Professional Documents

Culture Documents

MD+PRO Series Land Steel 8w

Uploaded by

ag cnc & wedm machining shopCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD+PRO Series Land Steel 8w

Uploaded by

ag cnc & wedm machining shopCopyright:

Available Formats

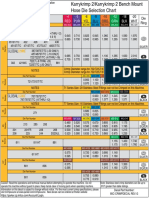

MD+PRO Series Wire Dia.

and Type Material Type Class

Digest .008 hard brass STEEL Standard

Thickness 0.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 941 HP 0.080

1 1001 HP 0.260 0.00510 0.00640 0.00660 Nozzle Gap

2 1002 MP 0.310 - 0.00440 0.00460 Upper .008"

3 1003 LC 0.240 - - 0.00420 Lower .004"

4 - - -

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 50 30 14

Thickness 0.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 941 HP 0.080

1 1011 HP 0.160 0.00530 0.00670 0.00690 Nozzle Gap

2 1012 MP 0.240 - 0.00450 0.00470 Upper .008"

3 1013 LC 0.180 - - 0.00420 Lower .004"

4 - - -

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 50 30 14

Thickness 0.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 942 HP 0.040

1 1021 HP 0.100 0.00540 0.00680 0.00710 Nozzle Gap

2 1022 MP 0.180 - 0.00440 0.00470 Upper .008"

3 1023 LC 0.150 - - 0.00420 Lower .004"

4 - - -

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 16

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .008 hard brass STEEL Standard

Thickness 1 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 943 HP 0.030

1 1031 HP 0.080 0.00560 0.00640 0.00700 0.00730 Nozzle Gap

2 1032 MP 0.280 - 0.00440 0.00500 0.00530 Upper .008"

3 1033 MP 0.200 - - 0.00440 0.00470 Lower .004"

4 1034 LC 0.200 - - - 0.00420

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 1.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 943 HP 0.030

1 1041 HP 0.070 0.00560 0.00650 0.00700 0.00730 Nozzle Gap

2 1042 MP 0.260 - 0.00450 0.00500 0.00530 Upper .008"

3 1043 MP 0.180 - - 0.00440 0.00470 Lower .004"

4 1044 LC 0.190 - - - 0.00420

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 1.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 943 HP 0.030

1 1051 HP 0.060 0.00560 0.00650 0.00710 0.00740 Nozzle Gap

2 1052 MP 0.260 - 0.00450 0.00510 0.00540 Upper .008"

3 1053 MP 0.160 - - 0.00450 0.00480 Lower .004"

4 1054 LC 0.190 - - - 0.00420

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .008 hard brass STEEL Standard

Thickness 1.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1061 HP 0.050 0.00570 0.00650 0.00710 0.00730 Nozzle Gap

2 1062 MP 0.260 - 0.00450 0.00510 0.00530 Upper .008"

3 1063 MP 0.170 - - 0.00450 0.00470 Lower .004"

4 1064 LC 0.180 - - - 0.00420

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 2 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1071 HP 0.040 0.00580 0.00650 0.00710 0.00730 Nozzle Gap

2 1072 MP 0.260 - 0.00450 0.00510 0.00530 Upper .008"

3 1073 MP 0.180 - - 0.00450 0.00470 Lower .004"

4 1074 LC 0.180 - - - 0.00420

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 2.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1081 HP 0.040 0.00580 0.00670 0.00730 0.00750 Nozzle Gap

2 1082 MP 0.240 - 0.00450 0.00510 0.00530 Upper .008"

3 1083 MP 0.160 - - 0.00450 0.00470 Lower .004"

4 1084 LC 0.170 - - - 0.00420

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .008 hard brass STEEL Standard

Thickness 2.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1091 HP 0.040 0.00580 0.00670 0.00730 0.00750 Nozzle Gap

2 1092 MP 0.220 - 0.00450 0.00510 0.00530 Upper .008"

3 1093 MP 0.140 - - 0.00450 0.00470 Lower .004"

4 1094 LC 0.160 - - - 0.00420

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 2.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1101 HP 0.030 0.00580 0.00670 0.00730 0.00740 Nozzle Gap

2 1102 MP 0.200 - 0.00460 0.00520 0.00530 Upper .008"

3 1103 MP 0.140 - - 0.00460 0.00470 Lower .004"

4 1104 LC 0.140 - - - 0.00430

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 3 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1111 HP 0.020 0.00580 0.00690 0.00750 0.00770 Nozzle Gap

2 1112 MP 0.180 - 0.00460 0.00520 0.00540 Upper .008"

