Professional Documents

Culture Documents

26-Spirax Sarco Tech 1.Ppp

Uploaded by

Farah OmarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26-Spirax Sarco Tech 1.Ppp

Uploaded by

Farah OmarCopyright:

Available Formats

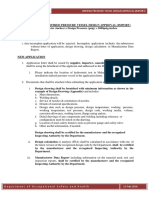

Steam & Condensate Pipe Sizing

Capacity of Steam Pipes in kg/h

Practical experience shows that reasonable velocities for dry saturated steam mains are 25-40m/s.

Longer branch lines should be restricted to a velocity below 15m/s unless the pressure drop is also calculated.

Nominal Size Pipe (mm)

15 20 25 32 40 50 65 80 100 125 150

Pressure Velocity

Bar (g) (m/s) Actual inside pipe diameter Schedule 40

15.80 20.93 26.64 35.04 40.90 52.50 62.70 77.92 102.26 128.20 154.05

Pipeline capacity (kg/h)

15 9 15 25 43 58 95 136 210 362 569 822

0.4 25 14 25 41 71 97 159 227 350 603 948 1369

40 23 40 66 113 154 254 363 561 965 1517 2191

15 10 18 29 51 69 114 163 251 433 681 983

0.7 25 17 30 49 85 115 190 271 419 722 1135 1638

40 28 48 78 136 185 304 434 671 1155 1815 2621

15 12 21 34 59 81 133 189 292 503 791 1142

1 25 20 35 57 99 134 221 315 487 839 1319 1904

40 32 56 91 158 215 354 505 779 1342 2110 3046

15 18 31 50 86 118 194 277 427 735 1156 1669

2 25 29 51 83 144 196 323 461 712 1226 1927 2782

40 47 82 133 230 314 517 737 1139 1961 3083 4451

15 23 40 65 113 154 254 362 559 962 1512 2183

3 25 38 67 109 188 256 423 603 931 1603 2520 3639

40 61 107 174 301 410 676 964 1490 2565 4032 5822

15 28 50 80 139 190 313 446 689 1186 1864 2691

4 25 47 83 134 232 316 521 743 1148 1976 3106 4485

40 75 132 215 371 506 833 1189 1836 3162 4970 7176

15 34 59 96 165 225 371 529 817 1408 2213 3195

5 25 56 98 159 276 375 619 882 1362 2347 3688 5325

40 90 157 255 441 601 990 1411 2180 3755 5901 8521

15 39 68 111 191 261 430 613 947 1631 2563 3700

6 25 65 114 184 319 435 716 1022 1578 2718 4271 6167

40 104 182 295 511 696 1146 1635 2525 4348 6834 9867

15 44 77 125 217 296 487 695 1073 1848 2904 4194

7 25 74 129 209 362 493 812 1158 1788 3080 4841 6989

40 118 206 334 579 788 1299 1853 2861 4928 7745 11183

15 49 86 140 242 330 544 775 1198 2063 3242 4681

8 25 82 144 233 404 550 906 1292 1996 3438 5403 7802

40 131 230 373 646 880 1450 2068 3194 5501 8645 12484

15 60 105 170 294 401 660 942 1455 2506 3938 5686

10 25 100 175 283 490 668 1101 1570 2425 4176 6563 9477

40 160 280 453 785 1069 1761 2512 3880 6682 10502 15164

15 80 141 228 394 537 886 1263 1951 3360 5281 7625

14 25 134 235 380 657 896 1476 2105 3251 5600 8801 12708

40 214 375 608 1052 1433 2362 3368 5202 8960 14082 20333

Capacity of Condensate Pipes in kg/h The Release of Flash Steam

For condensate pipe sizing, use the starting load which will in most cases

be about twice the running load. This will make allowance for flash steam

15

and avoid high back pressure on start up.

r

r

r

ar

r

ba

ba

ba

ba

14

ba

Size the line on a resistance of 1.4 mbar per metre of travel for steam

2.5

1 .5

1.0

0 .5

2 .0

20

pressure up to 10 bar. For higher pressures, increase the pipe size to

Pressure on the traps (bar)

12

allow for larger volumes of flash steam.

