Professional Documents

Culture Documents

Diaphragm Accumulator Materials and Applications

Uploaded by

Carlos Andrés CuelloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diaphragm Accumulator Materials and Applications

Uploaded by

Carlos Andrés CuelloCopyright:

Available Formats

Diaphragm Accumulators

SBO Series Diaphragm Materials

Not all fluids are compatible with every elastomer at all temperatures,

Diaphragm Accumulators therefore, HYDAC offers the following materials:

• NBR (Standard Nitrile)

• LT-NBR (Low Temperature Nitrile)

• ECO 30 (Epichlorohydrin)

• IIR (Butyl)

• FPM ( Fluorelastomer)

• others (available upon request)

To determine which material is appropriate, always refer to fluid

manufacturer’s recommendation.

Corrosion Protection

For use with certain aggressive or corrosive fluids, or in a corrosive

Description environment, HYDAC offers protective coatings and corrosive

Diaphragm accumulators are a cost effective option for numerous resistant materials (i.e. stainless steel) for the parts that interface with

functions involving energy storage, shock absorption or pulsation the fluid or are exposed to the hostile environment.

dampening in a hydraulic or fluid system. They are well suited for

applications where smaller fluid volumes and flow rates are adequate

and that require or involve: Mounting Position

• Compact design Diaphragm accumulators are designed to mount in any position.

In systems where contamination is a problem, we recommend a

• Low weight vertical mount with the fluid port oriented downward.

• Flexible mounting positions

• Extremely quick shock response

System Mounting

• Low cost

HYDAC diaphragm accumulators are designed to be screwed

• Low lubricity fluids, like water directly onto the system. We also recommend the use of our

mounting components, (detailed on page 86) to minimize the risk of

failure due to system vibrations.

Diaphragm Accumulators have been successfully applied in both

industrial and mobile applications for energy storage, maintaining

pressure, leakage compensation, and vehicle hydraulic systems.

Applications

Some common applications of diaphragm accumulators are:

HYDAC manufactures two types of diaphragm accumulators:

• Agricultural Machinery & Equipment

• Non-repairable (welded)

• Forestry Equipment

• Repairable (threaded)

• Machine Tools

• Mining Machinery & Equipment

Construction • Mobile & Construction Equipment

Both types of diaphragm accumulators have the same basic • Off-Road Equipment

construction. The difference is in the shell. The welded version

has a shell that is electron-beam welded, and therefore cannot be For specific examples of applications using diaphragm

repaired. The threaded type has a shell made up of two halves (top accumulators, please see pages 75 and 76.

and bottom) which are held together by a threaded locking ring.

PN#02068195 / 1.15 / ACU1102-1326 INNOVATIVE FLUID POWER 23

Diaphragm Accumulators

Model Code

Model Codes containing RED selections are non-standard items – Contact HYDAC for information and availability

Not all combinations are available

SBO 210 - 1 E4 / 112 S – 210 CK XXX

Series

SBO XXX = Diaphragm Accumulator (XXX = series designation)

(see tables on following pages for most common series and size selections)

Size (in Liters, see tables on dimension pages to follow)

0.075 = 0.075 Liters

...see tables on following pages for complete list of sizes, and which versions they are available in

3.5 = 3.5 Liters

Shell Construction and Gas Port Design

E1 = Welded Construction, rechargeable, HYDAC Gas Valve Version 1 (M 28 x 1.5)

E2 = Welded Construction, factory precharged and sealed, (not rechargeable)

(Not available on SBO330 or on any accumulator larger than 1.4 liters)

E4 = Welded Construction, rechargeable, HYDAC Gas Valve Version 4 (8VI-ISO 4570)

A6 = Threaded Construction, rechargeable, HYDAC Gas Valve Version 1 (M 28 x 1.5)

Material Code

Depending on Application

112 = Standard for oil service (mineral oil)

Fluid Port

1 = Carbon steel

3 = Stainless steel

4 = Chemically plated carbon steel (ONLY WETTED SURFACES for water service)

6 = Low temperature carbon steel (< -20°F)

Shell

0 = Synthetic coated carbon steel (Applied internally & externally for water service)

1 = Carbon steel

2 = Chemically plated carbon steel (internal & external for water service)

4 = Stainless steel (please note: MAWP decreases for most stainless models - see tables)

