Professional Documents

Culture Documents

Biological Treatmentof Hospital Wastewaterbyusing Batchand Rotating Biological Contractors

Uploaded by

varshaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biological Treatmentof Hospital Wastewaterbyusing Batchand Rotating Biological Contractors

Uploaded by

varshaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/343219350

Biological Treatment of Hospital Wastewater by using Batch and Rotating

Biological Contractors

Article in International Journal of Advanced Science and Technology · July 2020

CITATIONS READS

0 163

2 authors, including:

Jyothi Kaparapu

Andhra University

28 PUBLICATIONS 106 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Distribution of micro algae in ponds and reserviors View project

Treatment of Waste water using Microalgae View project

All content following this page was uploaded by Jyothi Kaparapu on 26 July 2020.

The user has requested enhancement of the downloaded file.

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

Biological Treatment of Hospital Wastewater by using Batch and Rotating

Biological Contractors

Krishna Prasad. M1, Jyothi.K2, Swetha Sri. V3& Nagaraju. G4

2

Department of Botany, Andhra University, Visakhapatnam

1,3,4

Department of Chemical EngineeringGMR Institute of Technology- Rajam, Srikakulam, A.P.

2

jyothikaparapu@gmail.com

Abstract

The wastewater generated from the hospital consists of pharmaceuticals, pathogenic

bacteria, drugs, suspended particles and bloodstains that may influence the ecosystem

possibly causes cancers that have been observed for decades. To overcome these, impacts,

the wastewater is started to treat before discharged to the water bodies. The treatment

process has evolved into various physical, chemical and biological methods. Biological

treatment methods are conducted in this paper to study the comparative analysis for the

BOD and COD removal efficiencies in the batch study and RBC model. A pilot scale of a

biofilm model of Rotatory Biological Contactor (RBC) was implemented as the extension of

batch experiments. The prepared synthetic hospital wastewater with high concentrations are

treated using the bacteria Pseudomonas aeruginosa and Vibrio cholera as a treatment

media. The substrate removal rate was analyzed by conducting the BOD and COD

experiments in the batch study. The Pseudomonas aeruginosa results indicated 78% BOD

removal efficiency from the batch study. This bacteria was used in the treatment of influent

by using an attached biofilm model RBC of 6 liters capacity with 4 discs, each having

surface area 0.4m2 and 45% submergence. Compared with batch experiments, RBC has

greatly removes the 67% of COD and 85% of BOD. This work also illuminates the

importance of Pseudomonas aeruginosa bacteria for the effective elimination proficiency of

a substrate in the cure of pharmaceutical discharge. The treated effluent will be reused for

decreasing the increasing demand for water. In the present study the biofilms have maximum

of dry matter and are at ease to dehydrate and settle in contrast to activated sludge. RBC

can significantly diminish the treatment price, related to commercial incineration processes

or advanced oxidation processes,. This work proves RBC is operative for an innately bio

obstinate wastewater even at lesser ambient temperature.

Keywords: Batch experiments, Rotatory Biological Contactor (RBC), Pseudomonas aeruginosa,

Vibrio cholera, COD and BOD

1 Introduction:

Hospitals are generally consuming an extensive amount of water ranging between 400 to 1200 liters/day

and equally creates the same volume of wastewater load which generates from different segments

including patient wards, clinical wards, surgery units, ICU, laboratories and holds a relatively inconstant

composition liable on the activities consists (Kumarathilaka et al., 2016). The effluent wastewater

comprises pharmaceuticals that are partially metabolized, pathogenic microorganisms, toxic chemical

substances, drugs, and radioactive elements. The effluent release criteria for hospital wastewater should

regard to EPA 1986 and the tolerance limits in India is according to BIS standards IS 4764 Hospitals are

generally consuming an extensive amount of water.

ISSN: 2005-4238 IJAST

4774

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

There is an increase in production and consumption of pharmaceuticals considerably during the last

decades, their yearly manufacture beyond thousands of tons (Santos et al., 2007; Sim et al., 2011). The

omnipresence of pharmaceuticals in surface water, groundwater and drinking water, with absorptions

wavering from ng L-1 to µg L-1 has been reported by many authors (de Jesus Gaffney et al., 2016; Koreje

et al., 2016). The occurrence of these compounds of the ecosystem will provoke the pollution by

involving biological imbalance and causes endocrine disruptions, bacterial resistance, ecotoxic effects

leads to death of marine biota (Pauwels and Verstraete, 2006; Chen et al.,2003de Jesus Gaffney et al.,

2016; Zhao et al., 2016; Kostich et al., 2014; Yan et al., 201). Antibiotics in wastewater may encourage

bacterial opposition, even at less contents (Hernandez et al., 2007). The by-products of hospital discarded

fluid are high-strength biological wastewater that is obstinate to biological treatment processes. In

general, hospital wastewaters (HWWs) are straightly quitted, lacking any treatment, into the gutter system

to be co-cured with municipal wastewaters (Al Qarni et al., (2016)). Generally, it is cured by incineration

in the pharmaceutical plant, however, this choice is appropriate for big initiatives because of its massive

investment and large operating cost (Tchobanoglous et al ., 2003; Yang et al., 2009). Inopportunely,

conventional Waste Water Treatment Plants are generally planned to isolated suspended solids and to

remove decomposable organic matter and they are commonly unable to entirely reduce pharmaceuticals,

their abolition reliant on their adsorption on biotic sludge and biodegradation (Santos et al., (2007).

To eradicate such risks, it is crucial to treat the influent wastewater and yield effluent free from pollutants

(Langenhoff et al.,2013). To remove such pollutants chemical treatment processes such as osmosis,

advanced oxidation processes, ozonation, photocatalysis, activated carbon, ultrasound oxidation, etc.,

which are expensive and energy consumptive. In contrast, biological treatment techniques are robust and

cost-effective when compared to chemical treatment (Langenhoff et al., 2013). It includes activated

sludge process, trickling filter, membrane bioreactor, up-flow anaerobic sludge blanket, aerated ponds,

stabilization lagoons, fluidized bed reactor, Rotatory Biological Contactors, and others wherein the

microbial groups are used as a treatment media for the deprivation of pollutants (Stalin, 2014). The

biological process is frequently used because it yields an elimination competence changing among 51 %

to 80% at a hydraulic retention time of 1- 4.5 days (Jeswani&Mukherji, 2015). Therefore, the fate of the

pollutants should be considered and a suitable treatment technique should be adopted.

The rotating biological contactor (RBC) biofilm (attached-growth) process was promoted in the 1970s

(Najafpour et al.,2005). Current curing amenities for municipal and industrial wastewater management

with intermediate strength (COD concentration is 600–2000mgL−1) of biological substances requires

RBC as an essential biofilm process (Akunna and Jefferies, 2000; Vidal et al., 2002). Biodegradation of

organic substances within the RBC depends on the biomass composition of the discs (Torkian et al.,2003;

Zheng et al.,2010). The advantages of RBC are the preservation of high concentration of microorganisms

in the exponential state, more capable for degrading biological composites, more aptness for fluxes in

movement rate and biological concentration (Chen et al.,2006; Wang et al.,2009), nitrification and

denitrification along with removal carbon (Hiras et al.,2004; Tawfik et al.,2005), easy operation, less

water in the sludge forming it to settle, less energy intake (Torkian et al.,2003), and requirement of small

land area (Taseli et al., 2008). Thus, an economically feasible process for managing real high strength

organic pharmaceutical wastewater is required.

In this research, the potential of the biological process is investigated to treat the prepared synthetic

pharmaceutical wastewater. The prepared synthetic wastewater was treated by conducting batch studies

and fabricated Rotatory Biological Contactor (RBC) on a small scale. The microorganisms Pseudomonas

aeruginosa and Vibrio cholera are used as a treatment media to treat the wastewater. The dry weight

density of microorganisms was also calculated to define the microorganisms count. The cultured

microorganisms are used in the batch study and the microorganism which gives the best removal

efficiency was used in the RBC process as a biofilm. This work aimed to determine the treatment result

computed by evaluating the removal of Chemical Oxygen Demand (COD) and a 5-day test Biological

ISSN: 2005-4238 IJAST

4775

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

Oxygen Demand (BOD5) in batch study and RBC. Investigation of the discharges COD and BOD needs

to be done and the values obtained used to establish an empirical relation of COD to BOD5. An

evaluation of BOD with COD measures whether the compound is readily decomposable. For BOD5, a

sign is that a COD: BOD proportion of more than 100 means that the compound is comparatively non-

biodegradable and a ratio of less than 10 is somewhat degradable (Prashant et al.,2013)

2 Materials and methods

2.1 Synthetic wastewater preparation

Synthetic hospital Waste Water was arranged in agreement with Seyhi et al., (2013). The synthetic

wastewater was prepared with different 9 assortments of tablets of every assortment of 2 tablets and by

adding glucose, (NH4)2SO4, KH2PO4, NH4Cl, and CaCl2 are diluted each 1mg/l in distilled water. For

maintaining microbial movement Nitrogen and phosphorus were added in excess to the synthetic effluent.

The concentrations of nitrogen, phosphorus, and glucose, are adapted to sustain a C: N: P ratio of

100:10:5. The concentrations of pharmaceuticals were selected according to those which detected in real

hospital effluents (Santos et al., 2013; Yilmaz et al., 2017). The prepared stock solution is kept for a

contact time of 96 hours and put in storage in dark at temperature 4 oC. The COD and BOD tests are

conducted for this prepared synthetic wastewater (Ouarda et al.,2018).

2.2 Analytical methods

Chemical and biochemical oxygen demand (COD & BOD) were the main factors selected to investigate

the RBC treatment process. The COD and BOD of prepared wastewater samples were estimated earlier

and later treatment. Analyses of COD, BOD5, were conducted to study the biodegradability of the

pharmaceutical discharges. The BOD is the amount of dissolved oxygen needed by microbes for the

oxidation of living content in wastewater in aerobic situations. The BOD5 test is a bioassay method

relating to the extent of oxygen spent by the bacteria while steadying the living material in the waste in

laboratory settings. The test is engaged for 5 days at 20°C (68°F) (APHA, 1989). COD tests were done

according to the Standard Methods (APHA 1992) by the ferrous ammonium sulfate method (APHA,

1989). Dissolved Oxygen (DO) was conducted by Winkler’s method (APHA, 1998). The pH value of

water was measured by pH meter (Systronics, India). Turbidity was determined by Nephelo - turbidity

meter. Additionally, microorganisms were observed by a microscope.

2.3 Microorganism’s characteristics:

Biological treatment involves microbial consortia as a treatment media.In the present work, the biological

treatment of the prepared wastewater involved two microorganisms Pseudomonas aeruginosa and Vibrio

cholera.

Table.1. Characteristics of microorganisms

Characteristics Pseudomonas aeruginosa Vibrio cholera

Gram type Negative Negative

Domain Bacteria Bacteria

Family Pseudomonadaceae Vibrionaceae

ISSN: 2005-4238 IJAST

4776

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

Shape Rod shape Coma shaped

Size 1-5µm long, 0.5-1.0 µm wide 0.3µ diameter, 1.3µ in length

Aerobe or Aerobic (at times facultative Facultative anaerobe

anaerobe anaerobic)

Colour Blue-green, red-brown Yellow-green

Diseases cause respiratory tract problems, skin cholera, diarrhea and vomiting,

problems, Ear and Eye coma and death.

infections, bones and joints

problems and blood and heart

diseases

2.4 Dry weight density of microorganisms:

From the subculture stock, a 10ml sample was taken and centrifuged at 6000 rpm for 20 minutes. After

centrifugation is completed, testers from the supernatant were studied for biomass composition which

were detected by filtering from 0.45 milli pore filter papers and defining dry weight after dehydrating in

an oven until stable weight (Kargi, F. 1996).

Dry weight density= (initial weight-final weight)*1000/ (volume of sample taken)

2.5 Experimental Setup

2.5.1 Batch experiment

In the batch mode, the experiments are carried out at an ambient temperature of 250C. The batch

experiments are carried out in the various flasks of 300ml capacity. Three 300ml flasks packed with 10ml

of Pseudomonas aeruginosa and wastewater and other three 300ml flasks are packed with 10ml of Vibrio

cholera and wastewater. These flasks were used to calculate the removal efficiency of COD and BOD.

The flasks were allowed in aerobic conditions for an incubation period of 5 days (Salama et al., 2015).

2.5.2 RBC Setup

In this study, the performance of laboratory Rotatory Biological Contactor (RBC) was tested for the

treatment of prepared synthetic wastewater. The RBC unit is fabricated with a semi-circulated trough of

volume 6litres capacity and provided with a PVC shaft on which discs are attached with a width of

200mm and the shaft is provided with the support of two bearings at each end. The rotating disks provide

the development of microbes of the sewage, which break down and steady organic pollutants. The shaft is

fixed overhead the water level in the tank. A motor of 30 RPM is used in this experiment. The motor can

vary its RPM from 1 to 30. Oxygen is acquired from the atmosphere as the discs revolve. As the microbes

progress, they construct upon the media until they shred off owing to shear forces by the revolving discs

in the wastewater. Effluent from the RBC is then passed through final clarifiers where the micro-

organisms in suspension settle as sludge. The sludge is withdrawn from the clarifier for further treatment

(Boyles, W. 1997; Donald et al., 2001). The experiment work is carried out in aerobic conditions. This

RBC work is intended to study the effective removal of COD and BOD with the help of Pseudomonas

aeruginosa (Wilson & Lee1997).

ISSN: 2005-4238 IJAST

4777

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

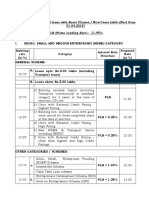

Table:2. Physical Parameters of Device

Physical parameter Value

Rotational speed (rpm) 2

Tank capacity (lts) 6

Number of discs 4

Diameter of disc (mm) 200

Surface area of the disc (mm2) 9.4x103

Diameter of discs (mm) 5

Space between the discs (mm) 100

Submergence (%) 45%

3 Results and Discussions

3.1 Dry weight density calculation of biomass

Biomass dry weight denotes the volume of the mass of microorganisms expressed as g/ml of sample. The

volume of biomass is calculated by a count of the number of cells per one ml of solution. The removal

efficiency of treatment depends on the number of microorganisms in the aeration tank. The presence of

more number of cells results in higher efficiency [Kargi, 1996].

Dry weight density= [(initial weight-final weight) / (volume of sample taken)] *1000

The dry weight density of Pseudomonas aeruginosa is 9180 mg/l and Vibrio cholera is 5130 mg/l.

3.2.Treatment of synthetic effluent in batch studies

The treatment performance of the batch study was evaluated for BOD analysis. The synthetic influent was

characterized by a COD content of 2000mg/l and a BOD range of 8600mg/l. The batch experiment is

conducted based on the concentration of initial COD concentration and the dilutions are prepared at

concentrations of 2000mg/l, 1500mg/l, and 1000mg/l. Two microorganisms are used separately in each

set of flasks to evaluate the removal efficiency capacity of those microorganisms. The batch mode results

shown that the Pseudomonas aeruginosa gives the best removal efficiency (Fig.1).

ISSN: 2005-4238 IJAST

4778

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

3.2.1 BOD removal efficiency by Pseudomonas aeruginosa

Fig:1. Comparison of BOD values between standard effluent and Pseudomonas aeruginosa

The graph gives the details of BOD removal efficiency in prepared synthetic wastewater before and after

conducting a batch study experiment by adding Pseudomonas aeruginosa as a treatment media after an

incubation period of 5 days. Three concentrations of 8600mg/l, 6450mg/l, and 4300mg/l are the initial

BOD values before conducting a batch study. The BOD values without microorganism after incubation

period are decreased to 7500mg/l from 8600mg/l, 2000mg/l from 6450mg/l, and 4000mg/l from 4300mg/l

due to the natural degradation of organic matter. At the same time, BOD values with organism after

incubation period are highly degraded from 7500mg/l to 3200mg/l, 6450mg/l to 600mg/l and 4300mg/l to

1100mg/l.

3.3.Treatment of synthetic effluent in Rotatory Biological Contactor (RBC):

RBC experimentwas conducted as the extension of the batch experiment. The evaluated samples from the

batch study are treated in the RBC to determine the higher efficiency. Pseudomonas aeruginosa results in

the higher efficiency in the batch study. Hence this microorganism is used in the RBC as a treatment

media.

ISSN: 2005-4238 IJAST

4779

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

3.3.1 COD removal efficiency of RBC by Pseudomonas aeruginosa

Fig:2. COD removal by Pseudomonas aeruginosa of standard effluent and RBC effluent

The COD removal efficiency by Pseudomonas aeruginosa of prepared synthetic wastewater is shown in

fig.2. The initial concentration of COD is 900mg/l before conducting the RBC experiment. The

wastewater without organism reduces COD by itself from 900mg/l to 620mg/l. After the treatment with

the organism in the RBC for 5 days is reduced to 300mg/l.

The quantity and kind of bacteria of the attached biofilms of the RBC starts adapting to new wastewater

or reproduced deviations fit for new wastewater. (Chen et al.,2003; Eckenfelder,2000)

3.3.2 BOD removal efficiency in RBC by Pseudomonas aeruginosa

Fig:3. BOD removal efficiency in RBC with Pseudomonas aeruginosa

ISSN: 2005-4238 IJAST

4780

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

Figure 3 represents the changes of BOD5 removal during acclimation presents the BOD removal

efficiency by Pseudomonas aeruginosa of prepared synthetic wastewater. The initial concentration of

BOD is 900mg/l. The wastewater without organism reduces BOD by itself from 900mg/l to 670mg/l.

After the treatment in RBC with organism for 5 days is greatly reduced to 125mg/l.

The BOD5 elimination diminished to around 60% according to the accumulation of pharmaceutical

wastewater enlarged. This is due to the rate of pharmaceutical wastewater addition was collecting rapidly

related to the initial addition rate and the microorganisms are not able to acclimatize in time. When the

additive amount of pharmaceutical wastewater was adjusted and the acclimation period became lengthier,

the removal of BOD5 starts to increase to about 80% in the end. This shows that the microbes in the

biofilms slowly amended to pharmaceutical wastewater and they capably detached the decomposable

organics. The above-mentioned trials indicate, even at less ambient temperature, the RBC system is

operative for treating pharmaceutical wastewater. This indicates that this RBC technology can

theoretically be used in reserved conditions.

3.3.3 COD removal efficiency of wastewater by Pseudomonas aeruginosa

Fig:4. Comparison between COD removal by Batch & RBC system

COD removal efficiencies in Batch experiments result in a slight increment because of the improper

collection of the sample. RBC gives the best removal results of COD, due to the high degradation of

pollutants by Pseudomonas aeruginosa which is provided with support media.

ISSN: 2005-4238 IJAST

4781

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

3.3.4.BOD removal efficiency of wastewater by Pseudomonas aeruginosa

Fig:5. Comparison between BOD removal by Batch & RBC system

The BOD5 removal efficiency of both batch experiments by Pseudomonas aeruginosaresults in the best

removal efficiency of 78% and 86.1%. The graph represents the increment, it is due to the presence of

support media provided for the microbial consortia for their growth. The BOD5elimination efficacy

reduced firstly with growing influent concentration, and then it steadied.

3.4. Treatment of Pharmaceutical Wastewater with RBC.

After acclimation, the outcome of influent COD concentration on the COD, and BOD5 deduction from

pharmaceutical wastewater was studied. After wastewater runs into the RBC device, the organic

complexes are gradually decomposed by microbes. There is greater organic content in wastewater close to

the inlet which causes microbes to replicate quicker. On the contrary, there is comparatively fewer

organic content in the downstream stages causing a lesser amount of microorganisms. Therefore, as the

water continues downstream, the amount of microbes on the stage lessens. Related with the mud in

activated sludge methods (Tchobanoglous et al., 2003) the amount of dry matter in the biofilms is greater

and the biofilms have more density that is easy to settle. In this experiment, RBC technology can

knowingly reduce the treatment cost and organic concentration. The key features influencing the

treatment of RBC comprise the kind of wastewater, influent concentration, stages of RBC, and

temperature.

The air and liquid temperatures flanked by 24-26°C respectively and as a result, the biomass grew on the

RBC disks noticeable within 3 to 4 days of operation which was a thick biofilm layer on each side of a

disk. The biofilm varied from dark to light golden-brown color under aerobic conditions initially. Under

high substrate and good growing conditions, it can be hypothesized that the high reaction rate in the

biomass will cause a high oxygen uptake and a subsequent rapid oxygen depletion in the reactors. The

circulation of oxygen into the biofilm and liquid mass is inadequate and further controlled by the low disk

rotating speed and relatively high temperature. Similar results were noticed by Kim et al. (1985) in

treating wastewater.

ISSN: 2005-4238 IJAST

4782

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

3.5.Concentration Vs Efficiency

80

78

76

74

72

70

68

66

0 500 1000 1500 2000 2500

Fig:6. Removal efficiency

The graph shows the relation between influent concentration and removal efficiency. As the concentration

decreases the efficiency is increases.

3.6.Outcome of Influent Concentration on elimination of COD

When the organic input concentration was below 1000mgL−1, the COD removal efficacy is near to 50%.

With an increase of organic input concentration from 400 to 800mgL−1, the COD elimination improved

somewhat. The total COD removal was not more related to the outcome of treating sewage wastewater.

This is due to the existence of biorecalcitrant substances in pharmaceutical wastewater (Yang et al.,

2009). The COD elimination proficiencies of varied kinds of wastewater progress consequently with

rising ambient temperature, (Badawy et al.,2009; Gebhardt and Schroder, 2007).

3.7.Outcome of Influent Concentration on elimination of BOD5

The BOD5values of the inlet and outlet water were measured to study the biodegradability of

pharmaceutical wastewater. Initially, with increasing influent concentration, the BOD5removal efficiency

decreased. This indicates that microorganisms decompose most of the biodegradable content of

pharmaceutical wastewater. The microbes in biofilms unable to destroy all of the organics in wastewater

because of the existence of some toxic substances biorecalcitrant and the low ambient temperature. This

has an effect on the BOD5 exclusion to some extent.

The present results indicated that a rise in the organic filling rates resulted in only a modest decline in the

elimination efficiency, while the deterioration in biomass extended progressively. Even when organic

overloading had developed throughout, efficiencies of 90-91 % were still obtained. It has been noticed

that the high bacterial activity supported by the constant high ambient temperature permitting rapid

substrate utilization of the present high strength synthetic wastewater. It is also observed that the system

although operating under organic overloading conditions acts effectively as a facultative process with the

air-exposed biofilm being in an aerobic condition and the submerged biofilm being in an anaerobic phase.

Based on the effects of influent concentration on COD, and BOD5removal, it is concluded that the

influent concentration does not substantially influence organic exclusion. This is due to the existence of

various stages in the RBC. The early phase safeguards the shock of influent concentration and toxins. One

ISSN: 2005-4238 IJAST

4783

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

more cause of resistance to more influent concentration is that the biofilms have a chunkiness of 0.5–3

mm, and the shock of input organics control the interior layer of the biofilms smaller than the exterior

layer, thus leaving a moderately active inner layer. Thus it is challenging to degrade the entire piece of

biofilm from one disc or all the biofilms from all disks. Therefore, RBC is proficient in repelling the

effect of influent concentration variation. This means that RBC has a robust aptness for the concentration

shock of wastewater related to the activated sludge method. After such a shock, it can reestablish its

purpose quickly. Nevertheless, related to activated sludge practice, it is only suitable for wastewater with

low influent concentration (Chen et al., 2003). With the decline of COD and BOD5downstream, metabolic

actions of microbes declined and their oxygen intake reduced. This leaves additional oxygen in the waste.

In extra, the RBCs are efficient at reaerating the water. The ambient temperature has an important

influence on treatment ability with greater temperature causes more effective treatment (Su, 2010).

4 Conclusion

The lab-scale rotating biological contactor (RBC) was operated while treating synthetic wastewater

utilizing Pseudomonasaeruginosa as a microbial consortia used in the RBC. The RBC experimented

aerobically which acts as an efficient method for handling high strength wastewaters under the rotational

speed of discs shaft of 2 rpm and with the submergence of 45%. The microorganism reduces the influent

COD from 1000mg/l to 300mg/l which was a 70% removal efficiency and also reduces the BOD of

influent from 1500mg/l to 125mg/l achieved an efficient removal of 86% at HRT 60h.

5 Acknowledgments:

One of the authors JyothiKaparapu appreciatively admits financial support of UGC, New Delhi (Post-

Doctoral Fellowship for women) No. F.151/2014-15/ PDFWM-2014-15-AND-26595(SAII).

References:

1. .Ahsan, N. (2012). Study of widely used treatment technologies for hospital wastewater and their

comparative analysis. International Journal of Advances in Engineering & Technology, 5(1), 227.

2. Akunna, J. C.and Jefferies, C. 2000. “Performance of family-size sequencing batch reactor and

rotating biological contactor units treating sewage at various operating conditions,” Water

Science and Technology, vol. 41, no. 1, pp. 97–104.

3. American Public Health Association (APHA), (1989) , Standard methods for Examination of

water and waste water, APHA, AWWA, WPCF, New York, 17th Ed.

4. American Public Health Association (APHA), (1998); Standard methods for the exmination of

water and waste water; 20th edition, Washington

5. American public association (APHA) (1992). Standard Methods for Examination of Water and

waste 18th ed. American Public health Association, Washing ton D.C

6. Badawy, M. I, Wahaab, R. A. and El-Kalliny, A. S. 2009.“Fentonbiological treatment processes

for the removal of some pharmaceuticals from industrial wastewater,” Journal of Hazardous

Materials, vol. 167, no. 1–3, pp. 567–574.

7. Boyles, W. 1997. Manganese III Chemical Oxygen Demand; Technical Paper. Hach Company,

U.S.A.

8. Chen, G, Li, G, D. Y and. Zhang, G.M. 2003. “Treatment technologies for highly concentrated

refractory organic wastewater,” Industrial Water Treatment, vol. 23, no. 3, pp. 10–14.

ISSN: 2005-4238 IJAST

4784

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

9. Chen, Z., Wen, Q.,Wang, J, and Li, F. 2006. “Simultaneous removal of carbon and nitrogen

frommunicipal-type synthetic wastewater using net-like rotating biological contactor (NRBC),”

Process Biochemistry, vol. 41, no. 12, pp. 2468–2472.

10. Chhetri, R. K., Ooi, G., Hansen, K. M., Litty, K., Christensson, M., Kragelund, C., & Bester, K.

(2015). Biodegradation of pharmaceuticals in hospital wastewater by staged Moving Bed Biofilm

Reactors (MBBR). Water research, 83, 293-302.

11. Donald G. Miller, Scott V. Brayton and Wayne T. Boyles . 2001, Water Environment Research,

73 (1), pp. 63-71

12. Eckenfelder W. W. Jr., 2000. Industrial Water Pollution Control, McGraw-Hill, New York, NY,

USA, 3rd edition.

13. Evans, F. L. 1985. Consideration of fin:t-stage organic overloading in rotating biological

contactor design, J. Water Pollut. Control Fed., 57, 1094-1098.

14. Gebhardt,W and Schroder,H.F.2007. “Liquid chromatography- (tandem) mass spectrometry for

the follow-up of the elimination of persistent pharmaceuticals during wastewater treatment

applying biological wastewater treatment and advanced oxidation,” Journal of Chromatography

A, vol. 1160, no. 1-2, pp. 34–43.

15. Hernandez, F. Sancho, J. V., Ibanez, M. and Guerrero, C. 2007.“Antibiotic residue determination

in environmental waters by LC-MS,” TrAC—Trends in Analytical Chemistry, vol. 26, no. 6,pp.

466–485.

16. Hiras, D.N. Manariotis, I.D and Grigoropoulos, S. G. 2004. “Organic and nitrogen removal in a

two-stage rotating biological contactor treating municipal wastewater,” Bioresource Technology,

93 (1), pp. 91–98.

17. Jeswani, H., &Mukherji, S. (2015). Treatment of simulated biomass gasification wastewater of

varying strength in a three stage rotating biological contactor. Chemical engineering journal, 259,

303-312.

18. Kargi, F. (1996). Biological treatment of high strength wastewater by fed-batch

operation. Bioprocess Engineering, 16(1), 35-38.

19. Kim, M. J., Ghim, Y. S. and Chang, H. N. 1985. Oxygen transfer in a rotating disk reactor with

continuous flow, Chemical Engg. Sci., 40, 2281-2286

20. Kumarathilaka, P., Jayawardhana, Y., Dissanayaka, W., Herath, I., Weerasundara, L.,

&Vithanage, M. (2016). General Characteristics of Hospital Wastewater from Three Different

Hospitals in Sri Lanka

21. Langenhoff, A., Inderfurth, N., Veuskens, T., Schraa, G., Blokland, M., Kujawa-Roeleveld, K.,

&Rijnaarts, H. (2013). Microbial Removal of the Pharmaceutical Compounds Ibuprofen and

Diclofenac from Wastewater. BioMed Research International, 2013, 1–9.

22. Najafpour,G, Yieng, H.AYounesi,H and Zinatizadeh, A. . 2005.“Effect of organic loading on

performance of rotating biological contactors using Palm Oil Mill effluents,” Process

Biochemistry, vol. 40, no. 8, pp. 2879–2884.

23. Ouarda, Y., Tiwari, B., Azaïs, A., Vaudreuil, M. A., Ndiaye, S. D., Drogui, P., ... &Dubé, R.

(2018). Synthetic hospital wastewater treatment by coupling submerged membrane bioreactor

and electrochemical advanced oxidation process: Kinetic study and toxicity

assessment. Chemosphere, 193, 160-169.

24. Pauwels,B and Verstraete,W,2006. “The treatment of hospital wastewater: an appraisal,” Journal

of Water and Health, vol. 4, no. 4, pp. 405–416.

25. PrashantA.Kadu, AmrutaA.Badge , Dr.Y.R.M.Rao,2013. Treatment of Municipal Wastewater by

using Rotating Biological Contractors (Rbc’s), American Journal of Engineering Research. 2(4),

pp-127-132

26. Salama, Y., Chennaoui, M., Mountadar, M., Rihani, M., &Assobhei, O. (2015). Influence of

support media on COD and BOD removal from domestic wastewater using biological treatment

in batch mode. Desalination and Water Treatment, 54(1), 37-43.

ISSN: 2005-4238 IJAST

4785

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 4774 - 4786

`

27. Santos, L.H., Gros, M., Rodriguez-Mozaz, S., Delerue-Matos, C., Pena, A., Barcelo, D.,

Montenegro, M.C., 2013. Contribution of hospital effluents to the load of pharmaceuticals in

urban wastewaters: identification of ecologically relevant pharmaceuticals. Sci. Total. Environ.

461-462, 302-316

28. Seyhi, B., Drogui, P., Buelna, G., Azais, A., Heran, M., 2013. Contribution of a submerged

membrane bioreactor in the treatment of synthetic effluent contaminated by Bisphenol-A:

mechanism of BPA removal and membrane fouling. Environ. Pollut. 180, 229-235.

29. Stalin, K. (2014). Performance of Rotating Biological Contactor in Wastewater Treatment–A

Review. International Journal of Scientific & Engineering Research, 5(1), 520-524.

30. Su, R., Zhang, G., Wang, P., Li, S., Ravenelle, R. M., & Crittenden, J. C. (2015). Treatment of

antibiotic pharmaceutical wastewater using a rotating biological contactor. Journal of

Chemistry, 2015.

31. Su, R.J.2010. “Study on treatment of canteen wastewater using rotating biological contactor,”

AdvancedMaterials Research, vol. 113-116, pp. 1597–1600.

32. Taseli, B. K, Gokcay C. F. and Gurol, A. 2008. “Influence of nickel (II) and chromium (VI) on

the laboratory scale rotating biological contactor,” Journal of Industrial Microbiology

andBiotechnology, vol. 35, no. 9, pp. 1033–1039.

33. Tawfik, A., Klapwijk, A., Gohary, F. El- and Lettinga, G. “Potentials of using a rotating

biological contactor (RBC) for posttreatment of anaerobically pre-treated domestic wastewater,”

Biochemical Engineering Journal, vol. 25, no. 1, pp. 89–98.

34. Tchobanoglous, G. Burton, F. L. and Stensel, H. D. 2003. Wastewater Engineering, Treatment,

Disposal and Reuse, Metcalf & Eddy- McGraw-Hill, 4th edition.

35. Torkian, A.,. Yazdani, O and Alinejad, K. 2003. “Treatability evaluation of municipal wastewater

and anaerobically-treated industrial effluent in a rotating biological contactor,” Industrial Journal

of Engineering, vol. 16, no. 6, pp. 16–22, 2003.

36. Vidal,N, Banares-Alcantara,R, Rodrıguez-Roda,I and Poch,M 2002.“Design of wastewater

treatment plants using a conceptual design methodology,” Industrial and Engineering Chemistry

Research, vol. 41, no. 20, pp. 4993–5005.

37. Wang,K, Liu, S, Zhang,Q and He,Y. 2009. “Pharmaceutical wastewater treatment by internal

micro-electrolysis-coagulation, biological treatment and activated carbon adsorption,”

Environmental Technology, vol. 30, no. 13, pp. 1469–1474.

38. Wilson, F., & Lee, W. M. (1997). Rotating biological contactors for wastewater treatment in an

equatorial climate. Water science and technology, 35(8), 177-184.

39. Yang,Y , Wang,P, Shi,S and Liu,Y. 2009. “Microwave enhanced Fenton-like process for the

treatment of high concentration pharmaceutical wastewater,” Journal of Hazardous Materials,

vol. 168, no. 1, pp. 238–245.

40. Yilmaz, G., Kaya, Y., Vergili, I., Gonder, Z.B., Ozhan, G., Celik, B.O., Altinkum, S.M., Bagdatli,

Y., Boergers, A., Tuerk, J., 2017. Characterization and toxicity of hospital wastewaters in Turkey.

Environ. Monit. Assess. 189.

41. Torkian,A, Yazdani,O and Alinejad, K. 2003.“Treatability evaluation Torkian et al.,2003; Zheng

et al.,2010 of municipal wastewater and anaerobically-treated industrial effluent in a rotating

biological contactor,” Industrial Journal of Engineering, vol. 16, no. 6, pp. 16–22.

42. Zheng, W. Li, X.M. , Hao, Z.M. , Wang, D.B. , Yang, Q. and Zeng, G.M. 2010. “Coal cinder

filtration as pretreatment with biological processes to treat pharmaceutical wastewater,” Water

Science and Technology, vol. 62, no. 1, pp. 15–20.

43. Yang, Y. Wang, P Shi,S and Y. Liu, Y. 2009.“Microwave enhanced Fenton-like process for the

treatment of high concentration pharmaceutical wastewater,” Journal of Hazardous

Materials,vol. 168, no. 1, pp. 238–245.

ISSN: 2005-4238 IJAST

4786

Copyright ⓒ 2020 SERSC

View publication stats

You might also like

- Indigenous Bacillus Paramycoides and Alcaligenes FDocument56 pagesIndigenous Bacillus Paramycoides and Alcaligenes Ftomisin adebanjoNo ratings yet

- Techno-Economical Evaluation of Coupling Ionizing Radiation and Biological Treatment Process For The Remediation of Real Pharmaceutical WastewaterDocument12 pagesTechno-Economical Evaluation of Coupling Ionizing Radiation and Biological Treatment Process For The Remediation of Real Pharmaceutical WastewaterMarita ElvinaNo ratings yet

- Biopolymer - A Sustainable and Efficacious Material System For Effluent RemovalDocument23 pagesBiopolymer - A Sustainable and Efficacious Material System For Effluent RemovalVeronica HernandezNo ratings yet

- Journalnx WasteDocument2 pagesJournalnx WasteJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- 1 s2.0 S2214714421001768 MainDocument11 pages1 s2.0 S2214714421001768 MainMihaiNo ratings yet

- Microalgae feasibility for industrial wastewater treatmentDocument52 pagesMicroalgae feasibility for industrial wastewater treatmentSacra PsyntergiaNo ratings yet

- Effect of Antibiotics On The Microbial Efficiency of Anaerobic Digestion of Wastewater: A ReviewDocument11 pagesEffect of Antibiotics On The Microbial Efficiency of Anaerobic Digestion of Wastewater: A ReviewCristian PîcălăuNo ratings yet

- Wastewater WetlandDocument12 pagesWastewater WetlandMuhammad MurtazaNo ratings yet

- Effluent Treatment System For Low Loads - Biodigester: Case StudyDocument7 pagesEffluent Treatment System For Low Loads - Biodigester: Case StudyIJAERS JOURNALNo ratings yet

- 1 s2.0 S2589014X21002693 MainDocument9 pages1 s2.0 S2589014X21002693 MainafrizalsatyapNo ratings yet

- Immobilization of Microbial Cells For The Biotreatment of Wastewater: A ReviewDocument17 pagesImmobilization of Microbial Cells For The Biotreatment of Wastewater: A ReviewEnas AlkhawajaNo ratings yet

- 1 s2.0 S095758202300825X MainDocument12 pages1 s2.0 S095758202300825X MainAbdullah SafiNo ratings yet

- In Tech Waste Water ChapterDocument16 pagesIn Tech Waste Water ChapterJames WachiraNo ratings yet

- Effectiveness of Algae in Wastewater Treatment SystemsDocument9 pagesEffectiveness of Algae in Wastewater Treatment SystemsIJRASETPublicationsNo ratings yet

- Nutrients Removal From Aquaculture Wastewater by Biofilter - Antibiotic-Resistant Bacteria SystemsDocument16 pagesNutrients Removal From Aquaculture Wastewater by Biofilter - Antibiotic-Resistant Bacteria SystemsEduard-Marius LungulescuNo ratings yet

- Microbiologia Articulo Comodin 1Document9 pagesMicrobiologia Articulo Comodin 1yennyNo ratings yet

- Current Advancement and Future ProspectDocument122 pagesCurrent Advancement and Future ProspectGILLES GOULEDEHINo ratings yet

- The Removal of Tetracycline From Water Using Biochar Produced From Agricultural Discarded MaterialDocument10 pagesThe Removal of Tetracycline From Water Using Biochar Produced From Agricultural Discarded MaterialRoshanNo ratings yet

- Recent Advances in Biochar ApplicationDocument34 pagesRecent Advances in Biochar ApplicationpreemeeNo ratings yet

- Recent Development of Advanced BiotechnologyDocument21 pagesRecent Development of Advanced BiotechnologyJuan Manuel RodriguezNo ratings yet

- Biochar Enhanced The Performance of Microalgae/bacteria Consortium For Insecticides Removal From Synthetic WastewaterDocument13 pagesBiochar Enhanced The Performance of Microalgae/bacteria Consortium For Insecticides Removal From Synthetic WastewaterggarzonjNo ratings yet

- Environment International: Review ArticleDocument13 pagesEnvironment International: Review ArticlevacomanoNo ratings yet

- 1 s2.0 S0013935123023046 MainDocument34 pages1 s2.0 S0013935123023046 MainkendlpNo ratings yet

- Wastewater Treatment With Microalgae A Literature ReviewDocument9 pagesWastewater Treatment With Microalgae A Literature ReviewgooietrifNo ratings yet

- Remediation of Noxious Wastewater Using Nanohybrid Adsorbent For Preventing Water PollutionDocument13 pagesRemediation of Noxious Wastewater Using Nanohybrid Adsorbent For Preventing Water PollutionMihaiNo ratings yet

- Mobile Solar Powered MembraneDocument12 pagesMobile Solar Powered MembraneDani Puji UtomoNo ratings yet

- Performance and Evaluation of Sewage Treatment Plant Based On MBBR and EBB TechnologiesDocument9 pagesPerformance and Evaluation of Sewage Treatment Plant Based On MBBR and EBB TechnologiesIJRASETPublicationsNo ratings yet

- Cold Plasma Technology: Advanced and Sustainable Approach For Wastewater TreatmentDocument21 pagesCold Plasma Technology: Advanced and Sustainable Approach For Wastewater Treatmenteze_firmatenseNo ratings yet

- Weerasooriyagedara 2022 Oxytetracycline RemovalDocument15 pagesWeerasooriyagedara 2022 Oxytetracycline RemovalIssaoui MansourNo ratings yet

- Reddy 2021Document18 pagesReddy 2021dineshkumar HICET STAFF CHEMICALNo ratings yet

- Science of The Total EnvironmentDocument9 pagesScience of The Total EnvironmentLaura Ximena Huertas RodriguezNo ratings yet

- 8. Uso de biocarbón y Moringa oleifera en el tratamiento de aguas grises para eliminarDocument10 pages8. Uso de biocarbón y Moringa oleifera en el tratamiento de aguas grises para eliminardora guzmanNo ratings yet

- Estimation of Nitrifying and Heterotrophic Bacterial Activity in Biofilm Formed On RASDocument12 pagesEstimation of Nitrifying and Heterotrophic Bacterial Activity in Biofilm Formed On RASMITESH JAISWALNo ratings yet

- Nutrients Removal From Aquaculture Wastewater by Biofilter/Antibiotic-Resistant Bacteria SystemsDocument17 pagesNutrients Removal From Aquaculture Wastewater by Biofilter/Antibiotic-Resistant Bacteria SystemsEduard-Marius LungulescuNo ratings yet

- Potabilización de AguaDocument9 pagesPotabilización de AguaSHEILA GINIVA BUSTOS YAIMANo ratings yet

- Purification of Wastewater by Metal Oxide NanoparticlesDocument12 pagesPurification of Wastewater by Metal Oxide NanoparticlesEditor IJTSRDNo ratings yet

- Algae Biorefinery - A Promising Approach To Promote Microalgae Industry and Waste UtilizationDocument16 pagesAlgae Biorefinery - A Promising Approach To Promote Microalgae Industry and Waste UtilizationBernardo RodriguesNo ratings yet

- Performance Assessment of Water Filtration Plants in Pakistan MDocument15 pagesPerformance Assessment of Water Filtration Plants in Pakistan MInternational Network For Natural SciencesNo ratings yet

- Helena Et Al (2023) Microalgae Systems - Environmental Agents For Wastewater Treatment and Further Potential Biomass ValorisationDocument15 pagesHelena Et Al (2023) Microalgae Systems - Environmental Agents For Wastewater Treatment and Further Potential Biomass ValorisationAldy KiatNo ratings yet

- Agua - WFI EndotoxinaDocument13 pagesAgua - WFI EndotoxinaraquelccaNo ratings yet

- Effluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseDocument7 pagesEffluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseIJRASETPublicationsNo ratings yet

- Effluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseDocument7 pagesEffluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseIJRASETPublicationsNo ratings yet

- Vol. 14 No. 1 Doi: ISSN: 1829 - 7285 E-ISSN: 2040 - 881XDocument10 pagesVol. 14 No. 1 Doi: ISSN: 1829 - 7285 E-ISSN: 2040 - 881XWanda AdamNo ratings yet

- Reuse of Wastewater For Irrigation Purposes - JBES 2021 by INNSPUBDocument12 pagesReuse of Wastewater For Irrigation Purposes - JBES 2021 by INNSPUBInternational Network For Natural SciencesNo ratings yet

- Culturing The Uncultured Microbial Majority in Activated Sludge: A Critical ReviewDocument26 pagesCulturing The Uncultured Microbial Majority in Activated Sludge: A Critical ReviewmizbaNo ratings yet

- 1 s2.0 S004896972307451X MainDocument19 pages1 s2.0 S004896972307451X Mainfatimarpri18No ratings yet

- Influence of Three Microalgal Based Cultivation Technologies On Different Domestic Wastewater and Biogas Purification in PhotobioreactorDocument10 pagesInfluence of Three Microalgal Based Cultivation Technologies On Different Domestic Wastewater and Biogas Purification in PhotobioreactorAslıhan KayaNo ratings yet

- Role of Environmental Biotechnology in Decontaminating Polluted WaterDocument15 pagesRole of Environmental Biotechnology in Decontaminating Polluted Waterani putkaradzeNo ratings yet

- Water Reuse and Aquaculture Pharmaceutical BioaccuDocument10 pagesWater Reuse and Aquaculture Pharmaceutical BioaccuevelynNo ratings yet

- Admin, 5 PDFDocument21 pagesAdmin, 5 PDFNiwat PhassayawanNo ratings yet

- Process Safety and Environmental Protection: Malihe Barahoei, Mohammad Sadegh Hatamipour, Saeed AfsharzadehDocument12 pagesProcess Safety and Environmental Protection: Malihe Barahoei, Mohammad Sadegh Hatamipour, Saeed AfsharzadehAbeer El ShahawyNo ratings yet

- 5 Ijietjun20195Document8 pages5 Ijietjun20195TJPRC PublicationsNo ratings yet

- Design and Applications of Photobioreactors - A ReviewDocument12 pagesDesign and Applications of Photobioreactors - A ReviewJoan BNo ratings yet

- 3 - Resource Recovery From Wastewaters Using Microalgae-Based ApproachesDocument15 pages3 - Resource Recovery From Wastewaters Using Microalgae-Based ApproachesElena Rojo de BenitoNo ratings yet

- Biotechnology Reports: Liliana Delgadillo-Mirquez, Filipa Lopes, Behnam Taidi, Dominique PareauDocument9 pagesBiotechnology Reports: Liliana Delgadillo-Mirquez, Filipa Lopes, Behnam Taidi, Dominique PareauHasnanurfajriahNo ratings yet

- 2021-Recent Advances in Polysaccharide-Based Adsorbents For Wastewater TreatmentDocument27 pages2021-Recent Advances in Polysaccharide-Based Adsorbents For Wastewater TreatmentCARLOS ALBERTO RAMIREZ BARRAGANNo ratings yet

- 2020 - Artigo - ProcessSafetyEnvProtectionDocument11 pages2020 - Artigo - ProcessSafetyEnvProtectionBárbara RicciNo ratings yet

- Document 13Document8 pagesDocument 13Kaira Patel 653No ratings yet

- Engineered BiocharDocument27 pagesEngineered BiocharDiệu Trần HươngNo ratings yet

- Soal Bahasa Inggris 7,8,9Document5 pagesSoal Bahasa Inggris 7,8,9Jo windyNo ratings yet

- Theories of AgingDocument6 pagesTheories of AgingBamba FloresNo ratings yet

- b2 Open Cloze - EpidemicsDocument3 pagesb2 Open Cloze - EpidemicsJose Manuel Morín BarriosNo ratings yet

- Pharmacy Service VA Design Guide: Final DraftDocument75 pagesPharmacy Service VA Design Guide: Final DraftAhmad Gamal Elden MAhanyNo ratings yet

- Parte 2 Segundo ParcialDocument23 pagesParte 2 Segundo ParcialJose Luis Rasilla GonzalezNo ratings yet

- Maritime Business Environment AssignmentDocument4 pagesMaritime Business Environment AssignmentsivaNo ratings yet

- Long Life Lithium Battery TitleDocument2 pagesLong Life Lithium Battery Titleluis_claudino6263No ratings yet

- Panelboard O&M ManualDocument7 pagesPanelboard O&M Manualchris100% (1)

- Road Kill Cafe MenuDocument1 pageRoad Kill Cafe MenuwjannuschNo ratings yet

- Math ProjectDocument18 pagesMath ProjectChar LotteNo ratings yet

- Tiic Interest RateDocument3 pagesTiic Interest RatePriyaNo ratings yet

- Petition For Modification of Child Support Order (Administrative Hearing)Document3 pagesPetition For Modification of Child Support Order (Administrative Hearing)Shared EmailNo ratings yet

- Intro To Psychology Crash Course Psychology 1Document3 pagesIntro To Psychology Crash Course Psychology 1Hahaha YeahNo ratings yet

- Lwtech HR Management FlyerDocument2 pagesLwtech HR Management FlyerAshlee RouseyNo ratings yet

- Pharmacy CUM L IIIDocument78 pagesPharmacy CUM L IIIashagrie100% (1)

- Aims & ObjectiveDocument80 pagesAims & Objectivevishaldhande007No ratings yet

- Genetic Disorders Project Rubric 17-18Document3 pagesGenetic Disorders Project Rubric 17-18api-394564312No ratings yet

- FliesDocument14 pagesFliesaguilarmvzNo ratings yet

- Ecb Recovery PlanningDocument20 pagesEcb Recovery PlanningMohamed MostafaNo ratings yet

- SS - 578 - 2012 - Use and Maintenance of Fire ExtinguishersDocument24 pagesSS - 578 - 2012 - Use and Maintenance of Fire Extinguishersrasanavaneethan100% (4)

- FLCCC Alliance's I RECOVER Management Protocol For Long Haul COVID 19 SyndromeDocument3 pagesFLCCC Alliance's I RECOVER Management Protocol For Long Haul COVID 19 SyndromeAlan N100% (1)

- Course Outline Cybersecurity FundamentalsDocument6 pagesCourse Outline Cybersecurity FundamentalsshanawsjNo ratings yet

- Inflammatory Bowel DiseaseDocument27 pagesInflammatory Bowel DiseaseMihai VladescuNo ratings yet

- Topic 3 BRUNEI The Oilfields LabourersDocument3 pagesTopic 3 BRUNEI The Oilfields LabourersRichmond BlancoNo ratings yet

- Case Study 2 MNTDocument11 pagesCase Study 2 MNTapi-242547654No ratings yet

- Hirschmann Connectivitiy CatalogDocument387 pagesHirschmann Connectivitiy Catalogstevenchan22No ratings yet

- Solar SystemDocument27 pagesSolar SystemSheena Jane Tioc100% (1)

- Handbook AdhesiveDocument68 pagesHandbook Adhesivec100% (2)

- IJST - Vol (7) - No (4) December 2012Document153 pagesIJST - Vol (7) - No (4) December 2012Taghreed hashim AlnoorNo ratings yet

- Long-Term Memory - ProcessDocument30 pagesLong-Term Memory - ProcessALEXANDRA SAN PEDRONo ratings yet