Professional Documents

Culture Documents

Selecting A Thermal Fluid Heater Ebook

Selecting A Thermal Fluid Heater Ebook

Uploaded by

hasrunizraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selecting A Thermal Fluid Heater Ebook

Selecting A Thermal Fluid Heater Ebook

Uploaded by

hasrunizraCopyright:

Available Formats

Selecting a Thermal Fluid Heater

There are many heater manufacturers out there, and what can seem like an endless array of heater design options. Each of

these myriad designs was conceived with a particular application, environment, or budget in mind. When selecting a thermal

fluid heater, one must first understand the application, installation requirements and space restrictions. Let’s review a few

important factors to consider when comparing heater types and heater options.

Cost is always a factor for any purchase; however the true cost of

a heater is more complex than just the initial purchase price. The When choosing a thermal fluid

tradeoff between capital costs, operating cost, and long term

heater, one must first understand

maintenance costs must be considered in a proper evaluation. A

well designed and efficient engineered heating system may cost you

the application, installation

more initially than an ‘off-the-shelf’ heater or a heater with a lower requirements and space restrictions.

efficiency, but the less expensive options can become far more

expensive than you think. Once operating costs such as fuel costs, By the Process Engineering Group, Sigma Thermal

thermal fluid replacement, parts and maintenance begin to

accumulate over the first years of use, your initial savings may

not seem so significant.

Fuel efficiency requirements vary depending on fuel type, fuel

availability, application, run time, etc… A simple process requiring

low supply temperatures and an inexpensive thermal fluid may not

demand a customized highly efficient system, in which case a less

expensive heater option may be ideal. In direct contrast, a more

complex or demanding application requiring high temperatures

and a more expensive fluid will certainly see the benefits of a

properly designed engineered heating system. The difference in

cost between a system designed specifically for an application with

higher efficiencies, higher heating temperatures, and /or heavy duty

operation can typically be made up in short payback periods when

looking at the total operating costs of the equipment.

Note: Pay close attention to the method of fuel efficiency calculation

used by different vendors. These numbers can be skewed based on

the chosen method of calculation, and seemingly small differences

in efficiency can actually represent large differences in operating cost.

Compare carefully and don’t be afraid to ask your potential vendors to

The single helical coil is simple to design and fabricate, and it can

explain their efficiency claims, support their design calculations, and be built in horizontal orvertical configurations.

guarantee the stated efficiency at your operating conditions.

4875 Deen Road, Marietta, GA 30066 P 770-427-5770 F 678-254-1762 www.sigmathermal.com sales@sigmathermal.com 2

Design Parameters to Consider

Surface area of the heater coil (heat transfer surface) is crucial. A generous surface area, whether the heater is fired or

electric, is the starting point for a sound heater design. Inadequate surface area in your heater coil or heating element will

limit your efficiency and lead to a higher film temperature. This ultimately means thermally degrading your expensive heat

transfer fluid. Running poor quality oil in your system will shorten coil life, coke heating elements and decreased heater

efficiency over time. Of course the primary benefit to a reduced coil or element surface is less cost. Be sure to carefully

consider coil and element surface area and relative heat flux rates when comparing heater options. This is an important area

where initial savings can result in massive costs down the road.

Fluid velocity and pressure drop are inherently related and vital in engineering an appropriate heater for any application.

In general, a higher fluid velocity means better heat transfer and lower film temperatures. This comes with a tradeoff though,

as pressure drop increases with fluid velocity. Higher pressure drop means more pump horsepower, which indirectly

increases your operating costs due to the increase in power consumption. You can have one heater design that has very low

pressure drop resulting in low fluid velocities that yield higher film temperatures, while another heater design is masking a

low coil surface area with extremely high velocities resulting in reasonable film temperatures, but very high pressure drop.

This design parameter is just one piece to the puzzle. In order to compare

more appropriately, be sure to obtain fluid velocities, pressure drops,

film temperatures, and heat flux rates. Be sure to discuss and

understand what pressure drops your heat user system may

allow in addition to what minimum and maximum flows are

safe for your heater.

Combustion chamber size and flame impingement are also

critical to heater design. The biggest potential for damaging

your coil and your fluid lies within the radiant zone of your

heater. A well sized combustion chamber will ensure proper

heat release within the radiant zone, but it also ensures that

there is no potential for flame impingement on the coil.

