Professional Documents

Culture Documents

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Uploaded by

Nibin OdukkathilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Uploaded by

Nibin OdukkathilCopyright:

Available Formats

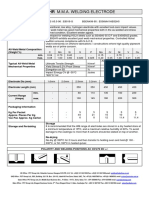

COVERED (STICK) ELECTRODES (SMAW)

LOW ALLOY ELECTRODES

OK 48.08

OK 48.08 is an LMA electrode with very good mechanical properties suitable for demanding applications, such as offshore. The weld metal contains approximately

1% Ni for high impact values down to -40°C. The coating is of the latest LMA type for optimum resistance to porosity and hydrogen cracking. OK 48.08 is CTOD

tested.

Classifications SFA/AWS A5.5 : E7018-G

EN ISO 2560-A : E 46 5 1Ni B 32 H5

Approvals ABS 3Y H5

CE EN 13479

DB 10.039.31

DNV-GL 4 Y40H5

LR 4Y40m H5

NAKS/HAKC 2.5-5.0 mm

RS 4Y H5

VdTÜV 05778

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current AC, DC+(-)

Diffusible Hydrogen < 5.0 ml/100g

Alloy Type Low alloyed (0.9 % Ni)

Coating Type Basic covering

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

ISO

As Welded 540 MPa 630 MPa 26 %

AWS

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

ISO

As Welded -50 °C 115 J

As Welded -60 °C 90 J

Typical Weld Metal Analysis %

C Mn Si Ni Cr Mo

0.06 1.2 0.35 0.95 0.02 0.001

Deposition Data

Diameter Current Voltage kg weld metal/kg Number of Fusion time per Deposition Rate

electrodes electrodes/ electrode at 90% I

kg weld metal max

2.0 x 300 mm 55-80 A 22 V 0.57 135.1 42 sec 0.60 kg/h

2.5 x 350 mm 75-110 A 27 V 0.57 88 41 sec 1.0 kg/h

3.2 x 350 mm 110-150 A 22 V 0.62 42.3 66 sec 1.30 kg/h

3.2 x 450 mm 110-150 A 22 V 0.66 30.0 85 sec 1.40 kg/h

4.0 x 450 mm 150-200 A 22 V 0.69 20.3 90 sec 2.00 kg/h

5.0 x 450 mm 190-275 A 23 V 0.69 14.0 85 sec 3.00 kg/h

410008-en_WW-FactSheet_Main-01 2021-03-18

esab.com/fillermetals

You might also like

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocument1 pageCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- Low alloy electrodes for welding high-strength steels with OK 75.75Document1 pageLow alloy electrodes for welding high-strength steels with OK 75.75corsini999No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Stainless steel electrode for welding martensitic and martensitic-ferritic steelsDocument1 pageStainless steel electrode for welding martensitic and martensitic-ferritic steelstarun kaushalNo ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocument1 pageCOVERED ELECTRODES FOR MILD STEEL WELDINGRys Multiventas SacNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- Covered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesKaung Sett LynnNo ratings yet

- Esab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- Ok Ni-Ci: Repair and Maintenance Cast Iron AlloysDocument1 pageOk Ni-Ci: Repair and Maintenance Cast Iron AlloysAmR ZakiNo ratings yet

- WB56S M.M.A. welding electrode specificationsDocument1 pageWB56S M.M.A. welding electrode specificationslathasri78No ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Esab 28: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageEsab 28: Covered (Stick) Electrodes (Smaw) Mild Steel Electrodesraghubhaimantra4136No ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- en WW FactSheet Main 01Document1 pageen WW FactSheet Main 01Samuel TanNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Laxisd47No ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- MIG/MAG WIRES (GMAW) - Purus 46Document1 pageMIG/MAG WIRES (GMAW) - Purus 46Yudhveer GrewalNo ratings yet

- WB88SHR M.M.A. welding electrode propertiesDocument1 pageWB88SHR M.M.A. welding electrode propertieslathasri78No ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- en - WW FactSheet - Main 01Document1 pageen - WW FactSheet - Main 01Mario FuentesklrlyNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDocument2 pagesProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNo ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Product Data Sheet: S 'Submerged Arc Welding'Document1 pageProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1No ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- EN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageEN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesKARLNo ratings yet

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Garde CorpsDocument2 pagesGarde Corpsattiori fabriceNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Trip RecieptDocument1 pageTrip RecieptNibin OdukkathilNo ratings yet

