Professional Documents

Culture Documents

Varilex WSF 1600: Operating Instructions Detail Drawing Spare Part List

Uploaded by

combra24grOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Varilex WSF 1600: Operating Instructions Detail Drawing Spare Part List

Uploaded by

combra24grCopyright:

Available Formats

VARILEX® WSF 1600

Operating Instructions

Detail drawing

Spare part list

Downloaded from www.Manualslib.com manuals search engine

VARILEX® WSF 1600

The new ‘Quick-Lock’ cable system allows a quick change of the machines (e. g. PTX300).

Safety advice:

• Please pay attention to the safety instructions in the attached leaflet!

• Do not pierce the motor housing as this could damage the double insulation (use adhesives).

• Always pull the plug from the mains before making any settings or carrying out maintenance.

• Only plug-in when machine is switched off.

• Keep mains lead clear from working range of the machine. Always lead the cable away behind you.

• Before use check machine, cable, and plug for any damages or material fatigue. Repairs should only be carried out

by authorised service agents.

• After switch off, the machine will not be idle immediately. (After-running of the work spindle.)

Allow the machine to come to a stop before putting down.

• Never reach into the danger area of the machine when it is running.

• Always wear safety goggles and ear protectors when working with this machine. It is further recommended to wear safety gloves, apron, as

well as sturdy non-slipping shoes.

• Always use the additional handle.

• Always use the protecting cap when roughi ng- down and separating.

• Only use tools whose permitted speed is at least as high as the highest no-load speed of the machine.

• Pay attention to the dimensions of the grinding disc. The mounting hole diameter must fit the mounting flange without play.

Do not use reducer pieces or adapters.

• Check grinding tools before use. The grindi ng tool must be properly mounted and turn freely.

Perform a test run for at least 30 seconds without load. Do not use damaged, out of round or vibrating grindi ng tools.

• Immediately switch off the machine in case of considerable vibrations or if other malfunctions occur.

Check the machine in order to find out the cause.

• Always use and store the grinding discs according to the manufacturer's instructions.

• When grinding metal, flying sparks are produced. Take care that no persons are endangered. Because of the danger of fire,

no combustible materials should be located in the vicinity (spark flight zone). Do not use dust extraction!

• Always hold the machine in a way that sparks or sanding dust fly in counter direction to your body.

• Dust that arises when working in stones with crystalline silicic acid can damage your health. do not work on any material containing asbestos.

Please note the safety regulations, VBG, of the employer's liability insurance association.

• Never use a cutting disc for grinding. Do not subject cutting discs to side pressure.

• When separating stone the guide shoe must be used!

• The adjusting nut must be tightened before starting to work with the machine.

• The workpiece must be fixed if it is not heavy enough to be steady. Never lead the workpiece to the grinding disk with your hand.

• In case of extreme operating conditions (e.g. when smoothing metals with the supporting disk and vulcanised fibre disks) strong contamina-

tion can build up inside the angle grinder.

In such cases it is recommended to shorten the cleaning cycles and/or add a residual current operated device.

A dvice for operation When grinding, do not press into the tool, but move it evenly to and fro on the work piece.

For best results, hold the disc at an angle of at least 30° to the working surface.

Rough grinding Putting too much weight on the machine will damage the angle grinder and increase the discs’ wear;

grinding performance will suffer.

Separating Never use a cutting disc for grinding. The cutting disc must have a proper cutting edge. When sepa-

rating stone, a guide shoe is prescribed!

Surface grinding For surface grinding use a plastic grinding disc with abrasive paper.

For removal of rust or old paint coats, we recommend to use a steel brush (saucepan brush).

Optimum speed range Application: Electron ics

Sanding of plastics with grinding disc and abrasive paper A-C

Sanding of wood and removal of paint with grinding disc and abrasive paper B-D

Sanding of metal with grinding disc and abrasive paper C-F

Removal of rust from metal with steel-wire brushes D-F

Grinding of steel, Cutting steel and stone G

Polishing with backing pa d and lambs wool bonnet A-B

Grinding with fan-type grinding discs F-G

Downloaded from www.Manualslib.com manuals search engine

VARILEX® WSF 1600

Measured noise value The A-valued machine’s noise level typically is::

Nois pressure level = 87 dB (A). Noise power level = 100 dB (A).

