Professional Documents

Culture Documents

Rectangular Flange 070122

Uploaded by

bytestefCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rectangular Flange 070122

Uploaded by

bytestefCopyright:

Available Formats

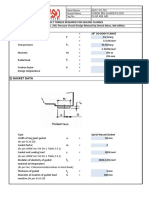

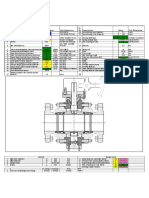

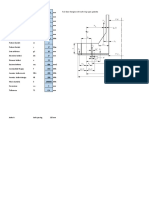

Rectangular Flange Design

Pressione di Design Pd 5 MPa

Sovraspessore di corrosione C.A. 3 mm

Outside lenght of Long side Al 2620 mm

Outside lenght of Short side As 775 mm

Inside lenght of Long side Bl 2373.5 mm

Inside lenght of Short side Bs 528.5 mm

End bolt c/ to c/ long side Cl 2520 mm

OK

Max spacing between bolts on long side Lmax_l 127.9 mm

End bolt c/ to c/ short side Cs 675 mm

OK

Max spacing between bolts on short side Lmax_s 127.9 mm

Altezza codolo g1 0 mm

Gasket OD long side Gol 2440 mm

Gasket ID long side Gil 2370 mm

Gasket OD short side Gos 600 mm

Gasket ID short side Gis 530 mm

Numero bulloni Nb 62

Gasket material EPDM

Gasket factor m 3.75

Design seating stress y 52 MPa

Material of Flanges P355 NH

Yield stress at ambient temperature Sfy 260 MPa

Allowable stress at design temperature Sfd 136 MPa

Allowable stress at ambient temperature Sfa 138 MPa

Youngs Modulus for flange @ Design Ef 185000 MPa

Material of bolt / studs SA-193 Gr. B7

Bolt size M42

Bolt diameter d 42 mm

Bolt hole diameter df 42 mm

Root area per bolt / studs Ra 1018.218 mm2

Yield stress at ambient temperature Sby 695 MPa

Allowable stress at design temperature Sbd 172 MPa

Allowable stress at ambient temperature Sba 172 MPa

Spessore verificato

Selecting flange thickness (excluding RF) tact 125 mm

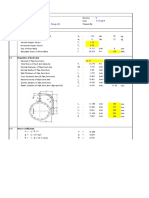

Width of gasket ( Go - Gi ) / 2 N 35.00 mm

When bo< 6.3 mm ; b = bo else b = 2.5 x root (bo)

Effective width of gasket (N/2) bo 17.50 mm

Effective width of gasket b 10.46 mm

Gasket reaction Long side ( Gol - 2b ) Gl 2419.08 mm

Gasket reaction Short side ( Gos - 2b ) Gs 579.08 mm

Hydrostatic end force ( Pd * Gl * Gs ) H 7004256.69 N

Compression Load on Gasket ( 2b * (2Gl + 2Gs) * m * Pd) HG 2351668.58 N

Hydrostatic end force applied via shell ( Pd * Bl * Bs ) HD 6271973.75 N

Hydrostatic end force due to pressure ( H-HD ) HT 732282.94 N

Min required bolting Loads

Min. bolt Load for Operating Condition ( HG + H ) Wm_1 9355925.27 N

Min. bolt Load for Gasket Seating Condition ( 2 * ( Gl + Gs ) * b * y ) Wm_2 3260980.42 N

Design Flange Load max ( WM1; Wm2 ) Ww 9355925.27

Bolt Area for operating condition Wm_1 / Sbd Am_1 54394.91 mm2

Bolt Area for gasket seating condition Wm_2 / Sba Am_2 18959.19 mm2

Min. Design Bolt Area requirement max.(Am1, Am2) Am 54394.91 mm2

Actual Bolt Area Ab 63129.516 mm2

The no. Of bolts selected is safe

Moment Arms

Radial distance from Bolt circle to I.D. - Long side ( Cl - Bl - g_1) / 2 hD_d 73.25 mm

