Professional Documents

Culture Documents

Characteristics of Plastic Materials 2: 'Technical Data

Uploaded by

djsiraj834Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characteristics of Plastic Materials 2: 'Technical Data

Uploaded by

djsiraj834Copyright:

Available Formats

Plastic resins

1 Plastic Materials Polyacetal Polybutyrene terephthalate Polyethylene terephthalate Polyphenylene sulfide Liquid-crystal polymer Fluororesin

JIS A.S.T.M

2 Grade General

Testing Testing Glass fiber Glass fiber Glass fiber Glass fiber Glass fiber

method method 3 Filler - 25% or less

- 30%

- 30%

- 30%

- 40%

-

4 Abbreviations POM POM-GF PBT PBT-GF PET PET-GF PPS PPS-GF LCP LCP-GF FEP

5 Drying temperature (A) 10 110 120 120 120 120 130~140 130~140 140~160 140~160 -

6 Drying time (hr) 2 2 4 4 4 4 2 2 4 4 -

’TECHNICAL DATA»

7 Injection forming cylinder temperature(A) 180~230 180~230 230~280 230~280 265~325 265~325 315~330 315~360 360~390 290~310 370~430

8 Injection molding tool temperature(A) 60~120 60~120 40~80 40~80 130~150 130~150 130~150 130~150 70~110 70~110 95~230

2

9 Injection molding pressure(kgf/cm ) 703~1410 730~1410 562~1800 562~1800 700~1400 400~700 500~1000 500~1400 400~900 400~900 352~1410

Molding properties

10 Compression molding temperature(A) - - - - - - - - - - 315~399

2

11 Compression molding pressure

(kgf/cm ) - - - - - - - - - - 70.3~141

Flow direction 0.3~0.4 Flow direction 0.1~0.2 Flow direction 0.1~0.15

12 Molding shrinkage rate (%) 2~2.5 0.4 1.5~2.0 0.2~0.8 2~2.5 0.2~0.9 0.6~0.8 2~3

Traverse direction 0.6~0.7 Traverse direction 0.6~0.9 Traverse direction 0.3~0.5

K6911,K7112 D792 13 Specific gravity(density) 1.41~1.42 1.61 1.31~1.38 1.52 1.29~1.40 1.55~1.67 1.30 1.60~1.67 1.35 1.70 2.15~2.17

2

K6911,K7113 D638 14 Tensile strength (kgf/cm ) 580~800 1250~1300 550~640 1100~1340 465~700 1400~1550 630 1500~1550 1060~1335 900 180~210

15 Tensile elongation (%) 25~75 3 50~300 2~4 30~300 2~7 1~2 0.9~4 1.3~4.5 1.8 250~330

K7208 16 Compressive strength (kgf/cm2 ) 1270 1200 605~1020 1270~1650 - - - - - - 155

2

K7203 17 Flexure strength (kgf/cm ) 991 1970 844~1170 1830 - - - - - - -

2

K7110,K7111 18 Izot impact strength (kgf/cm ) 5.4~13 10 4.4~5.4 7.0~8.7 1.4~3.8 8.7~11 <2.7 6~8 13~21 8.7 Non-destructive

Mechanical characteristics

K7202 D785 19 Rockwell hardness M78~94 M79 M68~78 M90 M94~101 M90~100 R123 R123 R60~63 R79 D60~80

20 Heat resistance temperature(continuous)(A) 90 104 49.8~121 115~176 - - - - - - 204

2

K7206,K7207 D648 21 Deflection temperature a)Bending stress18.6kgf/cm 124 110 49.8~85 220 21~38 210~225 135 250~265 337~335 319 -

under load(A)

2

b)Bending stress 4.6kgf/cm 170 158 115~193 225 - 243 69.8

Thermal characteristics

CHARACTERISTICS OF PLASTIC MATERIALS 2

Gears, cams Motor fans Textile Automobile PET bottles Gears Connectors High temperature

components insulation parts

Bearing Pump implant Containers Coil bobbins Connectors Electronic parts

Radio-frequency

Electromagnetic Gears Key top Consumer Automobile components device components

22 Applications valve cases electronics

Switch covers Electrical components Switches Insulating

Connector connectors tapes

Wire coverings

Thermoplastic resins

Melamine- Polydiallyl

1 Plastic Materials Epoxy(Epoxide) Phenol-formaldehyde Silicone Urea-formaldehyde Unsaturated polyester

formaldehyde phthalate

JIS A.S.T.M

2 Grade Low specific gravity High impact proof High strength Premix SMC

Testing Testing

method method 3 Filler Glass fiber Glass balls Cellulose Glass - Wood flour, cotton Glass fiber Glass fiber Å Cellulose Glass roving Glass fiber Glass fiber