Measured vibration value The valued acceleration typically is 7 m/s²

Usage This angle grinder can be used for separating and grinding many different materials, e.g.

metal or stone. In case of doubt please read the manufacturer’s instructions. Do not use this

Mains connection Connect only to a single-phase AC current supply and only to the mains voltage specified on

the rating plate. Connection to sockets without earth protection is possible as the appliance

features protective insulation to DIN 57740/VDE 0740 and CEE 20. Radio suppression com-

plies with the European standard EN 55014. When fitting the plug, make sure that the brown

(live) wire of this appliance is connected to the plug terminal marked L or coloured red, and

the blue (neutral) wire of this appliance is connected to the plug terminal marked N or col-

oured black. Under no circumstances must the wires of this appliance be connected to the

earth terminal of the plug marked either E, with the earth symbol, or coloured green or

green/yellow .

Smooth start The electronic smooth start will prolong the life of both the motor and the gears.

Switching on a nd off Switching on: Push the sliding switch forward. To lock, depress the front part of the switch.

Switching off: To unlock, depress the back part of the sliding switch. The switch will automati-

cally move back to "0".

Electronic The number of revs is adjusted electronically when the load increases.

In case of a longer overload period the speed is decreased electronically. The machine contin-

ues to run slowly to cool down the motor coil. After switching off and on the machine can be

used at rated load. The duration of cooling-down period depends on the gra de of overload.

Speed selection (A G 1300-125 XE) Speed pre-selection with the setting wheel:

A = lowest speed G = highest speed

Mounting the protective cover Open the clamping lever. Push the protective cover over the gear neck, if necessary slightly

loosen the nut of the tension screw.

Protective cap with clamping lever Align the protective cap as required and fasten the clamping lever. If the protective cap is not

tight enough, open the clamping lever, slightly fasten the nut of the tension screw and re-

fasten the clamping lever.

The protective cap must no t be movable when the clamping lever is locked. Take

care that the g rind ing disk can be f reely tu rned.

Fitting the working tool Always disconnect the plug from the socket before carrying out any work on the machine.

FIXTEC-quick-action adjusting nut Lock the work spindle by depressing the spindle lock. Mount the tension flange, the working

tool, and the adjusting nut as shown in illustration.

Customary adjusting nut Only tighten and loosen the FIXTEC quick-action adjusting nut by hand. Do not u se any

tools! Insure that the hoop of the FIXTEC quick-action adjusting nut is only placed in the

upward position for tightening/looseni ng. Loosen respectively tighten the adjusting nut with a

pin-type face spanner

Maintenance Keep the machine and the ventilation slots clean.

Only use Original accessories and spare parts. Should components which have not been de-

scribed need to be exchanged please contact one of our Atlas Copco service agents.

Service agents Worldwide service by Atlas Copco. The corresponding addresses are to be found in the at-

tached brochur e.

Technical data 1.520 Watt, 220 – 240 V, 50 – 60 Hz. Continuous speed control by speedo generator

(constant number of revs). Weight approx. 2,4 kg.

Guarantee A 12 month guarantee (as from invoice date) is given for all technical and mechanical parts,

except in the case of outside culpability.

Spares can be sup plied accord ing to the list. We will carry ou t necessary repairs.

Downloaded from www.Manualslib.com manuals search engine

VARILEX WSF 1.600

Typ 1.600 - 220 V + 110 V

Downloaded from www.Manualslib.com manuals search engine

VARILEX® WSF 1600

Model 220 V

Pos. Item-No. Designation Pos. Item-No. Artikel

3 52003-3 Screw 200 52200 Gear box

4 52004-3 Cable 4 m 201 52201 Sleeve

100 52100-3 Motor case 202 52210 Screw

101 52101-3 Case cover 203 52211 Compensating disc

105 52105-3 Magnetic field 204 52204 Ball bearing

106 52106a Armature 205 52230 Washer

107 52107 Fan 206 52206 Locking ring

108 52108 Ball bearing 207 52207 Locking pin

110 52110 Washer 208 52208 Compressing spring

113 52113 Magnetic ring 209 52209 Push button

116 52116-3 Flange 210 52240 screw

117 52117 Spacer ring 212 52205 Spindle incl. spring

120 52120-3 Carbon brush holder 215 52212v Spindle

127 52127-3 Electronic-unit 216 52213 Bearing shield (2010)

