

– 0.5 0.866 ] ...(a)

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-8 Computer Graphics

2. New position of line :

0.866 0.5 2

{ Q } = { 100

10 }

...(c)

{ P } = [ R ] { P } = [ – 0.5 0.866 ]{ }

3 and

2 0

[

{ R } = [ S ] { R } = 0 0.5

20

] { 140 }

{ P } = { 3.232

1.598 }

...(b)

{ R } = { 4070 } ...(d)

0.866 0.5 7

and { Q } = [ R ] { Q } = [ – 0.5 0.866 ]{ }8 The coordinates of the vertices for a scaled triangle are :

P (40, 10), Q (100, 10), and R (40, 70). This

{ Q } = { 10.062

3.428 }

...(c)

transformation is shown in Fig. P. 1.3.3. …Ans.

The coordinates of the end points for a rotated line are :

P (3.232, 1.598) and Q (10.062, 3.428). This transformation

is shown in Fig. P. 1.3.2. …Ans.

ge

io eld

ic ow

n

bl kn

at

Pu ch

Te

Fig. P. 1.3.2

Example 1.3.3 :

Fig. P. 1.3.3

A triangle PQR with vertices P(20, 20), Q(50, 20),and

R(20, 140) is to be enlarged twice along X-direction and 1.4 TWO-DIMENSIONAL

compressed to half along Y-direction. Determine the GEOMETRIC

coordinates of the vertices for a scaled triangle. TRANSFORMATIONS USING

Solution : HOMOGENOUS COORDINATES

Given : Sx = 2 Sy = 0.5.

(SPPU - Dec. 13, Aug 15(In Sem), Dec. 15)

1. Scaling matrix :

.University Questions.

Sx 0 2 0 Q. Write a generalized 2D homogeneous transformation

[S] = [ 0 Sy ]=[ 0 0.5 ] ...(a)

matrix and its forms. (Dec. 13)

Q. Explain the importance of homogeneous

2. New position of triangle :

representation in computer graphics.

2 0

{ P } = [ S ] { P }= 0 0.5[ ] { 2020 } Q.

(Aug. 15(In Sem))

In concatenated transformation, why translation

matrix to be written in homogeneous form ? (Dec. 15)

{ P } = { 4010 } ...(b)

2 0

{ Q } = [ S ] { Q }= 0 0.5[ ] { 5020 }

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-9 Computer Graphics

Need of homogeneous co-ordinates : or { P } = [ Th ] { P } ...(1.4.4)

The geometric transformations like : rotation, scaling, where,

reflection, and shear are accomplished by matrix

x

multiplication; while translation is accomplished by matrix { P } = y = original position of the point

addition. This makes it inconvenient to concatenate 1

transformations involving translation. Hence, in order to x

{ P } = y = new position of the point

make it convenient for concatenation or composite 1

transformation, it is desirable to express all the geometric

1 0 tx

transformations, including translation, in the form of matrix [ Th ] = 0 1 ty = translation matrix

multiplications only. This can be effectively achieved by 0 0 1

representing the points by their homogenous coordinates.

1.4.2 Rotation :

Homogenous coordinates :

x cos – sin 0 x

In homogenous coordinates, a point in n-dimensional space is

y = sin cos 0 y ...(1.4.5)

1 0 1 1

ge

represented by (n + 1) coordinates. A two-dimensional point 0

P with cartesian coordinates (x, y) has the homogenous

or { P } = [ R ] { P } ...(1.4.6)

coordinates (xh, yh, h), where h is any non-zero scalar factor.

io eld where,

The homogeneous coordinates are expressed in terms of two-

dimensional cartesian coordinates as : cos – sin 0

[R] = sin cos 0 = rotation matrix

xh = h x and yh = h y 0 1

ic ow

..(1.4.1) 0

A convenient value of h is 1. Therefore, any two-dimensional 1.4.3 Scaling :

n

point P (x, y) is expressed in homogenous coordinate system x Sx 0 0

x

y 0 Sy 0 y

bl kn

as P (x, y, 1). Hence, the 2 2 transformation matrices in = ...(1.4.7)

1 0 0 1 1

two-dimensional cartesian coordinate system are modified to

at

3 3 transformation matrices in homogenous coordinate or { P } = [ S ] { P } ...(1.4.8)

Pu ch

system. where,

Generalized transformation matrix in homogenous

Sx 0 0

Te

coordinate system : [S] = 0 Sy 0 = scaling matrix

0 0 1

The generalized transformation matrix in homogeneous

coordinate system is of form :

1.4.4 Reflection :

a d 0

(i) Reflection about X-axis :

0

[Th] =

b e

…(1.4.2) x 01 0 0

x

1

y = –1 0 y ...(1.4.9)

c f 1 0 0 1 1

Basic two-dimensional geometric transformations in

or { P } = [ Mx ] { P } ...(1.4.10)

homogenous coordinate system :

where,

1. Translation 2. Rotation

1 0 0

3. Scaling 4. Reflection [ Mx ] = 0 – 1 0 = reflection matrix about X-axis

0 0 1

5. Shear

(ii) Reflection about Y-axis :

1.4.1 Translation : (SPPU - Dec. 15) x – 01 0 0

x

y = 1 0 y ...(1.4.11)

1 0 0 1 1

.University Question.