Flame impingement causes local hot spots on a heater coil

which result in localized fluid degradation and potentially

even coil damage. Ask your potential suppliers to discuss their

combustion chamber size as it relates to the burner flame size

and its proximity to the heater coil.

The design of the double helical coil thermal fluid heater

incorporates two concentric helical coils, one inside of the other.

This allows for three passes of flue gases.

4875 Deen Road, Marietta, GA 30066 P 770-427-5770 F 678-254-1762 www.sigmathermal.com sales@sigmathermal.com 3

Heater Design Types

Armed with a basic understanding of what is important to your application and/or facility, you now need to select the right heater

design. Unfortunately it is not always obvious to the casual buyer which type is best for their application. Each manufacturer will

tout the merits of their specific designs, and you need to be able to understand how those differences relate to your needs. We

will try to summarize several types and discuss the pros and cons of each relative to performance, cost, and footprint.

Single Helical Coil Thermal Fluid Heater

• The single coil is a simple cost effective design. Utilizing a single helical coil, this design

allows for two passes of flue gas along the heat transfer surface. The single helical coil is

very simple to design and fabricate, and can be built in horizontal or vertical configurations

• Generally speaking, this heater style will have lower efficiencies than other heater with

more available surface area. In some cases a manufacturer will require an additional waste

heat recovery unit to achieve the efficiencies capable in other base heater designs.

• High exhaust temperatures at the first turn require internal insulation to protect the heater

shell from extreme temperatures. This internal insulation is subject to wear and could need

to be replaced over time. Single Helical Coil Heater

Double Helical Coil Thermal Fluid Heater

• This design incorporates two concentric helical coils, one inside of the other. This

allows for three passes of flue gasses, and this additional pass of flue gas (compared with

a single coil heater) allows for additional heat transfer surface for a comparably sized unit.

The additional surface area typically makes these heaters more efficient than a

comparable single coil design.

• The double helical coil is typically more expensive than a single helical coil design. It

can be configured in either a horizontal or vertical arrangement.

• A dual helical coil allows for a large heat duty in a small overall footprint. If size is an

issue for your facility this may very well be a deciding factor. Larger duty requirements

may dictate that a dual helical design be used, as it is difficult to build a shippable single

coil unit above 25MM Btu/hr. Double Helical Coil Heater

• The flue gasses are relatively cool when first contacting the heater shell, eliminating the need for most internal shell

insulation. This minimizes long term insulation maintenance and/or replacement.

4875 Deen Road, Marietta, GA 30066 P 770-427-5770 F 678-254-1762 www.sigmathermal.com sales@sigmathermal.com 4

Heater Design Types (cont.)

Radiant-Convective Thermal Fluid Heater

• Worldwide, the traditional radiant-convective style heater is the most well-known and

commonly used style of direct fired heater. These heaters are physically larger than their

helical coil counterparts, utilizing both a bare tube radiant zone in combination with a

separate bare / finned convection zone.

• Radiant-convective style heaters are more complicated to design and build, and are

therefore typically more expensive than other heater types.

• A wide range of design capabilities allow for flexible performance and configuration

Cabin Style Radiant-Convective Heater

options. Efficiencies of a new heater can also vary from 70 – 90%, and footprints can be

small and tall with vertical-cylindrical heaters, or shorter and wide with cabin style heaters.

• Several manufactures have their own proprietary design for this radiant convective style of heater, but the most widely

accepted standard is API 560. API 560 heaters have been used for many years in the oil & gas industry to heat petroleum

streams in various stages of production. This specification is often applied to thermal fluid systems, which in almost all cases

is unnecessary. This specification is extremely conservative in nature, and is really only necessary when heating a non-

homogenous petrochemical stream with varying thermophysical properties. When applied to a thermal fluid, which is an

engineered fluid with well-known and homogenous properties, it adds unnecessary size, cost and complexity.

4875 Deen Road, Marietta, GA 30066 P 770-427-5770 F 678-254-1762 www.sigmathermal.com sales@sigmathermal.com 5

Heater Design Types (cont.)

In-Line Electric Circulation Heater

• This design uses an electric flanged immersion heater with a shell to allow flow

directly over the heating elements. Since there is no combustion, virtually 100% of the

energy goes into the media being heated.

• Can be mounted in horizontal or vertical position for space savings.

• Typically a smaller footprint because of smaller duties. Mounting options include

saddles, skirts, legs or mounting blocks.

