Professional Documents

Culture Documents

Technical Specifications: Part A: Bill of Quantities Part B: Technical Specifications Division 3 Concrete

Uploaded by

Mohamed EsmaiilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specifications: Part A: Bill of Quantities Part B: Technical Specifications Division 3 Concrete

Uploaded by

Mohamed EsmaiilCopyright:

Available Formats

TECHNICAL SPECIFICATIONS

CONTENTS

PART A: BILL OF QUANTITIES

PART B: TECHNICAL SPECIFICATIONS

DIVISION 3 CONCRETE

03544 Cement-based Screeds

DIVISION 4 MASONRY

04810 Unit Masonry Assemblies

DIVISION 5 METALS

05500 Metal Fabrications

05521 Pipe and Tube Railing

05530 Gratings

05720 Ornamental Handrails and Railings

05811 Architectural Joint Systems

DIVISION 6 WOOD AND PLASTICS

06100 Rough Carpentry

06402 Interior Architectural Woodwork

06420 Paneling

DIVISION 7 THERMAL AND MOISTURE PROTECTION

07180 Traffic Coating

07210 Building Insulation

07460 Composite Wall Panel

07570 Coated Foamed Roofing

07620 Sheet Metal Flashing

07841 Through-Penetration Firestop Systems

07920 Joint Sealants

DIVISION 8 DOORS AND WINDOWS

08114 Custom Steel Doors and Frames

08164 Aluminum-Framed Glass Doors

08211 Flush Wood Doors

08311 Access Doors and Frames

08450 All-Glass Entrances and Storefronts

08461 Sliding Automatic Entrance Doors

08470 Revolving Door Entrance

08710 Door Hardware

08800 Glazing

08816 Decorative Glass

08830 Mirrored Glass

08912 Structural Sealant Glazed Curtain Walls

DIVISION 9 FINISHES

09220 Portland Cement Plaster

09260 Gypsum Board Assemblies

09310 Ceramic Tile

09512 Acoustical Tile Ceilings

09561 Gypsum Units Ceilings

09570 Wood Ceiling

09638 Stone Paving and Flooring

09751 Stone Facing

09911 Painting

DIVISION 10 SPECIALTIES

10155 Toilet Compartments

10180 Stone Toilet Compartments

10445 Signage

10450 Pedestrian Control Devices

10505 Metal Lockers

10616 Site-Assembled Demountable Partitions

10801 Toilet and Bath Accessories

10900 Aluminium composite panels

DIVISION 11 EQUIPMENT

11010 Maintenance Equipment

DIVISION 12 FURNISHING

12484 Floor Mats and Frames

PART C: LIST OF MANUFACTURERS

CONTENTS

SECTION 09570

WOOD CEILINGS

Page

PART 1 GENERAL 2

1.1 Related Documents 2

1.2 Summary 2

1.3 Submittals 2

1.4 Quality Assurance 3

1.5 Delivery, Storage, and Handling 4

1.6 Project Conditions 4

1.7 Coordination 4

1.8 Warranty 4

PART 2 PRODUCTS 5

2.1 Materials 5

2.2 Wood Ceiling Panel 5

2.3 Linear Wood Ceiling. 6

2.4 Massive Corniche: 6

2.5 SteelFramingComponentsforSuspendedandFurredCeilings 6

2.6 Fabrication, General 8

2.7 Shop Finishing 8

PART 3 EXECUTIONS 9

3.1 Preparation 9

3.2 Installation, General 9

3.3 Field Quality Control 10

3.4 Cleaning 10

Wood Ceiling Section 09570

XXX BUILDING Page 1 of 10

SECTION 09570

WOOD CEILINGS

PART 1 GENERAL

1.1 RELATED DOCUMENTS

1.1.1 Drawings and general provisions of the Contract, including Conditions of

Contract and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

1.2.1 This Section covers the work of the following:

− Suspended wood ceiling panel and concealed suspension system.

− Suspended linear wood ceiling and concealed suspension system.

− Massive hardwood cornice.

1.2.2 Related Sections:

− Division 6 Section "Rough Carpentry" for wood furring, blocking, shims,

and hanging strips required for installing woodwork and concealed with-

in other construction before woodwork installation.

− Division 6 Section “Interior Architectural Wood Work“

− Division 15 and 16 Sections for Lighting Fixtures, Sprinklers and Air

Distribution Components.

1.3 SUBMITTALS

1.3.1 Product Data: For each type of product indicated.

1.3.2 Shop Drawings: Reflected ceiling plans drawn to scale and coordinating

penetrations and ceiling-mounted items. Show the following.

