Professional Documents

Culture Documents

Satr H 2008

Satr H 2008

Uploaded by

Moghal AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Satr H 2008

Satr H 2008

Uploaded by

Moghal AliCopyright:

Available Formats

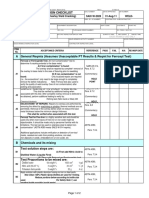

SAUDI ARAMCO ID/PIEU-30-Nov-2018 - Rev. 2018.11.00 (Standards Cutoff - Nov 30,2018) Rev.2018.11.

00 30-Nov-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

HOLIDAY TEST REPORT SATR-H-2008 27-Jan-19 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

A. COATING SYSTEM : ______________________ Coating DFT: _______________

HOLIDAY TEST VOLTAGE REQUIREMENT :

Type of Coating Type of Test Equipment Voltage Requirement

Phenolic Epoxy Wet Sponge Tester 67.5 Volts

Fusion Bonded Epoxy Pulse-Type DC Holiday Detector 1500 to 2000+/- 50 Volts DC

Polyethylene & PP Pulse-Type DC Holiday Detector 25,000 +/-1000 Volts DC

APCS-113A Pulse-Type DC Holiday Detector 2400 +/- 50 Volts DC

APCS-113B Pulse-Type DC Holiday Detector 4,000 + 100 Volts DC

APCS-113C Pulse-Type DC Holiday Detector 10,000 to 15,000 Volts DC

OTHER: ___________ ____________________ _____________________

HOLIDAY TEST EQUIPMENT FIELD CALIBRATION FUNCTIONAL GROUNDING TEST

FIELD VERIFICATION (At least once in 4 hrs) TEST

MODEL / S. No.: CALIB. DATE VDC TIME PASS FAIL PASS FAIL

B. TEST RESULTS :

Notes: a. Indicate in one (1) report all items, joints or sections tested and passed covered by the field calibration period.

b. Rejected items should be listed in another report, unless they were corrected within the same calibration period.

REPAIRED WITHIN

TEST LOCATIONS NO. of HOLIDAYS FIELD CALIB. PERIOD

RESULT REMARKS

NOTE: Limitations of repair areas and method of repair shall be referred to SAES-H-200, Para. 6.3.(24 Oct 2011) and their respective

coating system or applicable Inspection Checklist.

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-H-200, Storage, Handling and Installation of Externally Coated Pipe (Section 7), (7 February 2017)

2. SAES-H-002 Internal and External Coatings for Steel Pipelines and Piping,(2 June, 2012) APCS-Sheets for APCS-113 A,113 B

3. SAES-H-002VApproved Saudi Aramco Data Sheets for the Pipeline and Piping Coatings (07 February 2017) APCS-113C Data Sheets

4. SAES-H-001 Coating Selection & Application Requirements for Industrial plants and Equipment, (21 February 2018)

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Name, Title, Company, Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date:

Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: Name, Organization, T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-30-Nov-2018 - Rev. 2018.11.00 (Standards Cutoff - Nov 30,2018) Rev.2018.11.00 30-Nov-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

HOLIDAY TEST REPORT SATR-H-2008 27-Jan-19 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Satip W 014 01Document12 pagesSatip W 014 01spravin231No ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- Coatings Audit Handbook Nov 2011Document19 pagesCoatings Audit Handbook Nov 2011Neil PiersonNo ratings yet

- SQAE Velosi Interview PreparationDocument10 pagesSQAE Velosi Interview PreparationSebastian RajeshNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 MechDocument7 pagesSaudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 Mechnisha_khanNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Product Cost Planning MainDocument155 pagesProduct Cost Planning MainCELSO SANTOS100% (1)

- Global Fintech Fest Post Event Report PDFDocument62 pagesGlobal Fintech Fest Post Event Report PDFabhijitkortiNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniNo ratings yet

- Earned Value Analysis Template ExcelDocument4 pagesEarned Value Analysis Template ExcelIamEm B. MoNo ratings yet

- PID ResponsibilityDocument2 pagesPID Responsibilityimurugan06No ratings yet

- Cement Lining (Pipe & Fittings) : Inspection Assignment PackageDocument6 pagesCement Lining (Pipe & Fittings) : Inspection Assignment PackageShahul Hameed RazikNo ratings yet

- I Object: Repair Procedure For Tank BottomDocument6 pagesI Object: Repair Procedure For Tank BottomZouhair BenmabroukNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Internal NCR Log For Satellite 30aug18Document4 pagesInternal NCR Log For Satellite 30aug18GA JonNo ratings yet

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323No ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Company Profile - Rizhao Steel YingkouDocument41 pagesCompany Profile - Rizhao Steel Yingkourashid isaarNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Ucm02 022096Document2 pagesUcm02 022096Luis Miguel Rivera SoplopucoNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- Ai Hempadur 87540 EnglishDocument2 pagesAi Hempadur 87540 EnglishAmilcar BolagNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- 175 018200 PDFDocument2 pages175 018200 PDFAbu Anas M.SalaheldinNo ratings yet

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeAbu Anas M.SalaheldinNo ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Grados Termicos TN55TH y TN80THDocument10 pagesGrados Termicos TN55TH y TN80THgfwtNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument9 pagesSaudi Aramco Typical Inspection PlanAbhilashNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- TK®-236 Physical Properties: 1. HardnessDocument2 pagesTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Document3 pagesSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyNo ratings yet

- Flash Report #01: Industry & Facilities DivisionDocument4 pagesFlash Report #01: Industry & Facilities DivisionEduard GadzhievNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Paint For SteelDocument11 pagesPaint For SteelSaud PathiranaNo ratings yet

