Professional Documents

Culture Documents

PID Responsibility

Uploaded by

imurugan060 ratings0% found this document useful (0 votes)

171 views2 pagesroles and responsibilities

Original Title

PID responsibility

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentroles and responsibilities

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

171 views2 pagesPID Responsibility

Uploaded by

imurugan06roles and responsibilities

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

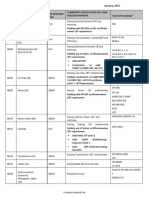

Coordination with inspection activities of the project to ensure compliance with the

applicable MSAERs and project specification.

Familiar with relevant project specifications and Saudi Aramco as well as international

standards for the works involved.

Ensuring the implementation of quality control procedures and inspection test plan.

Performing the inspection activities based on the Contractor inspectors RFI to fulfil the

inspection and project quality requirements

Assisting SAPMT in enforcing and interpreting the company standards and specification.

Reviewing the contractors two week look ahead schedule to assist in planning of

inspection coverage of the work activities.

Participating in the assessment schedules performed on the contractor quality systems

during the project phase.

Reviewing the qualification and experience of contractor QC personnel related to

construction phase, against the criteria specified in Schedule-Q.

Monitoring the contractor training program to ensure that all contractors and

subcontractors are familiar with the project quality requirement for their area of

responsibility.

Ensuring that the construction quality records are available and properly maintained by

the contractors.

Using the QMIS effectively for enrolling the proactive notifications, general comments

and the violations to MSAER, IFC drawings and project specifications.

Taking active involvement in the QMIS for the various RFI related activities and also

providing the proactive LBE’s to the contractors by predicting the potential of nonconformities

in the various stages of ongoing activities.

Taking active involvement in performing the FOCUS ASSESSMENT for the newly started

activities, preservation related issues and also for the repeated quality issues.

Trying to diagnose the reasons for the concerned issues thru the focused assessment

and to logged in the LBE’s based on their category of observation.

Properly maintain the status of the RFI in the QMIS as per their completeness

Performing the material receiving inspection activities based on the Contractor

inspectors RFI.

Reviewing of WPS and Welder Certificates and their Qualification limits

Reviewing of welding consumables and their respective test certificates during the

receiving inspection.

Reviewing of Contractor’s quality control procedure.

Making of daily and routine surveillance in site as well as in the fabshop welding

activities in order to avoid any rework and potential non-compliances.

Performing regular surveillance to the consumable store to check the welding

consumables are properly controlled and to avoid any rework and potential noncompliances.

Inspection of Welding Activities in On-plot Piping, fabshop welding and atmospheric

storage tanks.

Performing Inspection of the fit up, bevel edge, bevel angle, root gap, root face,

dimensional tolerance etc.

Reviewing of welding documentation for pre-welding, in-process welding and postwelding

activities for On-plot Piping, fabshop welding and atmospheric storage tanks.

Reviewing of documentation for weld maps, weekly weld rejection rate, weld summary

reports, welder tracers reports, daily Production Reports, daily weld Fit-Up reports and

also reviewing documentation for NDT activities.

Performing and ensuring the joint selection for the RT activities as per the standard

requirement and reviewing of radiographic films as required.

Attending all the inspection request of the contractor inspectors on the basis of the

inspection responsibility assignment as mentioned in the applicable SATIP to ensure the

compliance of quality requirements for the all ongoing construction activities of On-plot

Piping, atmospheric storage tanks and fab shops activities.

Stage wise inspection of atmospheric storage tanks erection works with respect to

isometric drawings and applicable standard requirements.

Reviewing of Hydro Test Package and Witnessing of Hydro Testing in On-plot Piping,

atmospheric storage tanks and also for fab shops spools as per applicable Standards and

specifications.

Co-ordination with field engineering department for various technical problems.

Review technical queries for site changes.

Review as-built diagrams for all field modifications.

Taking active participation in QC meetings and discuss quality issues.