− Show locations and sizes of furring and blocking, including concealed

blocking specified in other Sections.

− Ceiling suspension members.

− Method of attaching hangers to building structure.

− Ceiling-mounted items including light fixtures, diffusers, grilles, speak-

ers, and access panels.

− Minimum Drawing Scale: 1:50.

1.3.3 Samples for Initial Selection: Manufacturer's color charts consisting of

units or sections of units showing the full range of colors and patterning

Wood Ceiling Section 09570

XXXX BUILDING Page 2 of 10

available for each type of material indicated.

1.3.4 Samples for Verification: For each component indicated and for each ex-

posed finish required, prepared on Samples of size indicated below.

− Wood Panels: Set of full size Samples of each type, finish, color and

wood-grain patterning.

− Linear Wood Strips: Set of full size Samples of each type, finish, color

and wood-grain patterning.

− Exposed Moldings and Trim: Set of 300 mm long Samples of each type,

finish, and color.

− Suspension System Members: 300 mm long sample of each type.

1.3.5 Product Test Reports: Based on evaluation of comprehensive tests per-

formed by a qualified testing agency.

1.3.6 Product Certificates: Signed by manufacturers of wood ceiling panels cer-

tifying that products furnished comply with requirements.

1.3.7 Maintenance Data: For finishes to include in maintenance manuals.

1.3.8 Warranty: Sample of warranty.

− Provide manufacture’s written warranty covering materials and installa-

tion stating obligations, remedies, limitations and exclusions.

1.4 QUALITY ASSURANCE

1.4.1 Manufacture Qualifications: A firm experienced in producing wood pan-

els similar to that indicated for this Project and with a record of successful

in-service performance, as well as sufficient production capacity to produce

required units.

1.4.2 Installer Qualifications: An experienced installer who has completed wood

ceilings similar in material, design, and extent to that indicated for this Pro-

ject and whose work has resulted in construction with a record of successful

in-service performance.

1.4.3 Source Limitations: Obtain each wood ceiling panels and suspension sys-

tems from one source with resources to provide products of consistent quali-

ty in appearance, physical properties, and performance.

1.4.4 Fire-Test-Response Characteristics: Provide ceilings that comply with the

following requirements:

Underwriters Laboratories

− Fire-response tests were performed by UL or another independent testing

and inspecting agency that is acceptable to Engineer and performs testing

and follow-up services.

Wood Ceiling Section 09570

XXX BUILDING Page 3 of 10

− Surface-Burning Characteristics of wood ceiling comply with Class A

materials as determined by identical products per ASTM E84.

1.4.5 Seismic Standard: Provide wood tile ceilings designed and installed to

withstand the effects of earthquake motions according to the following:

− CISCA's Guidelines for Systems Requiring Seismic Restraint: Comply

with CISCA's "Guidelines for Seismic Restraint of Direct-Hung Sus-

pended Ceiling Assemblies--Seismic Zones 0 & 2."

1.4.6 Mockups: Build mockups to verify selections made under sample Submit-

tals and to demonstrate aesthetic effects and qualities of materials and exe-

cution.

− Approved mockups may become part of the completed Work if undis-

turbed at time of Substantial Completion.

1.5 DELIVERY, STORAGE, AND HANDLING

1.5.1 Deliver wood ceiling panels, suspension system components, and accesso-

ries to Project site in original, unopened packages and store them in a fully

enclosed, conditioned space where they will be protected against damage

from moisture, humidity, temperature extremes, direct sunlight, surface con-

tamination, and other causes.

1.5.2 Handle and store materials in accordance with manufacture written recom-

mendations

1.6 PROJECT CONDITIONS

1.6.1 Environmental Limitations: Do not deliver or install wood ceilings until

building is enclosed and weatherproof, wet work in space is completed and

dry, work above ceilings is complete, and HVAC system is operating and

will maintain temperature and relative humidity at occupancy levels during

the remainder of the construction period.

1.7 COORDINATION

1.7.1 Coordinate layout and installation of wood ceiling panels and suspension

system with other construction that penetrates ceilings or is supported by

them, including light fixtures, HVAC equipment, fire-suppression system,

and partition assemblies.

1.8 WARRANTY

1.8.1 Manufacturer’s Warranty: Furnish manufacture’s written material and

labor warranty signed by an authorized representative to repair or replace

work which exhibits material defects caused by manufacture or design and

installation of product. Defects is defined to include but not limited to dete-

rioration of failure to perform as required.