128 52128 Wire 217 52217 Sealing ring

129 52129 Bearing cover 420 52420 crownwheel incl. pinion

131 52131 Carbon brush 421 52422 Washer

133 52133-3 Ergonomic handle 422 52600v protection cover (2010)

135 52135-3 Switch 600 52699 Grip with foam M8x40

147 52003-3 Screw 701 65008 EASYLOCK nut

149 52149-3 Screw 702 52704v Flange

160 52160-3 Cable connection

Model 110 V

Pos. Item-No. Designation Pos. Item-No. Designation

4 52004-2 Cable (4 m) 110 V 127 52127-2 Electronic-unit 110 V

105 52105-2 Magnetic field 110 V 131 52131-1 Carbon brush 110 V

106 52106b Armature 110 V 160 52160-2 connection 110 V

Downloaded from www.Manualslib.com manuals search engine

Gerd Eisenblätter GmbH Jeschkenstr. 10 DE-82538 Geretsried

CE Declaration of conformity for

VARILEX WSF 1.600

Operating instructions

ENGLISH NEDERLA NDS

EC DECLARATION OF CO NFORMITY EC-KONFORMITEITSVERKLARING

We declare under our sole responsibility that this product is in conformity Wij verklaren op eigen vera ntwoording, dat dit produkt voldoet aan de

with the following standards or standardi- volgende normen of normatieve dok umenten: EN 60745, EN 55014-1,

zation documents: EN 60745, EN 55014-1, EN 55014-2, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 volgens de bepalingen van

EN 61000-3- 2, EN 61000-3-3 according to the provisions of the reg- de richtlijnen 2006/42/EG, 2004/108/EG.

ulations 2006/ 42/ EG, 2004/ 108/EG.

DEUTSCH DA NSK

CE-KONFORMITÄTSERKLÄRUNG CE-KONFORMITETSERKLÆRING

Wir erklären in alleiniger Verantwortung, dass dieses Produkt mit den Vi erklæerer under almindeligt ansvar, at dette produkt er i ove-

folgenden Normen oder normativen Dok umenten übereinstimmt: EN rensstemmelse med følgende normer eller normative dokumenter: EN

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000- 3-3 gemäß 60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000- 3-3 i hen-

den Bestimmungen der Richtlinien 2006/42/EG, 2004/108/ EG. hold til bestemmelserne i direktiverne 2006/42/EG, 2004/108/EG.

FRA NÇA IS NORGE

DÈCLARATION "CE" DE CO NFORMITÉ CE-ERKLÆRING AV KONFORMITET

Nous déclarons sous notre propre responsa bilité que ce produit est en Vi overtar ansvaret for at dette produktet er i overenstem-

conformité avec les normes ou documents normalisés: EN 60745, EN melse med følgende standar der eller standard-dok umenter: EN 60745,

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 conformément aux EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3 i samsvar med

termes des réglementations 2006/ 42/EG, 2004/ 108/ EG. bestemmelsene i direktivene 2006/42/ EG, 2004/108/EG.

ITA LIA NO SVENSKA

DICHIARAZIONE DI CONFORMITÀ CE CE-KONFORMITETSFÖRKLARINGEN

Assumendone la piena responsabilità, dichiariamo che il prodotto è con- Vi intygar och ansvarar för att denna produkt överensstämmer med

forme alle seguenti normative ed ai relativi documenti: EN 60745, EN följande norm och dokument: EN 60745, EN 55014-1, EN 55014-2, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 in base alle prescrizi- 61000-3-2, EN 61000- 3-3 enligt bestämmelserna i riktlinjerna 2006/42/

oni delle direttive 2006/42/EG, 2004/108/ EG. EG, 2004/ 108/ EG.