4 Abbreviations EP EP MF PDAP PF PF PF SI UF UP UP UP

5 Drying temperature (A) - - - - - - - - - - - -

6 Drying time (hr) - - - - - - - - - - - -

7 Injection molding cylinder temperature(A) - 121~149 143~171 149~176 - 183~222 165~199 - 143~160 - - -

8 Injection molding tool temperature(A) - - - - - - - - - - - -

2

9 Injection molding pressure(kgf/cm ) - 703~1050 1050~14101410~4220 - 703~1410 352~1410 - 1050~1410 - - -

Molding properties

10 Compression molding temperature(A) 149~165 121~160 138~188 143~193 132~160 143~193 149~193 154~182 135~176 76.5~160 138~176 132~176

2

11 Compression molding pressure(kgf/cm ) 21.1~35.2 7.03~141 105~562 352~281 123~263 123~334 70.3~422 70.3~350 141~562 17.6~141 35.2~141 21.1~94.4

12 Molding shrinkage rate (%) 0.1~0.5 0.6~1.0 0.5~1.5 0.1~0.5 1.0~1.2 0.4~0.9 0.1~0.4 0~0.5 0.6~1.4 0.02~0.2 0.1~1.2 0.1~0.4

K6911,K7112 D792 13 Specific gravity(density) 1.6~2.0 0.75~1.0 1.47~1.52 1.51~1.78 1.21~1.30 1.34~1.45 1.69~2.0 1.80~1.94 1.47~1.52 1.35~2.30 1.65~2.30 1.65~2.60

2

K6911,K7113 D638 14 Tensile strength (kgf/cm ) 703~1410 176~281 492~914 422~773 492~562 352~633 352~1270 281~457 387~914 1050~2110 211~703 562~1410

15 Tensile elongation (%) 4 - 0.6~0.9 3~5 1.0~1.5 0.4~0.8 0.2 - 0.5~1.0 0.5~5.0 0.5~2.0 3

K7208 16 Compressive strength(kgf/cm2 ) 1760~2810 703~1050 2810~31601760~2460 703~2190 155~253 1120~4920 103~1050 176~316 1050~2110 1410~2110 1050~2110

2

K7203 17 Flexure strength (kgf/cm ) 703~4220 352~492 703~1120 773 844~1050 492~984 703~4220 703~984 703~1270 703~1270 492~1410 703~2530

2

K7110,K7111 18 Izot impact strength(kgf/cm ) 10.9~163 0.82~1.36 1.31~1.91 2.18~81.6 1.09~1.96 1.31~3.27 1.63~100 1.63~43.5 1.36~2.18 10.9~109 8.16~87.1 38.1~120

Mechanical characteristics

barcol barcol barcol

K7202 D785 19 Rockwell hardness M100~110 - M115~125 E80~87 M124~128 M100~115 E54~101 M80~90 M10~120 50~80 50~80 50~70

20 Heat resistance temperature(continuous)(A) 149~260 - 99 149~204 121 149~176 176~288 >315 76.5 149~176 149~176 149~204

2

K7206,K7207 D648 21 Deflection temperature a)Bending stress 18.6kgf/cm 121~260 93~121 176~188 165~232 115~126 149~188 149~315 >482 126~143 >204 >204 190~260

under load(A)

2

b)Bending stress 4.6kgf/cm - - - - - - - - - - - -

Thermal characteristics

Electronics/telecom device parts Push buttons Micro Connector Electric parts Laminated sheets TV tuners

switches

High-insulating cases, covers Handles switches Lubricants Textile Fuses

Breakers

Semiconductor chips Knobs Connector Tuners Colorant

22 Applications Motor covers

IC Arc extinguishing panels relay parts Breakers Knobs Power distributor case covers

Capacitors Tableware Measuring Coils Tableware Press rings

instrument

Small-size transformers Bobbins Rectifier frames

components

You might also like

- Characteristics of Plastic Materials 2: 'Technical DataDocument1 pageCharacteristics of Plastic Materials 2: 'Technical Datadjsiraj834No ratings yet

- Hotel S+P+8E: Proiect de LicentaDocument1 pageHotel S+P+8E: Proiect de LicentaAlex BaleaNo ratings yet