Wood Ceiling Section 09570

XXX BUILDING Page 4 of 10

− Warranty Period: Manufacture shall warrant the products to be free from

material and labor Defects for a period of 5 years from date of Substan-

tial of completion

1.8.2 Installer’s Warranty: Furnish installer’s written workmanship warranty

signed by an authorized representative using installer’s standard form agree-

ing to provide labor required to repair or replace work which exhibits’

workmanship defects. “Defects” is defined to include but not limited to de-

terioration of failure to perform as required

− Warranty Period: Installer will warrant the installation to be from work-

manship Defects for a period of 2 years from date of Substantial Com-

pletion

PART 2 PRODUCTS

2.1 MATERIALS

2.1.1 General: Provide materials that comply with requirements of the AWI qual-

ity standard for quality grade specified, unless otherwise indicated.

2.1.2 Wood Products: Comply with the following:

− Medium-Density Fiberboard:

• Comply with ANSI A208.2, Grade MD-Exterior Glue.

• Density Rate: 785 kg/m³.

• Screw holding shall not be less than 1100 N for face and 900 N for

edge.

• Use boards of highly smooth exposed surfaces to increase resistance

to fungal growth.

− Particle Board:

• Comply with ANSI A208.1, Grade M-2-Exterior Glue.

2.2 WOOD CEILING PANEL

2.2.1 Construction: Medium density fiberboard veneer factory press-bonded to

face and edges as mentioned on Drawings Comply with panels with re-

quirements as specified on Division 6 Section “Paneling”.

2.2.2 Size: As indicated on Drawings.

2.2.3 Thickness: 12 mm.

2.2.4 Face Panel:

Wood Ceiling Section 09570

XXXX BUILDING Page 5 of 10

− Un-perforated.

− Extent of each type to be as indicted on Drawings.

2.2.5 Edge detail: regular, unless otherwise indicated.

2.2.6 Back surface of panel will be finished by clear sealer as recommended by

manufacture and specified in this Section

2.2.7 Suspension-System Installation Method: Concealed-fixed to suspension

system.

2.2.8 Lumber Trim and Edges: Trim and edges indicated as solid wood shall be

lumber compatible with grain and color of veneered panels.

2.2.9 Panel-Matching Method: Select and arrange panels for similarity of grain

pattern and color between adjacent panels.

2.2.10 Assemble by gluing and concealed fastening.

2.3 LINEAR WOOD CEILING.

2.3.1 Construction: Fire retardant Particle board with face cut veneer and facto-

ry applied black fleece on each plank to cover reveal as indicated on Draw-

ings.

2.3.2 Size: As indicated on Drawings.

2.3.3 Thickness: 20 mm.

2.3.4 Edge detail: Regular, unless otherwise indicated.

2.3.5 Suspension-System Installation Method: Concealed-fixed to suspension

system.

2.3.6 Lumber Trim and Edges: Trim and edges indicated as solid wood shall be

lumber compatible with grain and color of veneered panels.

2.4 MASSIVE CORNICHE:

2.4.1 To be constructed from hardwood of type as indicated On Drawings.

2.4.2 Fabricate to dimensions and details indicated. Furnish in length as long as

practice. Corners are to be mitered at 45 degrees.

2.4.3 Finish shall be transparent stained varnish as specified in Division 9, section

“Painting”.

2.5 STEEL FRAMING COMPONENTS FOR SUSPENDED AND

FURRED CEILINGS

Wood Ceiling Section 09570

XXX BUILDING Page 6 of 10

2.5.1 General: Provide components complying with ASTM C 754 for conditions

indicated.

2.5.2 Concealed system designed to support pans consisting of main runners sup-

ported by hangers attached directly to building structure with cross runners

attached to main runners, and complying with the following requirements:

− Angle Hangers: Angles with legs not less than 22 mm wide; formed from

1 mm thick, galvanized steel sheet complying with

ASTM A 653/A 653M, Z275 coating designation; with bolted connec-

tions and 8 mm diameter bolts.

− Main Runners: Formed from the following metal:

• Hot-Dip Galvanized Steel: ASTM A 653/A 653M, not less than Z180

zinc coating.

− Seismic Struts: Manufacturer's standard compression struts designed to

accommodate seismic forces.

− Seismic Clips: Manufacturer's standard seismic clips designed and

spaced to secure wood tile in place.

2.5.3 Post-installed Anchors in Concrete: Anchors of type indicated below, fab-

ricated from corrosion-resistant materials, with holes or loops for attaching

hanger wires, and with capability to sustain, without failure, a load equal to

5 times that imposed by ceiling construction, as determined by testing ac-

cording to ASTM E 488 conducted by a qualified independent testing agen-

cy.

− Type: Expansion anchor.

− Corrosion Protection: Stainless-steel components complying with

ASTM F 593 and ASTM F 594, Group 1 Alloy 304 or 316 for bolts; Al-

loy 304 or 316 for anchors.

