Professional Documents

Culture Documents

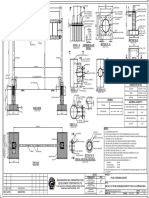

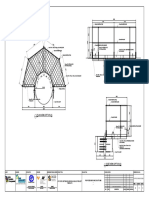

Section A: Bp. Type I Bp. Type I

Uploaded by

Anujith K BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section A: Bp. Type I Bp. Type I

Uploaded by

Anujith K BabuCopyright:

Available Formats

A

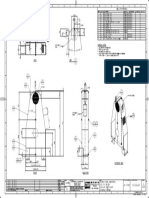

GI PIPE 48.3mm GI PIPE 48.3mm 3.2mm thick(HR)

3.2mm thick(HR)

1200

ISA 65X65X6 (HR V.Post) Ls 65 x 65 x 6

300

300

TUBE 66 X 33 X 2.9

TUBE 66 x 33 x 2.9

1200

3Nos 16 BOLTS

Ls 75 x 75 x 6

300

Ls 75 x 75 x 6

CHEQURED PLATE 8mm

10mm. FLAT PLATE 8mm. CHEQUERED

Ls 75 x 75 x 6 @ 1000c/c 40

40 PLATE

ISMB 450

A1 35 A1

ISMB 450

A2 A2

450

Ls 75 x 75 x 6 @ 2000 c/c

50 60

300

BEARING PLATE 300 x 400 x 16 10mm. FLAT PLATE

1028

1050

BP. TYPE I BP. TYPE I

20mm. BOLT A

16mm DIA. BOLTS ARE USED FOR CONNECTING Ls TO THE CONNECTING FLAT PLATES

Ls 75 x 75 x 6 Ls 75 x 75 x 6

SECTION A

BP. TYPE I BP. TYPE I

70 10mm. FLAT

CONNECTING PLATE

160

(150 x 415 x 10)

415

375

150

75

DETAIL AT A1 DETAIL AT A2

AREA=0.055m2 AREA=0.062m2

PERIMETER =1315mm PERIMETER =1130mm

NOTE 8mm. CHEQURED PLATE (1200mm WIDE)

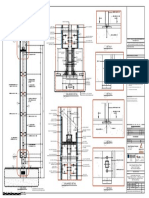

1 ALL DIMENSIONS ARE IN mm

2 FEASIBILITY OF THIS STRUCTURE SHALL BE CHECKED AT SITE IN EVERY RESPECT BY ENGINEER IN CHARGE BEFORE FABRICATION

3 ALL MEASUREMENTS TO BE VERIFIED AT SITE BEFORE EXECUTION IS TAKEN UP.

4

5

NO DIMENSIONS SHOULD BE SCALED FROM THIS DRAWING.

HOLLOW PIPE SHOULD BE CLOSED AT OPEN END TO REDUCE THE CHANCES OF CORROSION IN INNER SIDE OF HOLLOW PIPE.

BP. TYPE I BP. TYPE I

6 RECTANGULAR HOLLOW STRUCTURAL PIPE OF GRADE Yst 310 TO BE USED AS PER IS 4923:1997

7 ALL WELDS WILL BE IN FULL LENGTH AROUND THE MEMBERS AT EACH JOINTS.

8 ALL RIB PLATES ARE 10mm EXCEPT OTHERWISE SHOWN

9 SPECIFICATION OF BOLTS ARE AS PER IS 1367 PROPERTY CLASS 6.6 AND CLASS 8.8 FOR BOLTS CONNECTING THE BEARING PLATES TO DAM BODY.

16mm BOLTS (GRADE 6.6) ARE TO BE USED FOR CONNECTIONS BETWEEN STRUCTURAL STEEL PARTS AND 20mm (GRADE 8.8) ARE TO BE USED FOR

10

CONNECTION MADE TO DAM BODY

11 BOLT HOLES SHALL BE MADE IN WEB OF GIRDER TO REST THE STAIRCASE GIRDER

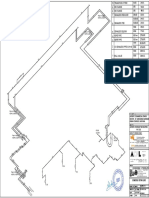

PAINTING :

a) PRIMING COAT-TWO COAT OF READY MIXED PAINT RED LEAD PRIMING TO IS 102 or ONE READY MIXED PAINT ZINC CHROMATE PRIMING TO IS:104