3 1113 MP 0.140 - - 0.00460 0.00480 Lower .004"

4 1114 LC 0.130 - - - 0.00430

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .008 hard brass STEEL Standard

Thickness 3.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1121 HP 0.020 0.00580 0.00710 0.00785 0.00810 Nozzle Gap

2 1122 MP 0.180 - 0.00460 0.00535 0.00560 Upper .008"

3 1123 MP 0.130 - - 0.00460 0.00485 Lower .004"

4 1124 LC 0.110 - - - 0.00430

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness 4 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 944 HP 0.020

1 1131 HP 0.020 0.00590 0.00720 0.00805 0.00835 Nozzle Gap

2 1132 MP 0.180 - 0.00460 0.00545 0.00575 Upper .008"

3 1133 MP 0.130 - - 0.00460 0.00490 Lower .004"

4 1134 LC 0.090 - - - 0.00430

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 55 40 32 16

Thickness inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A

1 Nozzle Gap

2 - Upper

3 - - Lower

4 - - -

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra

Version 1.0 (09-05)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 0.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2

E-pack Number Eno 941 1001 1002 1003

Power Supply PS HP HP MP LC

Servo SV NM NM NM NM

Voltage Open Vo 12 16 3 3

Power Setting IP 5 6 6 3

Off Time OFF 1 1 1 10

Stabilizer A SA 3 3 2 2

Stabilizer B SB 12 10 8 8

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 5 1 1

Voltage Gap VG 50 42 46 60

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 7 8 10 10

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 9 9 9 9

Feedrate Address FA 0.080 0.260 0.310 0.240

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00510 -------- --------

Rough & 1 Skim -------- 0.00640 0.00440 --------

Rough & 2 Skims -------- 0.00660 0.00460 0.00420

Rough & 3 Skims --------

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .480 ~ .520 .500 ~ .600 .460 ~ .540

Average Voltage Gap VG ~ 40 ~ 44 44 ~ 48 70 ~ 90

Avg. Linear Feedrate ALF 27.05 14.51 9.75

Surface Finish(µ in) Ra ~ 45 ~ 55 26 ~ 34 12 ~ 16

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 0.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2

E-pack Number Eno 941 1011 1012 1013

Power Supply PS HP HP MP LC

Servo SV NM NM NM NM

Voltage Open Vo 12 16 4 3

Power Setting IP 5 6 8 3

Off Time OFF 1 1 1 10

Stabilizer A SA 3 3 2 2

Stabilizer B SB 12 10 8 8

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 5 1 1

Voltage Gap VG 50 42 50 57

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 7 8 10 10

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 9 9 9 9

Feedrate Address FA 0.080 0.160 0.240 0.180

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00530 -------- --------

Rough & 1 Skim -------- 0.00670 0.00450 --------

Rough & 2 Skims -------- 0.00690 0.00470 0.00420

Rough & 3 Skims --------

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .260 ~ .290 .160 ~ .240 .340 ~ .420

Average Voltage Gap VG ~ 36 ~ 41 49 ~ 53 66 ~ 78

Avg. Linear Feedrate ALF 15.99 6.80 5.40

Surface Finish(µ in) Ra ~ 45 ~ 55 26 ~ 34 12 ~ 16

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 0.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2

E-pack Number Eno 942 1021 1022 1023

Power Supply PS HP HP MP LC

Servo SV NM NM NM NM

Voltage Open Vo 12 16 5 3

Power Setting IP 7 8 10 3

Off Time OFF 1 1 1 9

Stabilizer A SA 3 4 2 2

Stabilizer B SB 12 9 8 7

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 5 1 1

Voltage Gap VG 50 40 49 60

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 7 8 10 10

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 9 9 9 9

Feedrate Address FA 0.040 0.100 0.180 0.150

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00540 -------- --------

Rough & 1 Skim -------- 0.00680 0.00440 --------

Rough & 2 Skims -------- 0.00710 0.00470 0.00420

Rough & 3 Skims --------

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .190 ~ .220 .220 ~ .300 .280 ~ .360

Average Voltage Gap VG ~ 38 ~ 42 46 ~ 54 60 ~ 80

Avg. Linear Feedrate ALF 12.04 6.28 4.63

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 1.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 943 1031 1032 1033 1034

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 4

Power Setting IP 7 9 11 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 4 2 2 2

Stabilizer B SB 12 9 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 53 49 50

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.030 0.080 0.280 0.200 0.200

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00560 -------- -------- --------