ESPA ÑOL SUOMI

DECLARACION DE CO NFORMIDAD CE TODISTUS CE-STANDARDINMUKAISUUDESTA

Declaramos bajo neustra sola responsabilidad que este producto está en Todistamme täten ja vastaamme yksin siitä, että tämä tuote en allalue-

conformidad con las normas o docu-mentos normalizados siguientes : EN teltujen standardien ja standardoimisasiakirjojen vaatimusten mukai-

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000- 3-3 de acuer- nen: EN 60745, EN 55014-1, EN 55014-2, EN 61000- 3-2, EN 61000-3- 3

do con las regulaciones 2006/ 42/ EG, 2004/108/EG. seuraavien ohjeiden määräysten mukaisesti: 2006/42/ EG,

2004/108/EG.

PORTUGUES GREEK

DECLARAÇÃ0 DE CONFORMIDADE CE ∆΄HΛΩ∑Н ∑ΥМΒΑΤΙΚ΄ОΤΗΤОΣ

Declaramos sob nossa exclusiva responsabilidade que este producto ∆ηλώvoυµε υттεuθύvως óтı тo проїóv αuтó εіvαı καтασκεuασµέvo

cumpre as seguintes normas ou documentos normativos : EN 60745, EN ơúµφωvα µε тоuς εξής καvovισµοúς ή καтαơкεuασтıκές σuσтάσεıς: EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 de acordo com as 60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000- 3-3

disposições das directivas 2006/42/ EG, 2004/ 108/EG. σúµφωνα µε тıς

δıαтάξεıς тων Οδηуıών: 2006/42/ EG, 2004/108/EG.

Gerd Eisenblätter GmbH

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Operation Manual: Beveling and Deburring Device B5Document13 pagesOperation Manual: Beveling and Deburring Device B5bulentNo ratings yet

- WARNING! Read and Understand All Instructions. Failure To Follow All InstrucDocument5 pagesWARNING! Read and Understand All Instructions. Failure To Follow All InstruciconoclasticjarheadNo ratings yet

- Torque-Master Power Tile CutterDocument8 pagesTorque-Master Power Tile CutterAntoni StojanovskiNo ratings yet

- dw384 Manual PDFDocument7 pagesdw384 Manual PDFEfrain KaracNo ratings yet

- Manual Policorte CompletoDocument36 pagesManual Policorte CompletoDivino CésarNo ratings yet

- ManualDocument27 pagesManualJos TorNo ratings yet

- Ferm BGM1003Document80 pagesFerm BGM1003Cristian BujorNo ratings yet

- Work Sharp Tool Sharpener WS2000Document31 pagesWork Sharp Tool Sharpener WS2000ottuser100% (1)

- Skil 6513 User ManualDocument18 pagesSkil 6513 User ManualSyed Faiz QuadriNo ratings yet

- Turbo Sharp VDocument4 pagesTurbo Sharp Vnetuno777No ratings yet

- Sealey SMS2008Document3 pagesSealey SMS2008cabuloNo ratings yet

- Dewalt DW433 SanderDocument6 pagesDewalt DW433 SanderRichard SmithNo ratings yet

- Ferm FKZ205 ManualDocument26 pagesFerm FKZ205 Manualkorte1968No ratings yet

- 2022 Power Tools (BSME)Document26 pages2022 Power Tools (BSME)kkiyo2113No ratings yet

- ScrollSaw 572.24700Document6 pagesScrollSaw 572.24700Doug HigelNo ratings yet

- Oštrač BoreraDocument59 pagesOštrač BoreradinoNo ratings yet

- AEG HBS100 de PDFDocument32 pagesAEG HBS100 de PDFMaria MassanetNo ratings yet

- Instruction Manual Manual de Instrucciones Manual de Instruções Angle Grinder Esmeriladora Angular Esmerilhadeira AngularDocument12 pagesInstruction Manual Manual de Instrucciones Manual de Instruções Angle Grinder Esmeriladora Angular Esmerilhadeira Angular_blackmore_No ratings yet

- Kobalt - Lawn Mower GuideDocument21 pagesKobalt - Lawn Mower Guidessss23r5No ratings yet

- CE2800Document106 pagesCE2800Emanuel AVNo ratings yet

- D-500 Homogenizer ManualDocument12 pagesD-500 Homogenizer ManualalakhibNo ratings yet

- Makita Documentatie Polizor UnghiularDocument56 pagesMakita Documentatie Polizor UnghiularLiviu HendresNo ratings yet