12 FOLLOWED BY ONE COAT OF READY MIXED :PAINT RED OXIDE ZINC CHROME PRIMING PAINT TO IS:2074.

b)FINISHING COAT-TWO COATS OF ALUMINIUM PAINT TO IS:2339 KERALA STATE ELECTRICITY BOARD LTD

SPECIFICATION

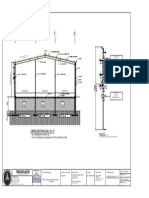

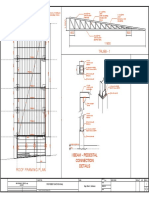

THE MAIN GIRDERS (ISMB 350) SHOULD BE CONNECTED WITH THE BEARING PLATE AT THE TOP OF THE SPILLWAY DIVIDE WALLS AS SHOWN WITH 20mm

13 BOLTS (8.8 GRADE). ALTERNATE BEARING PLATE AT THE TOP OF THE SPILLWAY DIVIDE WALL IS PROVIDED WITH SLOTTED HOLE FOR FACILITATION OF 1 STRUCTURAL STEEL DESIGN IS 800:2007

MOVEMENT OF GIRDER.

2 LOADING IS 875 PART (1)DEAD ,(2)IMPOSED,(3)WIND

14 WELDING IN THE MAIN GIRDER IS TO BE DONE BY SUBMERGED ARC WELDING (SAW) ONLY 3 WELDING IS 816:1969

4 WELD SYMBOL IS 813:1961

15 ALL WELDS WILL BE IN FULL LENGTH AROUND THE MEMBER AT EACH JOINT

5 TOLERANCE FOR ERECTION IS 12843:1989

16

MEMBERS ARE FILLET WELDED EXCEPT AT JOINTS MADE BY BOLTS AND WELDS SHOWN BY THE SYMBOL

DOUBLE V-BUTT WELDS ARE TO BE DONE.

. AT THESE PLACES FULLY PENETRATIVE 6 HOLLOW STRUCTURAL PIPE IS 806:1968 & IS 4923:1997 STRUCTURAL DETAILS OF SPILLWAY PORTION OF CATWALK

CONNECTION OF ISMC 300 (GIRDER) WITH OTHER IS FACILITATED BY SUITABLY CUTTING THE FLANGES OF THE GIRDER AND CONNECTING IT WITH 7 FITTED BOLTS IS 3640:1982 & IS 4923:1997

17

OTHER BY THE PROVISION OF L-CLEAT & 16mm. BOLTS AS SHOWN IN DETAILS 8 REINFORCED CONCRETE IS 456:2000

18 CARE SHALL BE TAKEN TO AVOIDS CRACKS IN THE DAM BODY DRILLED HOLES ON THE DAM BODY SHALL BE FILLED WITH EPOXY GROUTING 9 FOUNDATION BOLTS IS 5624:1993

10 REINFORCEMENT BARS IS 1786:2000

You might also like

- Structural - AOBDocument21 pagesStructural - AOBMr. Mark B.No ratings yet

- Astm IndexDocument30 pagesAstm IndexAnshul JainNo ratings yet

- Cast Iron Slide Gates-HYDROGATEDocument28 pagesCast Iron Slide Gates-HYDROGATEusamazarifeh100% (1)

- Truss 3 Detail Section Plan: 6Mm X 5Mm X 50Mm Angle Bar Top and Bottom Chords 2-6Mmx38Mmx38Mm Angle Bar Member ChordsDocument1 pageTruss 3 Detail Section Plan: 6Mm X 5Mm X 50Mm Angle Bar Top and Bottom Chords 2-6Mmx38Mmx38Mm Angle Bar Member Chordsalezandro del rossiNo ratings yet

- BOQ EX Fst-003-07Document43 pagesBOQ EX Fst-003-07Danudear DanielNo ratings yet

- Design & Detail Col Base PlateDocument19 pagesDesign & Detail Col Base PlateJoel MooreNo ratings yet

- Gypsum Ceilin22g ModelDocument1 pageGypsum Ceilin22g ModelDivnoor KaurNo ratings yet

- Navfac DM SteelDocument70 pagesNavfac DM SteelDianna LambertNo ratings yet

- Secondary Pipe Support Devices: Secondary Pipe Support DevicesDocument34 pagesSecondary Pipe Support Devices: Secondary Pipe Support DeviceszebmechNo ratings yet

- 039 TS Hardox 550 UKDocument5 pages039 TS Hardox 550 UKNguyen Duc DungNo ratings yet

- 50 Terms in RCDDocument92 pages50 Terms in RCDLloyd DelavegaNo ratings yet

- Plate Load Test On RockDocument9 pagesPlate Load Test On RockAnonymous v1blzDsEWANo ratings yet

