Professional Documents

Culture Documents

ER-6000-AT: In-Line PCB Separator Cut Machine

Uploaded by

bet52wOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ER-6000-AT: In-Line PCB Separator Cut Machine

Uploaded by

bet52wCopyright:

Available Formats

IN-LINE ER-6000-AT

PCB SEPARATOR CUT MACHINE

Specification:

01. Unilateral operating distance :400×420 ㎜

02. X、Y、A、cutting speed:1 ~100mm/s

03. X、Y、A、Repeat precision of the machine set:± 0.02mm

04. X、Y、A、Z、B、C Control method:Use the industrial IPC and PC

05. X、Y、A、Z、B、C driving method:AC servomotor

06. Operation interface:PC WINDOW

07. Cut the precision:± 0.1mm

08. Rotational speed of the spindle:MAX60000rpm

09. Host voltage:220V 1ψ 50 / 60HZ

10. Air pressure supply:4.5kg/cm2 a

11. Power consumption:3KVA

12. Dust collection machine:under dust collector

13. Dust collection machine voltage:220V (380V) 3ψ

14. Host size:2150×1300×2070mm (W×D×H)

Features

01. Host & dust collection machine integration design,reduce floor space,aesthetic appearance。

02. Use dust collection disposable dustbags,prevent secondary pollution,reduce the dust collector

maintenance fees。

03. use High efficiency dust collection machine,Improve dust collection Effect,Coupled withthe newly

developed dust collection architecture,Dust cleaner。

04. Dust collector built-in sensors,the dust fully loaded alarm notification replacing the dustbag,ensure

that the dust collection and protection dust collector。

05. X、Y、A -axis use gantry framework,improve cutting accuracy and speed。

06. PCB 取 Pick and place work area installation of safety facilities,comply with the requirements of

public safety。

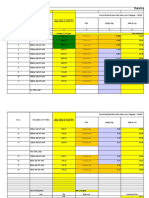

Fixture Dimensions

450

350

250

2- 8+0.05

+0.03鉸孔

※The standard board thickness 10mm

※Special fixture plate thickness of 25

8- 5.5- 9.5-DP5.5 mm (at the bottom of plus 15mm

335±0.01

345

357

370

225

25

75 225 100 50

T=10mm

You might also like

- Building SOR 18-19Document56 pagesBuilding SOR 18-19VenkataLakshmiKorrapatiNo ratings yet

- Kemco V Sepa enDocument2 pagesKemco V Sepa enDanilaGAdNo ratings yet

- Rfqr211351 - Enquiry For DriveDocument34 pagesRfqr211351 - Enquiry For DriveyuwonoNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsGANDHILAL mNo ratings yet

- EC Classification ENGLISH 9 2018 V2Document1 pageEC Classification ENGLISH 9 2018 V2HowTo HackNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- Petrography CatalogueDocument16 pagesPetrography CatalogueMR DaniNo ratings yet

- Catálogo - Tipo 21Document6 pagesCatálogo - Tipo 21Marcos Marcandali de JesusNo ratings yet

- Flat Ribbon Fibre Optic Patch CableDocument2 pagesFlat Ribbon Fibre Optic Patch CableAmir SalahNo ratings yet

- HTD Timing Pulleys PDFDocument13 pagesHTD Timing Pulleys PDFNielsen BlancoNo ratings yet

- Return Air Grilles: RM LouverDocument2 pagesReturn Air Grilles: RM LouverMinhNo ratings yet

- Return Air Grilles: RM LouverDocument2 pagesReturn Air Grilles: RM LouverYe Wunna TunNo ratings yet

- EC Classification ENGLISH 3 2013 V3 FINAL PDFDocument1 pageEC Classification ENGLISH 3 2013 V3 FINAL PDFAngel HilasacaNo ratings yet

- DCP264 Design and Fabrication of Abrasive Belt Grinding Attachment For LatheDocument4 pagesDCP264 Design and Fabrication of Abrasive Belt Grinding Attachment For LatheANAND KRISHNANNo ratings yet

- DSFO02008AR - Fiber Optic, Drop Cable, Indoor, 1-4 FibersDocument2 pagesDSFO02008AR - Fiber Optic, Drop Cable, Indoor, 1-4 FibersbakerNo ratings yet

