Professional Documents

Culture Documents

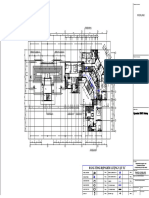

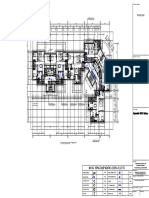

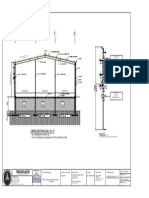

Kerala State Electricity Board LTD: Staircase Flight I Bracket Connection

Uploaded by

Anujith K BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kerala State Electricity Board LTD: Staircase Flight I Bracket Connection

Uploaded by

Anujith K BabuCopyright:

Available Formats

2984

1000

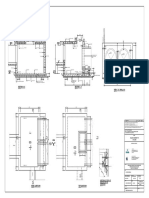

16mm THICK 70 16mm THICK

GI PIPE 48.3mm 3.2mm thick(HR)

250

160

160

Ls 65 x 65 x 6

200

100

ISA 65X65X6 (HR V.Post) 10mm. FLAT PLATE

200

350

100

TUBE 66 x 33 x 2.9

HR CONNECTING PLATE GUSSET PLATE E1

AREA=0.037m2 AREA=0.065m2

PERIMETER =988mm PERIMETER =1041mm

8mm. CHEQUERED PLATE

Ls 75 x 75 x 6

16mm THICK 16mm THICK 75

3

20

2 Nos Ls75 x 75 x 6

225

95

BACK TO BACK

229

C2 67

GUSSET PLATE E2 GUSSET PLATE E3

AREA=0.051m2 AREA=0.051m2

PERIMETER =912mm PERIMETER =894mm

E4 E5

D1 E1

560

C2

16mm THICK 16mm THICK

100 300

100

E3

200

200

1458

100

GUSSET PLATE E4 GUSSET PLATE E5

AREA=0.020m2 AREA=0.050m2

PERIMETER =600mm PERIMETER =924mm

7

333

E2

D1 20mm THICK a8

20mm. BEARING PLATE

300 x 300 x 20

200

300

16mm. GUSSET PLATE

150

300

BASE PLATE TO DAM BODY

1951

AREA=0.090m2

PERIMETER =1200mm

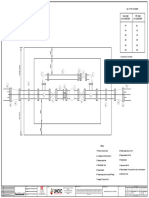

TRUSSBRACKET CONNECTION FOR STAIRCASE FLIGHT No.I AT 2.00m INTERVAL

Ls 75 x 75 x 6

using Ls 75 x 75 x 6 BACK TO BACK WITH 16mm GUSSET PLATE AT NODES 20mm. BEARING PLATE

300 x 300 x 20

200

300

NOTE 300

1

2

ALL DIMENSIONS ARE IN mm

FEASIBILITY OF THIS STRUCTURE SHALL BE CHECKED AT SITE IN EVERY RESPECT BY ENGINEER IN CHARGE BEFORE FABRICATION

SECTION C2

3 ALL MEASUREMENTS TO BE VERIFIED AT SITE BEFORE EXECUTION IS TAKEN UP.

4 NO DIMENSIONS SHOULD BE SCALED FROM THIS DRAWING. AREA=0.090m2

5 HOLLOW PIPE SHOULD BE CLOSED AT OPEN END TO REDUCE THE CHANCES OF CORROSION IN INNER SIDE OF HOLLOW PIPE. PERIMETER =1200mm

6 RECTANGULAR HOLLOW STRUCTURAL PIPE OF GRADE Yst 310 TO BE USED AS PER IS 4923:1997

7 ALL WELDS WILL BE IN FULL LENGTH AROUND THE MEMBERS AT EACH JOINTS.

8 ALL RIB PLATES ARE 10mm EXCEPT OTHERWISE SHOWN

9 SPECIFICATION OF BOLTS ARE AS PER IS 1367 PROPERTY CLASS 6.6 AND CLASS 8.8 FOR BOLTS CONNECTING THE BEARING PLATES TO DAM BODY.

16mm BOLTS (GRADE 6.6) ARE TO BE USED FOR CONNECTIONS BETWEEN STRUCTURAL STEEL PARTS AND 20mm (GRADE 8.8) ARE TO BE USED FOR

10

CONNECTION MADE TO DAM BODY

11 BOLT HOLES SHALL BE MADE IN WEB OF GIRDER TO REST THE STAIRCASE GIRDER

PAINTING :

SPECIFICATION

12

a) PRIMING COAT-TWO COAT OF READY MIXED PAINT RED LEAD PRIMING TO IS 102 or ONE READY MIXED PAINT ZINC CHROMATE PRIMING TO IS:104

FOLLOWED BY ONE COAT OF READY MIXED :PAINT RED OXIDE ZINC CHROME PRIMING PAINT TO IS:2074.

