Professional Documents

Culture Documents

POLAR Cutting Machine D 66 Productsheet

Uploaded by

Kanniyappan Gounder0 ratings0% found this document useful (0 votes)

70 views2 pagesPolar cutting machine manual

Original Title

POLAR_cutting_machine_D_66_Productsheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPolar cutting machine manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

70 views2 pagesPOLAR Cutting Machine D 66 Productsheet

Uploaded by

Kanniyappan GounderPolar cutting machine manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

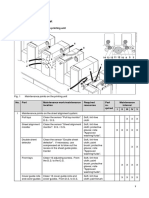

Cutting Machine

D 66 ECO

Pprogrammable cutter with hydraulic drive

and 5,5“ monochrome display

Description of the Polar D 66 ECO Technical data

Edition: 05.2019 \\ Subject to technical alterations.

The cutter POLAR 66 is designed for one-shift operation.

670 mm

The precise and gentle swing cut is carried out Cutting width

26.38 in

hydraulically. Thus, the time of the knife spent in the

lower dead end can be adapted to the material. The 670 mm

ultra-smooth stainless table surface allows an easy Feeding depth

26.38 in

handling of the material even without air jets. Within a

wide setting range the clamping pressure can be 80 mm

Feeding height max.

adjusted infinitely to each cutting material by means of a 3.15 in

turning knob with scale. Bright LEDs mark the cutting line

200 daN

clearly visible for the operator. Clamp pressure min.

441 lbs

The operation of the machine is done via an

1,500 daN

ergonomically positioned control panel with 5.5’’ Clamp pressure max.

3,307 lbs

monochrome display and additional membrane keypad.

Recurring cutting sequences can be memorized (memory Backgauge speed 70 mm/sec

capacity 198 programs) and adapted at any time. The on return way (0 - ...) 2.76 in/sec

creation of the cutting programs is done either manually

or menu-driven and intuitively via block programming. To Smallest cut, automatically, 15 mm

optimize the cutting quality the pre-clamping time can be without false plate 0.59 in

adjusted according to the material.

Smallest cut, automatically, 50 mm

Customer benefits with false plate 1.97 in

Extensive programming options with a memory 1,250 × 1,825 × 1,500 mm

Dimensions (w × d × h)

capacity of 198 programs 49.21 × 71.85 × 59.06 in

Minimal maintenance requirements due to the use

of novel materials Further technical data are available for download on our website.

Extended operating life of the knife as well as faster

knife change thanks to POLAR OptiKnife with knife

fine adjustment in the lower dead end

Machine frame with optimized stability for optimum

absorption of cutting forces and greatest cutting

accuracy

POLAR-Mohr Maschinenvertriebsgesellschaft GmbH & Co. KG

Hattersheimer Straße 16 – 42 \\ 65719 Hofheim \\ Germany

info@polar-mohr.com \\ www.polar-mohr.com

Cutting Machine

D 66 PLUS

Hydraulic cutter with 18.5” touch-screen display

and process visualization

Description of the Polar D 66 PLUS Technical data

Edition: 05.2019 \\ Subject to technical alterations.

The cutter POLAR 66 is designed for one-shift operation.

670 mm

The precise and gentle swing cut is carried out Cutting width

26.38 in

hydraulically. Thus, the time of the knife spent in the

lower dead end can be adapted to the material. The 670 mm

ultra-smooth stainless table surface allows an easy Feeding depth

26.38 in

handling of the material even without air jets. Within a

wide setting range the clamping pressure can be 80 mm

Feeding height max.

adjusted infinitely to each cutting material by means of a 3.15 in

turning knob with scale. Bright LEDs mark the cutting line

200 daN

clearly visible for the operator. The operation of the Clamp pressure min.