Approximate frictional resistance in mbar per m travel 10

0.3 0.5 0.6 0.8 1 1.4

8

(30 Pa) (50 Pa) (60 Pa) (80 Pa) (100 Pa) (140 Pa)

15mm 95 130 140 160 180 220 6

20mm 220 290 320 370 420 500

25mm 410 540 600 690 790 940 4

Flash Steam Pressure

32mm 890 1180 1300 1500 1700 2040

40mm 1360 1790 2000 2290 2590 3100 2

50mm 2630 3450 3810 4390 4990 6000

0

65mm 5350 6950 7730 8900 10150 12100 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18 0.20

80mm 8320 10900 12000 13800 15650 18700

kg Flash per kg Condensate

100mm 17000 22200 24500 28200 31900 38000

Spirax Sarco Limited Tel : 01242 521361

Charlton House Fax : 01242 573342

Cheltenham @Spirax_Sarco_UK

Gloucestershire Email : ukenquiries@spiraxsarco.com

GL53 8ER Website : www.spiraxsarco.com/uk

You might also like

- Performance Standard GuidelineDocument7 pagesPerformance Standard Guidelinemon monNo ratings yet

- Ross 308 grandparent stock performance goalsDocument2 pagesRoss 308 grandparent stock performance goalsWijianto WijiantoNo ratings yet

- Appendix CDocument5 pagesAppendix CUlliaNo ratings yet

- Top 100 ContestantsDocument1 pageTop 100 ContestantsKishor KhadkaNo ratings yet

- Tenure (In Months) # of Accounts# of Desks/MembersDocument4 pagesTenure (In Months) # of Accounts# of Desks/MembersMerecatNo ratings yet

- F 257416848Document11 pagesF 257416848bhupi5No ratings yet

- OWP2-SFEPVS-OSS.069-ST-DR-012-01 - Rev4 - Lifting Transformer DrawingDocument5 pagesOWP2-SFEPVS-OSS.069-ST-DR-012-01 - Rev4 - Lifting Transformer DrawingPhúc Linh NguyễnNo ratings yet

- Ass AsDocument2 pagesAss AsMukesh BishtNo ratings yet

- Enlarged LinkDocument7 pagesEnlarged LinkMarcos VieiraNo ratings yet

- F 257416808Document12 pagesF 257416808bhupi5No ratings yet

- Anchor Windlass Gypsy, Cable LifterDocument5 pagesAnchor Windlass Gypsy, Cable Liftergermain pinedaNo ratings yet

- VF730 & VF733 - AGA ApprovedDocument8 pagesVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNo ratings yet

- Final Answer Keys On Which Score Compiled OnDocument1 pageFinal Answer Keys On Which Score Compiled OnbairwayatendrakumarNo ratings yet

- GPAT 2022 Answer KeyDocument1 pageGPAT 2022 Answer Keysatyaroxx258No ratings yet

- Titan Level Potion To Level Up Emeralds To Level UpDocument3 pagesTitan Level Potion To Level Up Emeralds To Level UpJason PriceNo ratings yet

- Apy ChartDocument1 pageApy ChartSoumya Ranjan SwainNo ratings yet

- WC@ (Recovered)Document17 pagesWC@ (Recovered)bhupi5No ratings yet

- Safe Distance ChartDocument2 pagesSafe Distance ChartQADEER SHANNo ratings yet

- Safe Distance ChartDocument2 pagesSafe Distance ChartQADEER SHANNo ratings yet

- Cable Selection ChartDocument1 pageCable Selection ChartAsif MaqboolNo ratings yet

- Safe distance ChartDocument2 pagesSafe distance ChartQADEER SHANNo ratings yet

- Saluran Induk dan Sek LeworengDocument38 pagesSaluran Induk dan Sek LeworengNurwahidah WiwiNo ratings yet

