Professional Documents

Culture Documents

013 Stream Pe 100 Pipe Support Spacings

Uploaded by

mih1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

013 Stream Pe 100 Pipe Support Spacings

Uploaded by

mih1Copyright:

Available Formats

PE 100 PIPE SYSTEMS

PIPE SUPPORT SPACINGS

As polyethylene is a flexible material, adequate pipe supports must be provided

for pipes installed in above ground applications

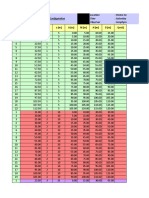

TABLE 7 ABOVE GROUND PIPEWORK MAX SUPPORT SPACING (Meters)

Pipe SDR 26 SDR21 SDR17 SDR13.6 SDR 11 SDR 9 SDR 7.4

Diameter

(mm)

20 0.70

25 0.70 0.75 0.80

32 0.75 0.80 0.85 0.85 0.90

40 0.90 0.90 1.00 1.05 1.05

50 0.95 1.00 1.05 1.15 1.15 1.20

63 1.05 1.10 1.20 1.25 1.30 1.40 1.40

75 1.20 1.25 1.35 1.40 1.50 1.55 1.60

90 1.30 1.40 1.50 1.55 1.65 1.70 1.80

110 1.35 1.50 1.60 1.65 1.70 1.80 1.85

125 1.50 1.65 1.75 1.85 1.95 2.00 2.05

140 1.65 1.80 1.90 2.00 2.10 2.20 2.25

160 1.80 1.90 2.05 2.15 2.25 2.35 2.40

180 1.90 2.00 2.15 2.25 2.40 2.55 2.55

200 2.00 2.15 2.30 2.40 2.55 2.65 2.70

225 2.15 2.30 2.50 2.60 2.70 2.80 2.90

250 2.25 2.40 2.60 2.70 2.85 3.00 3.05

280 2.40 2.60 2.75 2.90 3.05 3.15 3.25

315 2.50 2.70 2.90 3.05 3.20 3.30 3.40

355 2.70 2.90 3.10 3.25 3.40 3.55 3.65

400 2.90 3.00 3.30 3.45 3.65 3.80 3.90

450 3.00 3.20 3.40 3.60 3.75 3.90 4.00

500 3.15 3.40 3.60 3.80 4.00 4.15

560 3.35 3.60 3.85 4.00 4.25 4.40

630 3.60 3.85 4.10 4.30 4.55 4.70

710 3.80 4.10 4.40 4.60 4.85

800 4.05 4.30 4.65 4.90 5.15

900 4.30 4.50 4.95 5.15 5.45

1000 4.55 4.70 5.20 5.45 5.75

ABOVE GROUND INSTALLATION

As polyethylene is a flexible pipe material, adequate pipe support must be provided to prevent sagging when

polyethylene pipes have to be installed above ground. Pipe supports should be designed to support both the pipe

weights and its content and also accommodate the weight of any heavy fittings, valves etc. The pipe brackets, straps

or plinths should have non-abrasive surfaces to prevent damage to the pipe. The support and bracketing design

should allow for the stresses generated from thermal movement and if, for aesthetic reasons pipe deflection is

unacceptable, continuous pipe support should be provided. The table above gives recommendations for maximum

support spacing’s for a pipe full of water at an ambient temperature of 20˚C or below. At a temperature of 40˚C and

above continuous support is recommended for visual acceptance.

As the pipeline cools, any contraction will be resisted by the pipe clamps and when reheated to its normal operation

temperature pipe sagging between supports will be minimized. Polyethylene is a good insulating material (thermal

conductivity 0.4wm˚C) and will help prevent or delay the freezing of the pipe contents.

The pipe itself will not fail if the contents do freeze as polyethylene can safely expand to cater for increased volume.

It is however good practice for operational reasons to insulate pipe work to prevent freezing and to ensure the

insulation is water proof. Pipe work should be protected from possible impact damage and provision should be made

for draining down horizontal pipe runs at low points in the system.