- Truss-1 (Steel Truss) Det.: CB-1 CB-1 CB-1 CB-1 CB-1Document1 pageTruss-1 (Steel Truss) Det.: CB-1 CB-1 CB-1 CB-1 CB-1B R Paul FortinNo ratings yet

- Slab BridgesDocument115 pagesSlab BridgesAnujith K Babu100% (1)

- People's Republic of China Industry Standard Welded Steel Pressure VesselDocument78 pagesPeople's Republic of China Industry Standard Welded Steel Pressure VesselmightsrightNo ratings yet

- 2016 - DWG-DG - X - 16 - Pak Amir - Makassar - Tiang Lampu Sorot - h13 - OctagonalDocument1 page2016 - DWG-DG - X - 16 - Pak Amir - Makassar - Tiang Lampu Sorot - h13 - OctagonalHendra DarmawanNo ratings yet

- Signboard - Gantry 9.5m Carriage Way Sheet 1Document1 pageSignboard - Gantry 9.5m Carriage Way Sheet 1LALAN KUMARNo ratings yet

- Heat Exchanger Selection Webinar PDFDocument47 pagesHeat Exchanger Selection Webinar PDFAzar DeenNo ratings yet

- Specifications - Economizer Specification - RectangularDocument3 pagesSpecifications - Economizer Specification - RectangularTin Aung KyiNo ratings yet

- Plan of Splice: Section BB: Bracing at Upper Flange Level of Ismb 400Document1 pagePlan of Splice: Section BB: Bracing at Upper Flange Level of Ismb 400Anujith K BabuNo ratings yet

- Section DD: Bp. Type Ii (Slotted) Bp. Type Ii (Slotted)Document1 pageSection DD: Bp. Type Ii (Slotted) Bp. Type Ii (Slotted)Anujith K BabuNo ratings yet

- Truss - 02: Main Hall Building Block ofDocument1 pageTruss - 02: Main Hall Building Block ofPremasiri KarunarathnaNo ratings yet

- 304 To 305 PDFDocument1 page304 To 305 PDFAnonymous GoJpm9WbNo ratings yet

- Section B-B S/1:75: Typical Spot Detail 2 Blow Up Detail ADocument2 pagesSection B-B S/1:75: Typical Spot Detail 2 Blow Up Detail AEdison ClementeNo ratings yet

- Section B-B S/1:75: Typical Spot Detail 2 Blow Up Detail ADocument2 pagesSection B-B S/1:75: Typical Spot Detail 2 Blow Up Detail AEdison ClementeNo ratings yet

- WGS 1Document2 pagesWGS 1Edison ClementeNo ratings yet

- Splicing of Ismb 450: Section XDocument1 pageSplicing of Ismb 450: Section XAnujith K BabuNo ratings yet

- Specification: Section XDocument1 pageSpecification: Section XAnujith K BabuNo ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- AS BUILT PNG PIPING LAYOUT-Layout1Document1 pageAS BUILT PNG PIPING LAYOUT-Layout1Aditya MalhotraNo ratings yet

- LGS - 1Document2 pagesLGS - 1Edison ClementeNo ratings yet

- A705 - Typical Cat Ladder DetailsDocument1 pageA705 - Typical Cat Ladder DetailsØwięs MØhãmmedNo ratings yet

- Final Sheet-Model - PDF 1Document1 pageFinal Sheet-Model - PDF 1Prateek SharmaNo ratings yet

- Cable Run Rrs FPDocument1 pageCable Run Rrs FPvishnu kumar VyasNo ratings yet

- Drawing Tank 150KL 20M at Bodigama Bada, Distt. DungarpurDocument1 pageDrawing Tank 150KL 20M at Bodigama Bada, Distt. DungarpurBully TempNo ratings yet

- BMRCL 32m 007 Sheet 2 of 3Document1 pageBMRCL 32m 007 Sheet 2 of 3DOMNo ratings yet

- Koilwar-Bhojpur Toll Plaza TOOL BOOTH DETAILDocument1 pageKoilwar-Bhojpur Toll Plaza TOOL BOOTH DETAILManinder ChaudharyNo ratings yet

- Stairway Detail 1 of 2 (As Built) - SHEET 1-2-ModelDocument1 pageStairway Detail 1 of 2 (As Built) - SHEET 1-2-ModelBukti SiahaanNo ratings yet

- 2 Stair Details: Approved: DateDocument1 page2 Stair Details: Approved: DateRycca DeeNo ratings yet