- Insulated vs Uninsulated Ceiling Cooling Capacity ComparisonDocument2 pagesInsulated vs Uninsulated Ceiling Cooling Capacity ComparisonMyo Kyaw KyawNo ratings yet

- Deflections For Load Case C1: Proposed 2 Storey MS PlatformDocument96 pagesDeflections For Load Case C1: Proposed 2 Storey MS PlatformNyu123456No ratings yet

- Batt Cables NYYDocument1 pageBatt Cables NYYeplan drawingsNo ratings yet

- General Unarmoured Power CableDocument1 pageGeneral Unarmoured Power CableanuradhaNo ratings yet

- Creative Wash Ltd-03: Cycle Time Study Style Sheet-Wet Process Style Style Style StyleDocument1 pageCreative Wash Ltd-03: Cycle Time Study Style Sheet-Wet Process Style Style Style Stylemh raihanNo ratings yet

- Steam velocity of 25 m/s for saturated applicationsDocument42 pagesSteam velocity of 25 m/s for saturated applicationsJaswinder SinghNo ratings yet

- ICD-10 Diagnosis Codes ListDocument3 pagesICD-10 Diagnosis Codes ListManguharjo PuskesmasNo ratings yet

- MSE 410 Project Data With Different ServersDocument6 pagesMSE 410 Project Data With Different Serversvartan batmazyanNo ratings yet

- DC-8 Year 707 717 727 737 747 757 767 777: Boeing Delivery ScheduleDocument18 pagesDC-8 Year 707 717 727 737 747 757 767 777: Boeing Delivery ScheduleGirish KumarNo ratings yet

- Conversion To Equivalent TemperatureDocument2 pagesConversion To Equivalent Temperaturepejakm1No ratings yet

- Bit - Ly/cbexptable: CLICK: File Make ADocument2 pagesBit - Ly/cbexptable: CLICK: File Make AKim Oliver siatanNo ratings yet

- 23 SectionsDocument29 pages23 SectionsughkgbkjbNo ratings yet

- Dipstick Chart1Document2 pagesDipstick Chart1Sigit Adi PNo ratings yet

- CPT FinalDocument22 pagesCPT FinalSebastiánRiosNo ratings yet

- Filtration Experiment ResultsDocument6 pagesFiltration Experiment ResultsDewa Sang Putra DewataNo ratings yet

- Quantifying Bull Whip EffectDocument6 pagesQuantifying Bull Whip Effectpgp39339No ratings yet

- ElbowsDocument1 pageElbowsKokkieNo ratings yet

- Employee Data by Department, Business Unit, Job TitleDocument126 pagesEmployee Data by Department, Business Unit, Job TitleKarthik Raja 23No ratings yet

- Boeing ExhibitsDocument17 pagesBoeing Exhibitsincarn123No ratings yet

- Polycab Price List - 19 April 2018 PDFDocument4 pagesPolycab Price List - 19 April 2018 PDFSreegith ChelattNo ratings yet

- Grocery Gateway Simulated Demand DataDocument44 pagesGrocery Gateway Simulated Demand DataPiyush SharmaNo ratings yet

- 25lalitpur WardLevelDocument23 pages25lalitpur WardLevelabcdefgNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- PHASE SPACING AND GROUND CLEARANCE FOR STATION CLASS OUTDOOR AIR SWITCHESDocument1 pagePHASE SPACING AND GROUND CLEARANCE FOR STATION CLASS OUTDOOR AIR SWITCHESloubeenNo ratings yet

- Discharge of Smooth Nozzle - Gallons Per MinuteDocument2 pagesDischarge of Smooth Nozzle - Gallons Per MinuteRandiAndhikaNo ratings yet

- Balara High School 10 SummaryDocument52 pagesBalara High School 10 SummaryCristina Rocas-BisqueraNo ratings yet

- Binding Energy DeuteronDocument3 pagesBinding Energy DeuteronPhysicsNo ratings yet

