Professional Documents

Culture Documents

Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodes

Uploaded by

Mohammad Adil0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

410026-en_US-FactSheet_Main-01

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodes

Uploaded by

Mohammad AdilCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

COVERED (STICK) ELECTRODES (SMAW)

STAINLESS STEEL ELECTRODES

OK 61.81

Nb-stabilized MMA-electrode for welding Nb- or Ti-stabilized stainless steel of the 19Cr10Ni-type.

Classifications SFA/AWS A5.4 : E347-16

EN ISO 3581-A : E 19 9 Nb R 3 2

Werkstoffnummer : 1.4551

Approvals CE EN 13479

DNV-GL VL 347

NAKS/HAKC 3.2 mm

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current DC+, AC

Ferrite Content FN 6-12

Alloy Type Austenitic CrNi

Coating Type Rutile

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

ISO

AWS

As Welded 560 MPa (81 ksi) 700 MPa (102 ksi) 31 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

AWS

As Welded 20 °C (68 °F) 60 J (44 ft-lb)

ISO

As Welded -10 °C (14 °F) 71 J (53 ft-lb)

Typical Weld Metal Analysis %

C Mn Si Ni Cr N Nb Ferrite FN

0.06 1.7 0.7 9.7 20.2 0.08 0.72 7

Deposition Data

Diameter Current Voltage Number of Burn-off Time/ Deposition Deposition Rate @

electrodes/ Electrode Efficiency % 90% I max

kg weld metal

2.5 x 300.0 mm 50-80 A 29 V 82 36 sec 59 % 1.2 kg/h (2.6 lb/h)

(0.098 x 11.8 in.)

3.2 x 350.0 mm 75-115 A 23 V 44 66 sec 60 % 1.2 kg/h (2.6 lb/h)

(1/8 x 13.8 in.)

4.0 x 350.0 mm 80-160 A 24 V 32 66 sec 60 % 1.7 kg/h (3.7 lb/h)

(5/32 x 13.8 in.)

5.0 x 350.0 mm 140-210 A 25 V 20 78 sec 60 % 2.3 kg/h (5.1 lb/h)

(0.197 x 13.8 in.)

410026-en_US-FactSheet_Main-01 2022-01-18

esab.com/fillermetals

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- 10th National ISMO Class 5 Question PaperDocument10 pages10th National ISMO Class 5 Question Paperwhatever50% (2)

- Course Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Document14 pagesCourse Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Eushane Chiya SyNo ratings yet

- Ezy Math Tutoring - Year 5 AnswersDocument168 pagesEzy Math Tutoring - Year 5 AnswersVincents Genesius EvansNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- JLN550 InstalDocument54 pagesJLN550 InstalCostas PeppasNo ratings yet

- 660D14 Painting Schedule For Silo 1 - Rev 0Document1 page660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilNo ratings yet

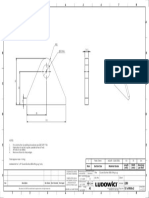

- 1301P02725 AS DRAWN 1301P02727 OPP - DRAWN: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 page1301P02725 AS DRAWN 1301P02727 OPP - DRAWN: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Item Release Note: 1 Already DespatchedDocument1 pageItem Release Note: 1 Already DespatchedMohammad AdilNo ratings yet

- 2200SRM1266 (06 2006) Uk enDocument28 pages2200SRM1266 (06 2006) Uk enEbied Yousif Aly100% (9)

- I R Shnametallurgical: Laboratories Pvt. LTDDocument1 pageI R Shnametallurgical: Laboratories Pvt. LTDMohammad AdilNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Ok Ni-Ci: Repair and Maintenance Cast Iron AlloysDocument1 pageOk Ni-Ci: Repair and Maintenance Cast Iron AlloysAmR ZakiNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesKaung Sett LynnNo ratings yet

- Esab 28: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageEsab 28: Covered (Stick) Electrodes (Smaw) Mild Steel Electrodesraghubhaimantra4136No ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Laxisd47No ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Lbevara santhoshkumarNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Esab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Chemical Composition: ASTM B103Document1 pageChemical Composition: ASTM B103MarcoAntonioNo ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- Purus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresDocument1 pagePurus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresYudhveer GrewalNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- en - WW FactSheet - Main 01Document1 pageen - WW FactSheet - Main 01Mario FuentesklrlyNo ratings yet

- Hyundai Supercored 71HDocument9 pagesHyundai Supercored 71HPongwitt BoonayamaneeNo ratings yet

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- en WW FactSheet Main 01Document1 pageen WW FactSheet Main 01Samuel TanNo ratings yet

- Adobe Scan 06 Jun. 2023Document1 pageAdobe Scan 06 Jun. 2023BayardoNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1No ratings yet

- ESAB Filler Metal GuideDocument1 pageESAB Filler Metal GuidekapsarcNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- Carbon Steel Coated ElectrodesDocument1 pageCarbon Steel Coated ElectrodesNautique SolutionsNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- TC NylonDocument1 pageTC NylonMohammad AdilNo ratings yet

- Arcoplate BrouchureDocument112 pagesArcoplate BrouchureMohammad AdilNo ratings yet

- 4 Inspection and Final Manufacturing: 4.1 Welding NDT (Non-Destructive Testing)Document2 pages4 Inspection and Final Manufacturing: 4.1 Welding NDT (Non-Destructive Testing)Mohammad AdilNo ratings yet

- Skirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyDocument4 pagesSkirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyMohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Skirt Board Assembly-5810 Skirt Board Assembly-5810Document3 pagesSkirt Board Assembly-5810 Skirt Board Assembly-5810Mohammad AdilNo ratings yet

- Caltech - Multipurpose GaugeDocument1 pageCaltech - Multipurpose GaugeMohammad AdilNo ratings yet