You might also like

- Dosis ObatDocument15 pagesDosis Obatfebry mailuhuNo ratings yet

- Perhitungan Unconfined TestDocument56 pagesPerhitungan Unconfined TestGents HeydNo ratings yet

- RK350-2 20000103TFDocument2 pagesRK350-2 20000103TFlutfiNo ratings yet

- Winkler SafeDocument1 pageWinkler SafeMañonMarianoMariaNo ratings yet

- Espectro E030 2003 Peru - MiDocument9 pagesEspectro E030 2003 Peru - MiOscarQuirogaNo ratings yet

- AccuracyDocument1 pageAccuracyVineeshNo ratings yet

- Rezkiya Laila Bilkis 201822201043Document12 pagesRezkiya Laila Bilkis 201822201043LALANo ratings yet

- Working Load Limits For SlingsDocument11 pagesWorking Load Limits For Slingstolis-gefNo ratings yet

- Cartão Folga SKF Com ChaveDocument2 pagesCartão Folga SKF Com ChaveAnderson vianaNo ratings yet

- Comap IDMT Trip Time Table (REF DEMCO SEL749 TOL)Document26 pagesComap IDMT Trip Time Table (REF DEMCO SEL749 TOL)kezsb01No ratings yet

- SKF Mounting Card - SRB Carb - 14231 enDocument2 pagesSKF Mounting Card - SRB Carb - 14231 enKevin AvilaNo ratings yet

- Modulo de Reaccion Del SueloDocument1 pageModulo de Reaccion Del SueloDaniel RabascallNo ratings yet

- Espectro De Diseño Sismico Gbds: Espectro Zona 3-Suelo S4 (1.5 Kg/cm2>σadm ≥ 0.5Kg/cm2)Document4 pagesEspectro De Diseño Sismico Gbds: Espectro Zona 3-Suelo S4 (1.5 Kg/cm2>σadm ≥ 0.5Kg/cm2)OscarQuirogaNo ratings yet

- Control de Metrados de Pases AereosDocument1 pageControl de Metrados de Pases AereosHV FicoNo ratings yet

- S.1 Parung BangkongDocument3 pagesS.1 Parung BangkongAde SetiawanNo ratings yet

- Duthch Cone Penetration Test (DCPT) : Soil Investigation and TopographyDocument2 pagesDuthch Cone Penetration Test (DCPT) : Soil Investigation and TopographyUlfi AlmizNo ratings yet

- DIN 2093 UNI 8737 Molle A TazzaDocument6 pagesDIN 2093 UNI 8737 Molle A TazzaRoby MastreNo ratings yet

- Precios de Pernos MilimetricosDocument1 pagePrecios de Pernos MilimetricosAnavel Hurtado TolentinoNo ratings yet

- Septic Tank and Its Suggested SizesDocument2 pagesSeptic Tank and Its Suggested SizesPrinces TuguinayNo ratings yet

- Syaikhu Umar Wahid - 220521603840 - Tugas Minggu Ke 7Document11 pagesSyaikhu Umar Wahid - 220521603840 - Tugas Minggu Ke 7TRISUCI ANGGUNNo ratings yet

- Stop LossDocument113 pagesStop LossSabyasachiDasNo ratings yet

- Data Geolistrik (Wenner)Document19 pagesData Geolistrik (Wenner)Anonymous IrESVWrTyiNo ratings yet

- Espectro E030 2003 Peru - MCDocument9 pagesEspectro E030 2003 Peru - MCOscarQuirogaNo ratings yet

- Hyosung - Tabla Pastillas CalibradasDocument2 pagesHyosung - Tabla Pastillas Calibradas19742020No ratings yet

- KV (NSPTmédio) - SAFE, MORRISON (1993)Document1 pageKV (NSPTmédio) - SAFE, MORRISON (1993)Naldinho MonteiroNo ratings yet

- 1.4 Sondir Jembatan S. Desa Burau PantaiDocument16 pages1.4 Sondir Jembatan S. Desa Burau PantaiNursusanti SyafruddinNo ratings yet

- Diametro Nominal (MM) (Pulg)Document2 pagesDiametro Nominal (MM) (Pulg)daniela caryNo ratings yet