- GRADE 7 ANALYSIS 2023Document8 pagesGRADE 7 ANALYSIS 2023merekaoNo ratings yet

- Recommended Cutting Speeds in R.P.M.: Size Revolutions Per MinuteDocument1 pageRecommended Cutting Speeds in R.P.M.: Size Revolutions Per MinuteAhac NavodnikNo ratings yet

- Data For Assignment#2Document18 pagesData For Assignment#2Hunny VermaNo ratings yet

- Zomato 2021 - RawdataDocument5 pagesZomato 2021 - RawdataSiddhant SrivastavaNo ratings yet

- Product Data Sheet General Data Air Consumption Imperial Hytork en 83216Document1 pageProduct Data Sheet General Data Air Consumption Imperial Hytork en 83216RSalehNo ratings yet

- DipstickDocument4 pagesDipsticksaeedNo ratings yet

- IEC Current CableDocument14 pagesIEC Current CableHuynh Ngoc NghiaNo ratings yet

- Material and Drill Diameter Cutting Speed ChartDocument1 pageMaterial and Drill Diameter Cutting Speed ChartKevin WellsNo ratings yet

- Tankcal (Version 1)Document8 pagesTankcal (Version 1)Raja ManiNo ratings yet

- Conversion Table: Imperial, Metric and Pakistani Land Area UnitsDocument3 pagesConversion Table: Imperial, Metric and Pakistani Land Area UnitsIshaq UmarNo ratings yet

- Steam Tables: Saturated Steam: TEMPERATURE TableDocument16 pagesSteam Tables: Saturated Steam: TEMPERATURE TableFarah OmarNo ratings yet

- INCOTERMS 2010 Definitions PDFDocument21 pagesINCOTERMS 2010 Definitions PDFIynulF.OmarNo ratings yet

- INCOTERMS 2020 Key ChangesDocument1 pageINCOTERMS 2020 Key ChangesFarah OmarNo ratings yet

- Incoterms 2020 - WallchartDocument1 pageIncoterms 2020 - WallchartAarón I. S. ZárateNo ratings yet

- INCOTERMS 2020 Crane Worldwide LogisticsDocument2 pagesINCOTERMS 2020 Crane Worldwide LogisticsFarah OmarNo ratings yet

- INCOTERMS 2020 - WallchartDocument1 pageINCOTERMS 2020 - WallchartFarah OmarNo ratings yet

- 12.20.01 Pressure Vessels PDFDocument71 pages12.20.01 Pressure Vessels PDF77389808100% (4)

- Petronas Technical Standards: Heat Exchangers - Shell and Tube TypeDocument40 pagesPetronas Technical Standards: Heat Exchangers - Shell and Tube TypeIynulF.Omar33% (3)

- 2016 Ve Upvapp Import m3000 RevisedDocument2 pages2016 Ve Upvapp Import m3000 RevisedZulfadli RaniNo ratings yet

- Registration of Pressure VesselsDocument21 pagesRegistration of Pressure VesselsLin Heng100% (1)

- Petronas Technical Standards: Plate and Frame Heat ExchangersDocument17 pagesPetronas Technical Standards: Plate and Frame Heat ExchangersIynulF.OmarNo ratings yet

- Design Drawing Appendix ExampleDocument1 pageDesign Drawing Appendix ExampleINSTECHNo ratings yet

- DOSHDocument2 pagesDOSHShanbiao YinNo ratings yet

- Example Form Jkj127Document1 pageExample Form Jkj127Farah OmarNo ratings yet

- Body Mechanics and Movement Learning Objectives:: by The End of This Lecture, The Student Will Be Able ToDocument19 pagesBody Mechanics and Movement Learning Objectives:: by The End of This Lecture, The Student Will Be Able TomahdiNo ratings yet

- "Network Security": Alagappa UniversityDocument1 page"Network Security": Alagappa UniversityPRADEEPRAJANo ratings yet