- Head End: Detail ADocument3 pagesHead End: Detail AMohammad AdilNo ratings yet

- Spring SnapDocument1 pageSpring SnapMohammad AdilNo ratings yet

- Assembly, Skeleton M2020FBM Assembly, SkeletonDocument2 pagesAssembly, Skeleton M2020FBM Assembly, SkeletonMohammad AdilNo ratings yet

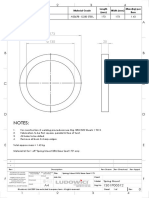

- 8-17.5 HOLES 100: Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 page8-17.5 HOLES 100: Item Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

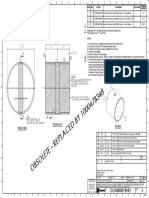

- Vibrating Screen Seal Gasket 80NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 80NB ASME B16.5Document1 pageVibrating Screen Seal Gasket 80NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 80NB ASME B16.5Mohammad AdilNo ratings yet

- 1 Plate 8mm AS3678 - G250 STEEL 588 230 8.3: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 page1 Plate 8mm AS3678 - G250 STEEL 588 230 8.3: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- 1313a00057 Bne1Document1 page1313a00057 Bne1Mohammad AdilNo ratings yet

- 3D View: Sideplate 1301P01499Document1 page3D View: Sideplate 1301P01499Mohammad AdilNo ratings yet

- Stamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Document1 pageStamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Mohammad AdilNo ratings yet

- For Internal Use Only: 1684A01608-BNE1 4Document1 pageFor Internal Use Only: 1684A01608-BNE1 4Mohammad AdilNo ratings yet

- PF052701 Bne1Document1 pagePF052701 Bne1Mohammad AdilNo ratings yet

- Vibrating Screen Seal Gasket 200NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 200NB ASME B16.5Document1 pageVibrating Screen Seal Gasket 200NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 200NB ASME B16.5Mohammad AdilNo ratings yet

- Proposal Drawing Not For ConstructionDocument1 pageProposal Drawing Not For ConstructionMohammad AdilNo ratings yet

- Preliminary Drawing Not For ConstructionDocument1 pagePreliminary Drawing Not For ConstructionMohammad AdilNo ratings yet

- 3D View: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 page3D View: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Stamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Document1 pageStamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Mohammad AdilNo ratings yet

- Notes:: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageNotes:: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Calculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareDocument12 pagesCalculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareAllen MNo ratings yet

- Automatic Control Systems, 9th Edition: Chapter 9Document50 pagesAutomatic Control Systems, 9th Edition: Chapter 9physisisNo ratings yet

- Particle Tracing Module Users GuideDocument306 pagesParticle Tracing Module Users GuideAlfonso BarbozaNo ratings yet

- EECS4421Z: Introduction To Robotics Sample Exam QuestionsDocument7 pagesEECS4421Z: Introduction To Robotics Sample Exam QuestionsMooeez BellaamineNo ratings yet

- Jimma Institute of Technology Faculty of Mechanical EngineeringDocument38 pagesJimma Institute of Technology Faculty of Mechanical EngineeringIsmail Ibn BehailuNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1Document17 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1samarrana1234679No ratings yet

- Edited C Spectra - APT and DEPTDocument4 pagesEdited C Spectra - APT and DEPTKasun RatnayakeNo ratings yet

- Mm1 Report Group2 FinalDocument17 pagesMm1 Report Group2 FinalMayumi Atisha KimNo ratings yet

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramNo ratings yet

- Assignment - 02 - ASP - NET Core Web API With EntityFramework and Web AppDocument7 pagesAssignment - 02 - ASP - NET Core Web API With EntityFramework and Web AppdrubypjnkNo ratings yet

- Chapter Seven: GS Ohlins Installation, Adjustment Tips & TricksDocument29 pagesChapter Seven: GS Ohlins Installation, Adjustment Tips & TricksWhattonNo ratings yet

- PNP Transistor OperationDocument5 pagesPNP Transistor OperationmohanNo ratings yet

- FDocument13 pagesFLUIS ANGEL CASTRO TZUNNo ratings yet

- Mechanism Analysis of Gas Solid Flow Non-Uniformity Problem of 330 MW CFB BoilerDocument10 pagesMechanism Analysis of Gas Solid Flow Non-Uniformity Problem of 330 MW CFB BoilerTan Nguyen HuuNo ratings yet

- Design of Adaptive Headlights For AutomobilesDocument5 pagesDesign of Adaptive Headlights For AutomobilesEditor IJRITCCNo ratings yet

- Mep - July 2013 - January 2010Document47 pagesMep - July 2013 - January 2010sunchit1986No ratings yet

- LoadRunner BasicsDocument74 pagesLoadRunner BasicsmadhugangulaNo ratings yet

- Answer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingDocument4 pagesAnswer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingKhaled faisalNo ratings yet

- Topic 9 - Transport in Animals: Blood and Lymph VesselsDocument15 pagesTopic 9 - Transport in Animals: Blood and Lymph Vesselsgytfnhj.comNo ratings yet

- NTSE Stage - 1 Mock Test - 3Document16 pagesNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- SSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Document14 pagesSSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Shrishanti Kale100% (1)

- University Insitute of Engineering Electrical EngineeringDocument85 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexNo ratings yet

- Physics Paper 2 Nov 2004Document16 pagesPhysics Paper 2 Nov 2004tommyliuNo ratings yet

- Worksheet 7-g6 MATHSDocument2 pagesWorksheet 7-g6 MATHSAhmedAR or main emailNo ratings yet

- Math Iv Chapter 3Document60 pagesMath Iv Chapter 3Benjamin AkingeneyeNo ratings yet