• Vessel can be ASME Section VIII Div 1. Certified and “U” stamped.

• Simple design and lower maintenance that fired heaters.

• Can be installed in hazardous areas

For questions about this article or its contents, contact Sigma Thermal at sales@sigmathermal.com or 770-427-5770.

4875 Deen Road, Marietta, GA 30066 P 770-427-5770 F 678-254-1762 www.sigmathermal.com sales@sigmathermal.com 6

You might also like

- Burnham Wetback Vs DrybackDocument2 pagesBurnham Wetback Vs Drybacksandi1111No ratings yet

- All Heat Exchangers Are Not EqualDocument5 pagesAll Heat Exchangers Are Not EqualGesar GesarNo ratings yet

- Heat Exchanger Design: Table of ContentDocument18 pagesHeat Exchanger Design: Table of ContenthellopaNo ratings yet

- Ganapathy PDFDocument90 pagesGanapathy PDFpinenamuNo ratings yet

- Tank Heating DiscussionsDocument26 pagesTank Heating DiscussionsTHERMAX007No ratings yet

- Cast Heater White PaperDocument3 pagesCast Heater White Paperssmith2007No ratings yet

- Brazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsDocument31 pagesBrazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsHitesh Panchal100% (1)

- BoilerEfficiency PDFDocument7 pagesBoilerEfficiency PDFMurugan VeluNo ratings yet

- District Cooling Systems (Energy Engineering)Document12 pagesDistrict Cooling Systems (Energy Engineering)Aouina ChokriNo ratings yet

- Proposal ScriptDocument9 pagesProposal ScriptFionaNo ratings yet

- Immersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006Document5 pagesImmersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006John UrdanetaNo ratings yet

- Catalog, Steam Hot Water Unit Heaters MODINEDocument28 pagesCatalog, Steam Hot Water Unit Heaters MODINECab_de_?No ratings yet

- Criteria For Selecting Heat ExchangerDocument7 pagesCriteria For Selecting Heat ExchangerKashaf TehreemNo ratings yet

- Waste Heat Recovery Considering Environmental FactorsDocument7 pagesWaste Heat Recovery Considering Environmental FactorsrvnesariNo ratings yet

- Oil HeatersDocument48 pagesOil HeaterstotalandromedaNo ratings yet

- Boiler Project FundamentalsDocument7 pagesBoiler Project FundamentalsAlejandro AlvarengaNo ratings yet

- Boiler Project Fundamentals: Back To BasicsDocument7 pagesBoiler Project Fundamentals: Back To BasicsChemical.AliNo ratings yet

- What Are Double Pipe Heat Exchangers and Their Working PrinciplesDocument8 pagesWhat Are Double Pipe Heat Exchangers and Their Working PrinciplesAngel RatuNo ratings yet

- Gea Red Heat Pumps North America 295686Document20 pagesGea Red Heat Pumps North America 295686wipiriNo ratings yet

- A Review of Gas-Gas Heat Recovery SystemsDocument39 pagesA Review of Gas-Gas Heat Recovery SystemspinenamuNo ratings yet

- Fired HeatersDocument20 pagesFired HeatersCal100% (5)

- Fired HeatersDocument19 pagesFired HeatersCelestine OzokechiNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Understanding Power Losses in Vacuum FurnacesDocument16 pagesUnderstanding Power Losses in Vacuum FurnacesHa yesmineNo ratings yet

- Heating Helper For Steam Boiler and Full CalculationDocument113 pagesHeating Helper For Steam Boiler and Full Calculation185412100% (1)

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Alfa Laval Gphe Catalog 2022Document20 pagesAlfa Laval Gphe Catalog 2022JUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Umar Plate Heat Exchangers and EthanolDocument13 pagesUmar Plate Heat Exchangers and EthanolTara EdwardsNo ratings yet

- Absorption Chillers 07Document52 pagesAbsorption Chillers 07Sujadi Cherbond100% (1)

- Air Conditioning 101 - Basics, Working Principle and Sizing Calculations - Engineering360Document7 pagesAir Conditioning 101 - Basics, Working Principle and Sizing Calculations - Engineering360rollrams100% (1)

- ABMA Boiler Types For Steam ApplicationsDocument27 pagesABMA Boiler Types For Steam Applicationshasrunizra100% (1)

- Understand Why Furnace Size Varies For Gas, Oil and Coal FiringDocument4 pagesUnderstand Why Furnace Size Varies For Gas, Oil and Coal FiringSanjiv ChNo ratings yet