- Sondir - Kelompok 1 - OkDocument3 pagesSondir - Kelompok 1 - OkAndri RikardoNo ratings yet

- Data Sondir FixDocument15 pagesData Sondir FixSah putraNo ratings yet

- Penetration Conus Test: (ASTM D 3441 - 86)Document1 pagePenetration Conus Test: (ASTM D 3441 - 86)Briana MarthandriNo ratings yet

- Tes Ip Xi tkj2Document5 pagesTes Ip Xi tkj2Sonny Indra PratamaNo ratings yet

- Kato NK 30Document2 pagesKato NK 30hasnanNo ratings yet

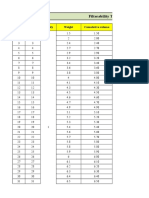

- Filterability Test: Sr. No. Time (T) Density Weight Cumulative VolumeDocument16 pagesFilterability Test: Sr. No. Time (T) Density Weight Cumulative VolumeRajeeb Chandra ShahaNo ratings yet

- HIDRODocument19 pagesHIDROrizkiNo ratings yet

- Data Geolistrik (Wenner)Document21 pagesData Geolistrik (Wenner)Anonymous IrESVWrTyiNo ratings yet

- Manual Grúa Terex 10 11Document2 pagesManual Grúa Terex 10 11Qanttum Sport ClubNo ratings yet

- Electrical DesignDocument6 pagesElectrical DesignxtianNo ratings yet

- Buil Physics and NotesDocument1 pageBuil Physics and NotesSHOTURU PNo ratings yet

- ViviendaUnifamiliar - Floor Plan - Level 3-ModelDocument1 pageViviendaUnifamiliar - Floor Plan - Level 3-ModelAnth LudNo ratings yet

- SDM Pipe Calculations (SI)Document28 pagesSDM Pipe Calculations (SI)sadegh firouzshahiNo ratings yet

- Equivalent Length TableDocument6 pagesEquivalent Length TableManikandan MNo ratings yet

- Uji Setting Time Beton: Tanggal: MutuDocument12 pagesUji Setting Time Beton: Tanggal: Mutuagus wahyudiNo ratings yet

- Oring Kanal OlcuDocument2 pagesOring Kanal Olcunuri özbakırNo ratings yet

- AIS Directory 766Document1 pageAIS Directory 766hansleyNo ratings yet

- Esfuerzo Admisible Winkler Asent kgf/cm2 Tonf/m2 Kpa kgf/cm3 Tonf/m3 Kpa/m CMDocument5 pagesEsfuerzo Admisible Winkler Asent kgf/cm2 Tonf/m2 Kpa kgf/cm3 Tonf/m3 Kpa/m CMArmando Sergio Teran BedoyaNo ratings yet

- Electricity TariffDocument2 pagesElectricity Tariffbrajeshchandra28No ratings yet

- Ratio GgalDocument176 pagesRatio GgalDiego DiegoteNo ratings yet

- Practica Levas ElementosDocument10 pagesPractica Levas ElementosAlan CamperoNo ratings yet

- Material List 2Document3 pagesMaterial List 2Salim BakhshNo ratings yet

- Trade Life Engineering and Consultancy Services: Gonzalo G. Ong, JR., Pee, RMP, Enp, Rea, RebDocument2 pagesTrade Life Engineering and Consultancy Services: Gonzalo G. Ong, JR., Pee, RMP, Enp, Rea, RebJoel ArjonaNo ratings yet

- Tubing Pipe Dimensions Weight ChartDocument1 pageTubing Pipe Dimensions Weight ChartTahiruddin AhmedNo ratings yet

- Curva de Crecimiento de Larvas de SábaloDocument3 pagesCurva de Crecimiento de Larvas de Sábalokarol job Sajami TorresNo ratings yet

- 6.000 V Linear (V)Document6 pages6.000 V Linear (V)ZZZYYYouNo ratings yet

- Trading PlanDocument4 pagesTrading PlanHouston ChalzNo ratings yet

- Data Sondir Rujab KonutDocument40 pagesData Sondir Rujab KonutErick CivilNo ratings yet