- TWF TozenDocument6 pagesTWF TozenAri WibowoNo ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- FJK6626M Ventilador Jason FanDocument2 pagesFJK6626M Ventilador Jason FanRichardNo ratings yet

- Laser Cutting Machine Infinity f1Document6 pagesLaser Cutting Machine Infinity f1Divyaba DodiyaNo ratings yet

- ZBS600 Marca ZERMADocument2 pagesZBS600 Marca ZERMAJuan Carlos Ortiz PimientaNo ratings yet

- Escogear NDocument5 pagesEscogear Nmarcelo castilloNo ratings yet

- E McmiDocument13 pagesE McmiFernando GómezNo ratings yet

- 3.new GENRATION SAP SEALSDocument21 pages3.new GENRATION SAP SEALSRavi MirzaNo ratings yet

- 04 RJDocument2 pages04 RJMinhNo ratings yet

- MultimediaDocument4 pagesMultimediaLeiden O'SullivanNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- Petrography EXPDocument16 pagesPetrography EXPYounes KoutayaNo ratings yet

- 02) Driven Pile SubmissionDocument29 pages02) Driven Pile Submissionalfredo100% (1)

- Slewing Ring ManualDocument7 pagesSlewing Ring ManualSaur EquipamentosNo ratings yet

- VSIII Manual Chain Hoist 250 KG To 50 T SWLDocument8 pagesVSIII Manual Chain Hoist 250 KG To 50 T SWLJuan LeonNo ratings yet

- MZ45 MZ45GDocument2 pagesMZ45 MZ45GSalpa AdenugrahaNo ratings yet

- Lock Forming MachineDocument5 pagesLock Forming MachineIBRAHIM AL-SURAIHINo ratings yet

- Bit Release Tool (BRT)Document2 pagesBit Release Tool (BRT)Evgeny100% (1)

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaNo ratings yet

- Data K EDocument1 pageData K ErodrigomessiasNo ratings yet

- Elephant Foot Ferrules: 36.1 General InformationDocument8 pagesElephant Foot Ferrules: 36.1 General InformationlowelNo ratings yet

- Product Data Sheet: USG Boral SHEETROCK® Standard PlasterboardDocument2 pagesProduct Data Sheet: USG Boral SHEETROCK® Standard Plasterboardkaval chhabraNo ratings yet

- StaripDocument2 pagesStaripTahir FadhilNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- T 606 PG 157-160 PDFDocument4 pagesT 606 PG 157-160 PDFJossimar PerezNo ratings yet

- Rupture DiscDocument2 pagesRupture Discbigs1303No ratings yet

- Jindal Metal Octagonal Brochure12112019Document12 pagesJindal Metal Octagonal Brochure12112019Sai KondlekarNo ratings yet

- 2-0L Duratec Engine Building Data SheetDocument2 pages2-0L Duratec Engine Building Data Sheetdomikass27No ratings yet

- Magnet CatalogueDocument5 pagesMagnet CatalogueDCR HealthtodayNo ratings yet

- F693ZZ Flanged Miniature Bearing 3x8x4mmDocument1 pageF693ZZ Flanged Miniature Bearing 3x8x4mmHector Alejandro Melin ContrerasNo ratings yet

- An Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringDocument3 pagesAn Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringManish MohananNo ratings yet

- X ST GR Data Sheet Technical Information ASSET DOC 7304093Document5 pagesX ST GR Data Sheet Technical Information ASSET DOC 7304093Matt ThompsonNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- NIC Components NRP SeriesDocument1 pageNIC Components NRP SeriesNICCompNo ratings yet

- CNC Glass Cutting TableDocument6 pagesCNC Glass Cutting TableMarcel PiersonNo ratings yet

- 9802/5530 B4-5-3 DIG END, PIVOT PINS: Item Part # Change No Description Usage Code QTYDocument2 pages9802/5530 B4-5-3 DIG END, PIVOT PINS: Item Part # Change No Description Usage Code QTYVictor Pescador AmorNo ratings yet

- Catalogue: Roller SieveDocument5 pagesCatalogue: Roller SieveDeadpool FulgueraNo ratings yet

- Air Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesDocument4 pagesAir Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesBiswanath LenkaNo ratings yet

