Professional Documents

Culture Documents

NAAFCO Pharma Ltd. Bhaluka, Mymensingh Title: Performance Qualification Report For Hoonga-Blister Machine

Uploaded by

bejoy karimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NAAFCO Pharma Ltd. Bhaluka, Mymensingh Title: Performance Qualification Report For Hoonga-Blister Machine

Uploaded by

bejoy karimCopyright:

Available Formats

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 1 of 17

PERFORMANCE QUILIFICATION REPORT

OF

HOONGA BLISTER MACHINE

Manufacturer : Hoong-A, Korea

Model: HM V3

Serial No: M5M000440

Equipment ID No: NPL-PRO-BPM-01

Location :

APPROVALS

NPL Approvals Name Designatio Signature Date

n

Prepared By:

Checked By:

Reviewed By:

Approve by:

CONTENTS

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 2 of 17

SL.No.. Title PAGE

NUMBER

1. INTRODUCTION 3

2. OBJECTIVE 3

3. SCOPE 3

5. RESPONSIBILITY 3

6. DOCUMENT VERIFICATION 4

7. PERFORMANCE TEST USING DIFFERENT PRODUCTS 5-15

8 DEVIATION 16

9. FINAL SUMMARY REPORTING 16

10. CONCLUSION 16

11. APPROVAL 17

1.0 INTRODUCTION:

Qualification is the planning carrying out and recording of test on equipment of tests on

equipment and systems which will form a part of the validated process to demonstrate that

it will perform as intended.

Qualification of instrument /equipment is not a single, continuous process but instead

results from many discrete activities .Qualification requirements of established

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 3 of 17

equipment /instruments are decided on the basis of performance data of that equipment.

2.0 OBJECTIVE

To determine that the blistering Machine PBM (HMV3) installed at packaging Section at

square pharmaceuticals Ltd. Perform as intended by repeatedly running the system on its

intended schedules and recording all relevant information and data.

Results must demonstrate that performance consistently meets predetermined

specifications under normal conditions and where appropriate for worse case situations.

3.0 SCOPE

This study is applicable to the performance qualification test of Blistering machine PBM

(HM V3) Weather the equipment can perform effectively and reproducibly based on

approved specification.

4.0 RESPONSIBILITY

4.1 Quality Assurance department

Prepare the protocol

Conduct the validation trials

Develop the sampling Plan (I.e Sampling location ,sample size sampling time and

procedure for collecting sample)

Collect samples and arrange analysis for testing

Accumulate complile and summarize all test results.

Generate Validation report and circulate for approval .

4.2 Production Department

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 4 of 17

Arrange accessories as started in the protocol.

In conjunction with the development identity critical process parameters.

Schedule time availability to validation execution.

4.3 Engineering Department

Help Validation team in setting machine parameters as per protocol.

Ensure the calibration of instruments .

Participate as a team member of qualification.

5.0 DOCUMENTS VERIFICATION

5.1.1 Installation Qualification Document (IQ).

Installation qualification documents are verified and showed that the equipment has been

properly installed and qualified in accordance with standard. The document was approved

for the next step of operation.The document no.is ………….

5.1.2 Operational Qualification Document (OQ)

The Operation qualification documents observed that the test is performed in compliance

with the specifications.All tests were confirmed by the assigned responsible concerns

persons. The document no. is………………

5.1.3 Machine Calibration Status and SOP. No

Machine Name Machine Code Calibration Status

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 5 of 17

Hoonga Automatic Calibrated

Blister packing

machine

Standard Operating Procedure(SOP) No.

1.Setup And Operating Procedure SOP No:PR-SOP-025

2. Cleaning Procedure SOP No:PR-SOP-026

6.0 PERFORMANCE TEST USING DIFFERENT PRODUCTS

Product Name Batch No. & Manufacturing Date

6.1 PRODUCT NAME:

Performance is to be carried out with this batch and observations of the critical

parameters are to be recorded in given below table:

Batch No.

6.1.1 Machine Setting parameters

Product: Results: Pass/Fail

Test Parameters Accessories Criteria B/N: B/N: B/N:

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 6 of 17

Preliminary The equipment should

Pass Pass

Preparation: run effectively according

1 Using the operation to the set value.

manual setup the

equipment as appropriate

.

