Professional Documents

Culture Documents

MTU 16V2000M90 - Maintenance Schedule

Uploaded by

Freddy ChenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTU 16V2000M90 - Maintenance Schedule

Uploaded by

Freddy ChenCopyright:

Available Formats

Maintenance Schedule Page 01

Diesel Engines

8V 2000 M 90 (BM 531.913)

12V 2000 M 90 (BM 535.913)

16V 2000 M 90 (BM 536.913)

Maintenance Schedule

M050542/01E

MTU Motoren- und Turbinen-Union Friedrichshafen GmbH

88040 Friedrichshafen / Germany

Telephone (07541) 90-0

Telex 734 280-0 mt d

Telefax (07541) 90-3928

Low operating and maintenance costs as well as operational reliability and availability depend on maintenance

and servicing being carried out in compliance with our specifications and instructions.

The overall system, of which the engine is an integral part, must be maintained in such a way as to ensure

trouble-free engine operation at all times. For this purpose always:

− ensure that sufficient fuel is available,

− ensure that the combustion air is dry and clean,

− use only clean, filtered raw water.

Moreover, it is essential that:

− maintenance tasks be completed by trained personnel,

− suitable tools be used,

− genuine spare parts and fluids and lubricants as per the current MTU Fluids and Lubricants Specification be

used.

Our Product Support Service will always be available should assistance be required.

Preventive maintenance instructions.

− Special care should be taken to keep the machinery plant in a clean and serviceable condition at all times to

facilitate early detection of possible leaks and prevent subsequent damage.

− Protect rubber and synthetic components from oil and fuel, never treat with organic detergents. Wipe with a dry

cloth only.

− Always replace all seals and gaskets.

MTU Maintenance Concept

The maintenance concept for MTU products is a preventive maintenance concept and features the maintenance

echelons W1 to W6 as outlined below.

Preventive maintenance facilitates advance planning and ensures a high degree of equipment availability.

Main features of the maintenance echelons:

− W1: Operational checks

− W2, W3 and W4: Periodic maintenance tasks to be performed during out-of-service periods without the need

for engine disassembly.

− W5: -

− W6: Major overhaul. This echelon requires complete engine disassembly.

The time intervals according to which the W2 to W6 Maintenance Echelons and the relevant checks and tasks

involved are to be completed are based on operational experience. They have been determined so as to ensure

correct engine operation until the next scheduled maintenance echelon.

Specific operational conditions may require modification of the Maintenance Schedule.

NOTE:

The codes on the following pages refer to the groups and subgroups in Section G of the Engine Operation Manual.

This Maintenance Schedule may refer to parts which are not installed on your engine, these may be disregarded.

M050542/01E 06-01 © MTU

Page 02 Maintenance Schedule

Application Group

1DS: Fast vessels with low load factors

Maintenance Frequency Chart

Maintenance W1: Operational checks, daily X

Echelon

W2: Operating hours 250

Limit, year 1

W3: Operating hours 500

Limit, year 1

W4: Operating hours 3 000

Limit, year(s) 2

W5: Operating hours -

Limit, year(s) -

W6: Operating hours 6 000

Limit, year(s) 18

Maintenance Task Schedule -Overall System-

See page 3

Maintenance Task Schedule -Engine-

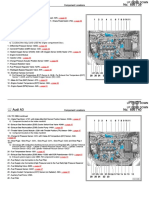

Code No. One-time operations after the first 50 operating hours.

− With a new engine, after W5 maintenance echelon, or after W6 major overhaul

G205.050.01 Valve gear Check valve clearances

G083.101.09 Fuel pre-filter Check, replace filter inserts if necessary

G140.000.03 Exhaust system Check tightness of securing screws and nuts

G202.051.01 Engine coolant pump Check relief bore for oil and coolant discharge and contamination

G207.051.01 Raw water pump Check relief bore for oil and coolant discharge and contamination

G213.051.01 Charging generator drive Check belt condition and tension

G231.051.01 Engine mounts Check tightness of securing screws and nuts

G250.000.01 Engine driving end Check tightness of securing screws and nuts

Code No. Maintenance Echelon W1:

− Operational checks

G000.000.13 Engine operation Check speed

G000.000.17 Engine operation Check temperatures (if gauges are provided)

G000.000.19 Engine operation Check running noises

G000.000.21 Engine operation Check engine and external pipework for leaks,

G000.003.15 Engine operation Check pressures (if gauges are provided)

G083.101.03 Fuel pre-filter Drain water and contaminants

G111.051.01 Intercooler Check drain line for water discharge and obstructions

G140.000.05 Exhaust system Check exhaust gas colour

G180.000.01 Engine oil Check level

G202.000.03 Engine coolant Check level

G213.051.01 Charging generator drive Check belt condition and tension

M050542/01E 06-01 © MTU

Maintenance Schedule Page 03

Code No. Maintenance Echelons W 2 3 4

G083.101.05 Fuel pre-filter Flush

G083.101.09 Fuel pre-filter Replace filter elements

G083.101.10 Fuel pre-filter Replace filter

G121.052.01 Air filter Check contamination indicator

G180.000.05 Engine oil Change

− with oil category 1, after every 250 operating hours

− with oil category 2, after every 500 operating hours

G183.052.03 Engine oil filter Replace

− accomplish when changing the oil

G202.000.05 Engine coolant Take sample and analyse

− every 2nd W2 maintenance echelon = 500 operating hours

− at least once annually

G205.050.01 Valve gear Check valve clearances

G083.051.03 Fuel duplex filter Replace filters inserts or change replaceable filters

G121.051.01 Air filter Replace

− every 2nd W3 maintenance echelon = 1000 operating hours

G123.051.01 Air-flow control flap(s) Check for ease of movement

G140.000.01 Exhaust system Check (visual inspection)

G144.051.01 Exhaust flow control flap(s) Check for ease of movement

G146.000.01 Exhaust system Check exhaust pipework security and insulation (shipside)

G202.051.01 Engine coolant pump Check relief bore for oil and coolant discharge and contamination

G207.051.01 Raw water pump Check relief bore for oil and coolant discharge and contamination

G309.001.01 Battery Check

G000.000.29 Engine Check hoses and hose connections

G018.101.01 Crankcase breather Check oil separator (visual inspection), replace if necessary

G073.051.04 Fuel injection pump(s) Replace

G075.051.05 Fuel injector(s) Replace

G077.050.01 Pressure pipe neck (bayonet) Fit new pressure pipe neck (bayonet) in cylinder head.

G111.051.03 Intercooler Clean drain line

G202.000.09 Engine coolant Change

G231.051.01 Engine mounts Check tightness of securing screws and nuts

G231.051.03 Engine mounts Check condition of resilient mounts (visual inspection)

G500.000.09 Engine wiring Check

G510.000.01 Monitoring system Check function of monitoring units

Maintenance Echelon W6

Requires complete engine disassembly to facilitate repair/overhaul of all relevant components.

The decisive factor is the component condition or the actual dimensions, referenced to the Tolerances and Wear

Limits List.

Out-of-Service Periods

Carry out maintenance tasks in accordance with the time limit schedule (see the Maintenance Frequency Chart).

In addition, the engine must be barred manually every month.

If the engine is to remain out of service for more than 1 month, carry out engine preservation in accordance with

Section K.

Maintenance Task Schedule -Overall System-

Code No.

G202.051.01 Universal shaft Lubricate

− after installation

− annually

−

M050542/01E 06-01 © MTU

Page 04 Maintenance Schedule

M050542/01E 06-01 © MTU

You might also like

- Maintenance Schedule 6R183 - M050525 - 02EDocument4 pagesMaintenance Schedule 6R183 - M050525 - 02EdattienNo ratings yet

- 16 V 4000Document4 pages16 V 4000aup0% (1)

- Diesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EDocument4 pagesDiesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EsxturboNo ratings yet

- Mtu - Technical Documentation: ServiceDocument7 pagesMtu - Technical Documentation: Servicekarbaran1391No ratings yet

- Мануал L33 - new - MS50199 - 01EDocument16 pagesМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Plan de Manteniemiento m53 MtuDocument9 pagesPlan de Manteniemiento m53 MtuNippur de LagashNo ratings yet

