Professional Documents

Culture Documents

Aggregate Production Planning-Continuation

Uploaded by

suraj nairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Production Planning-Continuation

Uploaded by

suraj nairCopyright:

Available Formats

Aggregate Production Planning-Continuation

A manufacturer of industrial motors produces four varieties of motors The Type 4 motor requires

a larger amount of customization than the other three The production planning department has

estimated the number of hours required for manufacturing one unit of motor of each variety Type

1 requires 125 hours; Type 2 ,175 hours: Type 3, 200 hours; and Type 4,350 hours The forecast

for the four varieties are given in Table below

Forecast for the Four Varieties

Month Forecast of Motor Demand(units)

Type 1 Type 2 Type 3 Type 4

April 100 40 60 10

May 90 30 30 5

June 80 50 50 10

July 130 40 70 20

August 70 30 30 15

September 90 50 50 5

October 100 40 50 10

November 110 30 40 15

December 60 60 80 5

January 110 20 30 10

February 120 40 40 5

March 140 50 70 10

The overtime premium is estimated to be Rs 20 per hour while undertime costs are 50 percent of

the OT premium The cost of carrying inventory is Rs 15 per hour per month and backordering /

shortage costs are 200 percent of inventory carrying costs The company can subcontract capacity

from a reputed vendor and the additional costs related to subcontracting is Rs 25 per hour of

capacity

Evaluate the following alternatives for AOP:

a) Prepare a level strategy Use inventory/backlogging to absorb the demand-supply

mismatch

b) Use constant production rate for the first six months, change the production rate to

another level and have a constant production rate for the next six months Use

inventory/backlogging to absorb demand-supply mismatch

c) Maintain a production level of 31,000 hours per month and use OT/UT alternatives to

chase the demand

d) Maintain a production level of 31,000 hours per month Build inventory during periods of

low demand and use subcontracting when the demand exceeds available capacity

You might also like

- Top 99 Wholesale Sources PDFDocument27 pagesTop 99 Wholesale Sources PDFAnonymous 8DYrvTUNo ratings yet

- Wealth Management & Asset ManagementDocument32 pagesWealth Management & Asset ManagementVineetChandakNo ratings yet

- NEC Cable Chart Article 310Document2 pagesNEC Cable Chart Article 310SalNo ratings yet

- UPS/Boeing 747: Aircraft Cargo Parts CatalogDocument26 pagesUPS/Boeing 747: Aircraft Cargo Parts CatalogJayson Baga100% (1)

- Formwork Design QIPDocument64 pagesFormwork Design QIPMadhava PadiyarNo ratings yet

- PartnershipDocument43 pagesPartnershipitik meowmeowNo ratings yet

- NEC 316.10 Ampacity Table For Cable Conductor SizingDocument1 pageNEC 316.10 Ampacity Table For Cable Conductor SizingHumayun RazaNo ratings yet

- Charts and Graphs TemplateDocument5 pagesCharts and Graphs Templatemy.nafi.pmp5283No ratings yet

- L2 Innovation Taxonomy 2019 2020Document40 pagesL2 Innovation Taxonomy 2019 2020JonasBasilioNo ratings yet

- Chapter 17 - Ppe - AssignmentDocument16 pagesChapter 17 - Ppe - Assignmentsabina del monteNo ratings yet

- Challenges in Public ProcurementDocument20 pagesChallenges in Public ProcurementEd Batowski100% (3)

- IMC 2014 Brochure JB 1Document16 pagesIMC 2014 Brochure JB 1tristanmaharajNo ratings yet

- Object-Oriented Systems Analysis and Design Using UML 3rd Edition (OCR'd Exact Images, DoPDF'd)Document347 pagesObject-Oriented Systems Analysis and Design Using UML 3rd Edition (OCR'd Exact Images, DoPDF'd)Alberto War67% (3)

- Course Title: Factory Planning Course Code: Year: 4 Date: Sep 2020 Allowed Time: 3 Hrs No. of PagesDocument2 pagesCourse Title: Factory Planning Course Code: Year: 4 Date: Sep 2020 Allowed Time: 3 Hrs No. of PagesAhmad Abo-ElnasrNo ratings yet