6 = Low temperature carbon steel (< -20°F)

Diaphragm Compound

2 = NBR (Buna N) Compound Oper. Temp Range Typical Fluids

3 = ECO (Hydrin) 5˚ to 180˚F mineral oils

4 = IIR (Butyl) NBR

32˚ to 180˚F water & water-glycols (5% minimum glycol)

5 = LT-NBR (low temp. Buna) Low Temp NBR -50˚ to 180˚F mineral oils

6 = FPM (fluoroelastomer) ECO...113... -20˚ to 250˚F mineral oils

ECO...663... -40˚ to 250˚F mineral oils & water (with low temperature CS shell)

7 = Others (available on request) IIR -20˚ to 200˚F phosphate esters & brake fluids

FPM 5˚ to 300˚F chlorinated hydrocarbons

Country of Installation

S = USA

(for other countries see page 3 for proper code designation)

Maximum Working Pressure in bar (see tables on dimension pages to follow)

100 = 1500 psi

140 = 2000 psi

200 = 3000 psi

210 = 3000 psi

250 = 3600 psi

330 = 4700 psi

400 = 5800 psi

450 = 6500 psi

500 = 7200 psi

750 = 10000 psi

Fluid Port Connection

AK = BSP connection

AB = Male / Female combination connection

CK = Standard SAE connection

(other fluid ports available upon request — consult factory)

Gas Precharge Pressure (P0 ) in bar (always required for E2 model gas valve)

xxx = 3 digits

24 INNOVATIVE FLUID POWER PN#02068195 / 1.15 / ACU1102-1326

Diaphragm Accumulators

Dimensions

Non-Repairable Welded Diaphragm Accumulators

Not available on

SBO330 or on any

accumulator larger than

1.4 liters, minimum lot

size 200pcs.

Thread-F

Effective A øD** CK AK AB K-Hex

Max. Size MAWP Weight Q

Series Gas Vol in in in

p2:p0 (L) psi/(bar) lbs/(kg) (BSPP - (BSPP - (DIN 13 - gpm

(in3 ) (mm) (mm) (SAE - female) (mm)

female) female) male)

3600 1.5 2.68 2.52 1.18

SBO 250 8:1 0.075 5 9/16-18 UNF G 1/2 N/A N/A 10

(250) (0.7) (68.0) (64.0) (30)

2600/(180)* 1.8 3.15 2.91 1.18

SBO 210 8:1 0.16 10 9/16-18 UNF G 1/2 N/A N/A 10

3000/(210) (0.8) (80.0) (74.0) (30)

2400/(160)* 2.9 3.66 3.66 1.42

SBO 210 8:1 0.32 20 3/4-16 UNF G 1/2 N/A N/A 25

3000/(210) (1.3) (93.0) (93.0) (36)

3000 3.7 4.35 4.13 1.42

SBO 210 8:1 0.5 30 3/4-16 UNF G 1/2 N/A N/A 25

(210) (1.7) (124.0) (105.0) (36)

4700 7.3 5.04 4.53 1.42

SBO 330 8:1 0.6 36 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(330) (3.3) (128.0) (115.0) (36)

2000/(140)* 6.2 4.88 4.76 1.42

SBO 210 8:1 0.75 45 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

3000/(210) (2.8) (124.0) (121.0) (36)

4700 8.9 4.78 4.96 1.42

SBO 330 8:1 0.75 45 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(330) (4.0) (122.0) (126.0) (36)

3000 7.9 5.39 5.35 1.42

SBO 200 8:1 1 60 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(210) (3.6) (137.0) (136.0) (36)

2000 8.6 5.91 5.71 1.42

SBO 140 8:1 1.4 85 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(140) (3.9) (150.0) (145.0) (36)

3000 11.9 6.14 5.91 1.42

SBO 210 8:1 1.4 85 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(210) (5.4) (156.0) (150.0) (36)

4700 16.6 6.33 6.1 1.42

SBO 330 8:1 1.4 85 3/4-16 UNF G 1/2 G 1/2 M33 x 1.5 25

(330) (7.5) (160.0) (155.0) (36)

1500/(100)* 8.8 6.57 6.3 1.81

SBO 100 8:1 2 120 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

1500/(100) (4.0) (167.0) (160.0) (46)

