Professional Documents

Culture Documents

SATR-W-2020 Rev 8

SATR-W-2020 Rev 8

Uploaded by

محمد علي النويصرCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SATR-W-2020 Rev 8

SATR-W-2020 Rev 8

Uploaded by

محمد علي النويصرCopyright:

Available Formats

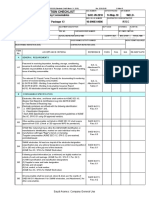

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Welding Consumable Receiving Insp Report SATR-W-2020 31-Dec-14 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Date ASME II C / AWS SIZE Manufacturer & Product Description Unique ID No. INSPECTION REMARKS

(UNIT PACKAGE TYPE & Batch/ * See Attachment for

Rec'd

SPEC CLASS Diam/L WEIGHT)

Blend/

Mix/Heat

Lot* Tests on Received Consumables

INSTRUCTIONS: DO NOT USE ELECTRODE OR FILLER MAT'L "LOTS" on SA Projects for production welding until PMI tests verify composition.

At the latest, test the first production weld. Test consumables immediately after receipt to avoid "surprise" of "bad batches". Specs requiring PMI at SA are:

SFA-5.4 SS Electrodes (SMAW) --- SFA-5.5 Low-Alloy Electrodes (SMAW) ---

SFA-5.6 Copper & Alloy Electrodes --- SFA-5.7 Copper & Alloy Rods & Electrodes ---- SFA-5.9 Bare SS Electrodes & Rods --- SFA-5.11 Nickel & Alloy Electrodes

(SMAW) --- SFA-5.12 Tungsten & Alloy Electrodes --- SFA-5.13 Surfacing Electr. (SMAW) --- SFA-5.14 Nickel & Alloy Bare Electrodes & Rods --- SFA-5.21 Bare

Electrodes & Rods, Surfacing --- SFA-5.22 SS Electrodes (FCAW) & SS Flux Cored Rods (GTAW) ---SFA-5.23 Low-Alloy Electrodes & Fluxes (SAW) --- SFA-5.28 Low-

Alloy Electrodes & Rods (GMAW) ---SFA-5.29 Low-Alloy Electrodes (FCAW)

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Electrodes are properly stored & segregated in stores, shops, or ovens to avoid SAES-A-206,

A1

mix-up. Use separate ovens for different type* consumables. (*CS, Low Alloy) Section 7.7.1

Ensure inventory control is established to account for ALL of those consumables SAES-A-206,

A2

that are checked-out. (Issue Slip/Proc). SATR-W-2010 Section 7.7.1

One consumable from each lot is PMI-tested. Remainder of lot shall be compared

SAES-A-206,

A3 to the identified consumable to verify that markings of electrodes & filler wires are

Section 7.7.2

correct. Log any unique markings (mfg codes)

PMI test of weld metal* (*deposited or undiluted "buttons") was performed prior to

SAES-A-206,

welding or during initial welding process. Note: Certain weld rods have alloying

Section 7.7

A4 elements contained in the flux, & do not meet alloy spec until welded. To weld

(See

"buttons" ... simply open the applicable spec (SFA 5.5, etc) and refer to the Figure

Attachment)

1 - Pad for Chemical Analysis of undiluted Weld Metal ... follow instruction

The above specified materials were received into stock for use on SA Projects on

Check

date(s) shown. Physical Inspection was performed along with review of the SA ASME SEC II C,

Application

Approved Consumable Manufacturer Test Reports (attached to report). Records

(WPS & PQR)

A5 included material & test certifications. These were checked against the applicable Consumables

before Issuing

ASME II C Consumable specification (SFA 5.1, 5.4, 5.5, etc) and all material & SFA 5.01

testing reqmts met the listed minimum acceptable requirements.Complete section

Consumables

using the applicable SAIC for Receiving Insp.

ASME SEC II C,

Above material (certs) were reviewed against the intended welding application Issue

(WPS, PQR). Essential variables & SA rqmts were checked per the applicable Consumables for

A6 Consumables

"SAIC" for Consumable Control (incl any WPS Cover Sheet Remarks by CSD). Project & WPS

Applicable

Consumable is acceptable for use on the WPS listed in Remarks listed below

SAES-W-Std

REMARKS:

References: 1. SAES-A-206-Positive Material Identification (30 April 2011).