- Splice Detail of C-Purlins: Proposed New PavementDocument1 pageSplice Detail of C-Purlins: Proposed New Pavementzab04148114No ratings yet

- Bill of Materials: Minara MinaraDocument1 pageBill of Materials: Minara MinaraJay ReyesNo ratings yet

- Ridge Det Vert Corner Det Panel Base Det: Ror-75 Roof Panel (Pir System)Document1 pageRidge Det Vert Corner Det Panel Base Det: Ror-75 Roof Panel (Pir System)WaleedAL-suheelyDNo ratings yet

- Schedule of Footings, Columns and Beams: Detail of C1F1 Detail of C1F3Document1 pageSchedule of Footings, Columns and Beams: Detail of C1F1 Detail of C1F3flor johnNo ratings yet

- S1 PDFDocument1 pageS1 PDFleeedeeemeeeNo ratings yet

- S1 PDFDocument1 pageS1 PDFleeedeeemeeeNo ratings yet

- Roof Truss: Bolted: Name: Athar Ellahi Note: All Dimensions Are in MMDocument1 pageRoof Truss: Bolted: Name: Athar Ellahi Note: All Dimensions Are in MMLikhith NNo ratings yet

- Working Platform-Option 2Document1 pageWorking Platform-Option 2Mark L. AlmencionNo ratings yet

- Detail Bekisting Precast-Layout4Document1 pageDetail Bekisting Precast-Layout4Mukhamad SolikhinNo ratings yet

- S 5 PDFDocument1 pageS 5 PDFlovely caturanNo ratings yet

- S-1.2 Proposed Filling Station (Caltex Station) : Typical Section Thru BDocument1 pageS-1.2 Proposed Filling Station (Caltex Station) : Typical Section Thru BCarmela Andrea BuenafeNo ratings yet

- Pintu 9 Set: Pandangan Samping Kanan & KiriDocument1 pagePintu 9 Set: Pandangan Samping Kanan & KiriJulius Anggara PanduNo ratings yet

- Spreader Bar SWL - SD.50 T Rev 01Document1 pageSpreader Bar SWL - SD.50 T Rev 01Amos PaintikNo ratings yet

- 63X63x5mm THK Angle Bar 2-25x25x3mm THK Angle Bar 25X25X3mm THK Angle BarDocument1 page63X63x5mm THK Angle Bar 2-25x25x3mm THK Angle Bar 25X25X3mm THK Angle BarRichard CuaresmaNo ratings yet

- Kerala State Electricity Board LTD: Staircase Flight I Bracket ConnectionDocument1 pageKerala State Electricity Board LTD: Staircase Flight I Bracket ConnectionAnujith K BabuNo ratings yet

- WEDDING AREA REVISED-s1Document1 pageWEDDING AREA REVISED-s1benjie baunNo ratings yet

- B2LN 140 259 580 - r1Document1 pageB2LN 140 259 580 - r1Eduardo Ramos MarquezNo ratings yet

- C.3-141-Temporary Fence H.5MDocument1 pageC.3-141-Temporary Fence H.5MYudi CasanovaNo ratings yet

- Sheet 01Document1 pageSheet 01Ashish GNo ratings yet

- Ce 5Document1 pageCe 5Cyril AleaNo ratings yet

- KIP - Blowodown Silencer Dia 2000mm 1 UnitDocument1 pageKIP - Blowodown Silencer Dia 2000mm 1 UnitGeneroman SembiringNo ratings yet

- VR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFDocument6 pagesVR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Section at G: Kerala State Electricity Board LTDDocument1 pageSection at G: Kerala State Electricity Board LTDAnujith K BabuNo ratings yet

- Bai Thuc Hanh So 5 1Document1 pageBai Thuc Hanh So 5 1Snow JohnNo ratings yet

- Septic Tank 16.08.19-ModelDocument1 pageSeptic Tank 16.08.19-ModelAnindit MajumderNo ratings yet

- Column Details 4Document1 pageColumn Details 4GENALYN PELAYONo ratings yet

- Ar 4 Architectural Details PDFDocument1 pageAr 4 Architectural Details PDFReden H. ArgawanonNo ratings yet

- Truss - 1: I Beam - Pedestal Connection DetailsDocument1 pageTruss - 1: I Beam - Pedestal Connection DetailslukoidsNo ratings yet

- Flowforge DetailsDocument1 pageFlowforge DetailsRaymond KinnairdNo ratings yet

- Drawing1 Bucket01Document1 pageDrawing1 Bucket01Ganang Dwi AtmajaNo ratings yet

