Professional Documents

Culture Documents

Packaging: Brican: Bricks Reinforced With Aluminum Cans

Packaging: Brican: Bricks Reinforced With Aluminum Cans

Uploaded by

Bloodmier Gabriel0 ratings0% found this document useful (0 votes)

5 views3 pagesOriginal Title

Research Paper

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesPackaging: Brican: Bricks Reinforced With Aluminum Cans

Packaging: Brican: Bricks Reinforced With Aluminum Cans

Uploaded by

Bloodmier GabrielCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

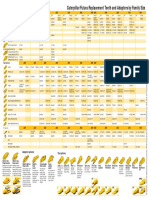

BriCan: weighing scale

BRICKS REINFORCED WITH

ALUMINUM CANS

Procedure

First, Aluminum cans were obtained and cut

Background of the Study

into pieces. A weighing scale was used to measure

An aluminum can, sometimes erroneously

masses of aluminum can pieces, mud and straw in

referred to as a "tin can", is a container

different proportions as shown below:

for packaging made primarily of aluminum. It is

commonly used for foods and beverages but also for

products such as oil, chemicals, and other liquids.

Aluminum is also of good strength that’s why the

researchers thought of using it as reinforcement

materials in making bricks.

A brick is a building material used to make

walls, pavements and other elements

All the measured ingredients were combined

in masonry construction. Traditionally, the term

and put into molds and left for drying for 2 days.

brick referred to a unit composed of clay, but it is

After drying, the products were removed from the

now used to denote any rectangular units laid in

mold and were tested.

mortar.

This study aims to reinforced bricks with

Product Testing

aluminum can with the goal of strengthening its

Materials

capacity while achieving the objective of

BriCan

contributing to the lessening of environmental

container

waste.

stop watch/timer

water

Making the BriCan

Materials and Equipment:

Procedure

Aluminum can

The product testing was composed of two

mud

parts: (a) Water Absorption Test and (b) Drop Test.

straw

For the Water Absorption Test, the bricks

big container were weighed before being submerged into water

blower for 24 hours. Afterwards, the bricks’ masses were

blender again measured to compare which brick partially

molder dissolved and mixed with water.

For the Drop Test, the bricks were drop

from a height of 1meter. Afterwards, the bricks

were observed and results were noted.

Data and Results

A. Physical Property of the Bricks

Table 3 shows the results of the Water

Absorption done on the bricks. It showed that Set 3

lost the most amount (14g) that may be dissolved or

Figure 1. Physical appearance of the bricks

mixed with water during the 24 hour submerging

process. As a result, the brick was broken. Set 4, on

the other hand, lost the least amount (5g) and the

brick did not break.

C. Drop Test

Table 2 shows that Set 1 (control) is slightly

smooth in texture because it has no aluminum cans

in it. Whereas among Sets 2-4, aluminum can

particles are most visible in Set 4 because it has the

most amount of aluminum cans in it. All sets 2-4

are slightly rough in texture.

B. Water Absorption Test

Figure 3 shows that all the bricks were not

broken even after being dropped from a height of 1

meter.

Conclusions Pictures of Experiment

Based on the results of the experiments 1 2 9

conducted, the researchers came up with the

following conclusions: (1) Aluminum cans can be

used to reinforce bricks; and (2) BriCans (Sets 2-4)

passed the 1 meter drop test but Set 4 (the one with

the most amount of aluminum cans) did not dissolve

that much during water submerging test and thus, is

3 4

the best proportion.

Recommendations

Recognizing the limits of this study, the

future researchers are recommended to:

(1) Determine the best proportion that will work

5 6

better than the results obtained by the researchers of

this study; and

(2) Achieve a finer aluminum can particles to be

mixed with other components to make a product

more appealing in terms of appearance.

References

Brick Industry Association. Technial Note 9A,

Specifications for and Classification of Brick.