- AAG Tolerances GBDocument2 pagesAAG Tolerances GBJayantNo ratings yet

- Tugas 6 BaprogDocument12 pagesTugas 6 BaprogAndy FadhilaNo ratings yet

- Data Hatco StatDocument3 pagesData Hatco StatSandrina NingrumNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmih1No ratings yet

- ++++++EMM ProjectsDocument104 pages++++++EMM Projectsmih1No ratings yet

- Weld Stress CalculationsDocument13 pagesWeld Stress Calculationsmih1No ratings yet

- E3d CommandsDocument21 pagesE3d Commandsmih1100% (7)

- Create Drawing of Pipe SupportsDocument16 pagesCreate Drawing of Pipe SupportsShyammurugesanNo ratings yet

- Pipe SupportsDocument62 pagesPipe Supportsmih1No ratings yet

- Numikon Katalog 2019Document42 pagesNumikon Katalog 2019mih1No ratings yet

- Optimal Pipe Support SpansDocument4 pagesOptimal Pipe Support Spansmih1No ratings yet

- Comparative Study On Pressure Equipment StandardsDocument32 pagesComparative Study On Pressure Equipment Standardsmih1No ratings yet

- TM 1870 Aveva Everything3d 2 1 Draw Administration Rev 20pdfDocument206 pagesTM 1870 Aveva Everything3d 2 1 Draw Administration Rev 20pdfmih1No ratings yet

- Qdoc - Tips - 304540999 Pipe Support Design Calculation Report 1Document28 pagesQdoc - Tips - 304540999 Pipe Support Design Calculation Report 1mih1No ratings yet

- Anchor Bolt Size Check For Legged Supported Vessels: Item No.: Active CarbonDocument2 pagesAnchor Bolt Size Check For Legged Supported Vessels: Item No.: Active Carbonmih150% (2)

- Tower Resonance Analysis: E-Mail Author: Uou99@mail - Ulsan.ac - KR Corresponding Author: Hkshin@ulsan - Ac.krDocument1 pageTower Resonance Analysis: E-Mail Author: Uou99@mail - Ulsan.ac - KR Corresponding Author: Hkshin@ulsan - Ac.krmih1No ratings yet

- Final 1Document3 pagesFinal 1mih1No ratings yet

- Clamps: Slurry Hose SystemsDocument2 pagesClamps: Slurry Hose Systemsmih1No ratings yet

- Platform Optimization of Large Floating Offshore WDocument6 pagesPlatform Optimization of Large Floating Offshore Wmih1No ratings yet

- Dynamic Restraints: Fronek Anchor/Darling Enterprises, Inc., An ASME "NS"Document2 pagesDynamic Restraints: Fronek Anchor/Darling Enterprises, Inc., An ASME "NS"mih1No ratings yet

- EWEA2012 PresentationDocument9 pagesEWEA2012 Presentationmih1No ratings yet

- HIPAC Catalog UK 2018 Web SmallDocument24 pagesHIPAC Catalog UK 2018 Web Smallmih1No ratings yet

- Energies 13 05820 v2Document22 pagesEnergies 13 05820 v2mih1No ratings yet

- Energies: Experimental Research For Stabilizing O Floating Wind TurbinesDocument15 pagesEnergies: Experimental Research For Stabilizing O Floating Wind Turbinesmih1No ratings yet

- Multi-Criteria Assessment Tool For Floating Offshore Wind Power PlantsDocument6 pagesMulti-Criteria Assessment Tool For Floating Offshore Wind Power Plantsmih1No ratings yet

- Multi-Objective Optimization of Mooring Systems For Offshore Renewable EnergyDocument8 pagesMulti-Objective Optimization of Mooring Systems For Offshore Renewable Energymih1No ratings yet

- Investigation of Response Amplitude Operators For Floating Offshore Wind TurbinesDocument10 pagesInvestigation of Response Amplitude Operators For Floating Offshore Wind Turbinesmih1No ratings yet