Rough & 1 Skim -------- 0.00640 0.00440 -------- --------

Rough & 2 Skims -------- 0.00700 0.00500 0.00440 --------

Rough & 3 Skims -------- 0.00730 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .150 ~ .180 .380 ~ .460 .200 ~ .280 .400 ~ .480

Average Voltage Gap VG ~ 40 ~ 44 48 ~ 56 46 ~ 54 55 ~ 75

Avg. Linear Feedrate ALF 10.13 6.92 4.67 3.91

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 1.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 943 1041 1042 1043 1044

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 4 2 2 2

Stabilizer B SB 12 9 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 55 49 50

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.030 0.070 0.260 0.180 0.190

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00560 -------- -------- --------

Rough & 1 Skim -------- 0.00650 0.00450 -------- --------

Rough & 2 Skims -------- 0.00700 0.00500 0.00440 --------

Rough & 3 Skims -------- 0.00730 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .130 ~ .150 .280 ~ .360 .180 ~ .260 .300 ~ .420

Average Voltage Gap VG ~ 38 ~ 42 50 ~ 58 46 ~ 54 55 ~ 75

Avg. Linear Feedrate ALF 8.83 5.91 4.01 3.41

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 1.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 943 1051 1052 1053 1054

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 10 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 36 55 49 50

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.030 0.060 0.260 0.160 0.190

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00560 -------- -------- --------

Rough & 1 Skim -------- 0.00650 0.00450 -------- --------

Rough & 2 Skims -------- 0.00710 0.00510 0.00450 --------

Rough & 3 Skims -------- 0.00740 0.00540 0.00480 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .115 ~ .135 .240 ~ .320 .160 ~ .240 .360 ~ .440

Average Voltage Gap VG ~ 34 ~ 38 50 ~ 58 46 ~ 54 55 ~ 75

Avg. Linear Feedrate ALF 7.53 4.90 3.36 2.91

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 1.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1061 1062 1063 1064

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 9 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 36 54 48 50

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.050 0.260 0.170 0.180

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00570 -------- -------- --------

Rough & 1 Skim -------- 0.00650 0.00450 -------- --------

Rough & 2 Skims -------- 0.00710 0.00510 0.00450 --------

Rough & 3 Skims -------- 0.00730 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .095 ~ .115 .220 ~ .300 .200 ~ .280 .360 ~ .440

Average Voltage Gap VG ~ 34 ~ 38 50 ~ 58 44 ~ 48 50 ~ 70

Avg. Linear Feedrate ALF 6.50 4.29 3.13 2.72

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 2.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1071 1072 1073 1074

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 10 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 36 53 46 50

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.040 0.260 0.180 0.180

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00650 0.00450 -------- --------

Rough & 2 Skims -------- 0.00710 0.00510 0.00450 --------

Rough & 3 Skims -------- 0.00730 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .080 ~ .100 .200 ~ .280 .240 ~ .320 .360 ~ .440

Average Voltage Gap VG ~ 34 ~ 38 50 ~ 58 44 ~ 48 50 ~ 70

Avg. Linear Feedrate ALF 5.47 3.68 2.90 2.54

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 2.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1081 1082 1083 1084

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 11 5 6

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 10 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 39 50 45 45

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.040 0.240 0.160 0.170

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00670 0.00450 -------- --------

Rough & 2 Skims -------- 0.00730 0.00510 0.00450 --------

Rough & 3 Skims -------- 0.00750 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .070 ~ .090 .190 ~ .270 .200 ~ .280 .340 ~ .420

Average Voltage Gap VG ~ 36 ~ 40 48 ~ 54 44 ~ 48 50 ~ 70

Avg. Linear Feedrate ALF 4.69 3.23 2.53 2.24

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 2.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1091 1092 1093 1094

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 10 4 5

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 10 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 38 50 45 45

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.040 0.220 0.140 0.160

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00670 0.00450 -------- --------

Rough & 2 Skims -------- 0.00730 0.00510 0.00450 --------

Rough & 3 Skims -------- 0.00750 0.00530 0.00470 0.00420

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .060 ~ .080 .180 ~ .260 .140 ~ .220 .320 ~ .400

Average Voltage Gap VG ~ 36 ~ 40 46 ~ 54 44 ~ 48 50 ~ 70

Avg. Linear Feedrate ALF 3.92 2.78 2.17 1.95

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 2.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1101 1102 1103 1104

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 11 5 6

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 10 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 39 49 45 45

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.030 0.200 0.140 0.140

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00670 0.00460 -------- --------