2. ASME SEC II C - Specification for Welding rods,Electrodes & Filler metals.(01 July 2011)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Saudi Aramco: Company General Use

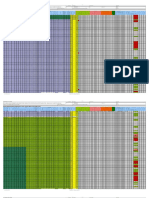

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Welding Consumable Receiving Insp Report SATR-W-2020 31-Dec-14 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Date ASME II C / AWS SIZE Manufacturer & Product Description Unique ID No. INSPECTION REMARKS

(UNIT PACKAGE TYPE & Batch/ * See Attachment for

Rec'd

SPEC CLASS Diam/L WEIGHT)

Blend/

Mix/Heat

Lot* Tests on Received Consumables

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

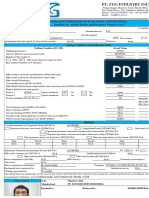

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Welding Consumable Receiving Insp Report (Attachment) SATR-W-2020 31-Dec-14 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

CSD RECOMMENDED SUPPLEMENTAL TESTS FOR CONSUMABLES - (Not mandatory per SA standards)

ITEM

ACCEPTANCE CRITERIA (Per Consumable Specification) REFERENCE PASS FAIL N/A RE-INSP DATE

No.

GROOVE WELD TEST & RADIOGRAPHIC TEST (RT): The backing

shall be removed, and both surfaces of the weld shall be machined or

ground smooth. In evaluating RT, 1 in. [25 mm] of the weld measured

from each end of the assembly shall be disregarded.

Groove Weld Test (passing RT

exam) is sent to an approved lab and provides all-weld-metal samples Consumable

A1

for the following tests: A) Specification

TENSION TEST (Per Spec & AWS B4.0)

B) BEND TEST (Per Spec & AWS B4.0)

C) IMPACT TEST (Per Spec & AWS

B4.0) One Coupon

= Five Tests

Consumable

A2 FILLET WELD TEST (per details in Consumable Spec)

Specification

CHEMICAL ANALYSIS (PMI ... "BUTTON"): Details vary per Spec.

Refer to Fig. 1 - Pad for Chemical Analyses of Undiluted Weld Metal

Consumable

A3

Specification

MOISTURE TEST & ABSORBED MOISTURE TEST: The moisture

content of the covering of the electrode, when required by Table 4, shall

Consumable

A4 be determined by any suitable method. In case of dispute, use methods

Specification

in AWS A4.4M, Std Procedure for Determination of Moisture Content

(Welding Fluxes & Welding Electrode Flux Coverings)

DIFFUSIBLE HYDROGEN TEST: shall be tested according to one of

the methods given in AWS A4.3, Standard Methods for Determination of Consumable

A5

the Diffusible Hydrogen Content of Martensitic, Bainitic, and Ferritic Specification

Steel Weld Metal Produced by Arc Welding.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Saudi Aramco: Company General Use

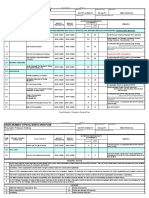

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Welding Consumable Receiving Insp Report (Attachment) SATR-W-2020 31-Dec-14 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- SATR-W-2005 Rev 6 PWHT ReportDocument1 pageSATR-W-2005 Rev 6 PWHT ReportAWAIS RAJANo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- 175 100100 PDFDocument2 pages175 100100 PDFThaksenNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- F-Number Reference ChartDocument2 pagesF-Number Reference ChartRichard BennardoNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeAbu Anas M.SalaheldinNo ratings yet

- Shieldinggases Aws 5.32 PDFDocument3 pagesShieldinggases Aws 5.32 PDFessnelsonNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- WPSDocument25 pagesWPSWaqas WaqasNo ratings yet

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- Saes W 013Document8 pagesSaes W 013Dhaval Patel100% (1)

- 7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Document28 pages7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Ksn HariNo ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- QW-403.2 InterpretationDocument1 pageQW-403.2 Interpretationlaz_kNo ratings yet

- SATR-W-2008 Rev 8 FD-1Document6 pagesSATR-W-2008 Rev 8 FD-1asiqna100% (1)

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- 175 012300Document2 pages175 012300Abu Anas M.SalaheldinNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- 175 018200 PDFDocument2 pages175 018200 PDFAbu Anas M.SalaheldinNo ratings yet

- Application Form For CSWIP 5 Year Renewal (Overseas) - v3 1Document7 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) - v3 1Bamarasan ArasanNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- 169 Gtaw Zug Asme (Fefri 5g) WPQDocument4 pages169 Gtaw Zug Asme (Fefri 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- 02 Samss 013Document18 pages02 Samss 013Kiran NikateNo ratings yet

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 Mechanicalمحمد علي النويصرNo ratings yet

- Pipeline Receiving Log Sheet@ Bending Area: Completed Bend Accepted Pipe in Yard Non-Accepted Pipe in YardDocument100 pagesPipeline Receiving Log Sheet@ Bending Area: Completed Bend Accepted Pipe in Yard Non-Accepted Pipe in Yardمحمد علي النويصرNo ratings yet

- CPP JPS1 1 QC NCR 0004 - 0Document5 pagesCPP JPS1 1 QC NCR 0004 - 0محمد علي النويصرNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test Reportمحمد علي النويصرNo ratings yet