Radial distance from Bolt circle to G.I.D. - Long side ( Cl - Gl) / 2 hG_g 50.46 mm

Radial distance from Bolt circle to circle at which HT acts ( 2 x Cl - Bl - Gl) / 4 hT_t 61.85 mm

Max Operating Moment ( HD*hd + HG*hg + HT*ht ) Mop 623377879.49581 N mm

Maximum Gasket Seating Moment ( Ww * hG_g ) Matm 472083619.13303 N mm

Flange thickness calculation check

Operating Condition (6 Mop / (Sfd * (2*(Cl+Cs)-n*df)))^0.5 to 85.23 mm

Gasket Seating Condition (6 Matm / (Sfa * (2*(Cl+Cs)-n*df)))^0.5 tg 73.63 mm

Min required thickness ( max. (to, tg ) tmon 85.23 mm

Max permissible spacing Pbmax 257.06 mm

Dimension check for Flange design (Al-Bl)-(As-Bs) = 0 0

The dimensions are acceptable

Dimension check for Flange design (Cl-Bl)-(Cs-Bs) = 0 0

The dimensions are acceptable

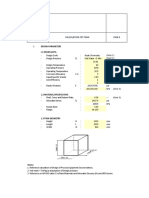

Lato a' 1000 mm

Lato b' 1000 mm

Pressione P 0.081 Mpa

Soll. Ammiss. F 150 MPa

Spessore SP 20 mm

c.a. 3 mm

TL 0.4 mm

a'/b' 1

fattore C3 0.66 da Fig. 10.7-2

e 18.73701 mm "<" 20 Spessore SP

You might also like

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Rectangular Flange DesignDocument3 pagesRectangular Flange Designshazan100% (5)

- Part-Uhx (U-Tube) .Document5 pagesPart-Uhx (U-Tube) .AKSHAY BHATKARNo ratings yet

- Bolt TorqueDocument5 pagesBolt TorqueTarunNo ratings yet

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975No ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocument10 pagesFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNo ratings yet

- .Document7 pages.Darshan Panchal100% (1)

- Saddle design calculationsDocument9 pagesSaddle design calculationsduf fuNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Document5 pagesFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- What Is An Appendix-2 Flange? - Key Design Engineering BlogDocument1 pageWhat Is An Appendix-2 Flange? - Key Design Engineering Blogsurefooted1100% (1)

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document17 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)threedlabsNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDocument5 pagesCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNo ratings yet

- AD 2000 HesapDocument11 pagesAD 2000 HesapBaşarŞenNo ratings yet

- Weld stress check for FAVID clips and demister clipsDocument3 pagesWeld stress check for FAVID clips and demister clipsrsubramaniNo ratings yet

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Collar bolt sizing calculationDocument2 pagesCollar bolt sizing calculationMohammad Zahid50% (2)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocument6 pagesSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNo ratings yet

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Body Flange Bolt TorqueDocument1 pageBody Flange Bolt TorqueLcm Tnl100% (1)

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocument5 pagesPRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- Calculation For Quick Opening Closure: Design ConditionDocument5 pagesCalculation For Quick Opening Closure: Design ConditionA.K.100% (3)

- Rectangular Tank (With Horizontal Stiffner)Document5 pagesRectangular Tank (With Horizontal Stiffner)DURGAIRAJ100% (1)

- Weld Neck Flange Design - As Per Denis MorisDocument2 pagesWeld Neck Flange Design - As Per Denis Morissouren1975No ratings yet

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Ejma7r2 Bellows Worksheet-1Document11 pagesEjma7r2 Bellows Worksheet-1odormicchiNo ratings yet

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Document11 pagesFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Blind Flange With Multiplpe Opening (U Stamp) )Document12 pagesBlind Flange With Multiplpe Opening (U Stamp) )Ashish Dhok0% (1)

- Design of large diameter slip on flangeDocument6 pagesDesign of large diameter slip on flangeAKSHAY BHATKARNo ratings yet