- SCILOGEX D-500 Homogenizer ManualDocument13 pagesSCILOGEX D-500 Homogenizer ManualAbel LopezNo ratings yet

- Circular Saw ManualDocument156 pagesCircular Saw Manualcci100% (1)

- Steam Cleaner Manual GE 106727Document39 pagesSteam Cleaner Manual GE 106727j SmithNo ratings yet

- Instructions For Use: Washing MachineDocument28 pagesInstructions For Use: Washing MachinebartzaNo ratings yet

- r00021v-1 r18736v2 Die Grinder ManualDocument24 pagesr00021v-1 r18736v2 Die Grinder ManualsanprojectNo ratings yet

- Atomic 3000: User ManualDocument28 pagesAtomic 3000: User ManualksracingNo ratings yet

- Skil Router 1830 ManualDocument136 pagesSkil Router 1830 Manualrorcacho100% (1)

- Craftex Table Saw CT146Document56 pagesCraftex Table Saw CT146TenGeesNo ratings yet

- Skil Table Saw Owners ManualDocument104 pagesSkil Table Saw Owners ManualPamela CloudNo ratings yet

- Palmgren ManualDocument20 pagesPalmgren ManualLiz CNo ratings yet

- Chop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawDocument64 pagesChop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawJacob B100% (3)

- Manual Cortadora de DiscoDocument14 pagesManual Cortadora de DiscoMartha JaquelinNo ratings yet

- Shaver Machine TS 200-600 Manual PDFDocument17 pagesShaver Machine TS 200-600 Manual PDFKo HlaingNo ratings yet

- SM5ce - V3 SawDocument9 pagesSM5ce - V3 SawBryan DixNo ratings yet

- Jaymac Bar Bending O&M Manual Ver3.1Document26 pagesJaymac Bar Bending O&M Manual Ver3.1prasanna221079% (14)

- Jig Saw 4170 (F0154170 - .) : PetunjukDocument20 pagesJig Saw 4170 (F0154170 - .) : PetunjukYaacob HgNo ratings yet

- KSC-SW11: Instruction Manual Mode D'Emploi Bedienungsanleitung GebruiksaanwijzingDocument60 pagesKSC-SW11: Instruction Manual Mode D'Emploi Bedienungsanleitung GebruiksaanwijzingTomas Garcia RoldanNo ratings yet

- JC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)Document15 pagesJC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)sharedfilepcNo ratings yet

- KAC-7252 KAC-7202: Instruction Manual Mode D'Emploi Manual de InstruccionesDocument20 pagesKAC-7252 KAC-7202: Instruction Manual Mode D'Emploi Manual de Instruccionesadix0904No ratings yet

- Gorenje User Manual 177417Document24 pagesGorenje User Manual 177417JohnNo ratings yet

- Instruction Manual For Baldor Grinders: MN903 No. 275P Replaces 275N LB7008Document4 pagesInstruction Manual For Baldor Grinders: MN903 No. 275P Replaces 275N LB70087023 widiastyNo ratings yet

- Instructions For Use: Washing MachineDocument32 pagesInstructions For Use: Washing MachineAngheluță Dănuț ȘtefanNo ratings yet

- N096694, D28710Document40 pagesN096694, D28710Jose ZuletaNo ratings yet

- Singer 4830 Manual Maquina de CocerDocument40 pagesSinger 4830 Manual Maquina de CocerFernanda100% (1)

- Blu-Ray Disc™ / DVD Player: Operating InstructionsDocument44 pagesBlu-Ray Disc™ / DVD Player: Operating Instructionszyzyh0327No ratings yet

- Model 52H Hydraulic Shear: Operation, Parts & Maintenance ManualDocument10 pagesModel 52H Hydraulic Shear: Operation, Parts & Maintenance ManualOmar SalmonNo ratings yet

- Graco Part ManualDocument22 pagesGraco Part ManualandraNo ratings yet

- Huskystar E10 Instruction Sewing Machine Instruction ManualDocument32 pagesHuskystar E10 Instruction Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 10 In. Table Saw: Operator's ManualDocument58 pages10 In. Table Saw: Operator's ManualmarkNo ratings yet

