Professional Documents

Culture Documents

Answer Any Three Questions.: Pages: 2

Uploaded by

amaljyothyrajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Answer Any Three Questions.: Pages: 2

Uploaded by

amaljyothyrajCopyright:

Available Formats

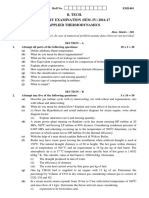

C B4C123S Pages: 2

Reg. No.______________ Name:_______________________

APJ ABDUL KALAM TECHNOLOGICAL UNIVERSITY

FOURTH SEMESTER B.TECH DEGREE EXAMINATION, JULY 2017

Course Code: ME204

Course Name: THERMAL ENGINEERING (ME)

Max. Marks: 100 Duration: 3 Hours

PART A

Answer any three questions.

1. Draw neat sketches of a Cochran and Babcock Wilcox boiler. List the boiler

mountings and accessories used in a boiler. Compare the merits and demerits of water

tube and fire tube boilers. (10)

2. In a Rankine cycle the steam at inlet to turbine is saturated at a pressure of 35bar and

exhaust pressure is 0.2bar. Determine i) The pump work ii) The turbine work iii) The

Rankine efficiency iv) The condenser heat flow v) The dryness fraction at the end of

expansion. Take a flow rate of 10kg/sec (10)

3. a) Derive the relationship for optimum blade speed ratio for an impulse turbine in

terms of inlet nozzle angle. Show that maximum blade or diagram efficiency is given

by Cos2α1 (5)

b) The velocity of steam leaving nozzles of an impulse turbine is 900m/s and the

nozzle angle is 200. Blade velocity is 300m/s and blade velocity coefficient is 0.7.

Calculate for a mass flow rate of 1kg/Sec and symmetrical blading i) The blade inlet

angle ii) Driving force on wheel iii) The axial thrust iv) Diagram power v) Diagram

efficiency. (5)

4. A Parsons reaction turbine running at 400rpm with 50% reaction develops 75KW per

kg of the steam. The exit angle of the blade is 200 and the steam velocity at inlet is 1.4

times blade velocity. Determine i) Blade velocity ii) Blade inlet angle. (10)

PART B

Answer any three questions.

5. a. Derive an expression for air standard efficiency of an Otto cycle citing all

assumptions involved (4)

b. In an Otto cycle air at 17°C and 1 bar is compressed adiabatically until the pressure

is 15bar. Heat is added at constant volume until the pressure rises to 40bar. Calculate

the air standard efficiency, compression ratio and maximum temperature in the cycle.

Cv=0.717 KJ/KgK and R0=8.314 KJ/KmolK. (6)

6. a. Explain the operation of a wankel engine. (4)

b. Draw line sketch showing the gas flow routes and components and explain the

supercharging and turbo charging with respect to IC engines. (4)

c. Out of CI and SI engines, which engine is more suitable to supercharging? Explain.

(2)

Page 1 of 2

For More Visit : KtuQbank.com

C B4C123S Pages: 2

7. During brake test of a four cylinder 4 stroke engine coupled to a dynamometer at

constant speed, the following results are obtained. BP with all cylinders

working=14.7kw. BP with cylinder 1 cut off=10.14kw. BP with cylinder 2 cut off

=10.3kw. BP with cylinder 3 cut off =10.36kw. BP with cylinder 4 cut off=10.21kw.

Petrol consumption=5.5kg/hr.CV of fuel=42000 Kj/Kg. Diameter of cylinder=8cm,

Stroke of piston=10cm, Clearance volume 0.1 litre. Calculate i) The mechanical

efficiency ii) Relative efficiency on the basis of IP. (10)

8. a. What are octane and cetane ratings? Mention important doping agents used to

control the values of octane number. (4)

b. Determine the air fuel ratio and the theoretical amount of air required by mass for

complete combustion of fuel containing (by mass) 85% carbon, 8% hydrogen, 3%

oxygen, 1% sulphur and remaining ash. If 40% excess air is used what is the volume

of air at 27°C and 1.03bar. (6)

PART C

Answer any four questions.

9. a. With a p-θ diagram, explain various stages of an SI engine combustion. (4)

b. Explain the influence of various factors that reduce Knock in SI engine. (6)

10. a. What are the important factors to be considered for the design of CI engine

combustion chamber? (4)

b. With sketches, discuss various designs of Indirect (Divided) Combustion chambers.