441 lbs

machine is done via an ergonomically positioned 18.5’’

touch-screen display. Recurring cutting sequences can be 1,500 daN

Clamp pressure max.

memorized (memory capacity 1,998 programs) and 3,307 lbs

adapted at any time. With the process visualization the

Backgauge speed 70 mm/sec

handling of the material is displayed graphically and so

on return way (0 - ...) 2.76 in/sec

the risk of errors significantly downsized. To optimize the

cutting quality the pre-clamping time can be adjusted Smallest cut, automatically, 15 mm

according to the material. Optionally, the machine can be without false plate 0.59 in

integrated into the digital workflow via P-NET

Compucut®. Smallest cut, automatically, 50 mm

with false plate 1.97 in

Customer benefits

1,250 × 1,825 × 1,500 mm

Process visualization for the graphical display of the Dimensions (w × d × h)

49.21 × 71.85 × 59.06 in

material handling to minimize the risk of errors

Greatest cutting accuracy due to the POLAR- Further technical data are available for download on our website.

Positioning-System DPS

Extended operating life of the knife as well as faster

knife change thanks to POLAR OptiKnife with knife

fine adjustment in the lower dead end

Machine frame with optimized stability for optimum

absorption of cutting forces and greatest cutting

accuracy

POLAR-Mohr Maschinenvertriebsgesellschaft GmbH & Co. KG

Hattersheimer Straße 16 – 42 \\ 65719 Hofheim \\ Germany

info@polar-mohr.com \\ www.polar-mohr.com

You might also like

- Description of Compucut® GO Scope of SupplyDocument2 pagesDescription of Compucut® GO Scope of SupplyKanniyappan GounderNo ratings yet

- Pages From Operation 78ed 176eedv400 - eDocument8 pagesPages From Operation 78ed 176eedv400 - eNaresh KumarNo ratings yet

- Computer Control: Control Processor UC Control Processor TVDocument23 pagesComputer Control: Control Processor UC Control Processor TVmaxxiss50% (2)

- EF-35 - Service ManualDocument53 pagesEF-35 - Service ManualsudalfaNo ratings yet

- POLAR Productsheet 137Document6 pagesPOLAR Productsheet 137Syed Hassan TariqNo ratings yet

- Sheet Alignment ControlDocument13 pagesSheet Alignment Controlمحمد محمودNo ratings yet

- Baumcut 26.4 ProgrammableDocument98 pagesBaumcut 26.4 ProgrammableraduroNo ratings yet

- Maintenance - Repair MO PDFDocument342 pagesMaintenance - Repair MO PDFjose100% (2)

- Cutting - in - Practice - Blades IndicationsDocument24 pagesCutting - in - Practice - Blades IndicationsHector Elias Mercedes HazimNo ratings yet

- POLAR - Cutting in PracticeDocument24 pagesPOLAR - Cutting in PracticePetrtmNo ratings yet

- Technical Data CD102 PDFDocument2 pagesTechnical Data CD102 PDFSegaf Sang Pengelana100% (2)

- Interface AdapterDocument16 pagesInterface AdapterAnthonyNo ratings yet

- 1 Preface: 1.1 Notes For The ReaderDocument14 pages1 Preface: 1.1 Notes For The Readerahmed samierNo ratings yet

- MACHINERY EUROPE HEIDELBERG SM 74 - 5 H OFFSET PRINTING MACHINEDocument2 pagesMACHINERY EUROPE HEIDELBERG SM 74 - 5 H OFFSET PRINTING MACHINEMagros TamNo ratings yet

- 1-1 Checking The Installation SpaceDocument9 pages1-1 Checking The Installation SpaceManuel VidalNo ratings yet

- 11493PQC Data Manager enDocument95 pages11493PQC Data Manager enHiếu TrầnNo ratings yet

- Schematic View of Rollers: WaterDocument11 pagesSchematic View of Rollers: Watersuhas k100% (1)

- 16 - Chapter 8 PDFDocument60 pages16 - Chapter 8 PDFJavier Martinez CañalNo ratings yet