- Detail 1: Safety, Health and Environmental InformationDocument1 pageDetail 1: Safety, Health and Environmental InformationvtalexNo ratings yet

- Tie Beam DetailDocument1 pageTie Beam DetailJerome AdduruNo ratings yet

- Ohe - TTCDocument1 pageOhe - TTCRAHUL RAUSHANNo ratings yet

- 53 WDHGST Det Osd Civil 001 A1Document1 page53 WDHGST Det Osd Civil 001 A1Adrin GanNo ratings yet

- Elevation: Location SketchDocument1 pageElevation: Location SketchAnujith K BabuNo ratings yet

- Specification: Section XDocument1 pageSpecification: Section XAnujith K BabuNo ratings yet

- TopicDocument2 pagesTopicAnujith K BabuNo ratings yet

- Kallarkutty - RESERVOIR - REPort - Prelim CommentsDocument36 pagesKallarkutty - RESERVOIR - REPort - Prelim CommentsAnujith K BabuNo ratings yet

- Letter To AXE Reg RE For MCFDocument3 pagesLetter To AXE Reg RE For MCFAnujith K BabuNo ratings yet

- R1 Cheruthony Truss 4 - 4Document1 pageR1 Cheruthony Truss 4 - 4Anujith K BabuNo ratings yet

- KTYM YARD HQ23-ModelDocument1 pageKTYM YARD HQ23-ModelAnujith K BabuNo ratings yet

- KTYM YARD HQ23-Sheet-2Document1 pageKTYM YARD HQ23-Sheet-2Anujith K BabuNo ratings yet

- R7 Letter From CE For Structural AssessmentDocument1 pageR7 Letter From CE For Structural AssessmentAnujith K BabuNo ratings yet

- AbstractDocument1 pageAbstractAnujith K BabuNo ratings yet

- QuarryDocument4 pagesQuarryAnujith K BabuNo ratings yet

- Design Basis Report Assignment No 1 Structural Design of A BuildingDocument67 pagesDesign Basis Report Assignment No 1 Structural Design of A BuildingAnujith K BabuNo ratings yet

- Protection of Adjacent Track During CN Works: Refersher Course Permanent WayDocument6 pagesProtection of Adjacent Track During CN Works: Refersher Course Permanent WayAnujith K BabuNo ratings yet

- Family Friend Asks For Quick Review of FireDocument9 pagesFamily Friend Asks For Quick Review of FireAnujith K BabuNo ratings yet

- INTRODUCTION Steel StructureDocument2 pagesINTRODUCTION Steel StructureSyamil NordinNo ratings yet

- Material ASTMDocument14 pagesMaterial ASTMAdit NugrahaNo ratings yet

- En19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/TDocument7 pagesEn19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/THugh O'Brien GwazeNo ratings yet

- Evaluation of Iron and Steel in Historic BridgesDocument8 pagesEvaluation of Iron and Steel in Historic BridgesjayaramanrathnamNo ratings yet

- People Also Ask: Web ResultsDocument4 pagesPeople Also Ask: Web ResultsAmit ChapagainNo ratings yet

- Architectural Code of The Philippines TO BE EDITEDDocument25 pagesArchitectural Code of The Philippines TO BE EDITEDFritzie LanternaNo ratings yet

- Strenx 700 PDFDocument3 pagesStrenx 700 PDFMarcelo Losekann0% (1)

- Arcelor Mittal HistarDocument32 pagesArcelor Mittal HistarAnonymous uNhWGqNzNo ratings yet

- GBT 9222-2008Document149 pagesGBT 9222-2008ecsuperal100% (2)

- BomDocument9 pagesBomAshokNo ratings yet

- Principles of WeldingDocument16 pagesPrinciples of WeldingMihajloDjurdjevicNo ratings yet

- BT5 - Composite Construction Method - PDF 1 PDFDocument21 pagesBT5 - Composite Construction Method - PDF 1 PDFLhyneth Fernando CorderoNo ratings yet

- Ef3b45ad 1Document70 pagesEf3b45ad 1David AndrésNo ratings yet

- Astm A875m-Zinc 5 % Alum-13Document8 pagesAstm A875m-Zinc 5 % Alum-13Ahmed SalehNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- Modern Steel Construction - April 2023Document84 pagesModern Steel Construction - April 2023DITL 1No ratings yet

- La Jolla Commons Phase II Office TowerDocument70 pagesLa Jolla Commons Phase II Office TowerMauricio Salinas BeltranNo ratings yet