“History of Brickmaking”. Encyclopedia Britannica

www.merriam-webster.com/dictionary/aluminumcans

http://www. google.com.ph/sodacans

You might also like

- When Glass meets Pharma: Insights about glass as primary packaging materialFrom EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNo ratings yet

- The Introduction: Most Essential Learning CompetenciesDocument25 pagesThe Introduction: Most Essential Learning CompetenciesBloodmier GabrielNo ratings yet

- Engineering Materials 2: An Introduction to Microstructures, Processing and DesignFrom EverandEngineering Materials 2: An Introduction to Microstructures, Processing and DesignNo ratings yet

- Presented by PATRICK ODUOR OTIENO EN251-6615/2015 GEORGE GITHINJI EN251-9297/2015Document11 pagesPresented by PATRICK ODUOR OTIENO EN251-6615/2015 GEORGE GITHINJI EN251-9297/2015Patrick Oduor OtienoNo ratings yet

- The end of concrete: Pros and cons of an unsuccesful technologyFrom EverandThe end of concrete: Pros and cons of an unsuccesful technologyRating: 1 out of 5 stars1/5 (1)

- Linagliptin - DRUG STUDYDocument1 pageLinagliptin - DRUG STUDYAcads useNo ratings yet

- 5 Cruces Cat-FuturaDocument1 page5 Cruces Cat-Futurakarijoseph02No ratings yet

- SisalDocument31 pagesSisalChaithra Shree100% (4)

- Fua Cun vs. SummersDocument1 pageFua Cun vs. SummersElreen Pearl AgustinNo ratings yet

- Pumice As SandDocument36 pagesPumice As SandArbie FerrerNo ratings yet

- Sale and Purchase Contract of Indonesian Bauxite: The SellerDocument13 pagesSale and Purchase Contract of Indonesian Bauxite: The SellerRadhitya Adzan Hidayah67% (3)

- Use of Fine Glass As ASR Inhibitor in Glass Aggregate MortarsDocument4 pagesUse of Fine Glass As ASR Inhibitor in Glass Aggregate MortarsHa Biba DoukhaneNo ratings yet

- Lab Brick Report UthmDocument18 pagesLab Brick Report UthmZahidahNo ratings yet

- Chapter 05Document20 pagesChapter 05Bek AsratNo ratings yet

- ME 006-ME41S1 - Materials Engineering: Ceramics 1. DefinitionDocument7 pagesME 006-ME41S1 - Materials Engineering: Ceramics 1. Definitionashley bendanaNo ratings yet

- Lightweight Concrete Drying TimeDocument11 pagesLightweight Concrete Drying TimeNuno FerreiraNo ratings yet

- Salt-Attack-Resistance of BrickworkDocument8 pagesSalt-Attack-Resistance of BrickworkBrett RobertsNo ratings yet

- Durability Studies On Concrete by Using Groundnut Shell Ash As Mineral AdmixtureDocument5 pagesDurability Studies On Concrete by Using Groundnut Shell Ash As Mineral AdmixtureIJIRSTNo ratings yet

- Comparative Study of Properties of Manual and Mechanized Bricks and Their Strength Behaviour As MasonryDocument4 pagesComparative Study of Properties of Manual and Mechanized Bricks and Their Strength Behaviour As MasonrySuno AliNo ratings yet

- Manufacturing of Brick Using Waste MaterialDocument19 pagesManufacturing of Brick Using Waste Materials yaswanth reddyNo ratings yet

- Concrete Technology: Ce 40/L Construction Materials and TestingDocument30 pagesConcrete Technology: Ce 40/L Construction Materials and TestingGabriel VergaraNo ratings yet

- IV ConcreteDocument30 pagesIV ConcretecamilleNo ratings yet

- IV ConcreteDocument31 pagesIV ConcreteJonel CorbiNo ratings yet

- Microstructure and Chemical Degradation of Adobe and Clay BricksDocument7 pagesMicrostructure and Chemical Degradation of Adobe and Clay BricksStefan GhidiuNo ratings yet

- Article Equipe Bachir. Etude de La Durabilité Des Bicouches Version Française-1Document9 pagesArticle Equipe Bachir. Etude de La Durabilité Des Bicouches Version Française-1Merveille CakpoNo ratings yet

- Water Absorption Characteristic of Interlocking Compressed Earth Brick UnitsDocument7 pagesWater Absorption Characteristic of Interlocking Compressed Earth Brick UnitsqamhNo ratings yet

- A Preliminary Study of Manufacture of Cement From Rice Husk AshDocument3 pagesA Preliminary Study of Manufacture of Cement From Rice Husk AshGaurav BangarhNo ratings yet

- 44 - Study On The Compressive Strength of Lime Mortar Using Admixtures PDFDocument3 pages44 - Study On The Compressive Strength of Lime Mortar Using Admixtures PDFsyed Masood khanNo ratings yet