(6)

11. a. What are various pollutants coming out of an IC engine? (3)

b. Explains methods for control of NOx. (3)

c. Explain the operation of a thermal and catalytic converter. (4)

12. Air enters the compressor of an ideal air standard Brayton cycle at 100Kpa, 300K and

is compressed to 1000Kpa. The temperature at the inlet to the first turbine is 1400K.

The expansion takes is entropically in two stages with reheat to 1400K between two

stages at a constant pressure of 300Kpa. Regenerator effectiveness 100%. Determine

thermal efficiency of the cycle. (10)

13. a. Show that optimum intermediate pressure for a two stage compressor is given by

(P1P2)0.5 where P1 and P2 are initial and final pressures. (6)

b. Discuss the stability loop of a gas turbine combustion chamber. (4)

14. a. Draw the combustion chamber of a gas turbine showing air entries at various

stages. (4)

b. An ideal gas turbine cycle with two stages of compression and two stages of

expansion has an overall pressure ratio of 8. Air enters each stage of compressor at

300K and each stage of turbine at 1300K. Determine the work ratio and thermal

efficiency of cycle. Assume regenerator efficiency of 100%. (6)

****

Page 2 of 2

For More Visit : KtuQbank.com

You might also like

- 2018 Dec. ME204-D - Ktu QbankDocument3 pages2018 Dec. ME204-D - Ktu QbankamaljyothyrajNo ratings yet

- 2018 April - ME204-C - Ktu QbankDocument2 pages2018 April - ME204-C - Ktu QbankamaljyothyrajNo ratings yet

- Thermal Engineering Exam Questions and AnswersDocument2 pagesThermal Engineering Exam Questions and AnswersamaljyothyrajNo ratings yet

- Rr312405 Thermal Engineering IIDocument8 pagesRr312405 Thermal Engineering IISrinivasa Rao GNo ratings yet

- Be Mech 4 Sem Applied Thermodynamics 484 Jun 2018Document1 pageBe Mech 4 Sem Applied Thermodynamics 484 Jun 2018mohdamaan.070015No ratings yet

- Model Question PaperDocument2 pagesModel Question PaperpvjotaniyaNo ratings yet

- JNTU Hyderabad B.Tech III Year I Semester Thermal Engineering-II exam questionsDocument3 pagesJNTU Hyderabad B.Tech III Year I Semester Thermal Engineering-II exam questionsAnonymous 5HYsyrddpNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2JanneNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- 2020 09 23SupplementaryME204ME204 H Ktu QbankDocument3 pages2020 09 23SupplementaryME204ME204 H Ktu QbankamaljyothyrajNo ratings yet

- 136EB052019Document3 pages136EB052019Naveen niratkarNo ratings yet

- Ic Engines (2) Question PaperDocument2 pagesIc Engines (2) Question Paperstalinrajesh143No ratings yet

- r05312002 Power Plant and Turbo MachineryDocument8 pagesr05312002 Power Plant and Turbo MachineryRafael ContrerasNo ratings yet

- 07a4ec05-Thermal Engineering - IDocument7 pages07a4ec05-Thermal Engineering - ISRINIVASA RAO GANTANo ratings yet

- 115 Er 032016Document2 pages115 Er 032016Anonymous 5HYsyrddpNo ratings yet

- rr310303 Thermal Engineering IIDocument9 pagesrr310303 Thermal Engineering IISRINIVASA RAO GANTANo ratings yet

- Ii Mech ThermalDocument8 pagesIi Mech ThermalRameez FaroukNo ratings yet

- Thermal Engineering - I Jntua Question PapersDocument15 pagesThermal Engineering - I Jntua Question PapersHimadhar SaduNo ratings yet

- rr310303 Thermal Engineering IIDocument8 pagesrr310303 Thermal Engineering IISrinivasa Rao GNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityfeyayel988No ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- MQP1 18ME44 ATD OBE Format JUNE2021Document4 pagesMQP1 18ME44 ATD OBE Format JUNE2021Hemanth LNo ratings yet

- 07 r05310306 Thermal Engineering IIDocument8 pages07 r05310306 Thermal Engineering IIandhracollegesNo ratings yet

- Propulsion - I: B.E. (Aeronautical Engineering) Fifth Semester (C.B.S.)Document2 pagesPropulsion - I: B.E. (Aeronautical Engineering) Fifth Semester (C.B.S.)fashion storeNo ratings yet