- Work Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyDocument2 pagesWork Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyLetacio OliveiraNo ratings yet

- Berger Lahr - Linear Tables PDFDocument16 pagesBerger Lahr - Linear Tables PDFofanNo ratings yet

- Lypds Adk-2022-2 FaDocument2 pagesLypds Adk-2022-2 Famicko kennoviyanaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Lecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceDocument7 pagesLecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceKim Cristian MaañoNo ratings yet

- Assembling Your Antenna SystemDocument27 pagesAssembling Your Antenna SystemKam MusNo ratings yet

- Manuall Cryton-Yamaha 2015Document57 pagesManuall Cryton-Yamaha 2015Abel PachecoNo ratings yet

- Book Review: Cancy Mcarn Issues in Teacher Education, Spring 2009Document4 pagesBook Review: Cancy Mcarn Issues in Teacher Education, Spring 2009juan_carlos0733No ratings yet

- Datasheet - Ewon Cosy 131Document3 pagesDatasheet - Ewon Cosy 131Omar AzzainNo ratings yet

- NBPME Part II 2008 Practice Tests 1-3Document49 pagesNBPME Part II 2008 Practice Tests 1-3Vinay Matai50% (2)

- Linberg V MakatiDocument2 pagesLinberg V MakatiChimney sweepNo ratings yet

- B. Tech. - CSE - R13-Syllabus JntuaDocument132 pagesB. Tech. - CSE - R13-Syllabus JntuaVasim AkramNo ratings yet

- Shakespeare Ubd Unit PlanDocument16 pagesShakespeare Ubd Unit Planapi-239477809No ratings yet

- 5CT PDVSA em - 18!00!05 EnglishDocument27 pages5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- Maruti FinalDocument23 pagesMaruti FinalYash MangeNo ratings yet

- Dual Nature of Radiation and MatterDocument5 pagesDual Nature of Radiation and Mattercopadag753No ratings yet

- Mini Test 2 - HSDocument4 pagesMini Test 2 - HSNgan Nguyen ThuNo ratings yet

- Chain Rule 3LNDocument2 pagesChain Rule 3LNsaad khNo ratings yet

- Pega DevOps Release Pipeline OverviewDocument200 pagesPega DevOps Release Pipeline OverviewArun100% (1)

- OMNI OptixDocument4 pagesOMNI OptixFelipe MoyaNo ratings yet

- Eimco Elecon Initiating Coverage 04072016Document19 pagesEimco Elecon Initiating Coverage 04072016greyistariNo ratings yet

- Honeymoon in Vegas Word FileDocument3 pagesHoneymoon in Vegas Word FileElenaNo ratings yet

- Train Collision Avoidance SystemDocument4 pagesTrain Collision Avoidance SystemSaurabh GuptaNo ratings yet

- SCI Annual Report 2017Document32 pagesSCI Annual Report 2017The Seamen's Church Institute100% (2)

- Beamer Example: Ethan AltDocument13 pagesBeamer Example: Ethan AltManh Hoang VanNo ratings yet

- Lecture # 3 Introduction To JqueryDocument88 pagesLecture # 3 Introduction To JqueryDanial AhmadNo ratings yet

- ProjectLookingGlassDeclassified PDFDocument13 pagesProjectLookingGlassDeclassified PDFAmi Ferguson83% (6)

- Welcome Speech For Seminar in College 2Document4 pagesWelcome Speech For Seminar in College 2Niño Jay C. GastonesNo ratings yet

- O RTIZDocument2 pagesO RTIZKhimberly Xylem OrtizNo ratings yet

- Congenital Abnormalities of The Female Reproductive TractDocument14 pagesCongenital Abnormalities of The Female Reproductive TractMary SheshiraNo ratings yet

- Lagundi/Dangla (Vitex Negundo)Document2 pagesLagundi/Dangla (Vitex Negundo)Derrick Yson (Mangga Han)No ratings yet

- Muscular System NotesDocument6 pagesMuscular System NotesZussette Corbita VingcoNo ratings yet

- ShowimgDocument76 pagesShowimgROSHAN ROBERTNo ratings yet

- TV ExplorerDocument2 pagesTV Explorerdan r.No ratings yet