Blister Forming All samples satisfy the Pass Pass

(Table:6.1.2) (Table:6.1.2 (Table:6.1.2)

,Sealing Embossing criteria detailed below:

)

Cutting & Leak testing Blister forming

challenge : ,Sealing ,Embossing,

2 Challenge the ability of Cutting &Leak test.

the equipment to Visual check accurate

consistently forming forming cavities .

perfect cavities ,product Visual check accurate

feeding the cavities

feeding in the cavities

Visual check accurate

,sealing ,embossing

sealing .

,perforation ,cutting and

Visual check accurate

finally leak test.

Embossing .

Enable the equipment Visual check accurate

,satisfy all inputs for perforation

normal operation and Visual check accurate

then supply sufficient cutting .

blister to the equipment Visual check accurate

and then operate the ejection.

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 7 of 17

machine. Visual check accurate

Sampling : Take leak test.

10blisters of each No Damaged Strips are

found

product form the drum

cutting for operation

challenge verification.

3 Faculty Management: All unqualified products

Challenge the ability of should be rejected by

the equipment to the the system and

controlled onto the

consistently respond

collecting container.

upon faulty events.

Enable the equipment

No Extra damages

,satisfy all inputs for Pass Pass

caused to faulty blister

normal operation

during rejection.

,randomly introduce the

following events:

Remove faulty products.

Missing Products

Inspect the rejection tray

Comments Satisfactory

Result: Pass/Fail Pass

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 8 of 17

6.1.2 Performance Test Results:

Name of Product

Checking Parameter

Proper Proper Proper Proper Proper Proper

Forming Feeding Sealing Embossing Perforation Cuttin

g

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 Mins

Last Well Well Well Well Well Well

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 9 of 17

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 mins

Last Well Well Well Well Well Well

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 mins

Last Well Well Well Well Well Well

20mins

Comments Satisfactory

Result:Pass/Fail Pass

6.2 Product Name:

Performance is to be carried out with this batch and observations of the critical

parameters are to be recorded in given below table:

Batch No.

6.2.1 Machine Setting Parameters

Product: Results: Pass/Fail

Test Parameters Accessories Criteria B/N: B/N: B/N:

Preliminary Preparation: The equipment should

Pass Pass

Using the operation run effectively according

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 10 of 17

1 manual setup the to the set value.

equipment as appropriate

Blister Forming ,Sealing All samples satisfy the Pass Pass

(Table:6.2.2) (Table:6.2.2 (Table:6.2.2)

Embossing Cutting & criteria detailed below:

)

Leak testing challenge : Blister forming

Challenge the ability of the ,Sealing ,Embossing,

2 equipment to consistently Cutting &Leak test.

forming perfect cavities Visual check accurate

,product feeding in the forming cavities .

cavities ,sealing, emboss- Visual check accurate

feeding the cavities

ing ,perforation ,cutting

Visual check accurate

and finally leak test.

sealing .

Enable the equipment

Visual check accurate

,satisfy all inputs for

Embossing .

normal operation and then Visual check accurate

supply sufficient blister to perforation

the equipment and then Visual check accurate

operate the machine. cutting .

Sampling : Take 10blisters Visual check accurate

of each product form the ejection.

Visual check accurate

drum cutting for operation

leak test.

challenge verification.

No Damaged Strips are

found

3 Faculty Management: All unqualified products

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 11 of 17

Challenge the ability of the should be rejected by

equipment to the the system and

consistently respond upon controlled onto the

faulty events.

collecting container.

Enable the equipment

,satisfy all inputs for

normal operation No Extra damages

Pass Pass

,randomly introduce the caused to faulty blister

following events: during rejection.

Remove faulty products.

Missing Products

Inspect the rejection tray

Comments Satisfactory

Result: Pass/Fail Pass

6.2.2. Performance Test Results:

Name of Product

Checking Parameter

Proper Proper Proper Proper Proper Proper

Forming Feeding Sealing Embossing Perforation Cuttin

g

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 Mins

Last Well Well Well Well Well Well

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 12 of 17

Middle Well Well Well Well Well Well

20 mins

Last Well Well Well Well Well Well

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 mins

Last Well Well Well Well Well Well

20mins

Comments Satisfactory

Result:Pass/Fail Pass

6.3. Product Name:

Performance is to be carried out with this batch and observations of the critical parameters

are to be recorded in given below table:

Batch No.