- EDGE ISO 13715: Where Not Indicated, A 0.7 of Minimum Thickness To Be Welded CornerDocument4 pagesEDGE ISO 13715: Where Not Indicated, A 0.7 of Minimum Thickness To Be Welded CornerPrincess GueribaNo ratings yet

- Detail 1 On/Off Control Valve Detail 2 On/Off Control Valve: Yanacocha Gold Mill ProjectDocument1 pageDetail 1 On/Off Control Valve Detail 2 On/Off Control Valve: Yanacocha Gold Mill ProjectNavarro Zavala AntonyNo ratings yet

- Drawings 1Document1 pageDrawings 1aisha nakatoNo ratings yet

- RDC Ius OuvertureDocument1 pageRDC Ius OuvertureTelesphore MoffoNo ratings yet

- 240K C2 3200 25J 019 3Document1 page240K C2 3200 25J 019 3Mario UyfNo ratings yet

- Ground FloorDocument1 pageGround FloorAyad GamalNo ratings yet

- Ground FloorDocument1 pageGround FloorAyad GamalNo ratings yet

- Catalogo PetmaticDocument2 pagesCatalogo PetmaticMARIA LUIZA DE MELO MOURANo ratings yet

- S001Document1 pageS001Yong Hui OngNo ratings yet

- EXW-P008-0003-SE-CCC-DG-41050-014 - Rev CADocument1 pageEXW-P008-0003-SE-CCC-DG-41050-014 - Rev CAAbdul basithNo ratings yet

- Onyx Quality Test PDFDocument1 pageOnyx Quality Test PDFHoffman Elizalde100% (1)

- Print Testing Tools: Colourretetiontime1 6Pt - 0 PT C Han GeDocument1 pagePrint Testing Tools: Colourretetiontime1 6Pt - 0 PT C Han GeSlavik TNo ratings yet

- AM05 GA R1Document1 pageAM05 GA R1sarukh.khanNo ratings yet

- Konka+KDL48MT625UN Top HouseDocument3 pagesKonka+KDL48MT625UN Top Housemiguelonsennin94No ratings yet

- 325 Sistema HidraulicoDocument2 pages325 Sistema HidraulicoHernan Edion100% (1)

- Bakalao Salao: TrombónDocument1 pageBakalao Salao: TrombónalvaroNo ratings yet

- Aliran Proses Aliran Proses KeteranganDocument2 pagesAliran Proses Aliran Proses KeteranganBurhanudin MuizNo ratings yet

- Catalog of quick-release hydraulic couplingsDocument404 pagesCatalog of quick-release hydraulic couplingsmecelberNo ratings yet

- Group 2 Electrical Circuit: Dashboard Part Frame / Engine PartDocument10 pagesGroup 2 Electrical Circuit: Dashboard Part Frame / Engine PartCamilo TorresNo ratings yet

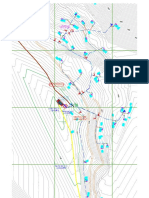

- Leyenda Proyecto-Perimetro Vertice Poligonal Nombre Vertice: Te TeDocument1 pageLeyenda Proyecto-Perimetro Vertice Poligonal Nombre Vertice: Te TeAlexis Rafael Asipali CoheloNo ratings yet

- PA-1 - CASETA - Rev 0Document1 pagePA-1 - CASETA - Rev 0Ingenieria BaldarragoNo ratings yet

- (Free Scores - Com) Marttala Ryan Interlude No 1 Radiance 2011 For Vibraphone 1 or 2 Performers 34137Document2 pages(Free Scores - Com) Marttala Ryan Interlude No 1 Radiance 2011 For Vibraphone 1 or 2 Performers 34137OlesNo ratings yet

- Base at level +37.00 floor and wall construction layersDocument1 pageBase at level +37.00 floor and wall construction layersVuk VusovicNo ratings yet

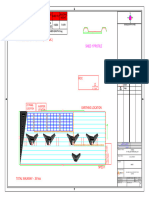

- Ban Ve PigDocument1 pageBan Ve PigNguyen Tien DatNo ratings yet

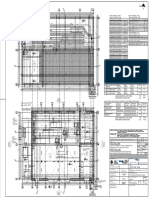

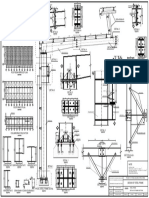

- Ban Ve ThepDocument1 pageBan Ve ThepNguyen Tien DatNo ratings yet

- CourtsMayCatalogueWMRaya PDFDocument4 pagesCourtsMayCatalogueWMRaya PDFFyrdaus GhanyNo ratings yet