- Technical Information For PERFECTA PREMIUM LineDocument9 pagesTechnical Information For PERFECTA PREMIUM LineDevraj KulasekarNo ratings yet

- IOControl SdokuDocument23 pagesIOControl Sdokushiva100% (1)

- CITYLINE EXPRESS 4 Page Newspaper Offset PressDocument4 pagesCITYLINE EXPRESS 4 Page Newspaper Offset Presssunil kambleNo ratings yet

- Accucut-Tc ManualDocument23 pagesAccucut-Tc ManualNaresh KumarNo ratings yet

- Overallcontrol SystemDocument36 pagesOverallcontrol SystemAnthony100% (3)

- Service Instructions: PERFECTA 76 / 92 / 115 / 132 / 168 Uc / TVDocument32 pagesService Instructions: PERFECTA 76 / 92 / 115 / 132 / 168 Uc / TVmaxxissNo ratings yet

- Module 5 - SoftwareDocument16 pagesModule 5 - Softwareshiva100% (1)

- Horizon - APC - M61 - D001 PDFDocument136 pagesHorizon - APC - M61 - D001 PDFomar tlebNo ratings yet

- Aggregates: Service Training MechanikDocument24 pagesAggregates: Service Training Mechanikfroilan ochoaNo ratings yet

- MC 8Document46 pagesMC 8Christian Marcelo VallejosNo ratings yet

- Computer Control: Control Processor UC Control Processor TVDocument23 pagesComputer Control: Control Processor UC Control Processor TVmaxxiss75% (4)

- Technical Training For Emc Ii EM SD - P: (Types 92, 115, 137, 155)Document9 pagesTechnical Training For Emc Ii EM SD - P: (Types 92, 115, 137, 155)Miguel Juan De DiosNo ratings yet

- Pqa-C: Operation ManualDocument46 pagesPqa-C: Operation ManualHuy Nguyen Q100% (3)

- Microcut HSTD ManualDocument25 pagesMicrocut HSTD ManualPedro IsmaelNo ratings yet

- 1 Printing Unit ChecklistDocument5 pages1 Printing Unit ChecklistMagnus BergmanNo ratings yet

- 4995A ICS BrochureDocument8 pages4995A ICS BrochureGerardo BernardoNo ratings yet

- Polar 76 Schema ElectronicaDocument13 pagesPolar 76 Schema ElectronicassdfsfNo ratings yet

- 'Docslide - Us - Prinect Signa Station Users Guide en PDFDocument359 pages'Docslide - Us - Prinect Signa Station Users Guide en PDFResimasc González100% (1)

- Ryobi 3200 PDFDocument139 pagesRyobi 3200 PDFKevinSuriyanNo ratings yet

- Manual - Speedmaster Motor ControlDocument88 pagesManual - Speedmaster Motor ControlTerence Wood100% (2)

- Technical Data For Speedmaster SM 74: Printing Stock Blanket CylinderDocument1 pageTechnical Data For Speedmaster SM 74: Printing Stock Blanket CylinderMatt DWorkNo ratings yet

- ZSK2 ErrorsDocument36 pagesZSK2 ErrorsHABUMUGISHA Dieudonne100% (1)

- Using Polar Guillotine CuttersDocument1 pageUsing Polar Guillotine Cutterswahyu nugroho100% (1)

- Gto Montaje de AlastraDocument88 pagesGto Montaje de AlastraTecnico Artes GraficasNo ratings yet

- Polar N 78 Eco High Speed CutterDocument140 pagesPolar N 78 Eco High Speed CutterMrGaffaNo ratings yet

- Special Equipment: Service Training MechanikDocument16 pagesSpecial Equipment: Service Training Mechanikfroilan ochoa100% (1)

- Input/output control and signal routingDocument29 pagesInput/output control and signal routingAnthony100% (2)