Q. Write translation matrix in homogeneous form. or { P } = [ My ] { P } ...(1.4.12)

(Dec. 15)

where,

x 1 0 tx x – 01 10 00

y 0 1 ty y [ y]

M = = reflection matrix about Y-axis

1

=

0 0 1 1

...(1.4.3) 0 0 1

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-10 Computer Graphics

(iii) Reflection about origin : 1.5 TWO-DIMENSIONAL INVERSE

x – 01 0 0

x TRANSFORMATIONS

y = –1 0 y ...(1.4.13)

1 0 0 1 1 (SPPU - Dec. 18)

or { P } = [ M0 ] { P } ...(1.4.14) .University Question.

Q. What is Inverse Transformation ? Discuss with

–1 0 0 suitable example. (Dec. 18)

where, [ Mo ] = 0 – 1 0 = reflection matrix about origin

0 0 1 Two Dimensional Inverse Transformations :

(iv) Reflection about line y = x : During the development of composite transformation matrix,

many a times, it is necessary to use the inverse of some basic

x 10 1 0

x

y = 0 0 y ...(1.4.15)

geometric transformation matrices.

1 0 0 1 1 Let,

or { P } = [ Myx ] { P } ...(1.4.16) x

{ P } = y = original position of point in

where, 1

ge

homogenous coordinate system

0 1 0

[ Myx ] = 1 0 0 = reflection matrix about line y = x x

0 0 1 { P } = y = new position of point in

io eld

1

(v) Reflection about line y = – x : homogenous coordinate system

x – 01 –1 0

x [ TR ] = transformation matrix

y 0 0

ic ow

= y ...(1.4.17)

0 0 1

–1

1 1 [ TR] = inverse transformation matrix

x x

n

or { P } = [ My – x ] { P } ...(1.4.18)

y = [TR] y

bl kn

1 1

where,

{ P } = [ TR ] { P } ...(1.5.1)

0 –1 0

at

[ My – x ] = – 1 0 0 = reflection matrix about line y = – x

Pu ch

–1 –1

[ TR ]

0 0 1 –1

{P} = [ TR ] [ TR ] { P }

[ TR ] { P } = {P}

1.4.5 Shear :

Te

–1

or { P } = [ TR ] { P } ...(1.5.2)

(i) X-direction shear : Various Inverse Transformation Matrices for Two

x 1 Shx 0 x Dimensional Geometric Transformations :

y = 0 1 0 y ...(1.4.19)

1 0 0 1 1

or { P } = [ Shx] { P } ...(1.4.20)

where,

1 Shx 0

[ Shx] = 0 1 0 = X-direction shear matrix

0 0 1

(ii) Y-direction shear :

x Sh1 0 0 x

y = y 1 0 y ...(1.4.21)

1 0 0 1 1 1.5.1 Inverse Translation :

or { P } = [ Shy] {P} ...(1.4.22) The inverse translation matrix is obtained by replacing the

translation parameters tx and ty with – tx and – ty respectively

where, in translation matrix.

Sh1 0 0 From Equation (1.4.4), the inverse translation matrix is

[ y] y 1 0 = Y-direction shear matrix

Sh = given by,

0 0 1

1 0 – tx

0 1 – ty

–1

[ Th ] = ...(1.5.3)

0 0 1

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-11 Computer Graphics

–1

Hence, {P} = [ Th ] { P } ...(1.5.4) 2. Coordinates of vertices of translated triangle :

1.5.2 Inverse Rotation :

{ P } = [ Th ] { P }

01 0 2

2 4

The inverse rotation matrix is obtained by replacing the or { P } = 1 4 1 = 5 ...(b)

0 0 1 1 1

rotation parameter with (– ) in rotation matrix .

From Equation (1.4.6), the inverse rotation matrix is given

{ Q } = [ Th ] { Q }

by , 01 0 2

4 6

or { Q } = 1 4 4 =8 ...(c)

cos (– ) – sin (– ) 0 0 0 1 1 1

sin (– ) cos (– ) 0

–1

[R] =

0 0 1 and { R } = [ Th ] { R }

cos sin 0 01 0 2

1 3

or [R]

–1

= – sin cos 0 ...(1.5.5) or { R } = 1 4 3 =7 ...(d)

0 0 1 0 0 1 1 1

–1 Hence, the coordinates of the vertices for a translated triangle

Hence, {P} = [R] { P } ...(1.5.6)

ge

are : P (4, 5), Q (6, 8), and R (3, 7). This transformation is

1.5.3 Inverse Scaling : shown in Fig. P. 1.5.1. …Ans.

io eld

The inverse matrix is obtained by replacing Sx and Sy with

1 / Sx and 1 / Sy respectively in scaling matrix.

From Equation (1.4.8), the inverse scaling matrix is given

ic ow

by,

1 / Sx 0 0

0 1 / Sy 0

–1

n

{S} = ...(1.5.7)

0 1

bl kn

0

–1

Hence, {P} = [S] { P } ...(1.5.8)

at

Pu ch

1.5.4 Inverse Reflection :

The inverse reflection matrix is same as the reflection matrix.