- CE 14 Study Guide Lesson 6Document14 pagesCE 14 Study Guide Lesson 6Riben CaratingNo ratings yet

- Retrofitting of Concrete Specimens and Reinforced Concrete Piles Using Basalt FibresDocument5 pagesRetrofitting of Concrete Specimens and Reinforced Concrete Piles Using Basalt FibrespraveenNo ratings yet

- A Study On Engineering Characteristics of Asphalt Concrete Using Filler With Recycled Waste LimeDocument9 pagesA Study On Engineering Characteristics of Asphalt Concrete Using Filler With Recycled Waste LimeMuhammad SarirNo ratings yet

- Phase 2Document28 pagesPhase 2prakruthiy03No ratings yet

- An Observation On Potential Alkali Silica Reactivity of Natural Aggregate in MyanmarDocument7 pagesAn Observation On Potential Alkali Silica Reactivity of Natural Aggregate in MyanmarRobert ThompsonNo ratings yet

- UntitledDocument60 pagesUntitled22ME38 yash PatilNo ratings yet

- Presented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversityDocument20 pagesPresented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversitySaurabh AgrawalNo ratings yet

- Development of Ceramic Tiles From Common Clay and Blast Furnace SlagDocument8 pagesDevelopment of Ceramic Tiles From Common Clay and Blast Furnace SlagJoão AzevedoNo ratings yet

- Jurnal Fathul PDFDocument12 pagesJurnal Fathul PDFDafin Algi FachriNo ratings yet

- Water Absorption Capacity Coefficient and Mass MoiDocument4 pagesWater Absorption Capacity Coefficient and Mass MoialinupNo ratings yet

- 4 PDFDocument10 pages4 PDFduaa alfaujiNo ratings yet

- Ma 2015Document8 pagesMa 2015Haya ZuaiterNo ratings yet

- Rapid Identification of Alkali Silica Reaction Products in ConcreteDocument3 pagesRapid Identification of Alkali Silica Reaction Products in ConcreteEvert RiveraNo ratings yet

- An Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteDocument5 pagesAn Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Materials Today: Proceedings: K. Naveen Kumar, D.S. Vijayan, R. Divahar, R. Abirami, C. NivethaDocument5 pagesMaterials Today: Proceedings: K. Naveen Kumar, D.S. Vijayan, R. Divahar, R. Abirami, C. NivethaAnandha SuthanNo ratings yet

- A Preliminary Research On The PropertiesDocument8 pagesA Preliminary Research On The PropertieslyesNo ratings yet

- Reuse of Water Treatment Plant Sludge in Brick ManufacturingDocument8 pagesReuse of Water Treatment Plant Sludge in Brick ManufacturingA Nicole Rodríguez OportoNo ratings yet

- Plastic BricksDocument13 pagesPlastic Bricksabdullahmemon3096No ratings yet

- 11 Low Cost Fly Ash Bricks 29-1-2015Document11 pages11 Low Cost Fly Ash Bricks 29-1-2015Sintayehu MeseleNo ratings yet

- Comparative Analysis of Mechanical Properties of Fly-Ash Concrete With Conventional ConcreteDocument4 pagesComparative Analysis of Mechanical Properties of Fly-Ash Concrete With Conventional Concreteabra cadabraNo ratings yet

- Technical Engineering Collage: Department: NameDocument9 pagesTechnical Engineering Collage: Department: NamePamcm XmncfNo ratings yet

- Porosity Under Continous CastingDocument7 pagesPorosity Under Continous CastingDiriba AbdiNo ratings yet

- Construction and Building Materials: Zühtü Onur Pehlivanlı, - Ibrahim Uzun, - Ilhami DemirDocument6 pagesConstruction and Building Materials: Zühtü Onur Pehlivanlı, - Ibrahim Uzun, - Ilhami DemirNur Ain Binti RustamNo ratings yet

- Chapter 6 Brick WorkDocument17 pagesChapter 6 Brick WorkFaisal KhanNo ratings yet

- AlccofineDocument9 pagesAlccofineMadan Mohan ReddyNo ratings yet

- Fisheries ResearchDocument4 pagesFisheries ResearchAxotic FarmNo ratings yet

- C: Introduction To Concrete: Prepared By: Engr. NmstabucalDocument26 pagesC: Introduction To Concrete: Prepared By: Engr. NmstabucalJohn Dharyl BilasNo ratings yet