6.3.1 Machine Setting Parameters

Product: Results: Pass/Fail

Test Parameters Accessories Criteria B/N: B/N: B/N:

Preliminary Preparation: The equipment should

Pass Pass

Using the operation run effectively according

1 manual setup the to the set value.

equipment as appropriate

Blister Forming ,Sealing All samples satisfy the Pass Pass

(Table:6.3.2) (Table:6.3.2 (Table:6.3.2)

Embossing Cutting & criteria detailed below:

)

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 13 of 17

Leak testing challenge : Blister forming

Challenge the ability of the ,Sealing ,Embossing,

2 equipment to consistently Cutting &Leak test.

forming perfect cavities Visual check accurate

,product feeding in the forming cavities .

cavities ,sealing, emboss- Visual check accurate

feeding the cavities

ing ,perforation ,cutting

Visual check accurate

and finally leak test.

sealing .

Enable the equipment

Visual check accurate

,satisfy all inputs for

Embossing .

normal operation and then Visual check accurate

supply sufficient blister to perforation

the equipment and then Visual check accurate

operate the machine. cutting .

Sampling : Take 10blisters Visual check accurate

of each product form the ejection.

Visual check accurate

drum cutting for operation

leak test.

challenge verification.

No Damaged Strips are

found

3 Faculty Management: All unqualified products

Challenge the ability of the should be rejected by

equipment to the the system and

consistently respond upon controlled onto the

faulty events.

collecting container.

Enable the equipment

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 14 of 17

,satisfy all inputs for

normal operation No Extra damages Pass Pass

,randomly introduce the

caused to faulty blister

following events:

Remove faulty products. during rejection.

Missing Products

Inspect the rejection tray

Comments Satisfactory

Result: Pass/Fail Pass

6.3.2 Performance parameters

Name of Product

Checking Parameter

Proper Proper Proper Proper Proper Proper

Forming Feeding Sealing Embossing Perforation Cuttin

g

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 Mins

Last Well Well Well Well Well Well

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 mins

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 15 of 17

Last Well Well Well Well Well Well

20mins

Batch No.

1st 20 Well Well Well Well Well Well

mins

Middle Well Well Well Well Well Well

20 mins

Last Well Well Well Well Well Well

20mins

Comments Satisfactory

Result:Pass/Fail Pass

7.0 DEVIATION

Deviation:

There was no deviation in the blistering process or physical and testing parameters

of final products.

Justification for acceptance

No other abnormality was observed.

Impact on operation :

The physical appearance of the product was satisfactory.

8.0 FINAL SUMMARY REPORTING

Qualification is an essential part of a pharmaceutical manufacturer’s quality assurance

system. The Performance qualification of automatic blister packaging machine was done

using three commercial products.

Forming of blister feeding sealing perforation cutting found ok in each batch of selected

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 16 of 17

three products. Products packed with primary packaging material found exit smoothly

through the delivery channel and machine was satisfactory.

The aforementioned findings concluded that the performance of blister packaging

Machine (PBM11) is qualified for packaging with consistent of GMP.

9.0 CONCLUSION

Review of the data generated by this study shows that the automatic blister packaging

machine(PBM11) installed in the online section of solid dosage form at square

pharmaceuticals Ltd. Meets all of the acceptance criteria for the performance qualification.

All items in the test sections of this protocol have been satisfactory completed. The Unit is

therefore considered ready for use for normal production operations.

10.0 APPROVAL

Based on the result reported & summary in the Validation reports, Validation study is

Approved

Not Approved

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

NAAFCO Pharma Ltd.

Bhaluka, Mymensingh

Title: Performance Qualification Report For Hoonga- Blister

Machine

Document No. Revision No. Date of Issued: Effective Date:

RR

00 Next Review due date: Page No. 17 of 17

Name Designation Signature Date

Prepared By Khandaker Tanvir Ahmed Production Officer

Checked By Md. Awlad Hossain Production Manager

Approved By Md. Nazrul Islam Khan Manager- QA

You might also like

- Performance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .Document14 pagesPerformance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .mehrdarou.qaNo ratings yet

- SOP of Line Clearance of Manufacturing AreaDocument3 pagesSOP of Line Clearance of Manufacturing Areashekhar khanal0% (1)

- PQ-Sample FOURDocument9 pagesPQ-Sample FOURcpkakopeNo ratings yet

- PQ-Sample fIVEDocument13 pagesPQ-Sample fIVEcpkakopeNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- Autocoater Performance Qualification ProtocolDocument10 pagesAutocoater Performance Qualification ProtocolYacine MadjidNo ratings yet