- Operating Manual: AUTOWELD Series Inverter DC Submerged Arc Welding MachinesDocument30 pagesOperating Manual: AUTOWELD Series Inverter DC Submerged Arc Welding MachinesKeval PatelNo ratings yet

- 01 js615brDocument2 pages01 js615brSonaina KhanNo ratings yet

- Owner's Manual: Main FeaturesDocument8 pagesOwner's Manual: Main FeaturesLaCortadera Balneario MarisolNo ratings yet

- Mastercraft JigSaw 54-8219 E 4.7Document9 pagesMastercraft JigSaw 54-8219 E 4.7shadowrider83No ratings yet

- CE3000 User ManualDocument124 pagesCE3000 User ManualMochamad MochamadNo ratings yet

- Manual SCR214Document51 pagesManual SCR214Maria SacaNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Varilex WSF 1600: Operating Instructions Detail Drawing Spare Part ListDocument6 pagesVarilex WSF 1600: Operating Instructions Detail Drawing Spare Part Listcombra24grNo ratings yet

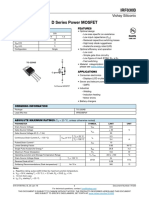

- N - Channel 800V - 3 - 4A - To-220/To-220Fp Powermesh MosfetDocument9 pagesN - Channel 800V - 3 - 4A - To-220/To-220Fp Powermesh Mosfetcombra24grNo ratings yet

- Fein CatalogDocument32 pagesFein Catalogcombra24grNo ratings yet

- Poly-Ptx 800: Detailed Schematic Spare Part ListDocument6 pagesPoly-Ptx 800: Detailed Schematic Spare Part Listcombra24grNo ratings yet

- Irf9540, Irf9541, Irf9542, Irf9543, RF1S9540, RF1S9540SMDocument7 pagesIrf9540, Irf9541, Irf9542, Irf9543, RF1S9540, RF1S9540SMcombra24grNo ratings yet

- IRF830B: Vishay SiliconixDocument8 pagesIRF830B: Vishay Siliconixcombra24grNo ratings yet

- Silicon N-Channel MOS FET: ApplicationDocument9 pagesSilicon N-Channel MOS FET: Applicationcombra24grNo ratings yet

- DMS Accessories: 50mV and 100mV Base-Mounted DC ShuntsDocument5 pagesDMS Accessories: 50mV and 100mV Base-Mounted DC Shuntscombra24grNo ratings yet

- Schott SEFUSE D6SC: Miniature Battery FuseDocument1 pageSchott SEFUSE D6SC: Miniature Battery Fusecombra24grNo ratings yet

- Aod472 PDFDocument6 pagesAod472 PDFJuan Carlos ChavezNo ratings yet

- SMS Playstation 2 Simple Media User ManualDocument101 pagesSMS Playstation 2 Simple Media User Manualcombra24grNo ratings yet

- BD243C BD244C: Complementary Power TransistorsDocument10 pagesBD243C BD244C: Complementary Power Transistorscombra24grNo ratings yet

- PLDT HOMEDSL Modem/Wifi Router BaudTec TW263R4Document16 pagesPLDT HOMEDSL Modem/Wifi Router BaudTec TW263R4benjwarmNo ratings yet

- War: Causation of War, Total War, Limited War, Strategic Culture: Determinants of Strategic Culture Deterrence: Theory and Practice With SpecialDocument52 pagesWar: Causation of War, Total War, Limited War, Strategic Culture: Determinants of Strategic Culture Deterrence: Theory and Practice With SpecialMazhar HussainNo ratings yet

- Keong Mas ENGDocument2 pagesKeong Mas ENGRose Mutiara YanuarNo ratings yet

- Etsi en 300 019-2-2 V2.4.1 (2017-11)Document22 pagesEtsi en 300 019-2-2 V2.4.1 (2017-11)liuyx866No ratings yet

- Coffee in 2018 The New Era of Coffee EverywhereDocument55 pagesCoffee in 2018 The New Era of Coffee Everywherec3memoNo ratings yet

- ColceruM-Designing With Plastic Gears and General Considerations of Plastic GearingDocument10 pagesColceruM-Designing With Plastic Gears and General Considerations of Plastic GearingBalazs RaymondNo ratings yet