- Inputoutput List EAKSEKDocument20 pagesInputoutput List EAKSEKAnthony100% (2)

- Ryobi-512 Crestlain - ESPAÑOLDocument68 pagesRyobi-512 Crestlain - ESPAÑOLvergamás1No ratings yet

- KBA Grafitrec Performa 74 enDocument20 pagesKBA Grafitrec Performa 74 enCovek Bez FejsbukaNo ratings yet

- Enthrone 29Document6 pagesEnthrone 29Adam Muhamad AliNo ratings yet

- Marketed and Distributed By:: Monotech Systems LimitedDocument7 pagesMarketed and Distributed By:: Monotech Systems Limitedkathir_cNo ratings yet

- SAK2 Memory Analog BoardDocument7 pagesSAK2 Memory Analog BoardErman GÖGENNo ratings yet

- Dampening Sistem SM52-1Document29 pagesDampening Sistem SM52-1Димитър ПетровNo ratings yet

- Coating Module: Service Training MechanikDocument28 pagesCoating Module: Service Training Mechanikfroilan ochoaNo ratings yet

- L1 L2 L3 F1 F2 F3: Guards - Air Supply - LubricationDocument2 pagesL1 L2 L3 F1 F2 F3: Guards - Air Supply - LubricationAnonymous 2YS5Pg7UJNo ratings yet

- Two-Color Small Offset Press: WarningDocument568 pagesTwo-Color Small Offset Press: WarningSachin NerkarNo ratings yet

- SM 74Document27 pagesSM 74mail4281No ratings yet

- High-Speed Cutter POLAR N 176 AT HD with Automatic Trim RemovalDocument3 pagesHigh-Speed Cutter POLAR N 176 AT HD with Automatic Trim RemovalGeheimnisvoller JoNo ratings yet

- 07 Polar High Speed Cutter 92 ProducsheetDocument2 pages07 Polar High Speed Cutter 92 Producsheethamidhosseini13766No ratings yet

- POLAR - High-Speed - Cutter - N - 155 - Productsheet MANUAL DE INSTRUCCIONESDocument3 pagesPOLAR - High-Speed - Cutter - N - 155 - Productsheet MANUAL DE INSTRUCCIONESPaul GraterolNo ratings yet

- BOMAG BM 500/15 and BM 600/15 Cold Planers. Productivity and Comfort Re-DefinedDocument16 pagesBOMAG BM 500/15 and BM 600/15 Cold Planers. Productivity and Comfort Re-DefinedRalf MaurerNo ratings yet

- Project Management Dashboard Non 365Document28 pagesProject Management Dashboard Non 365Kanniyappan GounderNo ratings yet

- POLAR Compucut ProductsheetDocument2 pagesPOLAR Compucut ProductsheetKanniyappan GounderNo ratings yet

- POLAR Cutting Machine D 66 ProductsheetDocument2 pagesPOLAR Cutting Machine D 66 ProductsheetKanniyappan GounderNo ratings yet

- Technical Data Cutter D 56 66 80 ECO PLUSDocument1 pageTechnical Data Cutter D 56 66 80 ECO PLUSKanniyappan GounderNo ratings yet

- Course Assignment: Language Analysis and Language Learning 681 Assignment 1Document11 pagesCourse Assignment: Language Analysis and Language Learning 681 Assignment 1Đinh Lan KhánhNo ratings yet

- Aplac TR 001 Issue 2Document48 pagesAplac TR 001 Issue 2gaunananguyenNo ratings yet

- Urban Form FactorsDocument56 pagesUrban Form FactorsEarl Schervin CalaguiNo ratings yet

- Quantum ComputingDocument2 pagesQuantum Computingakshit100% (3)

- Diploma in Cyber Security - Data Communication and NetworkingDocument57 pagesDiploma in Cyber Security - Data Communication and Networkingsrikant.singh62583No ratings yet