3000 14.6 6.81 6.57 1.81

SBO 210 8:1 2 120 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

(210) (6.6) (173.0) (167.0) (46)

4700 17.7 7.12 6.77 1.81

SBO 330 8:1 2 120 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

(330) (8.0) (180.0) (172.0) (46)

3000 18 8.94 6.57 1.81

SBO 210 4:1 2.8 170 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

(210) (8.2) (227.0) (167.0) (46)

3000 24.6 11.14 6.69 1.81

SBO 250 4:1 3.5 230 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

(210) (11.2) (283.0) (170.0) (46)

4700 30.6 10.78 6.77 1.81

SBO 330 4:1 3.5 230 1 1/16 -12 UNF G 3/4 G 3/4 M45 x 1.5 40

(330) (13.8) (274.0) (172.0) (46)

Dimensions are for general information only, all critical dimensions should be verified.

Dimensions are in inches/(mm) and lbs/(kg)

*Reduced MAWP values for stainless steel models

**Diameter at electron beam weld at shell seam may be up to +0.150” larger in diameter

PN#02068195 / 1.15 / ACU1102-1326 INNOVATIVE FLUID POWER 25

Diaphragm Accumulators

Repairable Threaded Diaphragm Accumulators

Thread F

K-

Eff Gas A B ØD ØL M N

Max. MAWP Weight CK AK Hex Q

Series Size Vol in/ in/ in/ in/ in/ in/

p2:p0 psi/(bar) Lbs/(kg) (SAE- (BSPP in/ gpm

(in3) (mm) (mm) (mm) (mm) (mm) (mm)

female) -female) (mm)

7200 4.2 4.33 1.18 3.74 3/4 - 16 1.26 2.68 0.87 1.38

SBO 500 10:1 0.1 6 G 1/2 25

(500) (1.9) (110) (30) (95) UNF (68) (68) (22) (35)

5000/(350)* 8.6 5.04 0.79 4.53 3/4 - 16 1.42 3.62 0.71 2.17

SBO 500 10:1 0.25 15 G 1/2 25

(3.9) (128) (20) (115) UNF (36) (92) (18) (55)

7200/(500)

8700/(600)*

19.8 5.35 0.43 6.02 3/4 - 16 1.42 4.49 0.59 2.48

SBO 750 10:1 0.25 15 10,000/ G 1/2 25

(9.0) (136) (11) (153) UNF (36) (114) (15) (63)

(750)

3600/(250)* 12.6 6.69 0.75 5.51 3/4 - 16 1.61 4.53 1.77 2.24

SBO 450 10:1 0.6 36 G 1/2 25

4700/(330) (5.7) (170) (19) (140) UNF (41) (115) (45) (57)

3000 18.7 7.48 0.31 6.69 3/4 - 16 1.26 5.71 2.24 2.17

SBO 210 10:1 1.3 80 G 1/2 25

(210) (8.5) (190) (8) (170) UNF (32) (145) (57) (55)

5800 24.7 7.75 1.1 7.91 3/4 - 16 1.97 6.3 1.97 2.56

SBO 400 10:1 1.3 80 G 3/4 25

(400) (11.2) (197) (28) (201) UNF (50) (160) (50) (65)

2600/(180)* 25.1 8.93 0.67 7.91 1 1/16- 1.61 6.61 2.44 2.52

SBO 250 10:1 2.0 120 G 3/4 40

3600/(250) (11.4) (227) (17) (201) 12 UNF (41) (168) (62) (64)

Dimensions are for general information only, all critical dimensions should be verified.

Dimensions are in inches/(mm) and lbs/(kg)

*Reduced MAWP values for stainless steel models

26 INNOVATIVE FLUID POWER PN#02068195 / 1.15 / ACU1102-1326

Diaphragm Accumulators

Diaphragm Spare Parts

2075359 Vent Screw M8 (w/ NBR Seal Ring) Version 1 2067728 Metal Valve Protection Cap, Version 1

2100344 Vent Screw M8 only 632865 Gas valve core (Version 4)

6004771 NBR Seal Ring, U9.3X13.3X1 237977 Valve seal cap (Version 4)

2127517 Plastic Valve Protection Cap, Version 1 626488 O-ring 7.5x2 (Buna)

Water Service Accumulators

RED selections are not standard item - Contact HYDAC for information and availability.