- Particulate: Actual ProfitsDocument6 pagesParticulate: Actual ProfitsPercyNo ratings yet

- Particulate: Actual ProfitsDocument8 pagesParticulate: Actual ProfitsPercyNo ratings yet

- Book 1Document3 pagesBook 1Christine Vel MarcianoNo ratings yet

- Chart 1Document4 pagesChart 1Gerald GarciaNo ratings yet

- Diffrent ChartsDocument7 pagesDiffrent ChartsChandan_RicharyaaNo ratings yet

- Ruffy Ariel S Cueryzon Bsee 2ADocument2 pagesRuffy Ariel S Cueryzon Bsee 2ASuper MoelasisNo ratings yet

- Data For ChartsDocument8 pagesData For ChartsSwati ShuklaNo ratings yet

- Charts and Graphs Template: Strictly ConfidentialDocument6 pagesCharts and Graphs Template: Strictly ConfidentialKnightspageNo ratings yet

- Transaction Amount Rate Q1 Q2 Q3 Q4Document21 pagesTransaction Amount Rate Q1 Q2 Q3 Q4Arnold BernasNo ratings yet

- Spreadsheet For Task 3 - Assignment 2Document5 pagesSpreadsheet For Task 3 - Assignment 2Nguyen Thanh LongNo ratings yet

- Syaikhu Umar Wahid - 220521603840 - Tugas Minggu Ke 7Document11 pagesSyaikhu Umar Wahid - 220521603840 - Tugas Minggu Ke 7TRISUCI ANGGUNNo ratings yet

- Monthly Sales Data of Air Compressors at Kirkland IndustriesDocument12 pagesMonthly Sales Data of Air Compressors at Kirkland Industriesian mercadoNo ratings yet

- The Commision of U Hein Thu Paing For September-2020Document4 pagesThe Commision of U Hein Thu Paing For September-2020Aye Theint Theint LwinNo ratings yet

- Ejerc Hietograma Lluvia V May 2019 Pag 78 ChowDocument5 pagesEjerc Hietograma Lluvia V May 2019 Pag 78 Chowjorge andres hereira cabanaNo ratings yet

- Charts and Graphs TemplateDocument4 pagesCharts and Graphs TemplateGolamMostafaNo ratings yet

- Nomor Mahasiswa Nilai UTS Nilai Tugas Nilai UAS Nilai IndeksDocument9 pagesNomor Mahasiswa Nilai UTS Nilai Tugas Nilai UAS Nilai IndeksYuma CahyaNo ratings yet

- Product Technical Data Sheet: Structural Steel SectionsDocument1 pageProduct Technical Data Sheet: Structural Steel SectionsDorian BugejaNo ratings yet

- 25 - Specific Chart TypesDocument51 pages25 - Specific Chart TypesMarcelo BuchNo ratings yet

- Dave Econ Act 6 FinalDocument3 pagesDave Econ Act 6 FinalilostmyselfintothewoodsNo ratings yet

- 013 Stream Pe 100 Pipe Support SpacingsDocument1 page013 Stream Pe 100 Pipe Support Spacingsmih1No ratings yet

- Pabrik/Gudang G1 G2 G3 G4 G5 G6 SDocument6 pagesPabrik/Gudang G1 G2 G3 G4 G5 G6 SEgie SugiyantoroNo ratings yet

- CMA SS August 2018Document12 pagesCMA SS August 2018Goremushandu MungarevaniNo ratings yet

- Untitled Spreadsheet-2Document2 pagesUntitled Spreadsheet-2api-398388514No ratings yet

- Neff ReceiptDocument9 pagesNeff ReceiptNsa OtonoNo ratings yet

- Simulation Waiting Line AnalysisDocument88 pagesSimulation Waiting Line AnalysisDimas ReynaldoNo ratings yet

- Uji Setting Time Beton: Tanggal: MutuDocument12 pagesUji Setting Time Beton: Tanggal: Mutuagus wahyudiNo ratings yet

- MONOGRAPHIE Ouarzazate 22Document14 pagesMONOGRAPHIE Ouarzazate 22Ghizlane NamiriNo ratings yet