- FAT ProcedureDocument61 pagesFAT ProcedureBagus SigitNo ratings yet

- PQ-Sample One PharmaDocument10 pagesPQ-Sample One Pharmacpkakope100% (5)

- Auto ClaveDocument12 pagesAuto Claveamr assadNo ratings yet

- Document and Data ControlDocument11 pagesDocument and Data ControlSagar ChavanNo ratings yet

- Cleaning Validation Sample ProtocolDocument7 pagesCleaning Validation Sample ProtocolArieTamaNo ratings yet

- Pump Performance Test ProcedureDocument11 pagesPump Performance Test ProcedureAryaNo ratings yet

- PVPRDocument47 pagesPVPRBRIJENDRA KUMAR SINGH100% (2)

- 215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDocument4 pages215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDeepak ChaudharyNo ratings yet

- Process Validation of LiquidDocument24 pagesProcess Validation of LiquidAshutosh Shukla100% (2)

- PQ Protocol of StripDocument18 pagesPQ Protocol of StripGMH LaboratoriesNo ratings yet

- Capsule Process ValidationDocument28 pagesCapsule Process ValidationNavdeep ChaudharyNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- UV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Document20 pagesUV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Fairuz Luthfa100% (1)

- Disinfectant Efficacy ValidationDocument12 pagesDisinfectant Efficacy Validationhbhatt8890% (10)

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDocument14 pagesJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104No ratings yet

- OQ Protocol Capsulating MachineDocument11 pagesOQ Protocol Capsulating MachineNadine LilleNo ratings yet

- A Review On Qualification of Auto Clave, RMG, FBD, Cone Blender, Tablet Compression Machine.Document11 pagesA Review On Qualification of Auto Clave, RMG, FBD, Cone Blender, Tablet Compression Machine.DANIBATANo ratings yet

- Qualification of Facility, Equipments, SystemsDocument4 pagesQualification of Facility, Equipments, SystemsHamidNo ratings yet

- D.Y.Patil. College of Pharmacy, Pune: Instrument DetailsDocument3 pagesD.Y.Patil. College of Pharmacy, Pune: Instrument DetailsNavdeep ChaudharyNo ratings yet

- Template Validation Plan For Equipment or ProcessDocument14 pagesTemplate Validation Plan For Equipment or Processkhilifi chaouki100% (1)

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- Ahub1-103 Iq Report - R2Document47 pagesAhub1-103 Iq Report - R2Adianto RahmanNo ratings yet

- Master Validation of All Equipment in ProductionDocument5 pagesMaster Validation of All Equipment in ProductionNaci TürüközüNo ratings yet

- Performance Qualification Protocol For Blister Packing MachineDocument9 pagesPerformance Qualification Protocol For Blister Packing Machinemehrdarou.qaNo ratings yet

- HH-4299.044-OQ-MDPI Checkweigher-00 - V1 - 0 - EngDocument50 pagesHH-4299.044-OQ-MDPI Checkweigher-00 - V1 - 0 - Engmmm islamNo ratings yet

- PQ-Sample TwoDocument11 pagesPQ-Sample Twocpkakope100% (5)

- DRP001 Puc Pro N 000 004 - 6Document58 pagesDRP001 Puc Pro N 000 004 - 6aasss100% (1)

- DQ Report For BrineDocument12 pagesDQ Report For BrineNishit SuvaNo ratings yet

- PEAR 4 Manufacturing - 20calibration TestDocument3 pagesPEAR 4 Manufacturing - 20calibration TestDay CruzNo ratings yet

- QC ManualDocument12 pagesQC ManualBikila RusiNo ratings yet

- Wnp-Qc-Sop-011 Procedure For Referenced & Working StandardsDocument6 pagesWnp-Qc-Sop-011 Procedure For Referenced & Working StandardsMuhammad ImranNo ratings yet

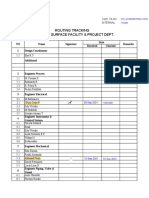

- Routing Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026Document8 pagesRouting Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026aurinkokelloNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- An Overview of Pharmaceutical ValidationDocument12 pagesAn Overview of Pharmaceutical ValidationNarongchai PongpanNo ratings yet

- Bin Washer-OqDocument11 pagesBin Washer-OqValeria Carlo BorroNo ratings yet

- TEMPLATE FOR PERFORMACE QUALIFICATION PROTOCOL - Pharmaceutical GuidanceDocument5 pagesTEMPLATE FOR PERFORMACE QUALIFICATION PROTOCOL - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- Ultratech India LTD Technical Specification Revision: P0 Air Shower Page 1 of 6Document6 pagesUltratech India LTD Technical Specification Revision: P0 Air Shower Page 1 of 6MUNINo ratings yet