- Rethink Specifications For Fired HeatersDocument7 pagesRethink Specifications For Fired HeatersAhmed SeliemNo ratings yet

- Radiator Design and OptimizationDocument12 pagesRadiator Design and Optimizationspandan shahNo ratings yet

- Advantages of Brazed Heat Exchangers in The Gas Processing IndustryDocument13 pagesAdvantages of Brazed Heat Exchangers in The Gas Processing IndustryWalter PasoliniNo ratings yet

- Cold Box - Advantages To Brazed Fin ExchangersDocument13 pagesCold Box - Advantages To Brazed Fin ExchangersEdison ChoiNo ratings yet

- Trane Chiller Plant Admapn014en - 0105Document4 pagesTrane Chiller Plant Admapn014en - 0105a_salehiNo ratings yet

- Waste Heat RecoveryDocument20 pagesWaste Heat RecoveryAMIT PRAJAPATINo ratings yet

- Heat Exchanger SludgeDocument2 pagesHeat Exchanger SludgeRrodriguezz22No ratings yet

- Rama HotrunnerDocument43 pagesRama Hotrunner1keyvan1No ratings yet

- Heat Pipe Heat ExchangerDocument20 pagesHeat Pipe Heat ExchangerrolwinNo ratings yet

- Immersion HeatersDocument5 pagesImmersion Heatersjuanper01No ratings yet

- Copyright © 2018Document19 pagesCopyright © 2018ElenaNo ratings yet

- Air PanassDocument10 pagesAir PanassSyaza FieqaNo ratings yet

- Des Champ - Heatpipe (Catalog)Document20 pagesDes Champ - Heatpipe (Catalog)picnarukNo ratings yet

- Good Heater Specifications Pay OffDocument6 pagesGood Heater Specifications Pay Offrvkumar61100% (1)

- Schmidt Bretten Brazed Plate Heat ExchangersDocument8 pagesSchmidt Bretten Brazed Plate Heat ExchangersCris_eu09No ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Company ProfileDocument6 pagesCompany ProfileprashanttutuNo ratings yet

- Selection of Heat Exchanger (Size and Weight, Type)Document3 pagesSelection of Heat Exchanger (Size and Weight, Type)Zati TarhiziNo ratings yet

- HP Feed Water PerformanceDocument22 pagesHP Feed Water Performancesr_mahapatraNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Making Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetFrom EverandMaking Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetNo ratings yet

- High-Performance Automotive Cooling SystemsFrom EverandHigh-Performance Automotive Cooling SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNo ratings yet

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Optimum Design of Pressure Vessel Subjected To Autofrettage ProcessDocument6 pagesOptimum Design of Pressure Vessel Subjected To Autofrettage ProcessPierluigiBusettoNo ratings yet

- How To Batch Convert Your IDWDocument6 pagesHow To Batch Convert Your IDWPierluigiBusettoNo ratings yet

- Heat Balance Calculation Sheet - Part ADocument1 pageHeat Balance Calculation Sheet - Part APierluigiBusettoNo ratings yet

- A Complete Design of Ship Propellers Using The New Computer SystemDocument6 pagesA Complete Design of Ship Propellers Using The New Computer SystemPierluigiBusettoNo ratings yet

- Overview Heat Transfer Fluid - Gilles Flamant PDFDocument51 pagesOverview Heat Transfer Fluid - Gilles Flamant PDFPierluigiBusettoNo ratings yet

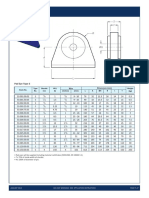

- Pad Eyes PDFDocument1 pagePad Eyes PDFPierluigiBusettoNo ratings yet

- Data Sheet - HFO Heavy Fuel OilDocument9 pagesData Sheet - HFO Heavy Fuel OilPierluigiBusettoNo ratings yet

- Cargo Oil Heating Requirements For An FSO Vessel Conversion PDFDocument11 pagesCargo Oil Heating Requirements For An FSO Vessel Conversion PDFPierluigiBusettoNo ratings yet

- Overview Heat Transfer Fluid - Gilles Flamant PDFDocument51 pagesOverview Heat Transfer Fluid - Gilles Flamant PDFPierluigiBusettoNo ratings yet

- Electrical Fuse MCQ Ebook PDFDocument26 pagesElectrical Fuse MCQ Ebook PDFshukla dhavalNo ratings yet