- ToejamandEarl PDFDocument4 pagesToejamandEarl PDFMarshallNo ratings yet

- 52 Week Saving PlanDocument10 pages52 Week Saving PlanpapimorokaNo ratings yet

- Van Westendorp ModelDocument7 pagesVan Westendorp ModelAtul AnandNo ratings yet

- EconomicsDocument2 pagesEconomicsprashant kumarNo ratings yet

- Tale of Immortal - Charisma ValuesDocument14 pagesTale of Immortal - Charisma ValuesArzelord ReinaonNo ratings yet

- Book 1Document2 pagesBook 1Ali SultanNo ratings yet

- Tes Ip Xi tkj2Document5 pagesTes Ip Xi tkj2Sonny Indra PratamaNo ratings yet

- Measures of Variability - 2Document4 pagesMeasures of Variability - 2Shubham HandeNo ratings yet

- Rezkiya Laila Bilkis 201822201043Document12 pagesRezkiya Laila Bilkis 201822201043LALANo ratings yet

- Excel Formula CollectorDocument1 pageExcel Formula CollectorCindyNo ratings yet

- Sextant Users GuideV6 PDFDocument28 pagesSextant Users GuideV6 PDFblackcaptain61No ratings yet

- Weight Gram Weight GramDocument1 pageWeight Gram Weight GramHalgurd HamadNo ratings yet

- Weight Gram Weight GramDocument1 pageWeight Gram Weight GramParaw SalmNo ratings yet

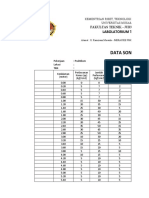

- Data Sondir FixDocument15 pagesData Sondir FixSah putraNo ratings yet

- Attendance Sheet: JAN 1 FEB 2 APR 4 MAY 5 JUN 6 JUL 7 AUG 8Document16 pagesAttendance Sheet: JAN 1 FEB 2 APR 4 MAY 5 JUN 6 JUL 7 AUG 8Anonymous HnJ4CBNGNo ratings yet

- Copper To Aluminum Conversion ChartDocument1 pageCopper To Aluminum Conversion Chartlester lorredoNo ratings yet

- Edtech3 SpreadsheetDocument9 pagesEdtech3 Spreadsheetapi-379685492No ratings yet

- Antonius Mario - Tugas Sesi 6 - Manajemen KuantitatifDocument3 pagesAntonius Mario - Tugas Sesi 6 - Manajemen KuantitatifAntonius MarioNo ratings yet

- Grafico Triangular Plantilla de DatosDocument5 pagesGrafico Triangular Plantilla de DatosMaria Camila Giraldo CarmonaNo ratings yet

- Índice de Acidentes Com LesãoDocument6 pagesÍndice de Acidentes Com LesãoJúlio CésarNo ratings yet

- 05 GamesDocument94 pages05 GamesAkshat NayakNo ratings yet

- Titik 2Document4 pagesTitik 2Andi BasoNo ratings yet

- Microsoft Excel TutorialDocument12 pagesMicrosoft Excel TutorialthomasNo ratings yet

- Risk and People ManagementDocument8 pagesRisk and People Managementsuraj nairNo ratings yet

- PA EndtermDocument1 pagePA Endtermsuraj nairNo ratings yet

- Endterm Mergers 21170Document7 pagesEndterm Mergers 21170suraj nairNo ratings yet

- ETOSCDocument4 pagesETOSCsuraj nairNo ratings yet

- 21167Document3 pages21167suraj nairNo ratings yet

- Blockchain For Good - Telecommunication Group 1Document10 pagesBlockchain For Good - Telecommunication Group 1suraj nairNo ratings yet

- Green & CompetitiveDocument10 pagesGreen & Competitivesuraj nairNo ratings yet

- Lean Service MachineDocument6 pagesLean Service Machinesuraj nairNo ratings yet

- LGM - TVS PresentationDocument19 pagesLGM - TVS Presentationsuraj nairNo ratings yet

- Green and Competitive Ending The Stalemate - Group ADocument9 pagesGreen and Competitive Ending The Stalemate - Group Asuraj nairNo ratings yet