2.5.4 Wire Hangers, Braces, and Ties: Provide wires complying with the fol-

lowing requirements:

− Zinc-Coated Carbon-Steel Wire: ASTM A 641/A 641M, Class 1 zinc

coating, soft temper.

− Size: Select wire diameter so that its stress at three times hanger design

load (ASTM C 635, Table 1, "Direct Hung") will be less than yield stress

of wire, but provide not less than 3.5 mm diameter wire.

2.5.5 Hanger Rods and Flat Hangers: Mild steel, zinc coated or protected with

rust-inhibitive paint.

2.5.6 Hold-Down Clips: Where indicated or required by authorities having juris-

diction, provide manufacturer's standard hold-down clips spaced 610 mm

o.c. on all cross tees.

Wood Ceiling Section 09570

XXXX BUILDING Page 7 of 10

2.5.7 Impact Clips: Where indicated or recommended by manufacturer, provide

manufacturer's standard impact-clip system designed to absorb impact forc-

es against wood tile.

2.5.8 Exposed Metal Edge Moldings and Trim: Provide exposed members to

conceal edges of and penetrations through ceiling, for fixture trim and

adapters, for fasciae at changes in ceiling height, and for other conditions; of

lumber and finish matching wood ceiling panels unless otherwise indicated

or directed by the Engineer.

2.6 FABRICATION, GENERAL

2.6.1 Panel Grade: Provide Premium grade wood ceiling panels complying with

the referenced quality standard.

2.6.2 Wood Moisture Content: Comply with requirements of the referenced

quality standard for wood moisture content in relation to ambient relative

humidity during fabrication and in installation areas.

2.6.3 Sand fire-retardant-treated wood lightly to remove raised grain on exposed

surfaces before fabrication.

2.6.4 Complete fabrication, including assembly and finishing, to maximum extent

possible, before shipment to Project site. Disassemble components only as

necessary for shipment and installation. Where necessary for fitting at site,

provide ample allowance for scribing, trimming, and fitting.

− Notify Engineer seven days in advance of the dates and times paneling

fabrication will be complete.

2.6.5 Shop cut openings, to maximum extent possible, to receive, appliances,

electrical work, and similar items. Locate openings accurately and use tem-

plates or roughing-in diagrams to produce accurately sized and shaped open-

ings. Sand edges of cutouts to remove splinters and burrs.

2.7 SHOP FINISHING

2.7.1 Quality Standard: Comply with AWI Section 1500, unless otherwise indi-

cated.

− Grade: Provide finishes of same grades as wood ceiling panels to be fin-

ished.

2.7.2 General: Finish transparent finished wood ceiling panels at fabrication shop

as specified in this Section. .

2.7.3 Preparations for Finishing: Comply with referenced quality standard for

sanding, filling countersunk fasteners, sealing concealed surfaces, and simi-

lar preparations for finishing panels, as applicable to each unit of work.

Wood Ceiling Section 09570

XXXX BUILDING Page 8 of 10

− Back priming: Apply two coats of sealer or primer, compatible with fin-

ish coats, to concealed surfaces of wood ceiling panels.

2.7.4 Transparent Finish: Comply with requirements indicated below for grade,

finish system, staining, and sheen, with sheen measured on 60-degree gloss

meter per ASTM D 523:

− Grade: Premium.

− AWI Finish System TR-6: Catalyzed polyurethane.

− Staining: As selected by Engineer.

− Sheen: As selected by Engineer.

PART 3 EXECUTIONS

3.1 PREPARATION

3.1.1 Condition wood ceiling tiles to average prevailing humidity conditions in

installation areas before installation.

3.1.2 Before installing wood ceiling panels, examine shop-fabricated work for

completion and complete work as required, including removal of packing

and application of back priming.

3.2 INSTALLATION, GENERAL

3.2.1 General: Install wood tile ceilings to comply with ASTM C 636 and seis-

mic requirements indicated, per manufacturer's written instructions and

CISCA's "Ceiling Systems Handbook."

3.2.2 Suspend ceiling hangers from building's structural members and as follows:

− Install hangers plumb and free from contact with insulation or other ob-

jects within ceiling plenum that are not part of supporting structure or of

ceiling suspension system.

− Splay hangers only where required to miss obstructions; offset resulting

horizontal forces by bracing, counter splaying, or other equally effective

means.

− Where width of ducts and other construction within ceiling plenum pro-

duces hanger spacing that interfere with location of hangers at spacing

required to support standard suspension system members, install supple-

mental suspension members and hangers in form of trapezes or equiva-

lent devices. Size supplemental suspension members and hangers to

support ceiling loads within performance limits established by referenced

standards and publications.