Effective

Size MAWP Part Fluid Connection

Gas Vol Model Code

(liters) psi/(bar) Number Thread Size

(in3)

Stainless Steel Port / Stainless Steel Shell

0.16 10 2600 / 180 SBO210-0.16E1/342S-180CA 3344456 SAE 3/4-16UNF-2A male

0.16 10 2600 / 180 SBO210-0.16E1/342S-180HA 2104224 1/2" NPTF male

0.16 10 2600 / 180 SBO210-0.16E1/346S-180HA 2108258 1/2" NPTF male

0.16 10 2600 / 180 SBO210-0.16E1/346U-180AK 3041996 G 1/2" BSPP female

0.25 15 5000 / 345 SBO500-0.25A6/342S-350AK 2110031 G 1/2" BSPP female

0.25 15 5000 / 345 SBO500-0.25A6/346S-350AK 2122000 G 1/2" BSPP female

0.25 15 10,800 / 745 SBO750-0.25A6/342S-750AK 2103443 G 1/2" BSPP female

0.25 15 10,800 / 745 SBO750-0.25A6/342S-750CK 2110811 SAE 3/4" -16 UNF female

0.25 15 10,800 / 745 SBO750-0.25A6/342U-750AK 3042064 G 1/2" BSPP female

0.32 20 2300 / 160 SBO210-0.32E1/342S-160HF 2111137 3/4" NPTF male

0.32 20 2300 / 160 SBO210-0.32E1/346S-160HF 2111138 3/4" NPTF male

0.6 36 3600 / 250 SBO450-0.6A6/342S-250AK 2121077 G 1/2" BSPP female

0.6 36 3600 / 250 SBO450-0.6A6/346U-250AK 3042074 G 1/2" BSPP female

0.75 45 2000 / 140 SBO210-0.75E1/342S-140HD 2108260 1" NPTF male

0.75 45 2000 / 140 SBO210-0.75E1/343S-140HD 2108850 1" NPTF male

0.75 45 2000 / 140 SBO210-0.75E1/346S-140HD 2106833 1" NPTF male

2.0 120 1450 / 100 SBO100-2E1/342S-100HC 2106047 1 1/4" NPTF male

2.0 120 1450 / 100 SBO100-2E1/342U-100AK 2105229 G 3/4" BSPP female

2.0 120 1450 / 100 SBO100-2E1/346S-100HC 2108262 1 1/4" NPTF male

2.0 120 2600 / 180 SBO250-2A6/342S-180AK 2103395 G 3/4" BSPP female

4.0 260 725 / 50 SBO50-4E1/342U-50AB 3107029 G 3/4" BSPP / M45 x 1.5

4.0 260 725 / 50 SBO50-4E1/346U1-50AB 3108261 G 3/4" BSPP / M45 x 1.5

4.0 260 2600 / 180 SBO250-4E1/344U-180CK 3586865 SAE 1 1/16" - 12 UNF female

Plated Port / Plated Shell

0.16 10 3000 / 210 SBO210-0.16E2/422S-210HB031 2067722 1/2" NPTF male

0.16 10 3000 / 210 SBO210-0.16E2/422S-210HB034 2100033 1/2" NPTF male

0.16 10 3000 / 210 SBO210-0.16E2/422S-210HB086 2106845 1/2" NPTF male

0.75 45 5000 / 340 SBO330-0.75E1/422S-345AK 2120586 G 1/2" BSPP female

Stainless Steel Port / Synthetic Coated Shell

0.6 36 4700 / 320 SBO330-0.6E1/302U-330AB 2111755 G 1/2" BSPP / M45 x 1.5

0.75 45 3000 / 210 SBO210-0.75E1/302S-210HD* 2114229 1" NPTF male

0.75 45 3000 / 210 SBO210-0.75E1/302S-210HD048 2084342 1" NPTF male

3.5 230 3000 / 210 SBO250-3.5E4/302S-210HC 2101745 1-1/4" NPTF male

Fluid Port / Shell Material Combinations Which Are Not Available

32x Stainless Steel Port Chemically Plated Shell

40x Chemically Plated Port Synthetic Coated Shell

44x Synthetic Coated Port Chemically Plated Shell

PN#02068195 / 1.15 / ACU1102-1326 INNOVATIVE FLUID POWER 27

You might also like

- Pulsation Dampeners: Protect Systems from Pressure FluctuationsDocument4 pagesPulsation Dampeners: Protect Systems from Pressure FluctuationssanthoshkrishnaNo ratings yet