- Measure RPM and Speeds with Contact/Non-Contact TachometerDocument7 pagesMeasure RPM and Speeds with Contact/Non-Contact TachometerNibin OdukkathilNo ratings yet

- Drain Interval StudyDocument2 pagesDrain Interval StudyNibin OdukkathilNo ratings yet

- Axle Maintenance KPM 004 0310 Rev12 1Document8 pagesAxle Maintenance KPM 004 0310 Rev12 1Nibin OdukkathilNo ratings yet

- 1 Updated Section E - AxleDocument58 pages1 Updated Section E - AxleNibin OdukkathilNo ratings yet

- IMSB Mechanical Suspensions KPM 002 0310rev11Document17 pagesIMSB Mechanical Suspensions KPM 002 0310rev11Nibin OdukkathilNo ratings yet

- IMSB Mechanical Suspensions KPM 002 0310rev11Document17 pagesIMSB Mechanical Suspensions KPM 002 0310rev11Nibin OdukkathilNo ratings yet

- Product Catalogue: Axle ComponentsDocument78 pagesProduct Catalogue: Axle ComponentsNibin OdukkathilNo ratings yet

- Product Catalogue: Axle ComponentsDocument10 pagesProduct Catalogue: Axle ComponentsNibin OdukkathilNo ratings yet

- Drain Interval StudyDocument2 pagesDrain Interval StudyNibin OdukkathilNo ratings yet

- Axle Maintenance KPM 004 0310 Rev12 1Document8 pagesAxle Maintenance KPM 004 0310 Rev12 1Nibin OdukkathilNo ratings yet

- Directional Control Valves English Imperial E215Document12 pagesDirectional Control Valves English Imperial E215Nibin OdukkathilNo ratings yet

- Landing Legs KPM 002 0612rev7Document4 pagesLanding Legs KPM 002 0612rev7Nibin OdukkathilNo ratings yet

- Landing Legs KPM 002 0612rev7Document4 pagesLanding Legs KPM 002 0612rev7Nibin OdukkathilNo ratings yet

- Product Catalogue: Axle ComponentsDocument10 pagesProduct Catalogue: Axle ComponentsNibin OdukkathilNo ratings yet

- MCN120 1P 6kA circuit breaker data sheetDocument3 pagesMCN120 1P 6kA circuit breaker data sheetNibin OdukkathilNo ratings yet

- Product Data Sheet: MCB 1P 6ka C-32A 1MDocument3 pagesProduct Data Sheet: MCB 1P 6ka C-32A 1MNibin OdukkathilNo ratings yet

- Trip RecieptDocument1 pageTrip RecieptNibin OdukkathilNo ratings yet

- Trip RecieptDocument1 pageTrip RecieptNibin OdukkathilNo ratings yet

- Hydraulic Complete Inch GB enDocument338 pagesHydraulic Complete Inch GB enNibin OdukkathilNo ratings yet

- VOX Cinema Booking ConfirmationDocument3 pagesVOX Cinema Booking ConfirmationNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Steel Grade Equivalents Guide - HillfootDocument5 pagesSteel Grade Equivalents Guide - HillfootNibin OdukkathilNo ratings yet

- Morse Modern Technical LLC: TEL: 00971-2-5541886 FAX: 00971-2-5541813Document1 pageMorse Modern Technical LLC: TEL: 00971-2-5541886 FAX: 00971-2-5541813Nibin OdukkathilNo ratings yet

- Pure Savings On Your New Mashreq Credit Card!: Offer A DetailsDocument4 pagesPure Savings On Your New Mashreq Credit Card!: Offer A DetailsNibin OdukkathilNo ratings yet

- Work Completion Certificate: To Whom It May ConcernDocument1 pageWork Completion Certificate: To Whom It May ConcernNibin OdukkathilNo ratings yet

- Fixed Asset List-Hamriyah Yard: SL No. Serial No. Equipment RemarksDocument1 pageFixed Asset List-Hamriyah Yard: SL No. Serial No. Equipment RemarksNibin OdukkathilNo ratings yet

- Chemical Reaction PresentationDocument45 pagesChemical Reaction Presentationapi-428687186No ratings yet

- U.S. Steel Minimills Lead Scrap RecyclingDocument16 pagesU.S. Steel Minimills Lead Scrap Recyclingratninp9368No ratings yet