1 STRUCTURAL STEEL DESIGN IS 800:2007 KERALA STATE ELECTRICITY BOARD LTD

b)FINISHING COAT-TWO COATS OF ALUMINIUM PAINT TO IS:2339 2 LOADING IS 875 PART (1)DEAD ,(2)IMPOSED,(3)WIND

3 WELDING IS 816:1969

THE MAIN GIRDERS (ISMB 350) SHOULD BE CONNECTED WITH THE BEARING PLATE AT THE TOP OF THE SPILLWAY DIVIDE WALLS AS SHOWN WITH 20mm

13 BOLTS (8.8 GRADE). ALTERNATE BEARING PLATE AT THE TOP OF THE SPILLWAY DIVIDE WALL IS PROVIDED WITH SLOTTED HOLE FOR FACILITATION OF 4 WELD SYMBOL IS 813:1961

MOVEMENT OF GIRDER. 5 TOLERANCE FOR ERECTION IS 12843:1989

14 WELDING IN THE MAIN GIRDER IS TO BE DONE BY SUBMERGED ARC WELDING (SAW) ONLY 6 HOLLOW STRUCTURAL PIPE IS 806:1968 & IS 4923:1997

7 FITTED BOLTS IS 3640:1982 & IS 4923:1997

15 ALL WELDS WILL BE IN FULL LENGTH AROUND THE MEMBER AT EACH JOINT

8 REINFORCED CONCRETE IS 456:2000

MEMBERS ARE FILLET WELDED EXCEPT AT JOINTS MADE BY BOLTS AND WELDS SHOWN BY THE SYMBOL . AT THESE PLACES FULLY PENETRATIVE

STAIRCASE FLIGHT I BRACKET CONNECTION

16 9 FOUNDATION BOLTS IS 5624:1993

DOUBLE V-BUTT WELDS ARE TO BE DONE.

10 REINFORCEMENT BARS IS 1786:2000

CONNECTION OF ISMC 300 (GIRDER) WITH OTHER IS FACILITATED BY SUITABLY CUTTING THE FLANGES OF THE GIRDER AND CONNECTING IT WITH

17

OTHER BY THE PROVISION OF L-CLEAT & 16mm. BOLTS AS SHOWN IN DETAILS

18 CARE SHALL BE TAKEN TO AVOIDS CRACKS IN THE DAM BODY DRILLED HOLES ON THE DAM BODY SHALL BE FILLED WITH EPOXY GROUTING

You might also like

- Kerala State Electricity Board LTD: Staircase Flight Ii Bracket ConnectionDocument1 pageKerala State Electricity Board LTD: Staircase Flight Ii Bracket ConnectionAnujith K BabuNo ratings yet

- Ban Ve ThepDocument1 pageBan Ve ThepNguyen Tien DatNo ratings yet

- Ban Ve PigDocument1 pageBan Ve PigNguyen Tien DatNo ratings yet

- APPBTM-002-CIV-CD-0002.2 - FOUNDATION & REINFORCEMENT TYPE 8 (Revisi)Document1 pageAPPBTM-002-CIV-CD-0002.2 - FOUNDATION & REINFORCEMENT TYPE 8 (Revisi)Adalah SiapaNo ratings yet

- PruebaInvias JDTB R0Document1 pagePruebaInvias JDTB R0Laura Cañon PelaaezNo ratings yet

- Road 8M: 500 MT SolarDocument1 pageRoad 8M: 500 MT SolarryosastradipuraNo ratings yet

- Shop Drawing: Shang Wackwack Properties IncDocument1 pageShop Drawing: Shang Wackwack Properties Incarcue quirozNo ratings yet

- Interland: PD GarbageDocument1 pageInterland: PD GarbageDuy Giáp NguyễnNo ratings yet

- Vicinity Map: Waterline, Plumbing and Storm Drainage Layout SCALE: 1:100 MTSDocument1 pageVicinity Map: Waterline, Plumbing and Storm Drainage Layout SCALE: 1:100 MTSLou PotesNo ratings yet

- Interland: PD GarbageDocument1 pageInterland: PD GarbageDuy Giáp NguyễnNo ratings yet

- STRCturalDocument1 pageSTRCturalGaberielle CuaNo ratings yet

- S-18-13306 - DR1214 - EA-083-03ABCD (28t)Document2 pagesS-18-13306 - DR1214 - EA-083-03ABCD (28t)puspa ningrumNo ratings yet