- DA Series Diaphragm Accumulators: Previously Known As ELM SeriesDocument18 pagesDA Series Diaphragm Accumulators: Previously Known As ELM SeriesglobalindosparepartsNo ratings yet

- Chevron Randon HDZDocument5 pagesChevron Randon HDZRonald José Silva CostaNo ratings yet

- SBO Series: Diaphragm AccumulatorsDocument0 pagesSBO Series: Diaphragm AccumulatorsnfisicaNo ratings yet

- Lubricants Technology For Steel IndustryDocument54 pagesLubricants Technology For Steel Industrysalah.a.abdelazimNo ratings yet

- BrochureDocument28 pagesBrochurePapa100% (1)

- TURBO Refrigerating Chiller-ManualDocument127 pagesTURBO Refrigerating Chiller-Manualchootymalli9760100% (1)

- Chiller Trouble Shooting 17Document28 pagesChiller Trouble Shooting 17akhilesh.kNo ratings yet

- Rando HDZ 46Document2 pagesRando HDZ 46Marcin MarcinkiewiczNo ratings yet

- Capella WF: Ultra High Performance Refrigeration Compressor LubricantDocument3 pagesCapella WF: Ultra High Performance Refrigeration Compressor LubricantJeremias UtreraNo ratings yet

- Durafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Document2 pagesDurafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Karthik ManiNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- High Pressure Drilling Hoses GuideDocument5 pagesHigh Pressure Drilling Hoses GuideitangNo ratings yet

- Diaphragm Accumulators: - AD SeriesDocument6 pagesDiaphragm Accumulators: - AD SeriesAFG AutomacaoNo ratings yet

- Shell Refrigeration Oil S4 FR-V 68: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Refrigeration Oil S4 FR-V 68: Performance, Features & Benefits Specifications, Approvals & RecommendationsMUHAMMAD LUTHFINo ratings yet

- Indium5.5LT Solder Paste: Product Data SheetDocument2 pagesIndium5.5LT Solder Paste: Product Data SheetluismcmcNo ratings yet

- GL XX Nyvac FR 200DDocument3 pagesGL XX Nyvac FR 200DHenry UntirtaNo ratings yet

- Wellcare Oil Tools PVT LTD: Product IndexDocument22 pagesWellcare Oil Tools PVT LTD: Product IndexParag PadoleNo ratings yet

- C H O AW: Hevron Ydraulic ILDocument2 pagesC H O AW: Hevron Ydraulic ILAmir Reza RashidfarokhiNo ratings yet

- GL EG Mobil EAL Arctic SeriesDocument3 pagesGL EG Mobil EAL Arctic SeriesShadi MuhammedNo ratings yet

- Ultramax 68 Hydraulic Oil-PI SheetDocument2 pagesUltramax 68 Hydraulic Oil-PI SheetNgila João AndréNo ratings yet

- Texamatic 1888: Proven Performance Automatic Transmission OilDocument3 pagesTexamatic 1888: Proven Performance Automatic Transmission Oilhoussem houssemNo ratings yet

- Aircol SW RangeDocument2 pagesAircol SW RangeDouglas Neves - UnaxNo ratings yet

- 12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDocument4 pages12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDiaconescu AdrianNo ratings yet

- Castrol Aero HF 585B Mineral Hydraulic Fluid Product DataDocument2 pagesCastrol Aero HF 585B Mineral Hydraulic Fluid Product Datanauta007No ratings yet

- 4 Refrigeration Oil S4 FR-V 68Document2 pages4 Refrigeration Oil S4 FR-V 68dnoaisapsNo ratings yet

- Product Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Document80 pagesProduct Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Muhammad Zhakri Muhammad KamalNo ratings yet

- Solenoid Valves 90barDocument31 pagesSolenoid Valves 90baralessandro silvaNo ratings yet

- BAR SY 100 en FR Motultech 20210420Document2 pagesBAR SY 100 en FR Motultech 20210420Victor ZhicayNo ratings yet

- Shell Spirax S5 ATF XDocument2 pagesShell Spirax S5 ATF Xhoussem houssemNo ratings yet