− Secure wire hangers to ceiling suspension members and to supports

above with a minimum of three tight turns. Connect hangers directly ei-

Wood Ceiling Section 09570

XXXX BUILDING Page 9 of 10

ther to structures or to inserts, eye screws, or other devices that are secure

and appropriate for substrate and that will not deteriorate or otherwise

fail due to age, corrosion, or elevated temperatures.

− Secure flat, angle, channel, and rod hangers to structure, including inter-

mediate framing members, by attaching to inserts, eye screws, or other

devices that are secure and appropriate for both structure to which hang-

ers are attached and type of hanger involved. Install hangers in a manner

that will not cause them to deteriorate or fail due to age, corrosion, or el-

evated temperatures.

− Do not support ceilings directly from permanent metal forms or floor

deck. Fasten hangers to cast-in-place hanger inserts, post-installed me-

chanical or adhesive anchors, which extend through forms into concrete.

− Do not attach hangers to steel deck tabs.

− Do not attach hangers to steel roof deck. Attach hangers to structural

members.

− Space hangers not more than 1200 mm o.c. along each member support-

ed directly from hangers, unless otherwise indicated; provide hangers not

more than 200 mm from ends of each member.

3.3 FIELD QUALITY CONTROL

3.3.1 Manufacture/Fabricator’s Field Service: Manufacture/fabricator’s quali-

fied technical representative, not a sales representative, shall inspect first

day work and periodically inspect work of this Section to insure installation

is proceeding in accordance with manufacture/fabricator’s recommendations

and warranty requirements. Representative shall submit written reports of

each visit indicating observations, findings and conclusion of inspection

3.3.2 Contractor shall engage and pay an approved qualified independent testing

laboratory to perform field quality control. Materials and installation failing

to meet specified requirements shall be replaced at Contractor’s expenses.

− The Ceiling systems shall be unresponsive to noise and vibration excita-

tion, including building movement, footfalls and above, door closure,

noise and vibration from mechanical or public health plant and occupa-

tional noise.

− The ceiling systems shall not produce any audible “rattling”, “ringing” or

other extraneous noise when excited by any of the sources listed above.

− Contractor shall include the cost for replacement or remedial work to any

ceiling elements deemed by the Acoustic consultant to be non-compliant

3.4 CLEANING

3.4.1 Clean panels on exposed surfaces. Touch up shop-applied finishes to re-

store damaged or soiled areas.

END OF SECTION 09570

Wood Ceiling Section 09570

XXXX BUILDING Page 10 of 10

PART C

LIST OF MANUFACTURERS

LIST OF MANUFACTURERS

The Contractor should abide by the manufacturers mentioned in the following list OR

equivalent, subject to the main consultant’s approval.

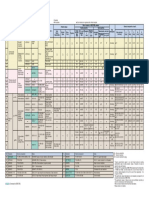

SECTION No. PRODUCT MANUFACTURER

03544 Cement-based Screeds BASF

Sika

Eamic

Huntsman

04810 Unit Masonry Assemblies Cimenta

Hassan Aalam Sons

Archirodon

Misrcrete

Masonry Accessories Metal X

05500 Metal Fabrications Valley of the Kings

Basco

05521 Pipe and Tube Railing Valley of the Kings

Basco Industrial

Mobica

05530 Gratings Tawakol

Meiser

Alpha

05720 Ornamental Handrails and Railings Valley of the Kings

Basco Industrial

Mobica

05811 Architectural Joint Systems Wabo-BASF

06402 Interior Architectural Woodwork Mobica

Living In

06420 Paneling Mobica

Style Design

Living In

07180 Traffic Coating BASF

Sika

Jotun

07460 Composite Wall Panel Egybond

07570 Coated Foamed Roofing Huntsman

07841 Through-Penetration Firestop Systems Comag

Hilti

Fire Service

07920 Joint Sealants BASF

Sika

Eamic

08114 Custom Steel Doors and Frames France Metal

08164 Aluminum-Framed Glass Doors Alico

Alu-Nile

Egybel

08211 Flush Wood Doors Mobica

Al Badry

Misr-Italy

Living In

08311 Access Doors and Frames Basco

08450 All-Glass Entrances and Storefronts Alico

Alu-Nile

Egybel

08461 Sliding Automatic Entrance Doors Besam (UK)

Dorma (USA)

08470 Revolving Door Entrance Besam (UK)

Boon Edam (Netherlands)

08710 Door Hardware Dorma (USA)

Hager (USA)

PDQ (USA)