- Weld Weave WidthDocument4 pagesWeld Weave Widthapply19842371No ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- PTS-1012 - RA Hardness Test ReportDocument1 pagePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNo ratings yet

- D3230 19 PDFDocument7 pagesD3230 19 PDFalexanderNo ratings yet

- 175 060100Document1 page175 060100Abu Anas M.SalaheldinNo ratings yet

- Din en 10204Document5 pagesDin en 10204QA QCNo ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- Hempadur Zinc 17380Document2 pagesHempadur Zinc 17380sizmaruNo ratings yet

- 09 Samss 071Document6 pages09 Samss 071inatt101100% (1)

- Satr M 1014Document2 pagesSatr M 1014DipuNo ratings yet

- Saudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKDocument2 pagesSaudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKshaikhbwcNo ratings yet

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNo ratings yet

- Saudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalDocument9 pagesSaudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection Plan: Coating Application On Concrete Surfaces SATIP-H-003 - 01 27-Jan-19Document10 pagesSaudi Aramco Typical Inspection Plan: Coating Application On Concrete Surfaces SATIP-H-003 - 01 27-Jan-19Moghal AliNo ratings yet

- Saudi Aramco Test Report: SATR-H-2011 27-Jan-19 Mech Surface Preparation of Internal Pipe End/Joints For FBE CoatingDocument2 pagesSaudi Aramco Test Report: SATR-H-2011 27-Jan-19 Mech Surface Preparation of Internal Pipe End/Joints For FBE CoatingMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Apcs 113 - Inorganic ZincDocument11 pagesApcs 113 - Inorganic ZincMoghal AliNo ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- The Marketing Mix - IntroductionDocument3 pagesThe Marketing Mix - Introductionabrar mahir SahilNo ratings yet

- The Global Media and ICT: PretestDocument7 pagesThe Global Media and ICT: PretestShiela Mae Saladaga TanNo ratings yet

- Affidavit of Non Identity Form MinnesotaDocument13 pagesAffidavit of Non Identity Form MinnesotaBobNo ratings yet

- ch5 UpdatedDocument31 pagesch5 UpdatedEsha 1277-FBAS/BSBT/F19No ratings yet

- Internship CompaniesDocument22 pagesInternship CompaniesKhalil FanousNo ratings yet

- Ss Activity 27Document2 pagesSs Activity 27api-356087485No ratings yet

- New - JMC - Dbm-Ccc-Dilg No. 2015 - 01 Tagging Climate Change Expenditures PDFDocument29 pagesNew - JMC - Dbm-Ccc-Dilg No. 2015 - 01 Tagging Climate Change Expenditures PDFArya StarkNo ratings yet

- PFDA Bid Documents - Design and Build For BalerDocument181 pagesPFDA Bid Documents - Design and Build For BalerJemuel PinongcosNo ratings yet

- 02A - Contoh RMK - Defining Corporate Governance 2Document3 pages02A - Contoh RMK - Defining Corporate Governance 2Ulan RachmawatiNo ratings yet

- Interview Questions Topic Wise PDFDocument7 pagesInterview Questions Topic Wise PDFBalaji KommaNo ratings yet

- SIP Topics For ReferenceDocument44 pagesSIP Topics For ReferenceMahesh KhadeNo ratings yet

- HR Consulting Firms and Their Collaboration With Internationla NetworksDocument20 pagesHR Consulting Firms and Their Collaboration With Internationla NetworksAyesha HaroonNo ratings yet

- Review of Norms For Classification of Urban Co-Operative Banks (Ucbs) Financially Sound and Well Managed (FSWM)Document2 pagesReview of Norms For Classification of Urban Co-Operative Banks (Ucbs) Financially Sound and Well Managed (FSWM)Bhavani BhushanNo ratings yet

- Climate Risk-Bii-Megaforces-December-2023Document7 pagesClimate Risk-Bii-Megaforces-December-2023zbg17No ratings yet

- Yume SDN BHD - Sample Business PlanDocument96 pagesYume SDN BHD - Sample Business PlanNur Afifah Shahrizal0% (2)

- Artroniq - Announcement (Proposals) (7 February 2023)Document27 pagesArtroniq - Announcement (Proposals) (7 February 2023)zul hakifNo ratings yet

- Diane chptr1 DoneDocument13 pagesDiane chptr1 DoneRosemenjelNo ratings yet

- Boston Beer Company: Case Analysis by Asish K BhattacharyyaDocument16 pagesBoston Beer Company: Case Analysis by Asish K Bhattacharyyaadrishm0% (1)

- Prepared by Anthony J. Avallone and Young K. Ro Sanders, Supply Chain Management Introduction To Supply Chain EconomicsDocument8 pagesPrepared by Anthony J. Avallone and Young K. Ro Sanders, Supply Chain Management Introduction To Supply Chain EconomicsNgọc MaiNo ratings yet

- Sport Center Business Process MappingDocument11 pagesSport Center Business Process MappingHani Nurul AzizahNo ratings yet

- Correspondence GuidebookDocument39 pagesCorrespondence GuidebookAni RukhadzeNo ratings yet

- Annexure-II (Prof EditDocument5 pagesAnnexure-II (Prof EditInformation Techn. HODNo ratings yet

- FAR Handout Depreciation Part 2Document7 pagesFAR Handout Depreciation Part 2Chesca Marie Arenal Peñaranda100% (1)

- Tally Exercise 006Document3 pagesTally Exercise 006Karthick KumarNo ratings yet

- Impact of Covid-19 On Mobile Banking ServiceDocument32 pagesImpact of Covid-19 On Mobile Banking ServiceRasel khanNo ratings yet

- Cover Letter Examples For Management PositionDocument5 pagesCover Letter Examples For Management Positionafllufama100% (1)