- Question Paper Code: X10699: (10×2 20 Marks)Document3 pagesQuestion Paper Code: X10699: (10×2 20 Marks)Chatheriyan ThangarajuNo ratings yet

- Coaching - I TEDocument2 pagesCoaching - I TEtagoreboopathyNo ratings yet

- NR-222001-Thermal Engineering and Heat TransferDocument8 pagesNR-222001-Thermal Engineering and Heat TransferSrinivasa Rao GNo ratings yet

- Ae2255 Propulsion-1 Question Bank UNIT-1Document5 pagesAe2255 Propulsion-1 Question Bank UNIT-1kanscse100% (1)

- MCE 508 Problem SetDocument4 pagesMCE 508 Problem SetDavid AkinrinolaNo ratings yet

- QP 2010Document25 pagesQP 2010samy_175No ratings yet

- Propulsion !Document3 pagesPropulsion !dickandballsNo ratings yet

- WWW - Jdrr5.co - CC: Model Question PaperDocument3 pagesWWW - Jdrr5.co - CC: Model Question PaperPavan KishoreNo ratings yet

- R16 Aug 2021Document2 pagesR16 Aug 2021Md. SunmunNo ratings yet

- ETD - III 2nd AssignmentDocument7 pagesETD - III 2nd Assignmentmallesh mendaNo ratings yet

- ME204THERMALENGINEERINGDocument3 pagesME204THERMALENGINEERINGVishnu Mohan M SNo ratings yet

- Thermal Engineering Exam QuestionsDocument4 pagesThermal Engineering Exam QuestionsDhanabal Palanisamy PNo ratings yet

- IES 1988 - CONV - EditedDocument7 pagesIES 1988 - CONV - EditedAyush NarayanNo ratings yet

- 2.thermal ScienceDocument9 pages2.thermal Scienceram jrpsNo ratings yet

- MET303 - Ktu QbankDocument16 pagesMET303 - Ktu QbankANAND V VNo ratings yet

- L-4ff-lIME: Internal Combustion Engines Exam QuestionsDocument25 pagesL-4ff-lIME: Internal Combustion Engines Exam QuestionsAdnan Shahariar AnikNo ratings yet

- GTU BE Semester VII Power Plant Engineering Exam QuestionsDocument2 pagesGTU BE Semester VII Power Plant Engineering Exam QuestionsRahNo ratings yet

- Heat Power EngineeringDocument2 pagesHeat Power Engineeringsameer_m_daniNo ratings yet

- Question Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhDocument5 pagesQuestion Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhSAJU UTHUPPANNo ratings yet

- Thermal EngineeringDocument1 pageThermal EngineeringSoumya BsoumyaNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISRINIVASA RAO GANTANo ratings yet

- Question Paper Code: 77006Document3 pagesQuestion Paper Code: 77006Vishnu Kumar G CNo ratings yet

- Propulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Document2 pagesPropulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Preshit SamNo ratings yet

- Code - No: 35089: Jawaharlal Nehru Technological University HyderabadDocument6 pagesCode - No: 35089: Jawaharlal Nehru Technological University HyderabadSRINIVASA RAO GANTANo ratings yet

- Aerospace Propulsion Exam Questions and AnswersDocument3 pagesAerospace Propulsion Exam Questions and AnswersCjananiNo ratings yet

- Docs METEIIAssignments2013Document8 pagesDocs METEIIAssignments2013shashi's Tips&Tricks Videos On DemandNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversDocument8 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversParviz GhadimiNo ratings yet

- Applied Thermodynamics Eme401Document2 pagesApplied Thermodynamics Eme401deepak GuptaNo ratings yet

- THERMAL ENGINEERING-IIDocument2 pagesTHERMAL ENGINEERING-IIraisa1No ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesFrom EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesRating: 3 out of 5 stars3/5 (1)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Verbal Maths by Abhas SainiDocument57 pagesVerbal Maths by Abhas SainiPrabas PaulNo ratings yet

- #General Knowledgesas234Document391 pages#General Knowledgesas234linuxmaniNo ratings yet

- 2020 09 23SupplementaryME204ME204 H Ktu QbankDocument3 pages2020 09 23SupplementaryME204ME204 H Ktu QbankamaljyothyrajNo ratings yet

- Answer Any 3 Questions. Ten Marks Each.: Pages: 2Document2 pagesAnswer Any 3 Questions. Ten Marks Each.: Pages: 2amaljyothyrajNo ratings yet