08800 Glazing Saint-Gobain (France)

AGC (USA)

08816 Decorative Glass Dr/Greich

08830 Mirrored Glass Saint-Gobain (France)

AGC (USA)

08912 Structural Sealant Glazed Curtain Walls Alico

Alu-Nile

Egybel

Reynaers

09220 Portland Cement Plaster Metal X

09260 Gypsum Board Assemblies Knauf (Germany)

09310 Ceramic Tile Gemma

Cleopatra

Cementious Waterproofing for Wet Area BASF

Henkel

Sika

Eamic

09421 Precast Terrazzo ElNile

Toblat

Elsoufi

Panar Kham

09512 Acoustical Tile Ceilings AMF (Germany)

Armstrong (USA)

USG (USA)

09570 Wood Ceiling Mobica

Armstrong (USA)

09638 Stone Paving and Flooring Marmonil

Kiro Marbel

UMG

Grable

Al Safwa

Stone Grouts BASF

Sika

Eamic

09645 Laminate Flooring (HDF) Pergo (Sweden)

Alloc (Norway)

09652 Resilient Sheet Flooring Forbo (Sweden)

Polyfloor (UK)

Gerfloor (France)

09653 Rubber Sheet Flooring Forbo (Sweden)

Polyfloor (UK)

Gerfloor (France)

09681 Carpet Tile Desso (Netherlands)

Forbo (Sweden)

Milliken (USA)

09751 Stone Facing Marmonil

Kiro Marbel

UMG

Grable

Al Safwa

Stone Grouts BASF

Sika

Eamic

09911 Painting Scib

Sigma

Pachin

10155 Toilet Compartments Gibca (UAE)

Bradley (USA)

10180 Stone Toilet Compartments Marmonil

Grable (UAE)

10200 Louvers and Vents Alico

Egybel

Alu-Nile

10265 Impact Resistant Wall Surface Protection BASF

10270 Access Flooring CBI (Italy)

Nesite (Italy)

Lindner (Germany)

10445 Signage Unilex

Graphilex

Graphia

10450 Pedestrian Control Devices Boon Edam (Netherlands)

Kaba (UK)

10505 Metal Lockers Mohm Link

Misr

Technometal

10616 Site-Assembled Demountable Partitions Mobica

10801 Toilet and Bath Accessories Jofel (Spain) Diva

(Italy) Smedbo

(Sweden)

11010 Maintenance Equipment Sky-Steel Systems (UAE)

Tracktel (USA)

12484 Floor Mats and Frames C/S (USA)

Pawling (USA)

Bonar (France)

You might also like

- Common Work Results For Openings 08 05 00 PDFDocument10 pagesCommon Work Results For Openings 08 05 00 PDFozsenerNo ratings yet

- 031120-Permanent Concrete FormingDocument7 pages031120-Permanent Concrete FormingjimmydomingojrNo ratings yet

- 084413-Glazed Aluminum Curtain Walls (MultiWall HS 2700)Document12 pages084413-Glazed Aluminum Curtain Walls (MultiWall HS 2700)Catharina SusantoNo ratings yet

- Standard Specification of Construction 2008Document20 pagesStandard Specification of Construction 2008Wah KhaingNo ratings yet

- FLDocument16 pagesFLomik8912No ratings yet

- Glazed Decorative Metal RailingsDocument7 pagesGlazed Decorative Metal Railingsbrian walter abarintosNo ratings yet

- A1-30 Sun-Screens and LouvresDocument15 pagesA1-30 Sun-Screens and LouvresZYWNo ratings yet

- 084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Document12 pages084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Md Jahangir AlamNo ratings yet

- Project Summary and Bill of QuantitiesDocument20 pagesProject Summary and Bill of QuantitiesEliminated ProNo ratings yet

- CHAD Tech Manual AAC EcoPanel V3.outputDocument68 pagesCHAD Tech Manual AAC EcoPanel V3.outputbadar_tsaniNo ratings yet

- ARCHITECTURAL SPECIFICATION FOR RESIDENTIAL HOUSEDocument4 pagesARCHITECTURAL SPECIFICATION FOR RESIDENTIAL HOUSERouzurin KunNo ratings yet

- Building Component Specification BUILDINDocument4 pagesBuilding Component Specification BUILDINChris RodopoulosNo ratings yet

- Guest Bedroom Furniture SpecsDocument5 pagesGuest Bedroom Furniture SpecsMØhãmmed ØwięsNo ratings yet

- BMW Center Show Room Final-01Document43 pagesBMW Center Show Room Final-01QC MEPNo ratings yet

- A - M 04 - Glass and GlazingDocument15 pagesA - M 04 - Glass and GlazingsuneethmohanNo ratings yet