- Dutypoint Dirt & Air SeparatorsDocument12 pagesDutypoint Dirt & Air SeparatorsdokundotNo ratings yet

- Sustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Document4 pagesSustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Nikhil SatavNo ratings yet

- SHS Micro Financing in NepalDocument24 pagesSHS Micro Financing in NepalparipranaNo ratings yet

- Offshore Pipe Line Design State of The ArtDocument33 pagesOffshore Pipe Line Design State of The ArtMvrnaidu MithraNo ratings yet

- Electrical Work SpecsDocument33 pagesElectrical Work SpecsusmanaliNo ratings yet

- ZRIMADocument494 pagesZRIMAأبو الأمين المغربيNo ratings yet

- Pressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrDocument12 pagesPressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrVidal Choque N.100% (1)

- JodhpurDocument2 pagesJodhpurPranita ShandilyaNo ratings yet

- ASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXDocument5 pagesASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXYoussef DaoudNo ratings yet

- Gait Analysis and Clinical ApplicationDocument123 pagesGait Analysis and Clinical ApplicationKanhu Mallik100% (4)

- Brakes Design Report: Objective - The Brakes Are One of The Most Important Safety Systems On The Vehicle. The CarDocument17 pagesBrakes Design Report: Objective - The Brakes Are One of The Most Important Safety Systems On The Vehicle. The CarTavi SharmaNo ratings yet

- Design and Implementation of Multiple Output Switch Mode Power SupplyDocument6 pagesDesign and Implementation of Multiple Output Switch Mode Power SupplyseventhsensegroupNo ratings yet

- Manual Yamaha YST-SW800 (Service)Document26 pagesManual Yamaha YST-SW800 (Service)Alex NikitinNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet

- ADB (2009) Sustainable Energy Efficiency Development Program PDFDocument542 pagesADB (2009) Sustainable Energy Efficiency Development Program PDFaanchanNo ratings yet

- Gate Questions On MosfetDocument16 pagesGate Questions On MosfetEsakkiPonniah100% (1)

- 1 6L GM Vortec SRVCDocument320 pages1 6L GM Vortec SRVCFred100% (2)

- SBSBattery VRLA Tubular Gel VRZ Series PDFDocument1 pageSBSBattery VRLA Tubular Gel VRZ Series PDFAleiska Victoria Gómez BetancourthNo ratings yet

- LEVEL I - ATA 28 FuelDocument66 pagesLEVEL I - ATA 28 Fuelwagdi100% (1)

- Arc Welding: Assignment in Ce12Document5 pagesArc Welding: Assignment in Ce12Analyn NatividadNo ratings yet

- RM3-400 Series Rectifier Magazine: Eaton DC Power SolutionsDocument2 pagesRM3-400 Series Rectifier Magazine: Eaton DC Power Solutionsaldariz201181No ratings yet

- Toyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFDocument5 pagesToyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFrodrivalentNo ratings yet

- Recommendations Regarding Fuel Quality For Diesel Engines: Number 21 2003Document36 pagesRecommendations Regarding Fuel Quality For Diesel Engines: Number 21 2003MiguelNo ratings yet

- Discussion Ecm433Document2 pagesDiscussion Ecm433Nina WalinNo ratings yet

- TEC5500 OM p10 - 9 Battery Test PDFDocument3 pagesTEC5500 OM p10 - 9 Battery Test PDFchanlalNo ratings yet

- Rectangular Double-Well Potential: HW9.nbDocument10 pagesRectangular Double-Well Potential: HW9.nbMendoza JohnyNo ratings yet

- Power Supplies Module 02Document20 pagesPower Supplies Module 02Isabela Dos SantosNo ratings yet

- Flash MixerDocument2 pagesFlash MixerKhaldoon AlnashiNo ratings yet

- A.s.t.m.22 Manual On The Use of ThermocouplesDocument312 pagesA.s.t.m.22 Manual On The Use of ThermocouplesAR RmsNo ratings yet

- Welding InspectorDocument5 pagesWelding InspectorqaqcnaviNo ratings yet