- Experimental Investigation of Mud Blocks Stabilized With Lime and CementDocument19 pagesExperimental Investigation of Mud Blocks Stabilized With Lime and CementChandrashekhara JainNo ratings yet

- Light Weight Flyash Brick Using Expanded Polystyrene (EPS)Document4 pagesLight Weight Flyash Brick Using Expanded Polystyrene (EPS)jasimabdNo ratings yet

- Prelim Exam (Reviewer Answer Key)Document3 pagesPrelim Exam (Reviewer Answer Key)ravenNo ratings yet

- Autoclaved Aerated Concrete BlockDocument53 pagesAutoclaved Aerated Concrete BlocksharanyaNo ratings yet

- IpsitaDocument15 pagesIpsitaIpsita MuduliNo ratings yet

- Jeenith CT UNIT - 1Document4 pagesJeenith CT UNIT - 1Revanth ChintuNo ratings yet

- Open Ended Lab ReportDocument19 pagesOpen Ended Lab ReporttpqrwvtmsfNo ratings yet

- Termkhajornkit2009 Study of Self Healing Ability of Flyash Cement SystemsDocument9 pagesTermkhajornkit2009 Study of Self Healing Ability of Flyash Cement SystemsDEEBA S 20PHD1159No ratings yet

- Properties and Uses of Concrete AdmixturesDocument5 pagesProperties and Uses of Concrete AdmixturesDS20CE017Bhaskar WabhitkarNo ratings yet

- High Performance Bricks From Fly Ash: Obada KayaliDocument13 pagesHigh Performance Bricks From Fly Ash: Obada Kayaliom_833654993No ratings yet

- SOCIAL SCIENCE Group 3 HUMSS 11 ADocument20 pagesSOCIAL SCIENCE Group 3 HUMSS 11 ABloodmier GabrielNo ratings yet

- Historical Context of The Emergence of Each DisciplinesDocument43 pagesHistorical Context of The Emergence of Each DisciplinesBloodmier GabrielNo ratings yet

- Longifolia) On Staphylococcus Aureus: Research Plan Researc H Title: Propon EntsDocument4 pagesLongifolia) On Staphylococcus Aureus: Research Plan Researc H Title: Propon EntsBloodmier GabrielNo ratings yet

- Research Plan Blank TemplateDocument2 pagesResearch Plan Blank TemplateBloodmier GabrielNo ratings yet

- Research Plan Research Title: ProponentsDocument4 pagesResearch Plan Research Title: ProponentsBloodmier GabrielNo ratings yet

- Research Title: Most Essential Learning Competencies: Designs A Research Used in Daily Life Writes A Research TitleDocument16 pagesResearch Title: Most Essential Learning Competencies: Designs A Research Used in Daily Life Writes A Research TitleBloodmier GabrielNo ratings yet

- Compound Interest: P21,073.92 Is The Compound Amount of P15,000 Compounded Annually For 3 Years at 12%Document4 pagesCompound Interest: P21,073.92 Is The Compound Amount of P15,000 Compounded Annually For 3 Years at 12%Bloodmier GabrielNo ratings yet

- Meaning of Extraction: Ethanol in ExtractionDocument7 pagesMeaning of Extraction: Ethanol in ExtractionBloodmier GabrielNo ratings yet

- Simple Interest: I P R TDocument7 pagesSimple Interest: I P R TBloodmier Gabriel100% (1)

- How This Pandemic Shaped Our Social CognitionDocument8 pagesHow This Pandemic Shaped Our Social CognitionBloodmier GabrielNo ratings yet

- Scores - Emergence - Sheet1Document2 pagesScores - Emergence - Sheet1Bloodmier GabrielNo ratings yet

- Racial DiscriminationDocument3 pagesRacial DiscriminationBloodmier GabrielNo ratings yet

- Writing The Research Proposal1Document1 pageWriting The Research Proposal1Bloodmier GabrielNo ratings yet

- PoS Jayesh Gogri 090618 PDFDocument117 pagesPoS Jayesh Gogri 090618 PDFMadhur BihaniNo ratings yet

- Eowave Weather Drones Building Instructions 3Document6 pagesEowave Weather Drones Building Instructions 3wfarnabydosNo ratings yet