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400No ratings yet

- Blind Flange DesignDocument1 pageBlind Flange DesignSachin5586No ratings yet

- WELD NECK BODY FLANGE DESIGN CALCULATIONDocument30 pagesWELD NECK BODY FLANGE DESIGN CALCULATIONravielb9873No ratings yet

- Flange 050122Document5 pagesFlange 050122bytestefNo ratings yet

- WELD NECK BODY FLANGE DESIGN CALCULATION DATADocument25 pagesWELD NECK BODY FLANGE DESIGN CALCULATION DATALipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Ssv/prop/72/22-01, Rev.0Document10 pagesSsv/prop/72/22-01, Rev.0parveshNo ratings yet

- Blind Flange Calculation11Document3 pagesBlind Flange Calculation11jaymuscatNo ratings yet

- Flange DesignDocument26 pagesFlange Designresume Fi-1401No ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- Lifting Lug & PartitionsDocument4 pagesLifting Lug & PartitionsbytestefNo ratings yet

- Design of Partition Plate BonnetDocument2 pagesDesign of Partition Plate BonnetbytestefNo ratings yet

- Design of Partition Plate ChannelDocument2 pagesDesign of Partition Plate ChannelbytestefNo ratings yet

- Design of Below-the-Hook Lifting Devices: ASME BTH-1-2014Document81 pagesDesign of Below-the-Hook Lifting Devices: ASME BTH-1-2014bytestefNo ratings yet

- Partition - Plate BonnetDocument1 pagePartition - Plate BonnetbytestefNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionfuffinoNo ratings yet

- Partition - Plate ChannelDocument1 pagePartition - Plate ChannelbytestefNo ratings yet

- AFG Forged Connectors StandardDocument8 pagesAFG Forged Connectors Standardkhot2000No ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionfuffinoNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- Tender Doc CPI7203P22Document540 pagesTender Doc CPI7203P22bytestefNo ratings yet

- Saari Heat Exchanger DimensioningDocument101 pagesSaari Heat Exchanger DimensioningMarcel SouzaNo ratings yet

- Ref. Code For Partition Plate TEMA (RCB-9.13) Nominal Pass Partition Plate Thickness As Per Table Rcb-9.131 Nominal Size Carbon Steel Alloy MatrialDocument5 pagesRef. Code For Partition Plate TEMA (RCB-9.13) Nominal Pass Partition Plate Thickness As Per Table Rcb-9.131 Nominal Size Carbon Steel Alloy MatrialbytestefNo ratings yet

- Rectangular Tank DesignDocument35 pagesRectangular Tank Designfaizal91% (11)

- 1 s2.0 S245232161930530X MainDocument10 pages1 s2.0 S245232161930530X MainbytestefNo ratings yet

- Supplementaty Specification To Pressure VesselsDocument27 pagesSupplementaty Specification To Pressure VesselsjohnNo ratings yet

- Flange 050122Document5 pagesFlange 050122bytestefNo ratings yet

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- Methods For Structural Stress Determination Accord PDFDocument9 pagesMethods For Structural Stress Determination Accord PDFSafa ÖzhanNo ratings yet

- User Manual: Full HD Led TVDocument12 pagesUser Manual: Full HD Led TVbytestefNo ratings yet

- Design of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeDocument11 pagesDesign of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeFelip PrietoNo ratings yet

- Hse RR509Document146 pagesHse RR509okboNo ratings yet

- Din en Iso 4014Document16 pagesDin en Iso 4014hasan_676489616100% (7)

- Asme b16.20 Spiral Wound Gaskets Technical BulletinDocument4 pagesAsme b16.20 Spiral Wound Gaskets Technical BulletinChristian Lopez Mendez100% (1)

- Rectangular FlangesDocument5 pagesRectangular FlangesstefanoNo ratings yet

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- Department of Main Roads - Rod Planning and Desingn Manual-Chapter16Document83 pagesDepartment of Main Roads - Rod Planning and Desingn Manual-Chapter16CesarNo ratings yet

- Hager Wiring Accessories Catalogue 1120Document64 pagesHager Wiring Accessories Catalogue 1120lizukyNo ratings yet

- Macedo-Et-Al Bray-2023-Seismic-Slope-Displacement-Procedure-For-Interface-And-Intraslab-Subduction-Zone-EarthquakesDocument19 pagesMacedo-Et-Al Bray-2023-Seismic-Slope-Displacement-Procedure-For-Interface-And-Intraslab-Subduction-Zone-EarthquakesxfvgNo ratings yet

- Drive Solutions For Cranes.Document3 pagesDrive Solutions For Cranes.dhaNo ratings yet

- Concept in Milling Tandem in Sugar IndustryDocument10 pagesConcept in Milling Tandem in Sugar IndustryGizachew BeyeneNo ratings yet

- Sound Pressure Meter (08-4c4)Document10 pagesSound Pressure Meter (08-4c4)Sri Krishna RakeshNo ratings yet

- Understand ElectrostaticsDocument39 pagesUnderstand Electrostaticsanup vermaNo ratings yet

- Stoichiometry and Chemical Equations (LE2 Reviewer)Document2 pagesStoichiometry and Chemical Equations (LE2 Reviewer)Tidal SurgesNo ratings yet

- Murthy, 2003Document3 pagesMurthy, 2003Stacy JohnsonNo ratings yet

- SANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsDocument158 pagesSANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsAliRouyou64% (11)

- Kouign Amann RecipeDocument59 pagesKouign Amann RecipeDanny DawsonNo ratings yet

- New Aluminium FormworkDocument34 pagesNew Aluminium FormworkSandip Jagdale0% (1)

- CB Mooring SystemsDocument5 pagesCB Mooring SystemsCojocaru LaviniaNo ratings yet

- SPDocument4 pagesSPbaraka08No ratings yet

- Monograph Function: Definition and AnalysisDocument13 pagesMonograph Function: Definition and AnalysisdesignbaseNo ratings yet

- JLG 450 A AJ II Parts 3121243 4-15-08 Global EnglishDocument492 pagesJLG 450 A AJ II Parts 3121243 4-15-08 Global EnglishCarlos E. Delius SciaroniNo ratings yet

- Consultancy ListDocument1 pageConsultancy Listrajpre1213No ratings yet

- ModelSim Users Manual v10.1c PDFDocument733 pagesModelSim Users Manual v10.1c PDFAmshi AbooNo ratings yet

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- MDD ResultDocument1 pageMDD ResultHasan al MahmudNo ratings yet

- Training Regulation: Provincial Training Center - ZN TM-CNZDocument28 pagesTraining Regulation: Provincial Training Center - ZN TM-CNZKindly LegarteNo ratings yet

- Ultralow-Noise, High PSRR, Fast RF 1-A Low-Dropout Linear RegulatorsDocument18 pagesUltralow-Noise, High PSRR, Fast RF 1-A Low-Dropout Linear RegulatorskarkeraNo ratings yet

- Study For Roof Louver Effect On Parapet WallDocument3 pagesStudy For Roof Louver Effect On Parapet WallKhawaja Kashif QadeerNo ratings yet

- In Situ Mechanical Characterization of Structural Bamboo Materials Under Flexural BendingDocument11 pagesIn Situ Mechanical Characterization of Structural Bamboo Materials Under Flexural BendingLuanna CamposNo ratings yet

- XB700 Operation ManualDocument13 pagesXB700 Operation ManualElvis Javier Gómez MonterreyNo ratings yet

- CLG862 200904001Document129 pagesCLG862 200904001mliugong75% (4)

- Catalogo HDessault 2024 GB WebDocument32 pagesCatalogo HDessault 2024 GB Webcyntia.dujsikovaNo ratings yet

- S1 Partner Sales Guide v2019!01!28Document2 pagesS1 Partner Sales Guide v2019!01!28SudeepNo ratings yet

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentSreekumarNo ratings yet