- CTPDocument60 pagesCTPsuraj nairNo ratings yet

- SDSDDocument56 pagesSDSDsuraj nairNo ratings yet

- Official DocumentsDocument7 pagesOfficial Documentssuraj nairNo ratings yet

- Suraj S Nair FinalDocument1 pageSuraj S Nair Finalsuraj nairNo ratings yet

- CTPDocument53 pagesCTPsuraj nairNo ratings yet

- The Lean Service Machine-R0310J-PDF-ENGDocument10 pagesThe Lean Service Machine-R0310J-PDF-ENGsuraj nairNo ratings yet

- Valuation Mergers ProjectDocument3 pagesValuation Mergers Projectsuraj nairNo ratings yet

- Mergers Mid TermDocument4 pagesMergers Mid Termsuraj nairNo ratings yet

- Select From Where: Q2 AVG Table - Name ConditionDocument2 pagesSelect From Where: Q2 AVG Table - Name Conditionsuraj nairNo ratings yet

- Groups Count Sum Average VarianceDocument4 pagesGroups Count Sum Average Variancesuraj nairNo ratings yet

- LPP ContinuedDocument2 pagesLPP Continuedsuraj nairNo ratings yet

- Govt. of Haryana: Standard Biding Document Procurment of Civil Work Rob & BridgesDocument147 pagesGovt. of Haryana: Standard Biding Document Procurment of Civil Work Rob & BridgesSunilNo ratings yet

- M&a AssignmentDocument19 pagesM&a AssignmentrakeshNo ratings yet

- Cambridge International AS & A Level: ECONOMICS 9708/42Document4 pagesCambridge International AS & A Level: ECONOMICS 9708/42MoynaNo ratings yet

- Tca (Customer Information)Document5 pagesTca (Customer Information)VenkatNo ratings yet

- Corporate VeilDocument18 pagesCorporate Veilsakshi srivastavNo ratings yet

- Statutory CompliancesDocument4 pagesStatutory CompliancesPratibha ChopraNo ratings yet

- LEBM 721 Case Study A Strategic Plan Under Political FireDocument8 pagesLEBM 721 Case Study A Strategic Plan Under Political FireLeonard MoodyNo ratings yet

- Haier - WikipediaDocument37 pagesHaier - Wikipediaayanmehdi96No ratings yet

- Audit and Assurance: Thursday 4 December 2014Document8 pagesAudit and Assurance: Thursday 4 December 2014Lei JianxinNo ratings yet

- Invest To Grow Concentrate Effort On Maintaining Strength Challenge For Leadership Build Selectively Reinforce Vulnerable AreasDocument9 pagesInvest To Grow Concentrate Effort On Maintaining Strength Challenge For Leadership Build Selectively Reinforce Vulnerable AreasRaj ThakurNo ratings yet

- Entreprepreneurship, Seminar TopicDocument13 pagesEntreprepreneurship, Seminar Topicadityakalani000oooNo ratings yet

- Chap4 (1-15)Document8 pagesChap4 (1-15)Jahanzaib JavaidNo ratings yet

- Aacounting For Musharakah FinancingDocument12 pagesAacounting For Musharakah Financingyiera ypienNo ratings yet

- TA Global Technology Fund - July 2020Document3 pagesTA Global Technology Fund - July 2020mulder95No ratings yet

- Iso 22316-2017Document18 pagesIso 22316-2017isosarista100% (1)

- Final Examination Principles of Finance (DPF 24153)Document9 pagesFinal Examination Principles of Finance (DPF 24153)USHA PERUMALNo ratings yet

- DevaluationDocument5 pagesDevaluationसागर मोहन पाटीलNo ratings yet

- PGPM Ex BrochureDocument13 pagesPGPM Ex BrochureVenkateshNo ratings yet

- The Only Resource Which Can Have An Output Greater Than The Sum of Its Arts Is The Human ResourceDocument2 pagesThe Only Resource Which Can Have An Output Greater Than The Sum of Its Arts Is The Human ResourceBaywad Bayambang WDNo ratings yet

- AWS Business Professional WorkbookDocument9 pagesAWS Business Professional WorkbookPulkit AroraNo ratings yet

- Module 3-Contract TypesDocument26 pagesModule 3-Contract TypesBernard OwusuNo ratings yet

- ABIR Global Underwriting Report - 2021Document2 pagesABIR Global Underwriting Report - 2021BernewsAdminNo ratings yet