- Lamidisc All Steel Coupling: CouplingsDocument20 pagesLamidisc All Steel Coupling: CouplingsvaleriyNo ratings yet

- MDS SHELL Refrigeration Oil S2 FR-A 68Document2 pagesMDS SHELL Refrigeration Oil S2 FR-A 68Antonio CardosoNo ratings yet

- Ebara Gs DatasheetDocument132 pagesEbara Gs DatasheetWalter PerezNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Biodegradable hydraulic oil specificationsDocument1 pageBiodegradable hydraulic oil specificationsD Wahyu BawonoNo ratings yet

- Tectyl HF 46 PDS ENDocument1 pageTectyl HF 46 PDS ENAdham TunggalNo ratings yet

- Hawe Hydraulic Oil RecommendationsDocument13 pagesHawe Hydraulic Oil RecommendationsJako MishyNo ratings yet

- Abatidor de Calo TR35799 Rbc200 FichaDocument4 pagesAbatidor de Calo TR35799 Rbc200 FichaFidelNo ratings yet

- Sinopec Antiwear Hydraulic Oil L-HMDocument3 pagesSinopec Antiwear Hydraulic Oil L-HMSumaya Akter100% (1)

- Performance Fluids Oh46zf Hydraulic OilDocument3 pagesPerformance Fluids Oh46zf Hydraulic Oilpancho7rNo ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Fincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignDocument2 pagesFincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignSuresh Damu BhadNo ratings yet

- Tds 1323203 enDocument2 pagesTds 1323203 enMartín BaezaNo ratings yet

- Technical Topic Refrigeration Oils (Jan 2011) - EN PDFDocument4 pagesTechnical Topic Refrigeration Oils (Jan 2011) - EN PDFPreeti gulatiNo ratings yet

- Bladder Accum - Gas PermeationDocument6 pagesBladder Accum - Gas Permeationahbipn1No ratings yet

- GIL IGE CatalogueDocument12 pagesGIL IGE CatalogueVishal Kumar JhaNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- Scenic CarLife 99Document4 pagesScenic CarLife 99Lendl dela CruzNo ratings yet

- Shell Irus C-NA Technical Data SheetDocument2 pagesShell Irus C-NA Technical Data SheetdtcuongNo ratings yet

- Chevron Regal RO PDSDocument4 pagesChevron Regal RO PDSVivekyathi BowanNo ratings yet

- Shell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsDocument2 pagesShell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsWajahat RasoolNo ratings yet

- Multipurpose Tug v1 4 SPDocument44 pagesMultipurpose Tug v1 4 SPJoanna LockNo ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- Shell Irus C: Performance, Features & BenefitsDocument2 pagesShell Irus C: Performance, Features & BenefitsGian TeryNo ratings yet

- Shell Irus Fluid C TDSDocument2 pagesShell Irus Fluid C TDSPhuong NguyenNo ratings yet

- Hydraulic Fluid CategoriesDocument3 pagesHydraulic Fluid CategoriesJako MishyNo ratings yet

- GMORS Rubber Especification O Rings Guidebook AS568ADocument90 pagesGMORS Rubber Especification O Rings Guidebook AS568AfeltofsnakeNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 22 Physical Asset ManagementDocument2 pages22 Physical Asset ManagementCarlos Andrés CuelloNo ratings yet

- Nuclear Industry (NPRDS) Offshore Industry (OREDA) Chemical Industry (CCPS)Document3 pagesNuclear Industry (NPRDS) Offshore Industry (OREDA) Chemical Industry (CCPS)Carlos Andrés CuelloNo ratings yet

- VSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedDocument2 pagesVSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedCarlos Andrés CuelloNo ratings yet

- Ekipirovka Za SmazvaneDocument105 pagesEkipirovka Za SmazvaneBobby BobbyNo ratings yet

- Ingersoll Rand UP6 50PEI Manual de PartesDocument245 pagesIngersoll Rand UP6 50PEI Manual de PartesCarlos Andrés CuelloNo ratings yet

- Throttle Check Valve Type Z2FSDocument8 pagesThrottle Check Valve Type Z2FSCarlos Andrés CuelloNo ratings yet

- Parker D1FLDocument20 pagesParker D1FLCarlos Andrés CuelloNo ratings yet

- Aventics QR1-S-RSM Push-In Fitting MetalDocument2 pagesAventics QR1-S-RSM Push-In Fitting MetalCarlos Andrés CuelloNo ratings yet