- Sub Sistema 01: Valvula de AIRE (01) Ø 4"Document1 pageSub Sistema 01: Valvula de AIRE (01) Ø 4"Lisde EspinozaNo ratings yet

- Dźwigar GOTOWY-ModelDocument1 pageDźwigar GOTOWY-Modelanes beckNo ratings yet

- Stuffing Box Packings: Sealing For A Safer and Greener TomorrowDocument4 pagesStuffing Box Packings: Sealing For A Safer and Greener TomorrowT. Sandy FajarNo ratings yet

- Plani I Pergjithshem I Pilotave (Perforcimi I Skarpatave) : CHS 350X13Document1 pagePlani I Pergjithshem I Pilotave (Perforcimi I Skarpatave) : CHS 350X13Alban HysomemajNo ratings yet

- A.ebal Cand - Zamb.pg13of14Document1 pageA.ebal Cand - Zamb.pg13of14LESTER PAOLO APINONo ratings yet

- 3 - FlautoDocument17 pages3 - FlautoJane YakimenkoNo ratings yet

- Pumpentechnik Screwpumps Product Range en - New - 1Document9 pagesPumpentechnik Screwpumps Product Range en - New - 1AhmdSbhyNo ratings yet

- Bridge Master Tma3prt2Document24 pagesBridge Master Tma3prt2Teyfik koyuncuNo ratings yet

- Denah PantryDocument1 pageDenah PantryHERI SURYADINo ratings yet

- PVF Pps-Mesh en 2017Document2 pagesPVF Pps-Mesh en 2017vkmsNo ratings yet

- 4021-DWG-CVT-SHD-005c_RCDocument1 page4021-DWG-CVT-SHD-005c_RCRido faturahmanNo ratings yet

- ZX80 Build034 LayoutDocument1 pageZX80 Build034 LayoutOscar Arthur KoepkeNo ratings yet

- Fci - Hermosa: Previous Accomplishment Report 75.92%Document1 pageFci - Hermosa: Previous Accomplishment Report 75.92%Jhn Cbllr BqngNo ratings yet

- Fondations - Persan-Fondation m1 m2Document1 pageFondations - Persan-Fondation m1 m2Soulanges YannickNo ratings yet

- Electricity generation and infrastructure project dataDocument1 pageElectricity generation and infrastructure project dataEd GonzalesNo ratings yet

- Effect of PHDocument1 pageEffect of PHSushil PantNo ratings yet

- Print Testing Tools: Colour Retetion Time 1 6Pt - 0Pt ChangeDocument1 pagePrint Testing Tools: Colour Retetion Time 1 6Pt - 0Pt ChangeMohamedNo ratings yet

- Order 9095263Document6 pagesOrder 9095263Florentina ValentinaNo ratings yet

- Проверка Струйной 6 Ти Цветной ПечатиDocument1 pageПроверка Струйной 6 Ти Цветной ПечатиПолиграфический центр МирандаNo ratings yet

- Print-Testing-Tools-Mir - Copy-MergedDocument2 pagesPrint-Testing-Tools-Mir - Copy-Mergedbelive itNo ratings yet

- Print Quality Testing ToolDocument1 pagePrint Quality Testing Toolぼくは エンヂNo ratings yet

- Tub PVC Sap C-7.5 L 124m: Sub Sistema 02Document1 pageTub PVC Sap C-7.5 L 124m: Sub Sistema 02Lisde EspinozaNo ratings yet

- Standard Tuning: P Sl. Sl. 1 2Document2 pagesStandard Tuning: P Sl. Sl. 1 2Земченков КонстантинNo ratings yet

- PS Mec Gen 001Document1 pagePS Mec Gen 001Anderson RodriguezNo ratings yet

- A Minha Vida É Do Mestre Alto SaxophoneDocument2 pagesA Minha Vida É Do Mestre Alto SaxophoneJosimar CostaNo ratings yet

- 5Document1 page5Anujith K BabuNo ratings yet

- Full download Ati Rn Proctored Comprehensive Predictor 2016 Form C pdfDocument26 pagesFull download Ati Rn Proctored Comprehensive Predictor 2016 Form C pdfcharles.norris476100% (16)

- LBPB22243226Document1 pageLBPB22243226Md Lukman KhanNo ratings yet

- Quick Setup Labradar ENDocument2 pagesQuick Setup Labradar ENAlexander PohlNo ratings yet