Te

Therefore,

–1

[ Mx ] = [ Mx ]

–1 Fig. P. 1.5.1

[ My ] = [ My ]

–1 Example 1.5.2 : (SPPU - Dec. 18, 6 Marks)

[ Mo ] = [ Mo ] ...(1.5.9)

–1

Derive the transformation matrix for rotating any point about

[ Myx ] = [ Myx ] Z-axis in X–Y plane. Determine the transformed coordinates

of point P (4,5) when rotated about Z-axis by 30 in clockwise

–1

and [ My – x ] = [ My – x ]

direction.

Example 1.5.1 :

Solution :

A triangle PQR with vertices P(2, 1), Q(4, 4), and R(1, 3) is to

Transformation matrix for rotation about Z – axis :

be translated by 2 units in X-direction and 4 units in

Y-direction. Using the homogenous coordinate system,

determine the coordinates of the vertices for a translated

triangle.

Solution :

Given : tx = 2 ty = 4.

1. Translation matrix :

1 0 tx

1 0 2

[ Th ] = 0 1 ty = 0 1 4 ...(a)

0 0 1 0 0 1

Fig. P. 1.5.2(a)

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-12 Computer Graphics

Consider a point P (x, y) is rotated about the origin (Z-axis) 5.964

or { P } = 2.33

by an angle ‘’ in counterclockwise direction to a new

position P (x, y), as shown in Fig. P. 1.5.2 (a).

Coordinates of transformed point are : P(5.964, 2.33)

Let, r = constant distance of the point from the origin

= original angular position of the point from ...Ans.

the horizontal This transformation is shown in Fig .P. 1.5.2 (b)

From Fig. P.1.5.2(a) ,

x = r cos

...(a)

and y = r sin

x = r cos ( + )

or x = r cos cos – r sin sin ...(b)

ge

and y = r sin ( + ) = r sin cos + r cos sin

or y = r cos sin + r sin cos ...(c)

io eld

Substituting Equations (a) in Equations (b) and (c), we get,

Fig. P. 1.5.2(b)

x = x cos – y sin

Example 1.5.3 : (SPPU - Dec. 17,6 Marks)

ic ow

...(d)

and y = x sin + y cos If a point P having coordinates (3, 3) is mirrored about X and

n

x cos – sin Y axis (i.e. about origin), determine new coordinates.

{ } [ ] { xy }

bl kn

= ...(e)

y sin cos Solution :

x cos – sin 0 x 1. Mirror about origin :

y sin 0 y

at

cos

Pu ch

= ...(f)

1 C 1 1 –1 0 0

[ Mxy ] = 0 –1 0

or { P } = [ R ] { P } ...(g)

1

Te

0 0

cos – sin 0

where, [ R ] = sin cos 0 = rotation matrix 2. New coordinates :

1

{ P } = [ Mxy ] { P }

Transformed coordinates :

–1 0 0

3 – 3

P (x, y) = (4, 5) ; = – 300 or { P } = 0 –1 0 3= – 3

1 1

cos – sin 0 0 0 1

[ R ] = sin cos 0

1 The new coordinates of point are : P (–3,–3). This

cos (–30) – sin 0 transformation is shown in Fig. P. 1.5.3.

= sin cos 0

1

0.866 0.5 0

or [ R ] = – 0.5 0.866 0

1

{P} = [ R ] {P}

x'

0.866 0.5 0

x

y' = –0.5 0.866 0 y

1 0 0 1 1

0.866 0.5 0

4

= –0.5 0.866 0 5

0 0 1 1 Fig. P. 1.5.3

Powered by TCPDF (www.tcpdf.org)

CAD/CAM & Automation (SPPU) 1-13 Computer Graphics

Example 1.5.4 : (SPPU - May 12,10 Marks) Rotation of line by – 90 about point P (5, 5) is achieved

A triangle with vertices A(8, 0), B(12, 0) and C(12, 3) has through following steps :

undergone reflection about line y = x. Find the concatenated (i) Translation :

transformation matrix and then find new coordinates of ABC Translate the line such that the rotation point P (5, 5)

using the transformation matrix. coincides with the origin. Hence, the translation distances are :

Solution : tx = – 5 and ty = – 5.

1 0 tx

1 0 –5

1. Mirror about line y = x : [Th] = 0 1 ty = 0 1 –5 ...(a)

0 0 1 0 0 1

0 1 0

[ Myx ] = 1 0 0 …(a)

(ii) Rotation :

0 0 1 Rotate the line about point P (5, 5) thought 90 in clockwise

2. New coordinates : direction. Hence, = – 90

{A} = [ Myx ] {A} cos – sin 0 cos (– 90) – sin (– 90) 0

[R] = sin cos 0 = sin (– 90) cos (– 90) 0

ge

0 1 0

8

0

0 0 1 0 0 1

{A} = 1 0 0 0 = 8

or

…(b)

– 01 1 0

io eld 0 0

1 or [R] = ...(b)

0 0 1 1

0 0 1

{B} = [ Myx ] {B}