- TOC-L OQR Rev1.04 ZEMH-8100DDocument24 pagesTOC-L OQR Rev1.04 ZEMH-8100DLolaNo ratings yet

- Template For Performace Qualification Protocol - Pharmaceutical GuidanceDocument4 pagesTemplate For Performace Qualification Protocol - Pharmaceutical GuidanceMIRZA AFAQ ALINo ratings yet

- 5 APQP 1 of 3Document3 pages5 APQP 1 of 3P G SumanNo ratings yet

- Cleaning Validation Protocol-1Document22 pagesCleaning Validation Protocol-1Bejoy Karim100% (4)

- Oq-Pouch Filling Machine (Kreation)Document5 pagesOq-Pouch Filling Machine (Kreation)Hemant SinghNo ratings yet

- Performance Qualification Protocol of Bin Blender (125 LTR) Equipment ID: PGT/BBL/001 Location: Blending AreaDocument12 pagesPerformance Qualification Protocol of Bin Blender (125 LTR) Equipment ID: PGT/BBL/001 Location: Blending Areaajay shandil100% (1)

- 023-SOP For Conducting Hold Time StudyDocument3 pages023-SOP For Conducting Hold Time StudyAshok Lenka100% (2)

- Indus Pharma (PVT.) LTD.: Protocol For Re-Qualification of Water Distillation Plant (Wfi), Storage & Distribution SystemDocument9 pagesIndus Pharma (PVT.) LTD.: Protocol For Re-Qualification of Water Distillation Plant (Wfi), Storage & Distribution SystemUmair Shekhani100% (1)

- Dust Extractor IqoqpqDocument10 pagesDust Extractor Iqoqpqpinnacle qaNo ratings yet

- Network TestingDocument78 pagesNetwork TestingMas Ahmad Safwan MasbahNo ratings yet

- Aml QM Process As-Is v1.0Document15 pagesAml QM Process As-Is v1.0NILADRI MUKHERJEENo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- System Verification: Proving the Design Solution Satisfies the RequirementsFrom EverandSystem Verification: Proving the Design Solution Satisfies the RequirementsRating: 1 out of 5 stars1/5 (2)

- Annexure - II Annexure To Biological Drug Manufacturing License No.: . of M/S SHINIL Pharma Ltd. B K Bari, Mirzapur, GazipurDocument10 pagesAnnexure - II Annexure To Biological Drug Manufacturing License No.: . of M/S SHINIL Pharma Ltd. B K Bari, Mirzapur, Gazipurbejoy karimNo ratings yet

- Annexure - I Annexure To Non-Biological Drug Manufacturing License No.: . of M/S SHINIL Pharma Ltd. B K Bari, Mirzapur, GazipurDocument4 pagesAnnexure - I Annexure To Non-Biological Drug Manufacturing License No.: . of M/S SHINIL Pharma Ltd. B K Bari, Mirzapur, Gazipurbejoy karimNo ratings yet

- Oxytetracycline PowderDocument1 pageOxytetracycline Powderbejoy karimNo ratings yet

- Butaphosphane+Cyanocobalamin InjectionDocument5 pagesButaphosphane+Cyanocobalamin Injectionbejoy karimNo ratings yet

- QA SOP 030 Document Review CommitteeDocument4 pagesQA SOP 030 Document Review Committeebejoy karimNo ratings yet

- A Semi-Detailed Lesson Plan in Visual Graphic Design Week 1 & 2Document3 pagesA Semi-Detailed Lesson Plan in Visual Graphic Design Week 1 & 2Christian Calderon100% (1)

- ECE 340-syllabus-Metlushko-Fall2019 PDFDocument2 pagesECE 340-syllabus-Metlushko-Fall2019 PDFPoopieNo ratings yet

- Project Report On Job SatisfactionDocument120 pagesProject Report On Job Satisfactionshaliniverma00287% (23)

- Hikvision ISAPI Core Protocol PDFDocument795 pagesHikvision ISAPI Core Protocol PDFByron Fischer0% (1)

- The Experiences of Black and Minority Ethnic Nurses Working in The UKDocument6 pagesThe Experiences of Black and Minority Ethnic Nurses Working in The UKMiquel GilNo ratings yet