- 12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EDocument5 pages12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EJuan Carlos Mino Eneque100% (2)

- Mtu Sales ProgramDocument36 pagesMtu Sales ProgrammajdirossrossNo ratings yet

- ZF 2000 Series: Product DetailsDocument4 pagesZF 2000 Series: Product DetailsJhonAlexRiveroNo ratings yet

- Man v28 33d STC Imo Tier II MarineDocument248 pagesMan v28 33d STC Imo Tier II MarineSea Man MktNo ratings yet

- Series 8000 Diesel Engines For Marine ApplicationsDocument3 pagesSeries 8000 Diesel Engines For Marine ApplicationsMaurizioNo ratings yet

- Operating Instructions: Diesel Engine 8 V 4000 M40A 8 V 4000 M40B Application Group 3BDocument170 pagesOperating Instructions: Diesel Engine 8 V 4000 M40A 8 V 4000 M40B Application Group 3BNerjan PetitNo ratings yet

- Spec Sheet Mtu 12v4000 Ds1750 NeaDocument6 pagesSpec Sheet Mtu 12v4000 Ds1750 NeaTri Hudami WibowoNo ratings yet

- D2842-LE402-sn7007455067A301-1993year-en-1148pages - PartsDocument148 pagesD2842-LE402-sn7007455067A301-1993year-en-1148pages - PartsBrianNo ratings yet

- MTU Solution Guide Marine Oct 2022Document59 pagesMTU Solution Guide Marine Oct 2022TwinNo ratings yet

- Mtu 16v4000 m53&m63 PDFDocument2 pagesMtu 16v4000 m53&m63 PDFJoan Manuel Rivas SantandreuNo ratings yet

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LDocument197 pagesOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.No ratings yet

- Diesel engines for fast vessels with high load factorsDocument1 pageDiesel engines for fast vessels with high load factorsghostt123No ratings yet

- Maintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BDocument27 pagesMaintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BDimas SaputroNo ratings yet

- Instruction Book L2738ed080120Document252 pagesInstruction Book L2738ed080120GiovanniJaraNo ratings yet

- 01 Introduction Bluevison NG V1 07Document60 pages01 Introduction Bluevison NG V1 07Abdul Muksith100% (1)

- MTU Gendrive Diesel Engine Sales ProgramDocument55 pagesMTU Gendrive Diesel Engine Sales ProgramEdutamNo ratings yet

- Mantenimiento s2000Document8 pagesMantenimiento s2000FabianNo ratings yet

- MTU 12V 4000 M60 Engine Maintenance MatrixDocument3 pagesMTU 12V 4000 M60 Engine Maintenance Matrixchief100% (2)

- 8V4000M70Document143 pages8V4000M70chuminhNo ratings yet

- Mtu - Oil & Gas Sales ProgramDocument63 pagesMtu - Oil & Gas Sales Programalamen ZayidNo ratings yet

- Maintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSDocument25 pagesMaintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSNabesterNajam0% (1)

- MTU White Paper Electronic Engine ManagementDocument4 pagesMTU White Paper Electronic Engine ManagementStefan LyamovNo ratings yet

- Mtu 16v2000g65 PDFDocument144 pagesMtu 16v2000g65 PDFPhạm Hoài AnhNo ratings yet

- Mtu 12v4000 Spec Sheet PDFDocument6 pagesMtu 12v4000 Spec Sheet PDFSomadbsiNo ratings yet

- Mtu 4000 Water Pump DismantleDocument93 pagesMtu 4000 Water Pump DismantlesxturboNo ratings yet

- MarineDocument210 pagesMarinecmendezNo ratings yet

- 0912 0913 deDocument218 pages0912 0913 deRath Asypaden100% (1)

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Document2 pagesDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- Daewoo P180leomDocument126 pagesDaewoo P180leomRicardo FonsecaNo ratings yet

- Marex OS II-Optimized For REINTJES Trolling Gearboxes With v-ADSDocument4 pagesMarex OS II-Optimized For REINTJES Trolling Gearboxes With v-ADSMohammed Saber100% (1)