- Unit 5 (3Document6 pagesUnit 5 (3akash agarwalNo ratings yet

- 'C' Programming Language - PresentationDocument11 pages'C' Programming Language - PresentationAchintya PayinNo ratings yet

- LP - Lesson 6 - Working With Layers Abiera - Baluyot PSTDocument25 pagesLP - Lesson 6 - Working With Layers Abiera - Baluyot PSTGillian AbieraNo ratings yet

- Daily Practice Problems (DPP) : Sub: Maths Chapter: Quadratic Equation DPP No.: 2Document4 pagesDaily Practice Problems (DPP) : Sub: Maths Chapter: Quadratic Equation DPP No.: 2Sanchit MukherjeeNo ratings yet

- Adam Implementation Guide v1.0Document81 pagesAdam Implementation Guide v1.0swapnarmreddyNo ratings yet

- Backup Meldas 320Document2 pagesBackup Meldas 320Phong HuynhNo ratings yet

- BS en Iso 4157-1 1999Document18 pagesBS en Iso 4157-1 1999Zengwen ZhangNo ratings yet

- Excel 2007 Hyperlink To PDF Cannot Open The Specified FileDocument2 pagesExcel 2007 Hyperlink To PDF Cannot Open The Specified FileTylerNo ratings yet

- IAS Lesson 3. Security Systems Development Life CycleDocument5 pagesIAS Lesson 3. Security Systems Development Life CycleJunard CalmaNo ratings yet

- Deploying ACI The Complete Guide To Planning, Configuring, and Managing Application Centric Infrastructure PDFDocument705 pagesDeploying ACI The Complete Guide To Planning, Configuring, and Managing Application Centric Infrastructure PDFCCIE Detect100% (3)

- Exam 1 - Math 212Document1 pageExam 1 - Math 212Taleb AbboudNo ratings yet

- Chemlab 1.Document3 pagesChemlab 1.jamila_aceberos33% (3)

- Lenze 8200 Motec Vector Frequency Converter Fieldbus Fuction ModulesDocument102 pagesLenze 8200 Motec Vector Frequency Converter Fieldbus Fuction ModulesEmmanuel Baldenegro PadillaNo ratings yet

- Iobm MBA Logistics & Supply ChainDocument10 pagesIobm MBA Logistics & Supply ChainMuhammad AdnanNo ratings yet

- Home Cinema 3900 Full HD 1080pDocument5 pagesHome Cinema 3900 Full HD 1080pShareefThabetAlmqtriNo ratings yet

- Bengal Sweater Fashion LTDDocument1 pageBengal Sweater Fashion LTDshoyebNo ratings yet

- Microgrid Experiences in Remote Island of PalawanDocument29 pagesMicrogrid Experiences in Remote Island of PalawanSun TzuNo ratings yet

- Bayesian Classifiers Introduction To Data Mining, 2 Edition by Tan, Steinbach, Karpatne, KumarDocument26 pagesBayesian Classifiers Introduction To Data Mining, 2 Edition by Tan, Steinbach, Karpatne, KumarAbhishek Kumar TiwariNo ratings yet

- HPHT PVT Analysis: ApplicationsDocument2 pagesHPHT PVT Analysis: ApplicationsJesseNo ratings yet

- Samsung: Competitors AnalysisDocument2 pagesSamsung: Competitors Analysisikhwan azmanNo ratings yet

- Calibration Proving Ring 50KNDocument1 pageCalibration Proving Ring 50KNmanish upadhyay100% (1)

- Write Thesis On IpadDocument4 pagesWrite Thesis On Ipadgjhs9pz8100% (2)

- Catalog A00013EpanasonicDocument24 pagesCatalog A00013EpanasonicMantención FastpackNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- T24 Internal Account - Close AccountDocument7 pagesT24 Internal Account - Close AccountlolitaferozNo ratings yet

- StewartPCalc7 01 04 OutputDocument33 pagesStewartPCalc7 01 04 OutputrawadNo ratings yet

- EER v9Document72 pagesEER v9NURTURE - Heal & Grow Dr. Anjali BhimajiyaniNo ratings yet

- IT6503 NotesDocument114 pagesIT6503 NotesKEERTHINo ratings yet

- 0000 46eg 0001 - 00Document21 pages0000 46eg 0001 - 00Budi HahnNo ratings yet