- Bureau of Design: Det. Plan of Stf-1Document1 pageBureau of Design: Det. Plan of Stf-1VWSSI Technical TeamNo ratings yet

- Top View Oil Trap: Bored File Ø 300 MM, Length 6 MDocument1 pageTop View Oil Trap: Bored File Ø 300 MM, Length 6 MHarianto RamadhanNo ratings yet

- 1-MB Mong - Detail FoundationDocument1 page1-MB Mong - Detail FoundationGialai ThanhphoNo ratings yet

- Foundation Plan Ground Floor Plan Ground Floor Plan 2/7: Typical StiffernerDocument1 pageFoundation Plan Ground Floor Plan Ground Floor Plan 2/7: Typical StiffernerAnthonio MaraghNo ratings yet

- Keterangan: Peta Plan Drill Blok Charly (Februari) Tapunopaka, 2021Document1 pageKeterangan: Peta Plan Drill Blok Charly (Februari) Tapunopaka, 2021novri putroNo ratings yet

- 2Nd Floor Framing Plan Foundation Plan: Two-Storey ResidentialDocument1 page2Nd Floor Framing Plan Foundation Plan: Two-Storey ResidentialByen VillanuevaNo ratings yet

- Site Plan: NeighborDocument1 pageSite Plan: NeighborMAN ENGINEERINGNo ratings yet

- QH03-Bản đồ quy hoạch tổng mặt bằng sử dụng đất2019.12.27-A3Document1 pageQH03-Bản đồ quy hoạch tổng mặt bằng sử dụng đất2019.12.27-A3giatuan85_728400728No ratings yet

- Interland: PD GarbageDocument1 pageInterland: PD GarbageDuy Giáp NguyễnNo ratings yet

- Detail of Beams - 1: Stair Detail C1/F1 Detail C2/F2 DetailDocument1 pageDetail of Beams - 1: Stair Detail C1/F1 Detail C2/F2 DetailEli SuarezNo ratings yet

- Silt Trap Details-1Document1 pageSilt Trap Details-1MahindaNo ratings yet

- Kanusin Church LayoutDocument1 pageKanusin Church LayoutCaleb RonoNo ratings yet

- TYPICAL Pipework Fittings DetailsDocument25 pagesTYPICAL Pipework Fittings DetailsAbuBakerNo ratings yet

- Section at Support Section at Centre Top Ring Beam DetailDocument1 pageSection at Support Section at Centre Top Ring Beam DetailVK Agarwal AgarwalNo ratings yet

- Sub Structure AnanyaDocument1 pageSub Structure AnanyaShubhadip MondalNo ratings yet

- Wechsel 2024Document4 pagesWechsel 2024Thomas ColmicheNo ratings yet

- Ab STR 103 B124Document1 pageAb STR 103 B124arainzada807No ratings yet

- Asf 607 02 Ad 535 Rev.bDocument1 pageAsf 607 02 Ad 535 Rev.bHaseeb RazviNo ratings yet

- Section (Post) : General NotesDocument1 pageSection (Post) : General Notesjerus lucineNo ratings yet

- Third Floor Plan: G H I Deck 5000 5000 3000 989 3323 13000Document1 pageThird Floor Plan: G H I Deck 5000 5000 3000 989 3323 13000Mark Kristoffer HilarionNo ratings yet

- MDDN PDFDocument1 pageMDDN PDFJaime DuranNo ratings yet

- Church Building Design.Document1 pageChurch Building Design.jojiowino1956No ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- SRE BNC V 203 0 - BkkNoiAbutDim PDFDocument1 pageSRE BNC V 203 0 - BkkNoiAbutDim PDFkeaoreNo ratings yet

- Vicinty Map: Main Panel Board Floor MountedDocument1 pageVicinty Map: Main Panel Board Floor MountedCasmir TayagNo ratings yet

- Rsmli Ch03 STD Bot 10 (Sheet 2 of 2)Document1 pageRsmli Ch03 STD Bot 10 (Sheet 2 of 2)bapernast100% (1)

- Menara TCM Infra Coordination PlanDocument1 pageMenara TCM Infra Coordination Planmaurice86No ratings yet

- H X Diagram Ammonia WaterDocument1 pageH X Diagram Ammonia Water蒲俊雄No ratings yet

- Check Structure Layout2Document1 pageCheck Structure Layout2WesNo ratings yet

- Check Structure Layout2Document1 pageCheck Structure Layout2Elaine Joyce GarciaNo ratings yet