- Sales Program Oil Gas Industry MTU ShopDocument83 pagesSales Program Oil Gas Industry MTU ShopBogdan ApostolNo ratings yet

- Operating Instructions: Downloaded From Manuals Search EngineDocument155 pagesOperating Instructions: Downloaded From Manuals Search EngineRis Wati100% (1)

- Marine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPDocument234 pagesMarine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPJuniorJavier Olivo Farrera100% (1)

- Technical Sales Document: - Product DataDocument27 pagesTechnical Sales Document: - Product DataLuis AyalaNo ratings yet

- Monitoring and Remote Control For MTU Ship Propulsion SystemsDocument8 pagesMonitoring and Remote Control For MTU Ship Propulsion SystemsThiha BoBo100% (1)

- MTU Marine DefenseDocument27 pagesMTU Marine DefenseAizat DakNavyNo ratings yet

- MTU 4r6r1000Document84 pagesMTU 4r6r1000eduardo chavezNo ratings yet

- MTU 16V 4000M73 Operation Instruction Manual PDFDocument298 pagesMTU 16V 4000M73 Operation Instruction Manual PDFThiha BoBo100% (1)

- Mtu Reach SVHC 2018-10-29 enDocument75 pagesMtu Reach SVHC 2018-10-29 enalawi50% (2)

- MTUDocument16 pagesMTUWira Karya Diesel40% (5)

- MTU 12V4000 Diesel EngineDocument2 pagesMTU 12V4000 Diesel Enginenastyn-1No ratings yet

- 2000M72 Maintenance Schedule MS50194 01E PDFDocument29 pages2000M72 Maintenance Schedule MS50194 01E PDFAbu Abdou SiyahyaNo ratings yet

- Operating Instructions: Diesel Engine 8 V 2000 M60/M61 12V 2000 M60/M61 16V 2000 M60/M61Document241 pagesOperating Instructions: Diesel Engine 8 V 2000 M60/M61 12V 2000 M60/M61 16V 2000 M60/M61Sidali KilardjNo ratings yet

- Business Portal Online Print 16-10-2019Document328 pagesBusiness Portal Online Print 16-10-2019Victor Medrado100% (1)

- MTU Preservations Strategy UpdateDocument49 pagesMTU Preservations Strategy Updatebambang100% (2)

- 8RPHX MK 7 Illustrated Parts ListDocument240 pages8RPHX MK 7 Illustrated Parts Listsxturbo100% (1)

- MTU Engine 4000-Series Functional DescriptionDocument42 pagesMTU Engine 4000-Series Functional DescriptionAlex100% (1)

- Manual MTU 12v1600 CompletoDocument72 pagesManual MTU 12v1600 CompletogmgsolucoesNo ratings yet

- Statistic Power IndonesiaDocument134 pagesStatistic Power IndonesiaM Farishadi RukandiNo ratings yet

- Engine Controller: N SerieDocument1 pageEngine Controller: N SerieBayanaka TehnikNo ratings yet

- Operating Instructions 395 SeriesDocument190 pagesOperating Instructions 395 Seriesjamal molana0% (1)

- MTU TurbochargingDocument6 pagesMTU Turbochargingguichen wang0% (1)

- Diesel Engines V 4000 M 70 Maintenance Schedule M050488/04EDocument4 pagesDiesel Engines V 4000 M 70 Maintenance Schedule M050488/04EsxturboNo ratings yet

- Maint Sched 12 or 8 V183 TE93Document4 pagesMaint Sched 12 or 8 V183 TE93dieseldogwillie100% (2)

- Hydraulic Excavator: Engine Power Operating Weight Ground PressureDocument4 pagesHydraulic Excavator: Engine Power Operating Weight Ground PressurePaing ZayNo ratings yet

- Jenbacher Engine DiagramsDocument6 pagesJenbacher Engine Diagramspalash11No ratings yet

- Correa de Distribución 1.4 - Tdci Ford FiestaDocument9 pagesCorrea de Distribución 1.4 - Tdci Ford FiestaFrancisco José MarotoNo ratings yet