- Zurima Barba Venezuelan Fashion ModelDocument8 pagesZurima Barba Venezuelan Fashion ModelvenezuelanwomenNo ratings yet

- Business Process Automation ProjectDocument3 pagesBusiness Process Automation ProjectPospaiGeorgelNo ratings yet

- Earth First!: Issue 52, October 1998 Docks Shut in Memorial ActionDocument8 pagesEarth First!: Issue 52, October 1998 Docks Shut in Memorial Actionfelipe_xhcxNo ratings yet

- CD - A.M. No. 10-10-4-SC, March 08, 2011Document3 pagesCD - A.M. No. 10-10-4-SC, March 08, 2011Ella Kriziana CruzNo ratings yet

- Dalubhasaan NG Lungsod NG Lucena (Formerly City College of Lucena)Document2 pagesDalubhasaan NG Lungsod NG Lucena (Formerly City College of Lucena)Accounting LayfNo ratings yet

- US Department of Justice Official Release - 00928-419crDocument2 pagesUS Department of Justice Official Release - 00928-419crlegalmattersNo ratings yet

- Ethics For UpscDocument134 pagesEthics For UpscÃnanya ĐeNo ratings yet

- Gaye Williams Ortiz, Clara A.B. Joseph - Theology and Literature - Rethinking Reader Responsibility (2006) PDFDocument253 pagesGaye Williams Ortiz, Clara A.B. Joseph - Theology and Literature - Rethinking Reader Responsibility (2006) PDFAnonymous Ipt7DRCRDNo ratings yet

- Internship ReportDocument3 pagesInternship ReportIrfan Ahmed ChowdhuryNo ratings yet

- Gandhi On Freedom, Rights and Responsibility by Dennis DaltonDocument12 pagesGandhi On Freedom, Rights and Responsibility by Dennis DaltonSubham Jain100% (1)

- BPP Guide-to-AAT PDFDocument16 pagesBPP Guide-to-AAT PDFTun MinNo ratings yet

- Ekici@bilkent - Edu.tr: Principles of Marketing, Philip Kotler and Gary Armstrong, 16Document8 pagesEkici@bilkent - Edu.tr: Principles of Marketing, Philip Kotler and Gary Armstrong, 16ArliNo ratings yet

- Internal Rules of ProcedureDocument7 pagesInternal Rules of ProcedureMary Mellicent Garcia BajalaNo ratings yet

- Lourdes College: Integrated Basic Education Department SY 2018 - 2019Document3 pagesLourdes College: Integrated Basic Education Department SY 2018 - 2019Elite MasterNo ratings yet

- Lib-Ushistory-Consumer-Economy-Radio-1920s-31355-Article OnlyDocument7 pagesLib-Ushistory-Consumer-Economy-Radio-1920s-31355-Article Onlyapi-346299352No ratings yet

- Ey Digital Directions Eyg No 005836-19gblDocument48 pagesEy Digital Directions Eyg No 005836-19gblakashNo ratings yet

- Dangerous RoadDocument8 pagesDangerous RoadWALDO RUIZ LOPEZNo ratings yet

- 04.corporate Sales PDFDocument173 pages04.corporate Sales PDFDaniel AguilarNo ratings yet

- Ethics ExamDocument4 pagesEthics ExamJulius IxohoxiNo ratings yet

- Aldaba v. Comelec DigestDocument3 pagesAldaba v. Comelec Digestkathrynmaydeveza100% (2)

- Module 1 Purposive Communication - 21st Century CommunicationDocument48 pagesModule 1 Purposive Communication - 21st Century CommunicationRovin Jae Esguerra86% (7)

- Barti AdvtDocument1 pageBarti AdvtAakash RuptakkeNo ratings yet

- Isse Miyake SlidesDocument28 pagesIsse Miyake Slidesjasleen bhatiaNo ratings yet

- Mscs - Leaflet (Aiub) 251007Document2 pagesMscs - Leaflet (Aiub) 251007api-27223531No ratings yet

- GRADES 1 To 12 Daily Lesson Log Grade 9 English Week 5 Fourth Quarter I. Objectives Monday Tuesday Wednesday Thursday FridayDocument4 pagesGRADES 1 To 12 Daily Lesson Log Grade 9 English Week 5 Fourth Quarter I. Objectives Monday Tuesday Wednesday Thursday FridayVince Rayos CailingNo ratings yet