- NRD Idg Gy Fiyf FofkDocument7 pagesNRD Idg Gy Fiyf FofkMERA MENTALNo ratings yet

- Basic Electrical-Chapter 3 TheoryDocument13 pagesBasic Electrical-Chapter 3 TheorySankar RijalNo ratings yet

- They Are Product, Price, Placement and PromotionDocument2 pagesThey Are Product, Price, Placement and PromotionVy HoàngNo ratings yet

- Law of Insurance Eighth Semester SyllabusDocument3 pagesLaw of Insurance Eighth Semester SyllabusAastha PrakashNo ratings yet

- Waste Disposal Issues in Lalur VillageDocument27 pagesWaste Disposal Issues in Lalur VillageAnjana_EdathadanNo ratings yet

- First Principle Applications in RoRo-Ship Design PDFDocument7 pagesFirst Principle Applications in RoRo-Ship Design PDFFerdy Fer DNo ratings yet

- GROUP 3 Questions Solved Problems in Gas Turbine and Geothermal Power PlantDocument62 pagesGROUP 3 Questions Solved Problems in Gas Turbine and Geothermal Power PlantCherry Obias0% (1)

- Lagnas CharacterDocument14 pagesLagnas CharactertechkasambaNo ratings yet

- ) Perational Vlaintena, Nce Manual: I UGRK SeriesDocument22 pages) Perational Vlaintena, Nce Manual: I UGRK Seriessharan kommiNo ratings yet

- Study PDFDocument10 pagesStudy PDFDaniel Cano QuinteroNo ratings yet

- Galloping Instability To Chaos - Albert C.J. Luo, Bo YuDocument213 pagesGalloping Instability To Chaos - Albert C.J. Luo, Bo YuHuy Thông NguyễnNo ratings yet

- Human Strategies For A Virtual World: Baldwin BergesDocument32 pagesHuman Strategies For A Virtual World: Baldwin BergesmoisesNo ratings yet

- Multi Answer Multiple Choice QuestionsDocument1 pageMulti Answer Multiple Choice Questionsrakibdx001No ratings yet

- 2010 IMCO CatalogDocument170 pages2010 IMCO Cataloggeav25653855No ratings yet

- Departmental Schedule, 2nd Sem 2017-2018Document70 pagesDepartmental Schedule, 2nd Sem 2017-2018Kim Kenneth Roca100% (3)

- Fabric in ArchitectureDocument28 pagesFabric in ArchitecturesubalakshmiNo ratings yet

- Lord Dyrron Baratheon, Warden of the StormlandsDocument2 pagesLord Dyrron Baratheon, Warden of the StormlandsDaniel AthertonNo ratings yet

- 3-5 Support Document - Phase IDocument38 pages3-5 Support Document - Phase Iapi-290854496No ratings yet

- University of Oxford, Financial Statements 2017-2018 PDFDocument120 pagesUniversity of Oxford, Financial Statements 2017-2018 PDFRano Digdayan MNo ratings yet

- 80312A-ENUS Error LogDocument10 pages80312A-ENUS Error LogSafdar HussainNo ratings yet

- VVCS v2v Convert VirtualBox To VMwareDocument37 pagesVVCS v2v Convert VirtualBox To VMwareraviNo ratings yet

- BD645, BD647, BD649, BD651 NPN Silicon Power DarlingtonsDocument4 pagesBD645, BD647, BD649, BD651 NPN Silicon Power DarlingtonsErasmo Franco SNo ratings yet

- Photogrammetry and Remote SensingDocument14 pagesPhotogrammetry and Remote SensingJoseph Dincht83% (6)

- Applying The PROACT RCA Methodology.4.26.16Document30 pagesApplying The PROACT RCA Methodology.4.26.16Alexandar ApishaNo ratings yet

- CCR Control System Interface Handbook - 6jun2012Document17 pagesCCR Control System Interface Handbook - 6jun2012Tomuta StefanNo ratings yet