- Mitsubishi Lancer Sportback Owner's Manual PDFDocument422 pagesMitsubishi Lancer Sportback Owner's Manual PDFwaelNo ratings yet

- Governor - Adjust: Testing and AdjustingDocument4 pagesGovernor - Adjust: Testing and AdjustingsxturboNo ratings yet

- C2.2 Marine-Generator Set Engine JAW00001-UP POWERED BY C2.2 Engine (SEBP3736 - 69) - DocumentationDocument3 pagesC2.2 Marine-Generator Set Engine JAW00001-UP POWERED BY C2.2 Engine (SEBP3736 - 69) - DocumentationFrancisco Eric CelestinoNo ratings yet

- Skidder H66 PDFDocument274 pagesSkidder H66 PDFWilson RsmNo ratings yet

- Mini Skid Steer: Optimal Power. Productivity. High StandardsDocument2 pagesMini Skid Steer: Optimal Power. Productivity. High StandardsMichael BrandonNo ratings yet

- Chapter 10: Automotive SystemsDocument71 pagesChapter 10: Automotive Systemsgabriela69sNo ratings yet

- Baudouin 6M16 Parts ManualDocument155 pagesBaudouin 6M16 Parts Manualmohammed mostafa100% (2)

- Lancia Beta Service ManualDocument321 pagesLancia Beta Service ManualDiego Hernan Piñeiro100% (1)

- Keihin Carburetor TuningDocument2 pagesKeihin Carburetor TuningBrianCook0% (2)

- Workshop Manual: 125/151 CC 4-STROKE ENGINE 2 Valves SYMDocument48 pagesWorkshop Manual: 125/151 CC 4-STROKE ENGINE 2 Valves SYMNader FarhatNo ratings yet

- Ignition SystemDocument21 pagesIgnition SystemAnanta Kumar NandiNo ratings yet

- Fuel System FAQDocument5 pagesFuel System FAQMonserrat Stevens PescadorNo ratings yet

- Catalogopistones PDFDocument91 pagesCatalogopistones PDFrenatoNo ratings yet

- SENR1013 Cнятие клапанов 3408ЕDocument7 pagesSENR1013 Cнятие клапанов 3408ЕAminadavNo ratings yet

- Coach & Bus EngineDocument2 pagesCoach & Bus EngineClegivaldoNo ratings yet

- 20 2 1 LX 570 PR Oduct Specifications: Exterior DimensionsDocument5 pages20 2 1 LX 570 PR Oduct Specifications: Exterior Dimensionsbestbest07No ratings yet

- Compression Test ProcedureDocument2 pagesCompression Test ProcedureMoh DeBrNo ratings yet

- Variable Injection Timing (Vit) For Wärtsilä Vasa 32 Lownox EnginesDocument3 pagesVariable Injection Timing (Vit) For Wärtsilä Vasa 32 Lownox EnginesenzobvNo ratings yet

- 350kVA User ManualDocument73 pages350kVA User ManualEvander Sarraff100% (1)

- Diesel Engines and Their Fuels 2009Document9 pagesDiesel Engines and Their Fuels 2009Merrel RossNo ratings yet

- 2023 Hyundai Palisade Window StickerDocument1 page2023 Hyundai Palisade Window StickerTrung ChenhNo ratings yet

- IELTS Reading Practice Test 5 - Vol 6Document14 pagesIELTS Reading Practice Test 5 - Vol 6Thu but biNo ratings yet

- 2.0+TDI+component+locationsDocument18 pages2.0+TDI+component+locationsalmir karahodzicNo ratings yet

- 2002 Blazer 4.3 PCM PinoutsDocument5 pages2002 Blazer 4.3 PCM PinoutsRobertoGomez67% (3)

- Sea Trial Data (SLM00483) 3512 SLMDocument5 pagesSea Trial Data (SLM00483) 3512 SLMCarlos ParanhosNo ratings yet

- E - Books+Guide Manuals LISTDocument36 pagesE - Books+Guide Manuals LISTJonnyNo ratings yet

- 800kw Cummins Marine GeneratrorDocument3 pages800kw Cummins Marine GeneratrorChen CarolineNo ratings yet