- Techstars Deal Two Pager (Shareable For MDS)Document2 pagesTechstars Deal Two Pager (Shareable For MDS)DragosnicNo ratings yet

- Chews A Puppy in Ocoee, Florida Has Announced Their Partnership With Chews AdoptionDocument2 pagesChews A Puppy in Ocoee, Florida Has Announced Their Partnership With Chews AdoptionPR.comNo ratings yet

- Spandan 2022 - Comprehensive ReportDocument17 pagesSpandan 2022 - Comprehensive ReportSSP GamerNo ratings yet

- Visa Application Form New ThailandDocument1 pageVisa Application Form New Thailandabhay_patil_22No ratings yet

- VPMA Foundation Board of Directors Recruitment & Leadership PacketDocument19 pagesVPMA Foundation Board of Directors Recruitment & Leadership PacketNadine RobertsonNo ratings yet

- PreviewpdfDocument76 pagesPreviewpdfvulananh838No ratings yet

- Ask For Andrea by Noelle W IhliDocument296 pagesAsk For Andrea by Noelle W IhliDayanara allanigueNo ratings yet

- Candidate's Signature: E-Admit Card - ProvisionalDocument4 pagesCandidate's Signature: E-Admit Card - Provisionalshubham vermaNo ratings yet

- Rep. Lee Zeldin, Nancy Marks, Dpty. Comptroller Louis Necroto, Vincent Trimarco & The American Patriot Heroes Fund (AMPAT)Document36 pagesRep. Lee Zeldin, Nancy Marks, Dpty. Comptroller Louis Necroto, Vincent Trimarco & The American Patriot Heroes Fund (AMPAT)Jacquelyn Gavron100% (1)

- Steel Sector Motilal OswalDocument30 pagesSteel Sector Motilal OswalBinod Kumar PadhiNo ratings yet

- 239Document191 pages239Faiza anwerNo ratings yet

- Wiac - Info PDF Make My Trip Invoice nf250627345867 PRDocument1 pageWiac - Info PDF Make My Trip Invoice nf250627345867 PRGopal SoneeNo ratings yet

- ZooscanDocument19 pagesZooscankpmanikandaanNo ratings yet

- Website: Vce To PDF Converter: Facebook: Twitter:: Des-6332.Vceplus - Premium.Exam.60QDocument18 pagesWebsite: Vce To PDF Converter: Facebook: Twitter:: Des-6332.Vceplus - Premium.Exam.60QRomeoNo ratings yet

- Software Project Management Plan For "Online Purchasing System"Document8 pagesSoftware Project Management Plan For "Online Purchasing System"Baban DeepNo ratings yet

- Paul Miller's ResumeDocument3 pagesPaul Miller's ResumePaul MillerNo ratings yet

- Presentation To Kochi Delegation: Barry HOWEDocument32 pagesPresentation To Kochi Delegation: Barry HOWELOHITH NNo ratings yet

- GRADE 10 MAPEH 3Rrd Grading HEALTH TOSDocument2 pagesGRADE 10 MAPEH 3Rrd Grading HEALTH TOSTobi MM100% (1)

- Low Loss GaN Waveguides For Visible Light On Si SubstratesDocument7 pagesLow Loss GaN Waveguides For Visible Light On Si SubstratesRoy RudnickNo ratings yet

- Principles - Ch1 - The Marketing Engineering ApproachDocument81 pagesPrinciples - Ch1 - The Marketing Engineering ApproachdaNo ratings yet

- Procédure de Test FABIAN EVO-TS-AA-03e - TI - 7250 - Rev04-2017 PDFDocument22 pagesProcédure de Test FABIAN EVO-TS-AA-03e - TI - 7250 - Rev04-2017 PDFDorian BuissonNo ratings yet

- PUB E: 5/31/2021 Top Builders Developers in Mumbai in 2020-2021 - Top and Best in 2021Document7 pagesPUB E: 5/31/2021 Top Builders Developers in Mumbai in 2020-2021 - Top and Best in 2021MINAKSHI SINGHNo ratings yet

- Cleaning Sanitation Solution - ProtekDocument11 pagesCleaning Sanitation Solution - ProtekAhsan Rizqi NashrullahNo ratings yet

- ECE 611 SP17 Homework 1Document3 pagesECE 611 SP17 Homework 1hanythekingNo ratings yet