- C.V. Gaspar Salvage - Lighterage Corp. v. LG Insurance Co., Ltd. (United States Branch)Document9 pagesC.V. Gaspar Salvage - Lighterage Corp. v. LG Insurance Co., Ltd. (United States Branch)Liz KawiNo ratings yet

- Intelligent Traffic SystemDocument14 pagesIntelligent Traffic Systemvaishnavi78006No ratings yet

- Dgex Form20180521Document1 pageDgex Form20180521Arif Tawil PrionoNo ratings yet

- PROPOSALDocument7 pagesPROPOSALBrynn EnriquezNo ratings yet

- 1Gcf530K0000-Brake Shoe Set - Rear/Front 1Gcf530K0000-Brake Shoe Set - Rear/FrontDocument6 pages1Gcf530K0000-Brake Shoe Set - Rear/Front 1Gcf530K0000-Brake Shoe Set - Rear/FrontArif MamunNo ratings yet

- REP pc12 Checklists ReferencesDocument30 pagesREP pc12 Checklists ReferencesWilton PingoNo ratings yet

- Build Sheet ServletDocument7 pagesBuild Sheet ServletVictor PopescuNo ratings yet

- 93LH 2Document72 pages93LH 2prueba5No ratings yet

- L H Materials Safety StandardDocument28 pagesL H Materials Safety StandardSachin VaidyaNo ratings yet

- Section-352 of Merchant Shipping ActDocument111 pagesSection-352 of Merchant Shipping ActEswar StarkNo ratings yet

- Bleek Logistics ProfileDocument7 pagesBleek Logistics ProfileThabangNo ratings yet

- Service Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTDocument56 pagesService Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTErnesto Turpo50% (2)

- Apron Weighfeeder MULTIDOSDocument5 pagesApron Weighfeeder MULTIDOSzaki3speedNo ratings yet

- Subram Chetty Road, Basavanagudi, Bengaluru, Karnataka: Directions To Nettakallappa Circle 8.0 KM - About 18 MinsDocument5 pagesSubram Chetty Road, Basavanagudi, Bengaluru, Karnataka: Directions To Nettakallappa Circle 8.0 KM - About 18 Minssugnan.prabhuNo ratings yet

- Luzon Stevedoring Vs CTADocument4 pagesLuzon Stevedoring Vs CTAAnn MarinNo ratings yet

- 757-767 Study Guide PDFDocument155 pages757-767 Study Guide PDFavianteNo ratings yet

- Spirit Airlines Booking ConfirmationDocument5 pagesSpirit Airlines Booking ConfirmationRoad Guy100% (1)

- Dept TixDocument2 pagesDept TixRicky TanNo ratings yet

- Overview of The Local Public Transport Route Plan of Butuan CityDocument18 pagesOverview of The Local Public Transport Route Plan of Butuan Cityclinton john minglanaNo ratings yet

- 1a5ja351f1 (Xv1600a)Document81 pages1a5ja351f1 (Xv1600a)Eva Bart-Kay Sanchez LopezNo ratings yet

- Sae J216-2021Document4 pagesSae J216-2021tiramisuweitaoNo ratings yet

- 1super King Air Series MTM V1Document590 pages1super King Air Series MTM V1C. CONTRERAS100% (1)

- James Fisher Offshore Air Winch Hoists Brochure OrganizedDocument1 pageJames Fisher Offshore Air Winch Hoists Brochure OrganizedMuhammad Nur FadlyNo ratings yet

- XC60 Owners Manual MY11 en-GB Tp18267Document430 pagesXC60 Owners Manual MY11 en-GB Tp18267nagyzoltan077No ratings yet

- The Containerised Car Transport GuideDocument34 pagesThe Containerised Car Transport GuideVALNo ratings yet

- Human Factors Principles in Civil Aviation Advisory CircularDocument10 pagesHuman Factors Principles in Civil Aviation Advisory CircularLuiz Fernando MibachNo ratings yet

- Hyster H05 BrochureDocument8 pagesHyster H05 BrochureAziz DarwishNo ratings yet

- 08 STD Specifications - Building - 2019 PDFDocument919 pages08 STD Specifications - Building - 2019 PDFalfieNo ratings yet

- TH 0608Document8 pagesTH 0608sylvaniaheraldNo ratings yet

- Highlander Brochure 06 18Document7 pagesHighlander Brochure 06 18Pang Chong HengNo ratings yet