- Movie ReviewDocument2 pagesMovie ReviewJohanna Gwenn Taganahan LomaadNo ratings yet

- The Craving Mind From Cigarettes To Smartphones To Love - Why We Get Hooked and How We Can Break Bad Habits PDFDocument257 pagesThe Craving Mind From Cigarettes To Smartphones To Love - Why We Get Hooked and How We Can Break Bad Habits PDFJacques Savariau92% (13)

- Global Supply Chain Top 25 Report 2021Document19 pagesGlobal Supply Chain Top 25 Report 2021ImportclickNo ratings yet

- MELSEC System Q: QJ71MES96 MES Interface ModuleDocument364 pagesMELSEC System Q: QJ71MES96 MES Interface ModuleFajri AsyukronNo ratings yet

- Singleton v. Cannizzaro FILED 10 17 17Document62 pagesSingleton v. Cannizzaro FILED 10 17 17Monique Judge100% (1)

- Corporate Plan 2018 2021Document94 pagesCorporate Plan 2018 2021Nkugwa Mark WilliamNo ratings yet

- VC++ Splitter Windows & DLLDocument41 pagesVC++ Splitter Windows & DLLsbalajisathyaNo ratings yet

- NetEco Commissioning Guide (V200R003C01 - 01) (PDF) - enDocument116 pagesNetEco Commissioning Guide (V200R003C01 - 01) (PDF) - enabdo elmozogyNo ratings yet

- Chapter 1Document4 pagesChapter 1Steffany RoqueNo ratings yet

- SMA Releases Online Version of Sunny Design For PV System ConfigurationDocument3 pagesSMA Releases Online Version of Sunny Design For PV System ConfigurationlakliraNo ratings yet

- LEGO Group A Strategic and Valuation AnalysisDocument85 pagesLEGO Group A Strategic and Valuation AnalysisRudmila Ahmed50% (2)

- Letter Response From AG Rob Bonta's Office Re: Batmobile InvestigationDocument2 pagesLetter Response From AG Rob Bonta's Office Re: Batmobile InvestigationLeah WorthingtonNo ratings yet

- Four Year Plan DzenitaDocument4 pagesFour Year Plan Dzenitaapi-299201014No ratings yet

- LEARNING MODULE Entrep Lesson 1-2Document19 pagesLEARNING MODULE Entrep Lesson 1-2Cindy BononoNo ratings yet

- Communication & Soft Skills: Deepak and Arvind Kumar Pgppe + Mba (Feb'11)Document19 pagesCommunication & Soft Skills: Deepak and Arvind Kumar Pgppe + Mba (Feb'11)deepaksingh16100% (1)

- FS 1 - Episode 1Document18 pagesFS 1 - Episode 1Bhabierhose Saliwan LhacroNo ratings yet

- Clasificacion SpicerDocument2 pagesClasificacion SpicerJoseCorreaNo ratings yet

- B B B B: RRRR RRRRDocument24 pagesB B B B: RRRR RRRRAnonymous TeF0kYNo ratings yet

- Freedom International School Class 3 - EnglishDocument2 pagesFreedom International School Class 3 - Englishshreyas100% (1)

- Computer Science Past Papers MCQS SolvedDocument24 pagesComputer Science Past Papers MCQS SolvedLEGAL AFFAIRS DIVISION100% (1)

- Botswana Ref Ranges PaperDocument7 pagesBotswana Ref Ranges PaperMunyaradzi MangwendezaNo ratings yet

- 39 Nts General Merit List 22 Mar 18Document26 pages39 Nts General Merit List 22 Mar 18Lakshmi VedanarayananNo ratings yet

- Indian Retail Industry: Structure, Drivers of Growth, Key ChallengesDocument15 pagesIndian Retail Industry: Structure, Drivers of Growth, Key ChallengesDhiraj YuvrajNo ratings yet

- Ad&d - Poison Costs & Poison CraftDocument4 pagesAd&d - Poison Costs & Poison Craftweb moriccaNo ratings yet

- Petition For Bail Nonbailable LampaDocument3 pagesPetition For Bail Nonbailable LampaNikki MendozaNo ratings yet