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- Feedback Control of Dynamic Systems Franklin 7th Edition Solutions ManualDocument36 pagesFeedback Control of Dynamic Systems Franklin 7th Edition Solutions Manualkilter.murk0nj3mx100% (31)

- Drainage Manual: State of Florida Department of TransportationDocument78 pagesDrainage Manual: State of Florida Department of TransportationghoyarbideNo ratings yet

- Teams Training GuideDocument12 pagesTeams Training GuideImran HasanNo ratings yet

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- Bohemian Flower Face Mask by Maya KuzmanDocument8 pagesBohemian Flower Face Mask by Maya KuzmanDorca MoralesNo ratings yet

- USA Gas TurbineDocument4 pagesUSA Gas TurbineJustin MercadoNo ratings yet

- Day3 PESTLE AnalysisDocument13 pagesDay3 PESTLE AnalysisAmit AgrawalNo ratings yet

- Arnica The Miracle Remedy - Case RecordsDocument4 pagesArnica The Miracle Remedy - Case Recordskaravi schiniasNo ratings yet

- Toyota's Marketing StrategyDocument14 pagesToyota's Marketing StrategyLavin Gurnani0% (1)

- Manual de Partes 501-601Document27 pagesManual de Partes 501-601camilo bautista100% (2)

- 2024 Yoga Vidya Training FormDocument8 pages2024 Yoga Vidya Training FormJohnNo ratings yet

- Dental Pulp TissueDocument77 pagesDental Pulp TissueJyoti RahejaNo ratings yet

- Gender Support Plan PDFDocument4 pagesGender Support Plan PDFGender SpectrumNo ratings yet

- PILE LOAD TEST PROCEDURE GUIDEDocument2 pagesPILE LOAD TEST PROCEDURE GUIDEJEFFY JACOBNo ratings yet

- CS Sample Paper 1Document10 pagesCS Sample Paper 1SpreadSheetsNo ratings yet

- India: Soil Types, Problems & Conservation: Dr. SupriyaDocument25 pagesIndia: Soil Types, Problems & Conservation: Dr. SupriyaManas KaiNo ratings yet

- Hps40 Tech Doc ScreenDocument20 pagesHps40 Tech Doc ScreenAnonymous oyUAtpKNo ratings yet

- Technical Document 3PAR Arrays Preparation PDFDocument14 pagesTechnical Document 3PAR Arrays Preparation PDFmikdadhussainNo ratings yet

- Introduction To Google SheetDocument14 pagesIntroduction To Google SheetJohn Rey Radoc100% (1)

- 2.e-Learning Chapter 910Document23 pages2.e-Learning Chapter 910ethandanfordNo ratings yet

- Ð.Ð.Á Valvoline Áóìá Áíáâáóç Ñéôóùíáó 9.6.2019: Omaäa ADocument6 pagesÐ.Ð.Á Valvoline Áóìá Áíáâáóç Ñéôóùíáó 9.6.2019: Omaäa AVagelis MoutoupasNo ratings yet

- His Quotes: Spirit of Shri Dhirubhai H. Ambani Quotes at Various ForumsDocument4 pagesHis Quotes: Spirit of Shri Dhirubhai H. Ambani Quotes at Various ForumspramodiniroutNo ratings yet

- The Facility Manager's HandbookDocument362 pagesThe Facility Manager's HandbookLuân Châu100% (14)

- Rectangle StabbingDocument49 pagesRectangle StabbingApurba DasNo ratings yet

- Cse 3003: Computer Networks: Dr. Sanket Mishra ScopeDocument56 pagesCse 3003: Computer Networks: Dr. Sanket Mishra ScopePOTNURU RAM SAINo ratings yet

- A Review of High School Economics Textbooks: February 2003Document27 pagesA Review of High School Economics Textbooks: February 2003Adam NowickiNo ratings yet

- Boost productivity and networking with a co-working café in Iligan CityDocument4 pagesBoost productivity and networking with a co-working café in Iligan CityJewel Cabigon0% (1)