Professional Documents

Culture Documents

Oil Tempered Chromium-Vanadium Wire Commercial Quality

Uploaded by

Horn MachineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Tempered Chromium-Vanadium Wire Commercial Quality

Uploaded by

Horn MachineCopyright:

Available Formats

Technical

Data Sheet

OIL TEMPERED CHROMIUM-VANADIUM WIRE

COMMERCIAL QUALITY

Chromium-vanadium is the most popular alloy steel for springs that are required to withstand a large number of operating

cycles. It is medium carbon steel with chromium and vanadium added to increase its hardness and tensile strength.

Springs can be used at extremely high stresses in applications where they will also be subject to extreme shock and impact

loading. For springs of high endurance, the alloy is usually used at a hardness of Rockwell C44-49. Where extreme

stresses and short life are expected, the hardness is increased to Rockwell C50-53.

In sizes .375” and under, chromium-vanadium alloy springs have no higher endurance limits than plain carbon steels of

valve spring quality. However, the alloy springs have less tendency to relax at temperatures as high as 400°F and

satisfactory operation can be obtained at temperatures up to 750°F. when loads are not severe, when the stress range is

narrow, or when stress changes are infrequent. The following tolerances are standard.

Recommendations for heat treatment: Immediately after coiling, the springs should be stress relieved

at about 400°C. (750°F.) for 30 minutes. After shot peening, the springs should be stress relieved at about

250°C.(480°F.) for 30 minutes.

Gibbs oil tempered commercial quality chromium-vanadium meets ASTM-A-231 specification. Wire is available in size

ranges from .125”-.625”

Chemical Composition Nominal Diameter (Inches) Tolerance (inch)

Per ASTM-A-231 *Max value

Carbon 0.48 – 0.53% Over .125 to .375 incl. +/- .002

Manganese 0.70 – 0.90% Over .375 to .500 incl. +/- .003

Phosphorus 0.040% *

Sulfur 0.040% *

Silicon 0.15 – 0.35%

Chromium 0.80 – 1.10%

Vanadium 0.15% Min.

Tensile Strength Table ( ASTM-A-231)

Dia. Tensile Tensile Dia. Tensile Tensile

Inch Min PSI Max PSI Inch Min PSI Max PSI

.135 235,000 255,000 .500 190,000 210,000

.162 225,000 245,000

.192 220,000 240,000

.244 210,000 230,000

.283 205,000 225,000

.312 203,000 223,000

.375 200,000 220,000

.438 195,000 215,000

The above charts are intended to provide general background information. You should also review the appropriate material

specification. Please contact Gibbs if you have any questions.

Gibbs Wire & Steel Company Inc.

Metals Drive, Southington, CT 06489 (860) 621-0121

No. 1010 01/14

You might also like

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument15 pagesGrade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsSenthil KumarNo ratings yet

- Introduction To SteelsDocument167 pagesIntroduction To Steelspaddiemaguire100% (1)

- ENI - Casing Design ManualDocument134 pagesENI - Casing Design Manualwelltest2012100% (14)

- CQI-9 Self Assessment in 2018Document36 pagesCQI-9 Self Assessment in 2018abadi100% (2)

- Safe Reinforcing SolutionsDocument14 pagesSafe Reinforcing SolutionsInternational companyNo ratings yet

- Mechanical Engineering Design Presentation Bsme01183097Document30 pagesMechanical Engineering Design Presentation Bsme01183097Waqar KhanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Anbao CatalogueDocument15 pagesAnbao CatalogueQAZI MUHAMMAD inamuddinNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Stainless Steel 202 Material Chemical CompositionDocument3 pagesStainless Steel 202 Material Chemical CompositionLelka2000No ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Overhead Aluminium Conductors 1Document24 pagesOverhead Aluminium Conductors 1mt6760No ratings yet

- Tecnofil Catalogo2022Document8 pagesTecnofil Catalogo2022Cesar OteroNo ratings yet

- Plate Asme Sa516 Grade 70Document10 pagesPlate Asme Sa516 Grade 70Deaz AmbrsNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- Overhead Aluminium ConductorsDocument23 pagesOverhead Aluminium ConductorsWayne KitchingNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- Viraj BookletaaDocument29 pagesViraj BookletaaSuhaib ShabandriNo ratings yet

- Tabla de Referencias de Aceros Inoxidables (ASTM A213)Document1 pageTabla de Referencias de Aceros Inoxidables (ASTM A213)Baltasar BuchiniNo ratings yet

- Coremax H43Document1 pageCoremax H43LIM hoon boonNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- Vautid 100, Engl 041016Document1 pageVautid 100, Engl 041016Maria TzagarakiNo ratings yet

- Chemical Composition of Carbon SteelDocument2 pagesChemical Composition of Carbon SteelAkilanNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