- VSO-SE-DL 055211X03Z Pilot Operated Check SingleDocument2 pagesVSO-SE-DL 055211X03Z Pilot Operated Check SingleCarlos Andrés CuelloNo ratings yet

- Hydac Return Line Filter RFDDocument4 pagesHydac Return Line Filter RFDCarlos Andrés CuelloNo ratings yet

- Aventics R412007432 Check-Choke Valve Series CC02-ALDocument2 pagesAventics R412007432 Check-Choke Valve Series CC02-ALCarlos Andrés CuelloNo ratings yet

- SuperSpool RCV Service Literature R434000181Document8 pagesSuperSpool RCV Service Literature R434000181Carlos Andrés CuelloNo ratings yet

- ISO 15552 Pneumatic CylindersDocument6 pagesISO 15552 Pneumatic CylindersCarlos Andrés CuelloNo ratings yet

- Aventics QR1-S-RTK T-Plug ConnectorDocument2 pagesAventics QR1-S-RTK T-Plug ConnectorCarlos Andrés CuelloNo ratings yet

- Directional Control Valves, Pilot-Operated, With Electrical Position Feedback and Integrated Electronics (OBE) Type 4WRDEDocument24 pagesDirectional Control Valves, Pilot-Operated, With Electrical Position Feedback and Integrated Electronics (OBE) Type 4WRDECarlos AugustoNo ratings yet

- 4WRA (E) B Válvulas Direccionales ProporcionalesDocument8 pages4WRA (E) B Válvulas Direccionales ProporcionalesCarlos Andrés CuelloNo ratings yet

- Fixed Plug-In Motors FMFDocument4 pagesFixed Plug-In Motors FMFCarlos Andrés CuelloNo ratings yet

- Coil Series CO1 SpecsDocument3 pagesCoil Series CO1 SpecsCarlos Andrés CuelloNo ratings yet

- Aventics Series QR2-S-RVT Elbow Fitting RotatableDocument3 pagesAventics Series QR2-S-RVT Elbow Fitting RotatableCarlos Andrés CuelloNo ratings yet

- Tie Rod Cylinder ISO 15552, Series TRBDocument4 pagesTie Rod Cylinder ISO 15552, Series TRBCarlos Andrés CuelloNo ratings yet

- 800 CatalogDocument19 pages800 CatalogDavid FonsecaNo ratings yet

- Asco 290 Válvula Proporcional PosicionadorDocument2 pagesAsco 290 Válvula Proporcional PosicionadorCarlos Andrés CuelloNo ratings yet

- Aventics T-Union QR1-S-RTT Standard SeriesDocument3 pagesAventics T-Union QR1-S-RTT Standard SeriesCarlos Andrés CuelloNo ratings yet

- PLL 1732 PDFDocument4 pagesPLL 1732 PDFHaytham Ammer MushtahaNo ratings yet

- Aventics Bearing Block AB7-HD Series CM1Document2 pagesAventics Bearing Block AB7-HD Series CM1Carlos Andrés CuelloNo ratings yet

- Aventics Coil Series CO1 Form ADocument3 pagesAventics Coil Series CO1 Form ACarlos Andrés CuelloNo ratings yet

- SMC VT307 Solenoid Valve Direct Operated Poppet TypeDocument11 pagesSMC VT307 Solenoid Valve Direct Operated Poppet TypeCarlos Andrés CuelloNo ratings yet

- Aventics 52-Directional Valve Series CD12 Single SolenoidDocument6 pagesAventics 52-Directional Valve Series CD12 Single SolenoidCarlos Andrés CuelloNo ratings yet

- BROCHUREDocument33 pagesBROCHURElegend guraraNo ratings yet

- Medidores Liquid Control 1Document8 pagesMedidores Liquid Control 1Carlos Andrés CuelloNo ratings yet

- Radar High-Speed Target Detection Based On The Frequency-Domain Deramp-Keystone TransformDocument10 pagesRadar High-Speed Target Detection Based On The Frequency-Domain Deramp-Keystone TransformChinh PhanNo ratings yet

- Siwes Report On Computer ScienceDocument29 pagesSiwes Report On Computer ScienceGiwa jelili adebayoNo ratings yet