- BACK ELEVATION Scale 1:100 SIDE ELEVATION Scale 1:100: Section A-A ViewDocument1 pageBACK ELEVATION Scale 1:100 SIDE ELEVATION Scale 1:100: Section A-A Viewdickson phiriNo ratings yet

- MAN B&W K/L/S80-90MC, MC-C: Control Room Control, Stop, Safety SystemDocument57 pagesMAN B&W K/L/S80-90MC, MC-C: Control Room Control, Stop, Safety SystemRakesh PadmanabhanNo ratings yet

- Loo - ElevationsDocument1 pageLoo - ElevationsNiket DalalNo ratings yet

- Flange Detail: Tolerances On Machined Surface Unless Otherwise StatedDocument1 pageFlange Detail: Tolerances On Machined Surface Unless Otherwise Statedcarlos antonioNo ratings yet

- Longitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialDocument1 pageLongitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialChristian Sean PaglomutanNo ratings yet

- 39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-ADocument1 page39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-ASUBHASH KUMARNo ratings yet

- Mæt B NGDocument1 pageMæt B NGbanhbaonongNo ratings yet

- A3 - Doors & Window ScheduleDocument1 pageA3 - Doors & Window Schedule62296bucoNo ratings yet

- Suite N°3 Bach-Saxophone - AltoDocument5 pagesSuite N°3 Bach-Saxophone - AltoLucas ToubeauNo ratings yet

- Potomac River EffectDocument2 pagesPotomac River EffectKumar SingamNo ratings yet

- Drawing Tank 150KL 20M at Bodigama Bada, Distt. DungarpurDocument1 pageDrawing Tank 150KL 20M at Bodigama Bada, Distt. DungarpurBully TempNo ratings yet

- Produced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Document1 pageProduced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Sang TrầnNo ratings yet

- Overhead Gantry Sign BoardDocument1 pageOverhead Gantry Sign Boardrao shoaib100% (5)

- MM-#42 Ground Floor Roof Details - R02Document1 pageMM-#42 Ground Floor Roof Details - R02Mohd SiddiqNo ratings yet

- 155 FANSHAWE - SD - RevO - 179Document1 page155 FANSHAWE - SD - RevO - 179Kuraba KvoRdzNo ratings yet

- AQ05 CortesDocument1 pageAQ05 CortesAngel Julian Guzman LopezNo ratings yet

- Elevation: Location SketchDocument1 pageElevation: Location SketchAnujith K BabuNo ratings yet

- Specification: Section XDocument1 pageSpecification: Section XAnujith K BabuNo ratings yet

- Section A: Bp. Type I Bp. Type IDocument1 pageSection A: Bp. Type I Bp. Type IAnujith K BabuNo ratings yet

- Letter To AXE Reg RE For MCFDocument3 pagesLetter To AXE Reg RE For MCFAnujith K BabuNo ratings yet

- TopicDocument2 pagesTopicAnujith K BabuNo ratings yet

- Kallarkutty - RESERVOIR - REPort - Prelim CommentsDocument36 pagesKallarkutty - RESERVOIR - REPort - Prelim CommentsAnujith K BabuNo ratings yet

- KTYM YARD HQ23-ModelDocument1 pageKTYM YARD HQ23-ModelAnujith K BabuNo ratings yet

- R7 Letter From CE For Structural AssessmentDocument1 pageR7 Letter From CE For Structural AssessmentAnujith K BabuNo ratings yet

- R1 Cheruthony Truss 4 - 4Document1 pageR1 Cheruthony Truss 4 - 4Anujith K BabuNo ratings yet

- KTYM YARD HQ23-Sheet-2Document1 pageKTYM YARD HQ23-Sheet-2Anujith K BabuNo ratings yet

- AbstractDocument1 pageAbstractAnujith K BabuNo ratings yet

- Protection of Adjacent Track During CN Works: Refersher Course Permanent WayDocument6 pagesProtection of Adjacent Track During CN Works: Refersher Course Permanent WayAnujith K BabuNo ratings yet

- QuarryDocument4 pagesQuarryAnujith K BabuNo ratings yet

- Slab BridgesDocument115 pagesSlab BridgesAnujith K Babu100% (1)

- Design Basis Report Assignment No 1 Structural Design of A BuildingDocument67 pagesDesign Basis Report Assignment No 1 Structural Design of A BuildingAnujith K BabuNo ratings yet

- Family Friend Asks For Quick Review of FireDocument9 pagesFamily Friend Asks For Quick Review of FireAnujith K BabuNo ratings yet

- Design of Steel Structures: Topic Iii THE 15 Edition Aisc Manual of Steel ConstructionDocument39 pagesDesign of Steel Structures: Topic Iii THE 15 Edition Aisc Manual of Steel ConstructionthulfNo ratings yet