- Phisical and Chemical Properties of Rocks and MineralsDocument19 pagesPhisical and Chemical Properties of Rocks and MineralsAllaine Trisha ManingatNo ratings yet

- Precipitation of Molybdenum (V) As The Hydroxide AND Its Separation From RheniumDocument3 pagesPrecipitation of Molybdenum (V) As The Hydroxide AND Its Separation From RheniumBrent WoottonNo ratings yet

- November 2015 (v3) QP - Paper 1 CIE Chemistry A-LevelDocument16 pagesNovember 2015 (v3) QP - Paper 1 CIE Chemistry A-LevelAnirudh BansalNo ratings yet

- Increasing wear resistance in high-chromium tool steelsDocument19 pagesIncreasing wear resistance in high-chromium tool steelsDaniel NavarroNo ratings yet

- Practical Windows and Inhibitors For Grade 2 Titanium Use in Alkaline Peroxide Bleach SolutionsDocument9 pagesPractical Windows and Inhibitors For Grade 2 Titanium Use in Alkaline Peroxide Bleach SolutionsGeetha ThiruvengadamNo ratings yet

- Elements Compounds and Mixtures WebquestDocument3 pagesElements Compounds and Mixtures WebquestRobNo ratings yet

- Combustion and Flame EssentialsDocument9 pagesCombustion and Flame Essentialssirswal kingNo ratings yet

- Rail WeldingDocument17 pagesRail WeldingAbdulhmeed Mutalat100% (2)

- For Questions 1 To 20, Work A Side Then Choose The Correct Answer. For Questions 21-23, Show All Your Workings in Logical StepsDocument6 pagesFor Questions 1 To 20, Work A Side Then Choose The Correct Answer. For Questions 21-23, Show All Your Workings in Logical StepsSaiam ShahNo ratings yet

- Mg L Mol Feso 4 ·7 H 20Document3 pagesMg L Mol Feso 4 ·7 H 20JHuvieCLaireNo ratings yet

- 2 - Chemistry - D&F Block Elements - 12 Classes PDFDocument42 pages2 - Chemistry - D&F Block Elements - 12 Classes PDFkrishna mohan G0% (1)

- Chem Form-6-Sem-1-01 PDFDocument44 pagesChem Form-6-Sem-1-01 PDFXuerong ChinNo ratings yet

- Solvay Process PresentationDocument19 pagesSolvay Process PresentationRiki Mandol67% (3)

- P-Block ElementsDocument10 pagesP-Block ElementsSubramanian Gk100% (1)

- Multistep Organic Synthesis GuideDocument5 pagesMultistep Organic Synthesis GuideBobskinnyNo ratings yet

- 2013 CTD CatalogDocument302 pages2013 CTD CatalogLuis LopezNo ratings yet

- Types Methods Manufacture Corundum AbrasivesDocument2 pagesTypes Methods Manufacture Corundum AbrasivessekarnttfNo ratings yet

- CHEM1LDocument3 pagesCHEM1LAndrew DonaireNo ratings yet

- 1Document49 pages1Asma'a AlmawasNo ratings yet

- Trends in Inorganic ChemistryDocument3 pagesTrends in Inorganic Chemistryrkstudyc_gmailNo ratings yet

- 10 Science Imp Ch3 1Document8 pages10 Science Imp Ch3 1rajkumar trivediNo ratings yet

- Cored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDDocument3 pagesCored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDBranko FerenčakNo ratings yet

- Controlled Scorodite Precipitation Immobilizes ArsenicDocument4 pagesControlled Scorodite Precipitation Immobilizes ArsenicmonkeyjackcnNo ratings yet

- Method for preparing anhydrous iron chloridesDocument4 pagesMethod for preparing anhydrous iron chloridesVioleta GrigorasNo ratings yet

- Arjuna (Jee) Some Basis Concept of ChemistryDocument30 pagesArjuna (Jee) Some Basis Concept of ChemistryNilay Sah100% (1)

- Science Class 7 Topic: Solutions Reinforcement WorksheetDocument7 pagesScience Class 7 Topic: Solutions Reinforcement WorksheetLee-Ann ZerimarNo ratings yet

- DPP No. 02 Topic: Types of Chemical Reaction 1.: Heat HeatDocument2 pagesDPP No. 02 Topic: Types of Chemical Reaction 1.: Heat HeatShreyas BurraNo ratings yet