- My First Ttcn-3 Project With TtworkbenchDocument19 pagesMy First Ttcn-3 Project With TtworkbenchPramod KumarNo ratings yet

- JNTUA R20 B.tech - ECE III IV Course Structure SyllabusDocument112 pagesJNTUA R20 B.tech - ECE III IV Course Structure SyllabusNaveenNo ratings yet

- Lexmark Cxx10 MFP: Machine Type 7527-2Xx, - 4Xx, - 63XDocument394 pagesLexmark Cxx10 MFP: Machine Type 7527-2Xx, - 4Xx, - 63XOmar SanchezNo ratings yet

- SAP ESS Emplpoyee Self Service Made Easy GuideDocument365 pagesSAP ESS Emplpoyee Self Service Made Easy GuideKhushbu DaveNo ratings yet

- GUIDELINES For Refund of Exam Fee CSCDocument5 pagesGUIDELINES For Refund of Exam Fee CSCChristine Joy VallejosNo ratings yet

- TH 250Document53 pagesTH 250ȘTEFAN LIVIU OCTAVIAN POPANo ratings yet

- CSA09 Programming in Java MediumDocument25 pagesCSA09 Programming in Java Mediumsometimesop7934No ratings yet

- rws100 3Document1 pagerws100 3Alexis Sepond AlexisNo ratings yet

- Valnav Reserves Management 2019Document83 pagesValnav Reserves Management 2019Jorge RomeroNo ratings yet

- Parts Manual: CascadeDocument10 pagesParts Manual: CascadeantonioNo ratings yet

- Marine Power System PDFDocument46 pagesMarine Power System PDFTen ApolinarioNo ratings yet

- Mini Split MlaDocument8 pagesMini Split MlaAmbar JuarezNo ratings yet

- Tungsram-LED-Bright-Stik-DataSheet-EN - SASODocument3 pagesTungsram-LED-Bright-Stik-DataSheet-EN - SASORoudy J. MhawasNo ratings yet

- Guide to creating a mine site reconciliation code of practiceDocument11 pagesGuide to creating a mine site reconciliation code of practicecajimenezb8872No ratings yet

- Document Management PDFDocument82 pagesDocument Management PDFTester25896No ratings yet

- Paradigms of HMIDocument23 pagesParadigms of HMITiến PhạmNo ratings yet

- Tender Document 4666Document128 pagesTender Document 4666KishoreNo ratings yet

- Bulletin 30RB-30RQ Option 12Document2 pagesBulletin 30RB-30RQ Option 12vickersNo ratings yet

- CSPro Android - Data Transfert GuideDocument9 pagesCSPro Android - Data Transfert GuideSADOUN SeNo ratings yet

- Lean Blow Out Limits of A Gas Turbine CombustorDocument10 pagesLean Blow Out Limits of A Gas Turbine CombustorFayçal MahieddineNo ratings yet

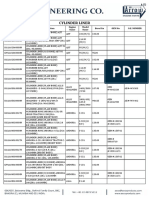

- Cylinder Liner: Item Code Item Description Engine Name Model Name Bore Dia Oem No O.E. NumberDocument49 pagesCylinder Liner: Item Code Item Description Engine Name Model Name Bore Dia Oem No O.E. NumberDuvacy0% (1)

- Virgin Mobile USA: Pricing for the First TimeDocument5 pagesVirgin Mobile USA: Pricing for the First Timebonfument100% (1)

- Delamination Repair ProcedureDocument2 pagesDelamination Repair ProceduregnanasekarNo ratings yet

- X1 Xdrive25I 98Mht1000J4A39779: Generated On Https://Bimmer - WorkDocument5 pagesX1 Xdrive25I 98Mht1000J4A39779: Generated On Https://Bimmer - WorksergioradNo ratings yet

- 1A 2021 Mid Sem TPDocument2 pages1A 2021 Mid Sem TPJason RoyNo ratings yet

- QC Inspector Functions Tests AnswersDocument8 pagesQC Inspector Functions Tests Answerszhangyili50% (2)

- Datasheet DT35S-B15551 1122103 enDocument8 pagesDatasheet DT35S-B15551 1122103 enROSSNo ratings yet

- Fisa Tehnica Autocolant Furnir LemnDocument1 pageFisa Tehnica Autocolant Furnir LemnCatalina PopNo ratings yet