- It's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentFrom EverandIt's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentNo ratings yet

- Multi Cavity Mold and Samples: H T Mould (China) LimitedDocument9 pagesMulti Cavity Mold and Samples: H T Mould (China) Limiteddjsiraj834No ratings yet

- Study Gap Certificate AffidavitDocument1 pageStudy Gap Certificate Affidavitdjsiraj834No ratings yet

- Multi Cavity Mold and Samples: H T Mould (China) LimitedDocument9 pagesMulti Cavity Mold and Samples: H T Mould (China) Limiteddjsiraj834No ratings yet

- Solidworks: Mold Design Using SOLIDWORKSDocument8 pagesSolidworks: Mold Design Using SOLIDWORKSdjsiraj834No ratings yet

- Je Design of Joints 33Document8 pagesJe Design of Joints 33djsiraj834No ratings yet

- TSPSC Aee Civil SyllabusDocument4 pagesTSPSC Aee Civil Syllabusapi-293926977No ratings yet

- Polymer ShrinkageDocument5 pagesPolymer ShrinkageGiap NguyenNo ratings yet

- 09 Mo1499Document1 page09 Mo1499djsiraj834No ratings yet

- Non Gazetted CategoryDocument1 pageNon Gazetted CategorySurendraSurenderNo ratings yet

- Finishing of Ejector Pins and Core Pin Tips Finishing of Corners of Rectangular Ejector PinsDocument1 pageFinishing of Ejector Pins and Core Pin Tips Finishing of Corners of Rectangular Ejector Pinsdjsiraj834No ratings yet

- P2Q emDocument6 pagesP2Q emdjsiraj834No ratings yet

- Je Power Transmission by Belts 48Document16 pagesJe Power Transmission by Belts 48djsiraj834No ratings yet

- Post Diploma in Plastics Mould Design With CAD/CAM (PD-PMD With CAD/CAM) Post Diploma in Plastics Mould Design With CAD/CAM (PD-PMD With CAD/CAM)Document3 pagesPost Diploma in Plastics Mould Design With CAD/CAM (PD-PMD With CAD/CAM) Post Diploma in Plastics Mould Design With CAD/CAM (PD-PMD With CAD/CAM)djsiraj834No ratings yet

- Plastic Injection Molding Material Shrink Rate ChartDocument1 pagePlastic Injection Molding Material Shrink Rate Chartdjsiraj834No ratings yet

- Main Applications of Cad Cam PDFDocument2 pagesMain Applications of Cad Cam PDFJīthiň Kůmăŕ ÑNo ratings yet

- Multi Cavity Mold and Samples: H T Mould (China) LimitedDocument9 pagesMulti Cavity Mold and Samples: H T Mould (China) Limiteddjsiraj834No ratings yet

- Polymer ShrinkageDocument5 pagesPolymer ShrinkageGiap NguyenNo ratings yet

- Training Course Description: Creo Mold DesignDocument2 pagesTraining Course Description: Creo Mold Designdjsiraj834No ratings yet

- Quantitative Aptitude Tricks - PDF Download: ImplificationDocument12 pagesQuantitative Aptitude Tricks - PDF Download: ImplificationSwapnarani JadavNo ratings yet

- 09 Mo1499Document1 page09 Mo1499djsiraj834No ratings yet

- Mold Components 2019Document204 pagesMold Components 2019djsiraj834No ratings yet

- Je Static Dynamic Fatigue Loadin 60Document25 pagesJe Static Dynamic Fatigue Loadin 60djsiraj834No ratings yet

- App Tricks Simple Interest and Compound Interest Tricks Article PDFDocument12 pagesApp Tricks Simple Interest and Compound Interest Tricks Article PDFSelvaraj VillyNo ratings yet

- Injection Mold Design Engineering: August 2007Document13 pagesInjection Mold Design Engineering: August 2007djsiraj834No ratings yet

- TSPSC TRT PetDocument5 pagesTSPSC TRT Petsangisetti ajay sangisetti ajayNo ratings yet

- Syllabus Paper-I: General Studies and General AbilitiesDocument1 pageSyllabus Paper-I: General Studies and General AbilitiesShiva Krishna GopuNo ratings yet

- AE SyllabusDocument5 pagesAE SyllabusammuvarshNo ratings yet

- AE SyllabusDocument5 pagesAE SyllabusammuvarshNo ratings yet

- Film & Dropwise Condensation UnitDocument16 pagesFilm & Dropwise Condensation UnitHafizszul FeyzulNo ratings yet