You might also like

- VATEUD Pilots ManualDocument32 pagesVATEUD Pilots ManualAndreas TzekasNo ratings yet

- Project QAQC Inspector - Quality MSDocument4 pagesProject QAQC Inspector - Quality MSAdil HasanovNo ratings yet

- Saep 381 PDFDocument17 pagesSaep 381 PDFAbdul Aziz100% (1)

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- SAEP-303: 2 Conflicts and DeviationsDocument19 pagesSAEP-303: 2 Conflicts and DeviationsnasirNo ratings yet

- Mofarreh Marzouq Al-Harbi & Partners Satellite GCP Site Development Project ARAMCO PROJECT BI-10-01996-0007 Internal NCR LOGSDocument4 pagesMofarreh Marzouq Al-Harbi & Partners Satellite GCP Site Development Project ARAMCO PROJECT BI-10-01996-0007 Internal NCR LOGSGA JonNo ratings yet

- QAQC Questions & AnswersDocument5 pagesQAQC Questions & Answersnafis2uNo ratings yet

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- CBT Introduction Slides PDFDocument28 pagesCBT Introduction Slides PDFManoj Kumar100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Document12 pagesSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNo ratings yet

- @coating Book - Aramco Inspection HandbookDocument126 pages@coating Book - Aramco Inspection HandbookUmair AhmadNo ratings yet

- Questions For Paint InspectorDocument20 pagesQuestions For Paint InspectorHosam Ahmed100% (3)

- BGAS Painting Grade 1Document83 pagesBGAS Painting Grade 1Durairaj ANo ratings yet

- Mechanical and Piping Inspector HDocument3 pagesMechanical and Piping Inspector HHafiz Shabbir HussainNo ratings yet

- ABDULLA QAQC Painting& Coating InspectorDocument5 pagesABDULLA QAQC Painting& Coating InspectorawaisNo ratings yet

- Bgas - Screen Tests-Part 3Document133 pagesBgas - Screen Tests-Part 3mudassarNo ratings yet

- 04 Greeting Card Activity RubricDocument1 page04 Greeting Card Activity RubricJon Jon Marcos100% (2)

- ARAMCO QM Number listDocument3 pagesARAMCO QM Number listMohamed Yousuf Syed MohamedNo ratings yet

- Dewpoint: Coating & Painting InspectionDocument6 pagesDewpoint: Coating & Painting InspectionMeet Patel100% (1)

- Coating Inspector ResumeDocument4 pagesCoating Inspector Resumetulasirao.nammiNo ratings yet

- BGAS PaperDocument9 pagesBGAS PaperMuhammad AsifNo ratings yet

- As Soon As The Contract Is Awarded,: Further For PO PlacementDocument9 pagesAs Soon As The Contract Is Awarded,: Further For PO PlacementMohammed SibghatullaNo ratings yet

- CSWIP-BGAS Grade-II Painting Inspector Online CourseDocument36 pagesCSWIP-BGAS Grade-II Painting Inspector Online CourseAnusreeNo ratings yet

- CBT 02-20Document3 pagesCBT 02-20Manoj KumarNo ratings yet

- Dhaka Epz Factory List & List of Inspected Factories by EIMS For AllianceDocument12 pagesDhaka Epz Factory List & List of Inspected Factories by EIMS For Alliancearman chowdhury100% (4)

- Visco-Elastic Coating MaterialDocument17 pagesVisco-Elastic Coating Materialosmanmop100% (1)

- QCS Q&aDocument6 pagesQCS Q&aMohammed Sibghatulla100% (1)

- CorrisionDocument56 pagesCorrisionUsab GamalNo ratings yet

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniNo ratings yet

- Corrosion Revision QuestionsDocument47 pagesCorrosion Revision QuestionsCERTSNo ratings yet

- Crew Supervisor Role and Painting RequirementsDocument2 pagesCrew Supervisor Role and Painting RequirementsShamshir Alam100% (1)