- Technical Data BookDocument38 pagesTechnical Data Bookk s bhaskara ramuNo ratings yet

- SSRN Id4447482Document7 pagesSSRN Id4447482Almas XamiNo ratings yet

- Pig Launchers Recievers PDFDocument9 pagesPig Launchers Recievers PDFgalih santosoNo ratings yet

- Stuctural Analysis Using AnsysDocument39 pagesStuctural Analysis Using AnsysVishnuPrasadNo ratings yet

- Tenmat Ferobide BrochureDocument12 pagesTenmat Ferobide BrochureJosé Alessandro Chiroque YoveraNo ratings yet

- Navtec Stretch CalculationFormula PDFDocument1 pageNavtec Stretch CalculationFormula PDFJon LawheadNo ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04100% (1)

- Ikundji Divin Cumulative Fyrdp ReportDocument83 pagesIkundji Divin Cumulative Fyrdp ReportDivin IkundjiNo ratings yet

- Monolithic With Orifice Wall 2. Unfactored Loads Are Taken Into ConsiderationDocument5 pagesMonolithic With Orifice Wall 2. Unfactored Loads Are Taken Into ConsiderationPRAVEEN CHAUDHARYNo ratings yet

- Crosby G450 Forged Wire Rope Clips Bulldog Clips - Rope Sizes Ranging 3mm To 90mm - LiftingSafetyDocument4 pagesCrosby G450 Forged Wire Rope Clips Bulldog Clips - Rope Sizes Ranging 3mm To 90mm - LiftingSafetymanoj_doshi_1No ratings yet

- 2012 Shed TechartDocument15 pages2012 Shed TechartMujNo ratings yet

- Interview Questions PDFDocument14 pagesInterview Questions PDFanil100% (1)

- Schneider QuotationDocument23 pagesSchneider QuotationPaulthiyagaraj S100% (1)

- Colour Codes For PipingDocument24 pagesColour Codes For PipingYusufNo ratings yet

- Seismic Earth Pressure of Deep Stiff Wall Based On FEMA P-750 & AASHTO/IBCDocument1 pageSeismic Earth Pressure of Deep Stiff Wall Based On FEMA P-750 & AASHTO/IBCجميل عبد الله الحماطيNo ratings yet

- The Bullitt Center ReportDocument32 pagesThe Bullitt Center ReportFatinur SyamimiNo ratings yet

- As Schneider Flush Rings enDocument2 pagesAs Schneider Flush Rings eneliasNo ratings yet

- GRP Tank Technical Data SheetsDocument39 pagesGRP Tank Technical Data Sheetsdavid JohnNo ratings yet

- Nanocomposites - Synthesis, Structure, Properties and New Application OpportunitiesDocument58 pagesNanocomposites - Synthesis, Structure, Properties and New Application OpportunitiesrajkumarNo ratings yet

- HDPE Pipeline Installation and DesignDocument13 pagesHDPE Pipeline Installation and DesignYoungtae Kim100% (4)

- FWDS 0245 ADocument4 pagesFWDS 0245 AAlanka PrasadNo ratings yet

- In-Line Inspection Tool and Standards: Presented by Suparerk Sirivedin 16 September 2020Document34 pagesIn-Line Inspection Tool and Standards: Presented by Suparerk Sirivedin 16 September 2020Suparerk SirivedinNo ratings yet

- Steel Standards - Equivalence - MP MétalDocument2 pagesSteel Standards - Equivalence - MP MétalIr AyenNo ratings yet

- Blocklaying, Bricklaying and ConcretingDocument6 pagesBlocklaying, Bricklaying and ConcretingIfiokobong Akpan100% (2)

- Design and Evaluation of Open Graded Hot Mix Asphalt Using Cement As A Grouting MaterialDocument9 pagesDesign and Evaluation of Open Graded Hot Mix Asphalt Using Cement As A Grouting MaterialijmremNo ratings yet

- BG Health Facilities Maintenance HLDocument5 pagesBG Health Facilities Maintenance HLChrisDcaNo ratings yet

- Seismic Analysis of Steel Liquid Storage Tanks by API-650Document6 pagesSeismic Analysis of Steel Liquid Storage Tanks by API-650engharshNo ratings yet

- ASTM B506-09 - Standard SpecificationDocument5 pagesASTM B506-09 - Standard SpecificationMarian Joyce MacadineNo ratings yet

- RW720FPT1X User ManualDocument12 pagesRW720FPT1X User ManualHuma SultanNo ratings yet