- Note 7 - Welder Test - Mechanical Test and X-RayDocument29 pagesNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiNo ratings yet

- Diaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use FeaturesDocument5 pagesDiaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use Featuresnotaden1849No ratings yet

- Chemistry Form 6 Sem 3 10Document29 pagesChemistry Form 6 Sem 3 10Anonymous WAnr0jvNo ratings yet

- Cable Cleats R2Document13 pagesCable Cleats R2Vishal RanjanNo ratings yet

- AHRI Standard 410-2001 With Addenda 1 2 and 3Document67 pagesAHRI Standard 410-2001 With Addenda 1 2 and 3Oziel Reyes100% (1)

- 3 Interfacial PhenomenaDocument8 pages3 Interfacial PhenomenaJames DayritNo ratings yet

- Articaine 30 Years LaterDocument19 pagesArticaine 30 Years LaterAlina Gafton100% (2)

- VCO and Transparent Soap RevisiDocument16 pagesVCO and Transparent Soap RevisiRikkoNo ratings yet

- Moles Molarity Dilution Worked SolutionsDocument14 pagesMoles Molarity Dilution Worked Solutionsopolla nianorNo ratings yet

- Volume II - EXPORTS - FTS 2015 Ebook - As of 05-02-17 PDFDocument664 pagesVolume II - EXPORTS - FTS 2015 Ebook - As of 05-02-17 PDFAJ SaNo ratings yet

- Effect of Immediate Dentin Sealing On The Bond Strength of Monolithic Zirconia To Human DentinDocument13 pagesEffect of Immediate Dentin Sealing On The Bond Strength of Monolithic Zirconia To Human Dentinilich sevillaNo ratings yet

- Treatment of Fertilizer Industry Wastewater by Catalytic Peroxidation Process Using Copper-Loaded SBA-15Document12 pagesTreatment of Fertilizer Industry Wastewater by Catalytic Peroxidation Process Using Copper-Loaded SBA-15Risa R AhyudanariNo ratings yet

- Waterproofing System To Submerge Structure (Lift Pit) General RequirementsDocument3 pagesWaterproofing System To Submerge Structure (Lift Pit) General Requirementsaldeto71No ratings yet

- CaseHard BS970-1955EN36ADocument2 pagesCaseHard BS970-1955EN36AtechzonesNo ratings yet

- CH 7 Problems 5th EditionDocument2 pagesCH 7 Problems 5th EditionnisannnNo ratings yet

- SEMINAR PERDANA KESELAMATAN & KESIHATAN PEKERJAANDocument18 pagesSEMINAR PERDANA KESELAMATAN & KESIHATAN PEKERJAANjhj01No ratings yet

- 2.preparation and Staining of Thick and Thin BloodDocument31 pages2.preparation and Staining of Thick and Thin Bloodbudi darmantaNo ratings yet

- Pex Vs Pert FlyerDocument2 pagesPex Vs Pert FlyerClaudiu BoariuNo ratings yet

- Asme B36.19M-2004 PDFDocument14 pagesAsme B36.19M-2004 PDFUlises Montao100% (1)

- Herbal Drug Technology (Thakur Publication)Document264 pagesHerbal Drug Technology (Thakur Publication)Munteshwar SinghNo ratings yet

- Resume Book Kelompok I English BiologyDocument5 pagesResume Book Kelompok I English Biologyuti nstNo ratings yet

- Pharmacology Exam ReviewDocument4 pagesPharmacology Exam Reviewapi-3721078100% (3)

- HAZMAT Training PresentationDocument44 pagesHAZMAT Training PresentationReyNo ratings yet

- List of major industries in MIDC Chikalthana and Waluj areasDocument33 pagesList of major industries in MIDC Chikalthana and Waluj areasRanadeep Reddy Chezerla100% (1)

- 5 Atomic Structure (Teacher)Document28 pages5 Atomic Structure (Teacher)otto wongNo ratings yet

- WaterDocument41 pagesWaterWeihan ChiewNo ratings yet

- Kemp TR 375Document3 pagesKemp TR 375S SURESHNo ratings yet

- 4D Printing A New Approach For Food Printing Effect of Var - 2022 - Applied FoDocument12 pages4D Printing A New Approach For Food Printing Effect of Var - 2022 - Applied FoLê Quốc Đăng KhoaNo ratings yet

- Astm B117 19Document6 pagesAstm B117 19quynhhuongNo ratings yet