- A M 09 Metalwork July 09Document21 pagesA M 09 Metalwork July 09suneethmohanNo ratings yet

- A1-10 Curtain WallsDocument58 pagesA1-10 Curtain WallsZYWNo ratings yet

- 09 50 00 Gypsum BoardDocument14 pages09 50 00 Gypsum BoardKiran D AnvekarNo ratings yet

- A1-30 Sun-Screens and LouvresDocument17 pagesA1-30 Sun-Screens and LouvresJacky TiongNo ratings yet

- Baguio BOQ Format-1Document97 pagesBaguio BOQ Format-1ronatabbuNo ratings yet

- DOMINGO PUA 08125 - Interior Aluminum FramesDocument9 pagesDOMINGO PUA 08125 - Interior Aluminum Framesjuristdaneniel.domingoNo ratings yet

- Ufgs 08 44 00Document63 pagesUfgs 08 44 00moudshahineNo ratings yet

- B 17Document15 pagesB 17Rochdi SahliNo ratings yet

- SPC-FXI-009 OBC Ducting MaterialsDocument8 pagesSPC-FXI-009 OBC Ducting MaterialsHemant ChauhanNo ratings yet

- MANDA-TOWNHOUSE - Technical SpecificationsDocument10 pagesMANDA-TOWNHOUSE - Technical SpecificationsMark Nathan Sta. MonicaNo ratings yet

- Boq AliaDocument126 pagesBoq AliaMuhammad Shakil JanNo ratings yet

- Baguio BOQ FormatDocument176 pagesBaguio BOQ FormatronatabbuNo ratings yet

- PERU TEMPLE INTERIOR WOODWORKDocument60 pagesPERU TEMPLE INTERIOR WOODWORKJesusVelardeNo ratings yet

- A1-80-2 External Wall Tiling - 1 PDFDocument15 pagesA1-80-2 External Wall Tiling - 1 PDFZYWNo ratings yet

- Best Practice Guide FinalDocument64 pagesBest Practice Guide Finalamirice70No ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNo ratings yet

- 07 42 96 Phenolic Wall PanelsDocument9 pages07 42 96 Phenolic Wall Panelstaghreed shabanNo ratings yet

- A2-20 Tile RoofingDocument21 pagesA2-20 Tile RoofingJacky Tiong100% (1)

- Section 08500 Windows Rev 0Document35 pagesSection 08500 Windows Rev 0Our SalahEddineNo ratings yet

- Proposed Marassi Park Flush Wood DoorsDocument6 pagesProposed Marassi Park Flush Wood DoorsshajbabyNo ratings yet

- ETICS InsulationDocument100 pagesETICS InsulationrusuoctavianNo ratings yet

- Guide For Writing Outline SpecificationsDocument11 pagesGuide For Writing Outline SpecificationsReggie HoltNo ratings yet

- Fusion™ - Glass Partitions With Wood Doors Constitutes An Innovative Mixed Media Concept: CoolDocument14 pagesFusion™ - Glass Partitions With Wood Doors Constitutes An Innovative Mixed Media Concept: CoolSyed AbuthahirNo ratings yet

- Bong Bom FinalDocument12 pagesBong Bom FinalAr John Bernard AbadNo ratings yet

- Timber Structures, Instructions, 2016Document35 pagesTimber Structures, Instructions, 2016Mark Angelo M. MarcoNo ratings yet

- Aluminum CurtainwallDocument8 pagesAluminum CurtainwallvtalexNo ratings yet

- Final PDF of Standard SpecificationDocument179 pagesFinal PDF of Standard SpecificationabualamalNo ratings yet

- 2808-084413 - Glazed Aluminum Curtain WallsDocument52 pages2808-084413 - Glazed Aluminum Curtain WallsAmro Ahmad AliNo ratings yet

- 09 51 00asiDocument17 pages09 51 00asiAngelica Dela CruzNo ratings yet

- BOQ Lotus Hotel Final 080709Document26 pagesBOQ Lotus Hotel Final 080709Jane NixonNo ratings yet

- Aluminum FramesDocument5 pagesAluminum Frameseromax1No ratings yet

- Cladding EvaluationDocument7 pagesCladding EvaluationJezreel LacsiNo ratings yet

- SECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsDocument3 pagesSECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsTheJohnnyBravoooNo ratings yet

- FL - Aluminum Doors and WindowsDocument9 pagesFL - Aluminum Doors and WindowsAmro Ahmad AliNo ratings yet