- Saep 119Document11 pagesSaep 119Demac SaudNo ratings yet

- CBT Coatings QuestionsDocument5 pagesCBT Coatings QuestionsSUNIL RAJPUTNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Role of QA/QC Professionals in Engineering ProjectsDocument38 pagesRole of QA/QC Professionals in Engineering Projectsarunkumar100% (2)

- Chandler V MillerDocument2 pagesChandler V MillerJay Cezar100% (1)

- Bgas Test 1 PDFDocument14 pagesBgas Test 1 PDFMathew CherianNo ratings yet

- Painting Inspection Grade 2Document17 pagesPainting Inspection Grade 2Midhun K Chandrabose100% (3)

- General Mechanical-2 PDFDocument6 pagesGeneral Mechanical-2 PDFAhmed Shaban KotbNo ratings yet

- Experienced QC Inspector CVDocument7 pagesExperienced QC Inspector CVBaraneedharanNo ratings yet

- Renovation Coating Inspection PlanDocument10 pagesRenovation Coating Inspection PlanMoghal AliNo ratings yet

- Weld Weave WidthDocument4 pagesWeld Weave Widthapply19842371No ratings yet

- Project Quality RequirementsDocument8 pagesProject Quality RequirementsSIVANo ratings yet

- QM-QA-QC Basic Infos, LinksDocument8 pagesQM-QA-QC Basic Infos, LinksbehringerzsoltNo ratings yet

- QMISDocument14 pagesQMISLopez Gardo0% (1)

- SAIC-H-2001 Rev 7Document3 pagesSAIC-H-2001 Rev 7Satheesh Rama SamyNo ratings yet

- Ipcoat Exam Test Paper 123Document1 pageIpcoat Exam Test Paper 123Senthil Kumar100% (1)

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- OLD BGAS Grade-1 - Revision Questions - 2007Document11 pagesOLD BGAS Grade-1 - Revision Questions - 2007Alex joseph alexNo ratings yet

- Cswip-Bgas Grade-II Painting Inspector Course: Online Preparatory Class September 2020Document6 pagesCswip-Bgas Grade-II Painting Inspector Course: Online Preparatory Class September 2020AnusreeNo ratings yet

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNo ratings yet

- Saudi Aramco welding checklistDocument13 pagesSaudi Aramco welding checklistAnonymous S9qBDVky100% (1)

- Paint Types - Important NotesDocument3 pagesPaint Types - Important Notesmushroom0320No ratings yet

- Saudi Aramco Leak Test ChecklistDocument1 pageSaudi Aramco Leak Test ChecklistLegend AnbuNo ratings yet

- B Gas Grade 3 QuestionsDocument2 pagesB Gas Grade 3 QuestionsMathew Cherian100% (1)

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- Ansar Ahmad Updated CV - Present-WordDocument6 pagesAnsar Ahmad Updated CV - Present-WordansarNo ratings yet

- Resume of Nure AlamDocument8 pagesResume of Nure AlamEngr. Shahidul IslamNo ratings yet

- Witness InspectionDocument2 pagesWitness InspectionJlkKumarNo ratings yet

- Interseal 1052Document4 pagesInterseal 1052Engr Saeed AnwarNo ratings yet

- Interthane 990SG: Protective CoatingsDocument4 pagesInterthane 990SG: Protective CoatingsajuhaseenNo ratings yet

- Inspection Photos DT 25-01-2019Document7 pagesInspection Photos DT 25-01-2019imurugan06No ratings yet

- Inspection Photos DT 23-01-2019 PDFDocument4 pagesInspection Photos DT 23-01-2019 PDFimurugan06No ratings yet

- TWI Enrolment Form PDFDocument4 pagesTWI Enrolment Form PDFacadjournals. comNo ratings yet

- TWI Enrolment Form PDFDocument4 pagesTWI Enrolment Form PDFacadjournals. comNo ratings yet

- 11.Mpt ReportDocument1 page11.Mpt Reportimurugan06No ratings yet

- 11.MPT Report PDFDocument1 page11.MPT Report PDFimurugan06No ratings yet

- Honeywell 393690 Inlet Outlet Flange Kits 69-0256Document2 pagesHoneywell 393690 Inlet Outlet Flange Kits 69-0256Alfredo Castro FernándezNo ratings yet

- Subhasis Patra CV V3Document5 pagesSubhasis Patra CV V3Shubh SahooNo ratings yet

- Chapter 6Document53 pagesChapter 6Sam KhanNo ratings yet

- Agfa CR 10 X User ManualDocument4 pagesAgfa CR 10 X User ManualpietrokoNo ratings yet

- TMA2 12 09 2021 UploadDocument3 pagesTMA2 12 09 2021 UploadG.G. PRABHATH CHINTHAKANo ratings yet

- Improved Line Maze Solving Algorithm For PDFDocument2 pagesImproved Line Maze Solving Algorithm For PDFRaja Joko MusridhoNo ratings yet

- LeCroy 1996 Catalog (Reduced Size) PDFDocument196 pagesLeCroy 1996 Catalog (Reduced Size) PDFpetrocelliNo ratings yet

- Instructions To Employee For Submitting Online Application For Transfer Under Rule - 38 of Postal Manual Vol.-IVDocument6 pagesInstructions To Employee For Submitting Online Application For Transfer Under Rule - 38 of Postal Manual Vol.-IVSankarMathi VaigundhamNo ratings yet

- PSC Vacancy Government SpokespersonDocument3 pagesPSC Vacancy Government SpokespersonMoreen WachukaNo ratings yet

- Lesson 3.3: The Third Wave: The Information/Knowledge AgeDocument3 pagesLesson 3.3: The Third Wave: The Information/Knowledge AgeFaith PrachayaNo ratings yet

- To Register Your IGP Please Visit or Scan The QR Code Below To Register Your IGP Please Visit or Scan The QR Code BelowDocument1 pageTo Register Your IGP Please Visit or Scan The QR Code Below To Register Your IGP Please Visit or Scan The QR Code BelowLester Jao SegubanNo ratings yet

- The King's Avatar - A Compilatio - Butterfly BlueDocument8,647 pagesThe King's Avatar - A Compilatio - Butterfly BlueDarka gamesNo ratings yet

- DES-3611.prepaway - Premium.exam.65q: Number: DES-3611 Passing Score: 800 Time Limit: 120 Min File Version: 1.1Document22 pagesDES-3611.prepaway - Premium.exam.65q: Number: DES-3611 Passing Score: 800 Time Limit: 120 Min File Version: 1.1Emre Halit POLATNo ratings yet

- Process Costing-FifoDocument8 pagesProcess Costing-FifoMang OlehNo ratings yet

- FLIX Booking 1068813091Document2 pagesFLIX Booking 1068813091Pavan SadaraNo ratings yet

- Shangri La Hotels and Resorts SWOTDocument2 pagesShangri La Hotels and Resorts SWOTHadi Agustana100% (1)

- California Evaluation Procedures For New Aftermarket Catalytic ConvertersDocument27 pagesCalifornia Evaluation Procedures For New Aftermarket Catalytic Convertersferio252No ratings yet

- (WMN46VD) DrawingDocument13 pages(WMN46VD) DrawingStedzavayNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Gas LiftDocument4 pagesGas LiftSteve MarfissiNo ratings yet

- List of Company Name EtymologiesDocument9 pagesList of Company Name EtymologiesElizabeth ArosteguiNo ratings yet

- DVD S2300Document106 pagesDVD S2300cristakeNo ratings yet

- Basf TapesDocument3 pagesBasf TapesZoran TevdovskiNo ratings yet

- FEA Finite Element Analysis Tutorial ProblemsDocument16 pagesFEA Finite Element Analysis Tutorial ProblemsVinceTanNo ratings yet

- Hcin 543 Entity Relationship Diagram For Diabetes DataDocument4 pagesHcin 543 Entity Relationship Diagram For Diabetes Dataapi-534036919No ratings yet