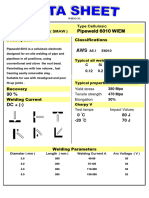

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- TDSWE 5356 Wire TSDocument2 pagesTDSWE 5356 Wire TSbalamuruganNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

- ACUWELD MIG &TIG Welding WiresDocument38 pagesACUWELD MIG &TIG Welding WiresALOKE GANGULYNo ratings yet

- 3003Document1 page3003YovitaAyuningtyasNo ratings yet

- Datasheet-Sanmac-2205-En-V2021-10-07 13 - 03 Version 1Document10 pagesDatasheet-Sanmac-2205-En-V2021-10-07 13 - 03 Version 1simone.mauriNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- Avesta MA 253Document2 pagesAvesta MA 253Denar PurnamaNo ratings yet

- Mac CalDocument4 pagesMac Calvhs mechatronicsNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayNo ratings yet

- CZ 130Document1 pageCZ 130Taner DemirelNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- Iron Special Iron Material Spec Finecast Foundry 28.8.20Document4 pagesIron Special Iron Material Spec Finecast Foundry 28.8.20Lê ChiếnNo ratings yet

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- Techalloy 55Document1 pageTechalloy 55Muhammad FajriNo ratings yet

- 15 CDV 6Document1 page15 CDV 6Vijaymohan KanugulaNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- Stanley Model J Control ManualDocument19 pagesStanley Model J Control ManualHorn MachineNo ratings yet

- Centari Topcoat 5.0 VOC (A Quality) : GeneralDocument3 pagesCentari Topcoat 5.0 VOC (A Quality) : GeneralHorn MachineNo ratings yet

- KudezojituweDocument2 pagesKudezojituweHorn MachineNo ratings yet

- Final Fantasy VI AdvanceDocument26 pagesFinal Fantasy VI AdvanceHorn MachineNo ratings yet

- Final Fantasy VI AdvanceDocument26 pagesFinal Fantasy VI AdvanceHorn MachineNo ratings yet

- Astm A105 - 05Document5 pagesAstm A105 - 05Stéphane LevasseurNo ratings yet

- Ams H 6875Document22 pagesAms H 6875qcromoilfieldNo ratings yet

- International Standard: Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Bright Steel ProductsDocument11 pagesInternational Standard: Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Bright Steel ProductsMiruna MetesNo ratings yet

- Microstructural Characterization and Production of High Yield Strength Rebar-Mansutti-DanieliDocument7 pagesMicrostructural Characterization and Production of High Yield Strength Rebar-Mansutti-DanieliSergio RonchiNo ratings yet

- Hardox 600: General Product DescriptionDocument2 pagesHardox 600: General Product DescriptionNguyên NguyễnNo ratings yet

- Chapter20 Quenching PDFDocument93 pagesChapter20 Quenching PDFM Ghais VitoNo ratings yet

- B88-14 Standard Specification For Seamless Copper Water TubeDocument7 pagesB88-14 Standard Specification For Seamless Copper Water TubeislamakthamNo ratings yet

- Palladium-Silver-Copper Electrical Contact Alloy: Standard Specification ForDocument3 pagesPalladium-Silver-Copper Electrical Contact Alloy: Standard Specification ForMohamad ShafeyNo ratings yet

- Fatigue 2010Document40 pagesFatigue 2010GazeNo ratings yet

- Som Lab Manual NnceDocument39 pagesSom Lab Manual Nncelogeshboy007No ratings yet

- Sa 20 PDFDocument46 pagesSa 20 PDFmr.aghelNo ratings yet

- Astm A387 A387mDocument5 pagesAstm A387 A387mArunkumar DasarathanNo ratings yet

- 23MnB4 - 1.5535 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument2 pages23MnB4 - 1.5535 - SteelNumber - Chemical Composition, Equivalent, PropertiesSergiNo ratings yet

- TemperedDocument5 pagesTemperedPutri Desty AmeliaNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 EDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 Ebaskaran ayyapparajNo ratings yet

- 6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021Document30 pages6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021harieduidNo ratings yet

- Study and Operation of Tempering ProcessDocument11 pagesStudy and Operation of Tempering ProcessMostafizur Rahman SobujNo ratings yet

- Alloy Steels 8620: Chemistry DataDocument6 pagesAlloy Steels 8620: Chemistry DataVijay PalNo ratings yet

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Document5 pagesDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinNo ratings yet

- Chapter 14Document11 pagesChapter 14bhushan_963No ratings yet

- PB Uddeholm Calmax EnglishDocument12 pagesPB Uddeholm Calmax EnglishxulubNo ratings yet

- 1.PL Drilling Main CatDocument42 pages1.PL Drilling Main CatBojan RadovanovicNo ratings yet

- Astm A335-A335m-2021Document11 pagesAstm A335-A335m-2021Carlos100% (1)