- 03 35 00sesDocument17 pages03 35 00sesHitesh SachaniNo ratings yet

- Section 067300 - Composite DeckingDocument4 pagesSection 067300 - Composite DeckingWENDING HUNo ratings yet

- Doors-Method StatementDocument4 pagesDoors-Method StatementMuhib sadeddeinNo ratings yet

- Architectural Wood Door SpecificationsDocument12 pagesArchitectural Wood Door SpecificationswalidNo ratings yet

- 22 - Prefabricated Elements in BuildingDocument30 pages22 - Prefabricated Elements in BuildingTemur LomidzeNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Interior Detailing: Concept to ConstructionFrom EverandInterior Detailing: Concept to ConstructionRating: 4 out of 5 stars4/5 (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Chapter 7 - Strain EnergyDocument35 pagesChapter 7 - Strain EnergyWee Soon Chai100% (1)

- CM20150421 35555 26171Document68 pagesCM20150421 35555 26171motasem alqaisiNo ratings yet

- Electrochemical TechniquesDocument35 pagesElectrochemical Techniquesfatema100% (1)

- How Air Duct Cleaning Can Help Prevent: Dallas, TX CALL US: (972) 884-555Document6 pagesHow Air Duct Cleaning Can Help Prevent: Dallas, TX CALL US: (972) 884-555Infinity Air Duct ProNo ratings yet

- The Profesional's Advisor On ProceedureDocument136 pagesThe Profesional's Advisor On ProceedureINSTECH ConsultingNo ratings yet

- Septic Tank and Soakage Pit1Document4 pagesSeptic Tank and Soakage Pit1Ovindi WimalarathnaNo ratings yet

- Exergy: A Measure of Work Potential Study Guide in PowerpointDocument27 pagesExergy: A Measure of Work Potential Study Guide in PowerpointKent_RichieanNo ratings yet

- Marine Grease SeparatorsDocument2 pagesMarine Grease SeparatorsMuzami ThahirNo ratings yet

- Min. Requirements For Retaining Wall/Sloping BackfillDocument6 pagesMin. Requirements For Retaining Wall/Sloping Backfillfostbarr0% (1)

- Exercise 1Document4 pagesExercise 1Soh Ming LunNo ratings yet

- ITP of Backfill Behind Quay Wall C01Document6 pagesITP of Backfill Behind Quay Wall C01魏利强No ratings yet

- Appendix A - Flame Radiation ReviewDocument10 pagesAppendix A - Flame Radiation ReviewTorero02No ratings yet

- Conductive Plastics For Electrical and Electronic Applications PDFDocument4 pagesConductive Plastics For Electrical and Electronic Applications PDFsonchemenNo ratings yet

- Corona Effect in Transmission LineDocument11 pagesCorona Effect in Transmission LineSammar AbbasNo ratings yet

- Casting Steel Alloys PDFDocument6 pagesCasting Steel Alloys PDFIAmaeyNo ratings yet

- Dulux Weather Shield Sealer A93118177Document3 pagesDulux Weather Shield Sealer A93118177zorozulNo ratings yet

- K&J Magnetics - SpecificationsDocument5 pagesK&J Magnetics - SpecificationsMilad TilaNo ratings yet

- ESA SyllabusDocument2 pagesESA SyllabusAshish VajirNo ratings yet

- Material Safety Data Sheet - Polyfelt TS Non-WovenDocument4 pagesMaterial Safety Data Sheet - Polyfelt TS Non-WovenJezreel FlotildeNo ratings yet

- HLB System Crodas Time Saving Guide To SDocument22 pagesHLB System Crodas Time Saving Guide To SRishiNo ratings yet

- Et ChantsDocument5 pagesEt ChantsVenkatakrishna.ANo ratings yet

- Kcse 2023 Joint Mocks s1Document265 pagesKcse 2023 Joint Mocks s1micah isabokeNo ratings yet

- International CatalogDocument16 pagesInternational CatalogDesmond KhorNo ratings yet

- First Aid Box Inspection ChecklistDocument2 pagesFirst Aid Box Inspection ChecklistGopal ChoudharyNo ratings yet

- Rural Electrification, Agricultural Processing, Agricultural Structures Allied SubjectsDocument29 pagesRural Electrification, Agricultural Processing, Agricultural Structures Allied SubjectsJewellord CabatitNo ratings yet

- Gsi, Q, RMRDocument8 pagesGsi, Q, RMRDeepthi AcharNo ratings yet

- Steel SectionsDocument33 pagesSteel Sectionssam_antony2005No ratings yet

- Comparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteDocument9 pagesComparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteIJRASETPublicationsNo ratings yet

- Various Types of CastingDocument146 pagesVarious Types of CastingKaushik SreenivasNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet