Professional Documents

Culture Documents

Engine Life Optimization Final Document Version 00 8-9-21

Uploaded by

shivOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Life Optimization Final Document Version 00 8-9-21

Uploaded by

shivCopyright:

Available Formats

Engine Life Optimization Process

AUTHOR: Jared Black

CONTRIBUTORS: Kevin Bowers, Dan Brandt, Brian Beyer

DATE OF PUBLICATION: 1 June 2021

VERSION: 00

Caterpillar: Confidential Green

Contents

Executive Summary ....................................................................................................................................... 3

Process Map .............................................................................................................................................. 3

Intended Audience .................................................................................................................................... 3

Identification of the Customer and Opportunity .......................................................................................... 4

Sources ...................................................................................................................................................... 4

Selection Considerations........................................................................................................................... 5

Establishing the Charter ................................................................................................................................ 7

Team ......................................................................................................................................................... 7

Charter Refinement .................................................................................................................................. 8

Measuring the As-Is Condition ...................................................................................................................... 8

Measurements .......................................................................................................................................... 8

Delineating the Fleet ..................................................................................................................... 8

Site .............................................................................................................................................. 10

Customer ..................................................................................................................................... 10

Dealer .......................................................................................................................................... 10

Caterpillar.................................................................................................................................... 11

Development of the Life Optimization Program......................................................................................... 13

Key Activities ........................................................................................................................................... 13

Other Considerations .............................................................................................................................. 14

Program Commercial Agreements and Establishment of Metrics ............................................................. 14

Key Activities ........................................................................................................................................... 15

Implementation .......................................................................................................................................... 16

Key Activities ........................................................................................................................................... 17

Control ........................................................................................................................................................ 17

Key Activities ........................................................................................................................................... 18

Example ................................................................................................................................................... 18

Conclusion ................................................................................................................................................... 20

Caterpillar: Confidential Green

Executive Summary

Engine Life Optimization is a process that focuses on achieving the lowest Total Cost of Ownership (TCO)

over the life of an asset by determining the most efficient timing of component replacements and

engine rebuilds. In many cases this effectively translates to extending the life of the engine while

simultaneously minimizing risk and enhancing productivity. Engine Life Optimization fits under the

umbrella of Engine Fleet Management as the final step in the future planning pillar. The process

requires a close working partnership between the customer, dealer, and Caterpillar and it relies heavily

upon the foundational pillars of Engine Fleet Management (Figure 1) and key enablers (Figure 2).

Process Map

Identification of the Customer and Opportunity

Establishment of the Charter

Measuring the As-Is Condition

Development of the Life Optimization Program

Engine Field Trial Agreements and Establishment of Metrics

Implementation

Control

Intended Audience

This process instruction is written for those who will sponsor, lead, and sustain Engine Life

Optimization projects. It is not an exhaustive document, but provides the framework, process,

reference tools, and examples for successfully optimizing engine life.

Figure 1: Foundational Pillars of Engine Fleet Management.

Caterpillar: Confidential Green

Figure 2. Key enablers for successfully optimizing engine life.

Identification of the Customer and Opportunity

Quantitative evidence has clearly established that the most successful sites are those at which the

customer demonstrates a strong loyalty and willingness to work with Caterpillar and the local dealer.

Caterpillar possesses deep product domain expertise and the ability to capture customer and dealer

critiques and pain and answer those challenges with engineering solutions. The dealer has

maintenance, operational, and rebuilding expertise, while the customer brings site knowledge, product

experience, a significant data set, and key performance indicators to the table. When these elements

are combined and communication paths are established, life optimization succeeds. Note that in cases

where the dealer has a CVA (Customer Value Agreement) with the customer, the dealer will fill many or

most of the traditional roles that the customer would otherwise fill when a CVA is not in place.

Sources

Customer: The customer may approach Caterpillar or the dealer directly and request

assistance in extending engine life. This often occurs when engine life is not meeting the

understood OMM (Operating and Maintenance Manual) target, engine life is perceived as

not matching a competitive product life, or additional life has become a customer

expectation. At a site with a strong CVA it may be the dealer that fills this role.

Caterpillar Commercial Product Groups: Large Mining Trucks, as an example, may approach

LPSD and suggest a customer that would benefit from an engine life optimization program:

particularly, those customers that are loyal, have opportunity for fleet replacements, or

could benefit from a CVA.

Caterpillar LPSD: It may be recognized that a certain customer and/or site could benefit

from extending the planned life of Caterpillar engines. This requires working with

Caterpillar: Confidential Green

Caterpillar commercial product groups to engage the customer and dealer in an engine life

optimization program.

Selection Considerations

Customer Considerations

1. Define the customer loyalty, history, and engagement.

2. Has the Next Best Customer Pugh Matrix (Figure 3) been completed and what is the

score and relative ranking?

3. Are there any roadblocks to a close working relationship between the customer, dealer,

and Caterpillar? These may need to be addressed prior to an Engine Life Optimization

project launch.

4. Does the customer and/or dealer have the necessary resources, and what are the

current communication tools in place [e.g. dealer technical services, condition

monitoring, monthly PPM (Product Problem Management) meeting]?

Caterpillar Resources

1. Does Caterpillar have a Site Performance Manager (SPM), or Fleet Manager (FM)

imbedded with the customer?

2. Does Caterpillar have an Account Manager and Technical Representative that works

closely with the customer and site/s?

3. Does LPSD have an Engine Field Engineer as a resource who knows the customer and

has been engaged with the other Caterpillar resources?

Figure 3. Next Best Customer - Pugh Matrix may help in determining prioritization of Engine Life Optimization Projects.

Caterpillar: Confidential Green

Dealer Capability and Capacity

1. What is the current working relationship between the local dealer and customer? What

is the current working relationship between any on site dealer resources, the dealer’s

rebuild facility, and the dealer’s technical services?

2. Does the dealer have a continual presence or dedicated resources (such as a dealer SPM

or FM) at the site, and what is the nature of any agreements in place?

3. Does the dealer have a CVA with the customer and fill many of the roles that would

otherwise be customer responsibilities?

4. Does the dealer have any Caterpillar certifications for their rebuild facilities, or has a

Large Engine Rebuild Assessment been completed?

Opportunity

1. A cursory review of engine removals (hours to removal - planned and unplanned, engine

source (i.e. new, reman, or dealer rebuild) over the previous three years is helpful in

defining the opportunity (Figure 4).

2. A high-level analysis of the stated reasons for the unplanned engine removals is key

information for those looking to launch an Engine Life Optimization project.

3. A review of failure analysis reports should be completed for any engine removals that

are unexplained or deviate from understood historical failure modes.

Figure 4: An example of a visualization that will help in understanding the opportunity that a customer has for an Engine Life

Optimization Project.

4. An interview should occur with the site-supporting LPSD field engineer.

5. Line of sight should exist for engine life optimization commensurate with the current

fleet, capabilities, and realistic customer expectations. A fleet that is already achieving

life well beyond the OMM guidelines is not a sensible choice for a life optimization

project, but may benefit from other aspects of Engine Fleet Management.

Summary

These are the basic questions that should be answered and activities that should occur prior to

selecting a customer as a life optimization candidate. A negative response to any of these

Caterpillar: Confidential Green

questions is not intended to rule out a customer, but necessitates actions, built into the Engine

Life Optimization Program, to resolve deficiencies, remove roadblocks, and further define the

opportunity so that expectations are aligned among the partners.

Establishing the Charter

Once the customer and opportunity have been identified for engine life optimization, a charter for the

project must be created (Figure 5). A charter should consist of a Business Case, Opportunity Statement,

Goal Statement, the Scope, a Project Plan (i.e. timeline), and Identification of the Team. The initial work

involved with identifying the customer and opportunity should be refined and flow into the Business

Case and Opportunity Statement. The Goal statement is simply one side of the equation (i.e. what

defines success?). The scope limits engine assets and locations which the goal will be applied to. The

plan or project timeline provides a basic expectation for when the project will reach certain

accomplishments and be completed. This should all be accomplished at a high level and some of the

boxes can remain vacant, as once the team is defined the Charter will be further developed and refined.

Figure 5. This is an outline of a charter and the information that should be included in each section. Additional example

charters are available in the Engine Life Optimization Process folder.

Team

Careful attention should be given to choosing a team. The Team Leader should be chosen first and once

that individual has reviewed or created the charter, he/she should be involved in choosing additional

team members, stakeholders, SMEs, and the process owner(s). Engine life optimization objectives are

more likely to be realized if the Team Leader has a working knowledge of the engine application,

customer site(s), dealer support, and Caterpillar support, or has previous experience as a life

optimization project team member. Having experiential knowledge in at least a portion of these

domains will provide the Team Leader with advantages in credibility and time savings.

Caterpillar: Confidential Green

Remember

The project folder has many useful examples and templates.

Charter Refinement

Once the Team has been formed and the stakeholders and process owners have been identified, the

project charter should be given additional substance. Refining the project charter should begin with

specific attention given to:

1. Scope – What information should be gathered early on to refine the scope if necessary?

2. Goals – Once the scope is defined the goals and goal inputs, or the other side of the goal

equation, can start being specified.

3. Plan – Finally, the rough project timeline can be established.

Remember

1. After the team has been established and the charter has been refined a RACI Matrix can be

a beneficial tool for the team, particularly if it is a larger team with working members from

the customer, dealer, and Caterpillar.

2. Each section of the charter should be periodically reviewed throughout the life of the

project. This simple activity can provide direction, assist in rationalizing actions, and remind

the team of resources.

3. The inputs to the goals can and should be revised throughout the evaluation of the

customer site(s) and assets process, as additional information comes to light.

Measuring the As-Is Condition

Developing a comprehensive and effective Life Optimization Program starts with understanding the As-

Is condition. Collecting and reviewing fleet, application, site, customer, dealer, and Caterpillar

information are all key characteristics that will flow into solidifying the project charter, identifying

deficiencies, and developing the Life Optimization Program. It is helpful to collect and analyze this

information and fill out a process capability chart as part of the measure phase of the project.

Measurements

Delineating the Fleet

During the Customer and Opportunity Identification phase some of this work will have already

been completed, however a deeper dive into the data is warranted and a comparison should be

made to similar assets and then further refined to similar site operating conditions. Engines or

assets should be separated into like groups and key information gathered.

1. Type, Size of Fleet, and Age of the Assets (Figure 6)

2. Physical Availability and Mechanical Availability of the Assets

3. Engine Unscheduled Downtime and Engine Scheduled Downtime (% points)

Caterpillar: Confidential Green

Figure 6: Knowing type, size of the fleet, and the average age of the assets is instructive and should be documented in this phase.

Figure 7: Other methods of delineating the fleet so team members and others understand and have reference materials.

Caterpillar: Confidential Green

4. Load Factor Analysis (Fuel burned per hour of operation - seasonality)

5. Scheduled and Unscheduled Engine Removals (Hours and reason) ≥ 3 years (Figure 4)

6. Application – Ambient Temperature, Barometric Pressure, Operating Environment (ex.

dirt accumulation, dust, moisture conditions)

7. Engine history (new, reman, dealer rebuild, and 1 st, 2nd, and 3rd engine rebuild) (Figure 7)

Site

The site evaluation is a combination of inputs that is best outlined by the pillars of Engine Fleet

Management (Figure 1). Each category of the pillars should be reviewed to define and

characterize the customer or dealer activity and documented standard work that addresses

each (Engine Fleet Management Matrix). The Engine Fleet Management document will clarify

fundamental principles for each category. Keep in mind that this should be accomplished for

each engine platform and site included within the scope of the project charter. The Engine Fleet

Management Matrix check sheet that is part of the Engine Fleet Management Workbook

identifies activities, standard work, and if roadblocks are present in each category and allows

the user to document the nature of each. Answers to these questions will flow directly into the

Life Optimization Program as recommendations for refinement or establishment of standard

work in each category.

Customer

It is important to understand the customer and document goals and expectations. Remember

that these may change over time and can be strongly influenced by business conditions. The

SPM may have a Site Performance Strategy document will have most of this information. These

documents should include:

1. A list of customer goals at each site for each engine group (ex. alignment of engine

rebuilds with transmission or generator rebuild, lowest cost rebuilds, highest engine

hours possible while maintaining low failure risk, highest possible production, etc.).

2. The Key Performance Indicators (KPIs) that the customer measures and puts emphasis

on should also be understood and recorded (MTBF, Availability, Unscheduled downtime,

etc.).

3. The customers perceived reasons for meeting or underperforming KPIs or other

expectations should be documented.

4. A review of any commercial agreements should be completed as these may further

define expectations.

Dealer

The dealer and customer often have a close working relationship. The dealer will ordinarily have

an onsite imbedded presence and an offsite supporting structure (ex. Technical Services,

Component Rebuild Center, Condition Monitoring). The site evaluation using Engine Fleet

Management will answer questions pertaining to the onsite dealer support and the dealer may

be the source for a large portion of the Engine Fleet Management Pillars evaluation and may

further include KPIs or goals, particularly at sites with Customer Value Agreements (CVAs). The

off-site supporting services should be evaluated to determine their overall effectiveness in

supporting and sustaining any Life Optimization Program.

Caterpillar: Confidential Green

1. A Large Engine CRC Assessment of the Dealer’s Component Rebuild Center (CRC) should

be completed and analyzed to determine overall capability and capacity. The LPSD field

engineering team is the best resource to schedule and complete this analysis of the

dealer CRC. Cat Inspect should be utilized to complete the assessment and determine if

the dealer CRC has in place foundational, advanced, or best in class solutions. This

information can then be put to use in the Engine Life Optimization Workbook which will

be used to develop the Engine Life Optimization Program. In areas where foundational

practices are not in place recommendations will be made, and actions taken to enhance

the dealer capabilities.

2. Dealer or customer capabilities in condition monitoring should also be evaluated using

the principles and structure set forth in Engine Fleet Management. Current condition

monitoring (data, recommendations, and prioritization) should be evaluated by LPSD or

a Caterpillar commercial condition monitoring team. Depending upon the evaluation, it

may be necessary to have the LPSD Analytics group condition monitor assets for a time

to understand dealer or customer capabilities and make recommendations.

Caterpillar

Consist Analysis, failure history, component condition, understanding the load factor, and key

component change intervals during the life of the engine are all used within Engine Fleet

Management and are essential to any Life Optimization Program development.

1. Caterpillar knows the consist of each asset as it leaves the factory, providing initial

conditions, but loses this traceability as components are changed in the field and as

dealers rebuild engines. By maintaining an up to date consist (parts and/or SNs) of key

components that make up the engine, Caterpillar can cross reference known failure

modes and corresponding CPI (Continuous Product Improvement) projects and fixes.

This information should then be used in developing a plan for each asset and those

assets that have the least risk, or if the risk of failure is able to be mitigated, can be

selected for Life Optimization. This continual tracking of the consist produces a

historical record that Caterpillar can also utilize to reveal part, application, or site-

specific failures modes. Equipped with traceability information, additional data analysis,

testing, or inspections may also be warranted (Engine Tracking File)(Figure 8).

Figure 8: Engine consist analysis and part traceability are important aspects of Engine Life Optimization. This is one example

of tracking engine component changes and service letter applications. Additional example spreadsheets are in the folder.

Caterpillar: Confidential Green

2. Another important aspect of Engine Life Optimization is understanding wear rates and

component condition at engine or subcomponent teardown. The dealer CRC

(Component Rebuild Center) and Caterpillar must work together to gather and analyze

data and subject matter experts should be utilized for detailed part examinations to

determine the amount of life remaining (Figure 9). The engine consist and traceability

information play an important role in this analysis as parts will need to be checked for

hours of operation and special conditions that may have occurred.

Figure 9: Component condition analysis during engine teardown is an important part of measuring the As-Is conditions.

Detailed inspection of parts will reveal life-limiting wear conditions and provide the team with an understanding of risk,

necessary inspections, and possible parts changes required to reach the life optimization goals.

3. A load factor analysis and the expected fuel burn at full life should be considered. The

Operating and Maintenance Manual provides general engine life guidance for hours and

total fuel burn commensurate with a typical high fuel burn rate for the application.

These values are recommendations, but as the fuel burn (i.e. load factor) deviates from

this value, and as the pillars of Engine Fleet Management are utilized, adjustments can

be made to optimize the engine life.

4. Certain subcomponents of the engine have limited life, depending upon the engine

platform and application, and are expected to be changed as part of normal

maintenance (e.g. turbos, fuel pumps, injectors, alternators, etc.). Reviewing historical

failure information, condition at teardown, and maintenance intervals of these

subcomponents is important, as it allows the alignment of the life between these

subcomponents and the engine itself. For example, if the high pressure fuel pump life is

known to be approximately 12K hours at a site, then attempting to run the engine to

26K hours and having to consume 3 high pressure fuel pumps during the life of the

engine will drive up TCO and reduce asset availability.

During the last stages of measuring the As-Is condition it is valuable to review the charter and

ensure consistency between the scope, goal statement, and timeline and what has been

accomplished to this point in time by the team.

Caterpillar: Confidential Green

Development of the Life Optimization Program

Developing the plan for optimizing engine life will flow directly out of measuring the initial conditions,

understanding customer goals and expectations, and analyzing the capabilities of current standard work.

Once the measure phase of the project has defined the As-Is condition using the Engine Fleet

Management Workbook an evaluation of the activities and standard work of the customer, dealer, and

Caterpillar, in each of their responsible areas, can be completed. The Life Optimization Program is then

developed as the evaluation reveals no actions are in place, or that current activities are deficient or lack

consistency, or the standard work is not adequately documented or unknown. Engine Fleet

Management should be used to evaluate and create recommendations for the Life Optimization

Program for both the customer and dealer in their respective areas of responsibility. CRC Best Practices

and the Large Engine CRC Assessment should be used to evaluate and make recommendations for the

off-site dealer activities. Caterpillar should ensure that failure modes are addressed through CPI

projects, that proven fixes are in place (documented and parts are available), and that the consist of

each engine has been analyzed to determine failure risk. In addition to recommended actions a

communication plan should be outlined ensuring that robust and consistent communication occurs after

the Life Optimization Program has been implemented.

Example: C175 Life Optimization Process

Example: 3500 Life Optimization Process

Key Activities

Generate a workbook with initial conditions for each of the customer, dealer, and

Caterpillar measured As-Is conditions and dividing them into their three respective

groups (Engine Fleet Management Workbook).

Rank each activity and standard work documentation that the customer, dealer, and

Caterpillar has in place:

1. Standard Work Documented (Yes/Deficient/No)

2. Execution (Yes/Deficient/No)

3. Short Description of the Deficiency, Roadblocks

Each engine should be analyzed by Caterpillar to establish failure risk and define a

mitigation plan. This may include:

1. Scheduled Inspections and Measurements

2. Required Parts or Component Changes with a Schedule

3. Targeted Condition Monitoring

4. A ranking of risk for each engine in the fleet and the extent of required

mitigation (e.g. Low, Medium, and High) will help in establishing a control or

pilot group of engines for increased PCR life

The load factor analysis that was completed during the measure phase of the

project should be further studied to determine if the As-Is condition will change

over time due to operational changes (e.g. a downhill haul changing to an uphill

Caterpillar: Confidential Green

haul). A subject matter expert in the application and engine platform should be

consulted and site-specific information should be considered. This will allow

adjustments to be made to engine life expectations (i.e. PCR hours) over time as fuel

burn rates may change.

Alignment of engine subcomponent replacements with the full engine life is

necessary to ensure the lowest TCO and highest availability of the asset while

optimizing the engine life. Each life-limited subcomponent (e.g. midlife

subcomponent) should be considered in this analysis. Additional actions to

condition monitor, increase component life, or adjustments to maintenance

intervals for these subcomponents will be necessary for Engine Life Optimization.

Other Considerations

There are many other recommendations that can be included within a Life Optimization

Program outside of the purview of this document. A Site Performance Manager or Fleet

Manager will be helpful in determining other gaps in processes that may be affecting

engine life. Some examples of other recommendations include:

1. Customer Site Evaluation (e.g. SPM Site Strategy Document)

2. Operator Training

3. Production Studies

4. Maintenance Strategy Review

5. Technician Training

6. Contamination Control Auditing

7. Parts Stocking Review and Recommendation

The team has worked together for some time and understands the pre-existing

framework for communication between the customer, dealer, and Caterpillar.

Using as much of the existing communication structure as is reasonable (i.e. PPM

meetings and who leads them), an outline of a communication plan with

recommendations for any additional meetings should be established. This is simply

an outline with defined responsibilities so that as the project moves into the

implementation phase the evolving team can take recommendations to results.

Program Commercial Agreements and Establishment of Metrics

Once the Life Optimization Program has been developed and well documented, commercial agreements

can be produced, and metrics established. The customer, dealer, and Caterpillar will need to agree on,

or refine for agreement, the recommendations made in the Life Optimization Program. Each party

should have actions or standard work that must be implemented to achieve engine life optimization. It

is encouraged that the Life Optimization Program include a commercial agreement that applies to a

control group of engines, sometimes referred to as a pilot. It is important that all the Caterpillar

partners who are involved with the customer and dealer regarding the engines or powered assets be

involved in developing or reviewing these commercial agreements. It is recommended that Caterpillar

LPSD condition monitoring be applied to any pilot group of engines for data collection and advanced

analytics for an initial period of observation, and that recommendations and urgency of action be

Caterpillar: Confidential Green

communicated through the dealer. This engine condition monitoring is a key enabler to the success of

the life optimization program and will be a powerful tool in determining product, operational, and

maintenance related issues. It is most effective when a communication tool or meeting is established to

review the recommendations, urgency, and resolutions. This is likely to result in parts being returned to

Caterpillar for failure analysis and additional planning for special conditions to occur in the Future

Planning Pillar of Engine Fleet Management (Figure 1).

Key Activities

Attain agreement on the Life Optimization Program recommendations that will turn

into actions or standard work for the customer, dealer, and Caterpillar. When a

strong relationship exists many of the recommendations will likely already be

underway or will have been implemented.

Define the primary and secondary metrics that will be used to describe success

based on the customer goals that were documented during the measure portion of

the process [e.g. Primary = PCR hours for a Control Group, Secondary = MTBFEngine

(Mean Time Between FailureEngine), % Points of Unscheduled Engine Downtime and

Included Components/Systems, Maintenance and Repair Cost per Hour]. Having

secondary metrics is important as it ensures that Life Optimization of the engine

does not come at the expense of other customer goals.

Select the Engines that constitute the Control Group / Pilot:

1. This Pilot is typically the subset of Engines from Caterpillar’s engine consist

analysis that have the lowest risk and least disruptive risk mitigation plan.

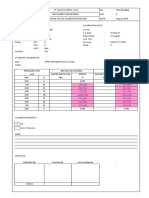

2. Field test agreements should be written and signed for each asset that clearly

define the responsibilities of the customer, dealer, and Caterpillar regarding

each engine (Figure 10).

Caterpillar: Confidential Green

Figure 10: This is the beginning of an example commercial test agreement. Note that machines and engines should be identified

by serial number, and by customer specific unit ID.

Implementation

The Life Optimization Program has been refined and agreed upon, and commercial test agreements for a

control group of engines have been created and signed. The team now moves into the implementation

stage of the project and will require some changes or additions in resources (Figure 11). The changes in

the team should be closely tied to the recommendations agreed upon in the Life Optimization Program.

Each recommendation should have an individual(s) listed who will be responsible for ensuring the

agreed upon changes are implemented from the Engine Fleet Management Workbook.

Figure 11: It will be important to establish an implementation team and define supporting roles where necessary. Most of these

individuals will come directly out of the Engine Fleet Management Workbook responsible parties for each recommendation

listed.

Caterpillar: Confidential Green

Once these individuals have been identified and are part of the team, the order and complexity of

implementation of each recommendation should be established. Easily implemented standard work or

actions that are enablers for other recommendations should be accomplished first, and changes to

engine consists that are part of the control group and are time sensitive should be completed early in

the program implementation. At this point the communication plan outlined at the end of the Engine

Life Optimization Program portion of this document should be revisited, further defined, and put into

action. The implementation stage of the project requires heightened communication between a larger

implementation team and application of change management principles. Each agreed upon

recommendation should have actions listed with responsible parties, completion dates, a status, and

change management activities all defined. A regularly scheduled meeting should be established, or a

portion of an existing meeting should be used to report on each recommendation, the status of the

actions taken, and the time frame to completion of the recommendation. This will ensure that

roadblocks are resolved or that additional attention and resources can be deployed as required.

Key Activities

1. List the individuals who will be responsible for ensuring execution of the

recommendations set forth in the Life Optimization Program and add those

individuals to the team. Ensure they have time to review the recommendations for

which they will be responsible.

New team members should be selected carefully based on their disposition

toward trying new or changing existing processes. The last challenge you want

to face at this point is an idea assassin. Critical review is merited, but without

changes in activities or to standard work, there should be no expectation of an

improvement in results.

2. Evaluate the order and complexity of each customer, dealer, and Caterpillar

recommendation and begin execution.

3. Control Group engine consist changes should begin immediately, and any enhanced

condition monitoring should be implemented simultaneously.

4. Control Group inspections should be planned, and work orders written as necessary.

5. A communication plan is important for program implementation success.

Depending upon the number of agreed upon recommendations, it may be necessary

to break up these meetings into smaller and more manageable groups. Remember

that these meetings are about putting recommendations into action and require

recommendation, actions listed, responsible parties, completion dates, a status, and

change management activities.

Control

Significant amounts of work have occurred to bring the Life Optimization Program through the

implementation phase. However, some longer-term activities are still ongoing – particularly dealer and

Caterpillar actions related to design changes, end-of-life iron evaluations, consist updates due to CPI,

condition monitoring, and consideration for extracting additional life from the engine. In addition to

these ongoing actions, reviews should be scheduled for the customer, dealer, and Caterpillar team

members, to ensure that the implemented standard work is effective and ongoing at the customer and

Caterpillar: Confidential Green

dealer and ownership of these reviews defined. Each of the metrics identified in the Commercial

Agreements and Metrics Identification portion of the project should also be periodically assessed to

determine the effectiveness of the Life Optimization Program and any weakness in the metrics should

be analyzed to determine causation. It takes time (months and years) for the benefits of a life

optimization program to be fully realized, so it is important that the team create a graduated plan for re-

evaluation of the standard work, metrics, engine consists, condition monitoring, PCR iron review,

consideration for additional life extension, and have a defined responsible party to ensure these actions

are taken. This should fit within an overall Project Governance plan (Figure 12) and the responsibility for

these actions should be led by the Site Performance or Fleet Manager from Caterpillar and will ideally

include a small team with some of the original team members.

Figure 12: Project Governance will be helpful throughout the life of the project. It becomes especially useful in the

implementation and control phases when team members and overall responsibilities change.

Key Activities

1. Close to the conclusion of the implementation phase of the project the team should

define a graduated schedule for review of the standard work, metrics, engine

consists, and PCR iron review, condition monitoring, and have a defined responsible

party to ensure these actions are taken.

Example

Customer Review (Standard Work), Metric Review – 2 Months after Project

Completion: Team Leader

Dealer CRC Large Engine Assessment Update – 3 Months after Implementation

Phase: Field Engineer

A review of Condition Monitoring Data on Control Group – 3 Months after

Implementation Phase: Dealer Designate and Field Engineer

Engine Consist Review: 4 Months after Project Closure: Dealer Designate and

Field Engineer

Customer Review (Standard Work) and Metric Review – 6 Months after Project

Closure: Site Performance Manager

Caterpillar: Confidential Green

Dealer CRC Large Engine Assessment update 9 Months after Project Closure:

Dealer Designate

Consideration for additional engine life as assets achieve previously targeted

hours or fuel burn (Figure 13).

Note: The Site Performance Manager or Fleet Manager should be the

responsible party ensuring these actions are taken by each designated party at

the assigned time, after the Team Leader has completed the initial (2 Month)

review.

2. As benefits are realized from engine consist changes, inspections, and condition

monitoring of the control group of engines, the dealer, Caterpillar Technical

Representative, and LPSD Field Engineer should not hesitate to engage the

customer and dealer to continue with applying these benefits to the broader group

of engines. It may make sense to apply many of the learnings of the pilot group to

additional engines outside of the scope of the commercial agreements.

3. Condition monitoring information and PCR Iron review should have some additional

defined ongoing activities that provide information back to Caterpillar for continued

enhancement of the product.

4. A thorough search of CPI issues using the CPI website for SN prefixes and

subsequent consist analysis for the application of those fixes should be done to

evaluate each engine in the pilot group and for the entire fleet of engines. This kind

of targeted analysis will go a long way with the customer.

5. As engine assets achieve the initial targeted life (hours or fuel burn) customers

and/or dealers may want to extend the life of the asset beyond the original target

based on what has been learned during the project and as a result of Engine Fleet

Management benefits. When this situation occurs, it is important to apply an asset

specific methodology [e.g. Engine Life Optimization – Extending Life (Figure 13)],

which will answer questions in key areas and help make an informed decision.

Caterpillar: Confidential Green

Figure 13: As engine assets reach targeted hours for rebuild consideration using the Engine Life Optimization – Extending Life

should be used to evaluate the validity of increasing engine life.

Conclusion

When these process steps are followed and there is collaboration between the customer, dealer, and

Caterpillar, Engine Life Optimization becomes a reality. Customers and dealers will vary in business

structure, goals, capabilities, resources, and methods of communication, so each Life Optimization

Program will need to be tailored accordingly. Engine Fleet Management provides the framework, and

Engine Life Optimization provides the process to extract the most value out of Caterpillar engines.

Caterpillar: Confidential Green

You might also like

- Cat Dealer Contamination Control Compliance GuideDocument221 pagesCat Dealer Contamination Control Compliance GuideIrham Faisal100% (2)

- BP Publication Backlog Management Rev01Document14 pagesBP Publication Backlog Management Rev01leaw81No ratings yet

- SOS Service Fluid Analysis PDFDocument12 pagesSOS Service Fluid Analysis PDFCorina Stanculescu0% (1)

- 777F ManualDocument243 pages777F ManualJose Manuel Carcamo Saez100% (3)

- Handbook On Knowledge Management Knowledge Directions by Eric TsuiDocument10 pagesHandbook On Knowledge Management Knowledge Directions by Eric TsuiNabilah Mahardika PNo ratings yet

- Backlog Management - Setting Effective Backlog Execution TargetsDocument18 pagesBacklog Management - Setting Effective Backlog Execution TargetsJuan Pablo Virreyra Trigueros100% (1)

- Caterpillar - System Selection GuideDocument11 pagesCaterpillar - System Selection GuidefvmattosNo ratings yet

- ISolutions Lifecycle Cost ToolDocument8 pagesISolutions Lifecycle Cost ToolpchakkrapaniNo ratings yet

- BP Publication - Fluid Cooler D&a FixtureDocument4 pagesBP Publication - Fluid Cooler D&a Fixtureleaw81No ratings yet

- 8 Step PM Process BPDocument7 pages8 Step PM Process BPwilsonNo ratings yet

- BP - Wheel Stud ToolDocument4 pagesBP - Wheel Stud Toolwhmidi7331No ratings yet

- SOS Wear Table - June 2015Document3,089 pagesSOS Wear Table - June 2015ricardo manriquez100% (2)

- HA Training PDFDocument30 pagesHA Training PDFBahadır CoşkunerNo ratings yet

- Automotive Process Approach Audit For IATF 16949 - 2016Document4 pagesAutomotive Process Approach Audit For IATF 16949 - 2016isolongNo ratings yet

- Salesforce CPQ AssignmentsDocument18 pagesSalesforce CPQ AssignmentsRamkumar Poovalai100% (1)

- Planning Process For PartsDocument7 pagesPlanning Process For PartsVikranth ReddyNo ratings yet

- CER Management GuideDocument24 pagesCER Management GuideANDREI26No ratings yet

- BP Repair, Rebuild, RemanStrategyDocument7 pagesBP Repair, Rebuild, RemanStrategyJean Claude EidNo ratings yet

- CAT CGM Mining CM Strategy 17-01-08Document14 pagesCAT CGM Mining CM Strategy 17-01-08MOHAMEDNo ratings yet

- BP Publication - Considerations When Extending A MARCDocument3 pagesBP Publication - Considerations When Extending A MARCleaw81No ratings yet

- BP Publication - Fluid Cleanliness Management - Rev01Document6 pagesBP Publication - Fluid Cleanliness Management - Rev01leaw81100% (1)

- BP Publication - CRC Component TurnaroundDocument6 pagesBP Publication - CRC Component Turnaroundleaw81No ratings yet

- Rebuild Options Guide - EAME VersionDocument27 pagesRebuild Options Guide - EAME Versionenjoythedocs100% (1)

- Cat Overload PolicyDocument7 pagesCat Overload Policyait mimouneNo ratings yet

- 776d Tractors 777d TrucksDocument7 pages776d Tractors 777d TrucksJavier Pagan TorresNo ratings yet

- SOS Web User GuideDocument85 pagesSOS Web User Guidericardo manriquez0% (1)

- BP - Electrical System With Extreme ConditionsDocument17 pagesBP - Electrical System With Extreme Conditions----No ratings yet

- Product Comparison: Cat 385B and Hitachi EX800H-V Hydraulic ExcavatorsDocument24 pagesProduct Comparison: Cat 385B and Hitachi EX800H-V Hydraulic ExcavatorsMuhammad Purwa Prasetya100% (1)

- PEO003 - SGD - V4 (Personal Devt)Document60 pagesPEO003 - SGD - V4 (Personal Devt)Jela ParadiseNo ratings yet

- TA2 Visual & Technical Inspection Form Master - Off-Highway TruckDocument166 pagesTA2 Visual & Technical Inspection Form Master - Off-Highway TruckSandeep Nikhil0% (1)

- CAT CylindersDocument32 pagesCAT CylindersРинат Сагидов100% (3)

- Machine Profiles: D11R Track-Type TractorsDocument6 pagesMachine Profiles: D11R Track-Type TractorsJavier Pagan TorresNo ratings yet

- Standard Jobs How To UseDocument7 pagesStandard Jobs How To UseenjoythedocsNo ratings yet

- SOS Fluid Analysis: Maintenance Products & ServicesDocument53 pagesSOS Fluid Analysis: Maintenance Products & ServicesVane Gamboa MedinaNo ratings yet

- VIMS ParameterDocument65 pagesVIMS ParameterTLK ChannelNo ratings yet

- CI OverviewDocument41 pagesCI OverviewGilmer PatricioNo ratings yet

- 793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction ControlDocument2 pages793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction Controlpercy de la cruzNo ratings yet

- Caterpillar Literature - PPTv1.0Document122 pagesCaterpillar Literature - PPTv1.0SviazRus100% (2)

- MinMach HomePage15Document46 pagesMinMach HomePage15miningnova2No ratings yet

- Equipment Maint Strategies by CaterpillarDocument45 pagesEquipment Maint Strategies by CaterpillarSohibul AminNo ratings yet

- C Dealer CCC Guide StandardsDocument224 pagesC Dealer CCC Guide StandardsLuis HuirseNo ratings yet

- Belaz Competitive Bulletin - 20180403Document19 pagesBelaz Competitive Bulletin - 20180403PATRICIO CARRASCONo ratings yet

- Repair Options Guide 2 2019 PDFDocument113 pagesRepair Options Guide 2 2019 PDFMaksim Panfilov100% (1)

- CAT Contamination ControlDocument34 pagesCAT Contamination ControlРинат Сагидов100% (1)

- Hose Management Guide: SN: 7KK Lines Group - Injector Hydraulic PumpDocument34 pagesHose Management Guide: SN: 7KK Lines Group - Injector Hydraulic PumpJose luis ConsuegraNo ratings yet

- Competitive Bulletin: Cat New H-Series EPA Tier II Engine Emissions Certified vs. Volvo B-Series Motor GradersDocument68 pagesCompetitive Bulletin: Cat New H-Series EPA Tier II Engine Emissions Certified vs. Volvo B-Series Motor GradersRulver Quiroz CabanillasNo ratings yet

- CAT Product LinkDocument5 pagesCAT Product LinkMarcial Jr. MilitanteNo ratings yet

- 777FDocument93 pages777FAlcanfred Cte Bto100% (6)

- Cat Certified Rebuild: Machines Power Train Engines Hydraulics ComponentsDocument12 pagesCat Certified Rebuild: Machines Power Train Engines Hydraulics ComponentsEmilio Castillo TamayoNo ratings yet

- PTOS Key Metrics For More Accurate OutputDocument9 pagesPTOS Key Metrics For More Accurate OutputlisahunNo ratings yet

- Fixture For 3500 Cylinder Head MachiningDocument7 pagesFixture For 3500 Cylinder Head MachiningAndrés BlancoNo ratings yet

- ESCO CastlipDocument8 pagesESCO CastlipRiady SulindroNo ratings yet

- Time Model Edited April 4 2013 Version 6Document41 pagesTime Model Edited April 4 2013 Version 6André Gutiérrez100% (1)

- Caterpillar 797F OverviewDocument35 pagesCaterpillar 797F OverviewAndrés RodríguezNo ratings yet

- 01 AfricanMarket E KomatsuDocument17 pages01 AfricanMarket E Komatsugirish_patkiNo ratings yet

- FILTERSDocument35 pagesFILTERSeng100% (2)

- Way For Extending UC Life: UCFN04-001-2 3/5/04 MaintenanceDocument14 pagesWay For Extending UC Life: UCFN04-001-2 3/5/04 MaintenanceMiguelito Para Todos100% (1)

- Bus002 - SGD - V4 (Cat Lit)Document78 pagesBus002 - SGD - V4 (Cat Lit)Joseph Emmanuel Paredes100% (1)

- Service Courses - Final VersionDocument1 pageService Courses - Final VersionDanuth Yashantha IllukkumburaNo ratings yet

- TKPHDocument6 pagesTKPHTiago Rodrigues50% (2)

- Transmission Dealer Rebuild Readiness Playbook For Large Off Highway Truck 797Document25 pagesTransmission Dealer Rebuild Readiness Playbook For Large Off Highway Truck 797David Turpo100% (3)

- CAT MSR Philosophy 01-2003Document17 pagesCAT MSR Philosophy 01-2003MOHAMEDNo ratings yet

- The Field Service Scheduling & Routing Optimization Solution Selection ReportDocument35 pagesThe Field Service Scheduling & Routing Optimization Solution Selection ReportenercolsaNo ratings yet

- G3600 PKG Tips - Cooling SystemsDocument57 pagesG3600 PKG Tips - Cooling SystemsshivNo ratings yet

- Oil & Gas Ratings Guide: Edition 2021 (March)Document48 pagesOil & Gas Ratings Guide: Edition 2021 (March)shivNo ratings yet

- Engine Fleet Management - Final Document Version 00 - 8 9 21Document21 pagesEngine Fleet Management - Final Document Version 00 - 8 9 21shivNo ratings yet

- How Does A Generator Create Electricity - Article On How Generators WorkDocument7 pagesHow Does A Generator Create Electricity - Article On How Generators WorkshivNo ratings yet

- 2020 Cat DatabookDocument21 pages2020 Cat DatabookshivNo ratings yet

- Walk Around InspectionDocument3 pagesWalk Around InspectionshivNo ratings yet

- Engine Oil and FilterDocument5 pagesEngine Oil and FiltershivNo ratings yet

- Hoses and ClampsDocument6 pagesHoses and ClampsshivNo ratings yet

- Oil Sampling IntervalsDocument3 pagesOil Sampling IntervalsshivNo ratings yet

- Cat Batteries: Application GuideDocument546 pagesCat Batteries: Application GuideshivNo ratings yet

- G3600 PKG Tips - Air Intake & ExhaustDocument49 pagesG3600 PKG Tips - Air Intake & ExhaustshivNo ratings yet

- OLT-high Quality-1325 3kw CNC Machine-LinaDocument9 pagesOLT-high Quality-1325 3kw CNC Machine-LinaThona MetNo ratings yet

- Project Engg and Construction Management SyllabusDocument3 pagesProject Engg and Construction Management SyllabusTanushree RayNo ratings yet

- FS - MM - Vendor GET OPEN PO DETAILSDocument13 pagesFS - MM - Vendor GET OPEN PO DETAILSSUBHOJIT BANERJEENo ratings yet

- FPSC Modification: 1. InstallationDocument4 pagesFPSC Modification: 1. InstallationfacebookishjupidNo ratings yet

- PDF To WordDocument71 pagesPDF To WordSyed ShaarikhNo ratings yet

- Web Intelligence XI3 On NetWeaver BW (External)Document73 pagesWeb Intelligence XI3 On NetWeaver BW (External)JorgeNo ratings yet

- The Yogavacara's Manual of Indian Mysticism, Practiced by Buddhists - Davids (1896)Document153 pagesThe Yogavacara's Manual of Indian Mysticism, Practiced by Buddhists - Davids (1896)WaterwindNo ratings yet

- Narratologi Ludology Jack PostDocument6 pagesNarratologi Ludology Jack PostIgor RamadyNo ratings yet

- Module 4Document36 pagesModule 4MD SHAHRIARMAHMUDNo ratings yet

- VLSI TutorialDocument16 pagesVLSI Tutorialthanos_3333No ratings yet

- Mathematical Practices and Processes Chart: Appendix BDocument7 pagesMathematical Practices and Processes Chart: Appendix BHrpozasNo ratings yet

- Tutorial 5 - With SolutionDocument5 pagesTutorial 5 - With Solutionhoboslayer97No ratings yet

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 pagesDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUNo ratings yet

- The T-SCAN System in Evaluating Occlusal Contacts: Original Article, Dental MedicineDocument9 pagesThe T-SCAN System in Evaluating Occlusal Contacts: Original Article, Dental MedicineSparsh Bhaskar SrivastavaNo ratings yet

- Dodge Neon RadioDocument5 pagesDodge Neon RadioJuan Carlos ZepedaNo ratings yet

- C++ Programming: Trainer: Akshita ChanchlaniDocument15 pagesC++ Programming: Trainer: Akshita ChanchlaniANIL KUMARNo ratings yet

- Add and Subtract Integers InvestigationDocument12 pagesAdd and Subtract Integers InvestigationSamuelNyaungaNo ratings yet

- Show 15Document51 pagesShow 15api-3749967100% (2)

- Form Pressure Gauge Rev.1Document3 pagesForm Pressure Gauge Rev.1ismail BCMNo ratings yet

- Iot: Challenges and Issues in Indian PerspectiveDocument5 pagesIot: Challenges and Issues in Indian PerspectiveJaime Andres Coronado MeriñoNo ratings yet

- Smi Low Pressure: Digital / Analog SensorDocument15 pagesSmi Low Pressure: Digital / Analog SensorhajaNo ratings yet

- PolynomialsDocument19 pagesPolynomialsMerun BoseNo ratings yet

- Tibco IprocessDocument8 pagesTibco IprocessYechuri SathishbabuNo ratings yet

- Practical File of Computer NetworksDocument29 pagesPractical File of Computer NetworksRahul Chauhan50% (2)

- Iscas2007 Biosensors TutorialDocument172 pagesIscas2007 Biosensors TutorialAlex WongNo ratings yet

- Your Whatsapp InformationDocument6 pagesYour Whatsapp Informationferdian rizkyNo ratings yet