Rough & 2 Skims -------- 0.00730 0.00520 0.00460 --------

Rough & 3 Skims -------- 0.00740 0.00530 0.00470 0.00430

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .050 ~ .070 .160 ~ .240 .140 ~ .220 .250 ~ .330

Average Voltage Gap VG ~ 36 ~ 40 44 ~ 52 44 ~ 48 50 ~ 70

Avg. Linear Feedrate ALF 3.40 2.49 2.00 1.79

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 3.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1111 1112 1113 1114

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 12 6 7

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 4 2 2 2

Stabilizer B SB 12 11 8 6 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 48 44 45

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.020 0.180 0.140 0.130

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00690 0.00460 -------- --------

Rough & 2 Skims -------- 0.00750 0.00520 0.00460 --------

Rough & 3 Skims -------- 0.00770 0.00540 0.00480 0.00430

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .040 ~ .060 .140 ~ .220 .140 ~ .220 .240 ~ .320

Average Voltage Gap VG ~ 38 ~ 42 44 ~ 52 42 ~ 46 55 ~ 75

Avg. Linear Feedrate ALF 2.88 2.21 1.83 1.64

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 3.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1121 1122 1123 1124

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 13 10 8

Power Setting IP 7 9 12 9 3

Off Time OFF 1 1 1 1 10

Stabilizer A SA 3 4 2 2 2

Stabilizer B SB 12 12 8 6 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 41 45 43 46

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.020 0.180 0.130 0.110

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00580 -------- -------- --------

Rough & 1 Skim -------- 0.00710 0.00460 -------- --------

Rough & 2 Skims -------- 0.00785 0.00535 0.00460 --------

Rough & 3 Skims -------- 0.00810 0.00560 0.00485 0.00430

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .025 ~ .045 .140 ~ .220 .140 ~ .220 .200 ~ .280

Average Voltage Gap VG ~ 40 ~ 44 42 ~ 50 40 ~ 44 55 ~ 75

Avg. Linear Feedrate ALF 2.19 1.77 1.51 1.35

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.008 hard brass STEEL Standard 4.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3

E-pack Number Eno 944 1131 1132 1133 1134

Power Supply PS HP HP MP MP LC

Servo SV NM NM NM NM NM

Voltage Open Vo 12 16 14 14 9

Power Setting IP 7 9 12 10 3

Off Time OFF 1 1 1 1 9

Stabilizer A SA 3 4 2 2 2

Stabilizer B SB 12 12 8 6 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 42 42 47

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 7 8 10 10 10

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 6 6 6

Liquid Resistivity LR 9 9 9 9 9

Feedrate Address FA 0.020 0.020 0.180 0.130 0.090

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00590 -------- -------- --------

Rough & 1 Skim -------- 0.00720 0.00460 -------- --------

Rough & 2 Skims -------- 0.00805 0.00545 0.00460 --------

Rough & 3 Skims -------- 0.00835 0.00575 0.00490 0.00430

Rough & 4 Skims --------

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 2.2 2.2 2.2

Lower Flow Rate 5.0 6.0 2.0 2.0 2.0

RESULTS

Feedrate Cutting FC ~ .020 ~ .040 .120 ~ .200 .100 ~ .180 .160 ~ .240

Average Voltage Gap VG ~ 40 ~ 44 40 ~ 48 40 ~ 44 55 ~ 75

Avg. Linear Feedrate ALF 1.88 1.55 1.31 1.18

Surface Finish(µ in) Ra ~ 50 ~ 60 36 ~ 44 28 ~ 36 14 ~ 18

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- MD+PRO Series SPD Steel 10wDocument19 pagesMD+PRO Series SPD Steel 10wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series STD WC 10wDocument19 pagesMD+PRO Series STD WC 10wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series STD Cu 12wDocument20 pagesMD+PRO Series STD Cu 12wag cnc & wedm machining shopNo ratings yet

- NC Specs 3 18 21Document2 pagesNC Specs 3 18 21ai007.rusmanaNo ratings yet

- ST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNDocument46 pagesST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNRAKESH KUMARNo ratings yet

- Base Slab - BBS TramaniDocument16 pagesBase Slab - BBS TramaniDevesh GuptaNo ratings yet

- Apex Dynamics, Inc.: AB / ABR SeriesDocument14 pagesApex Dynamics, Inc.: AB / ABR SeriesIqtidar GulNo ratings yet

- Detail Q Detail R: SC 1:2 SC 1:2 5-200Document1 pageDetail Q Detail R: SC 1:2 SC 1:2 5-200Patrick Tripusaka SoloNo ratings yet

- GKM H4000 StrainerDocument2 pagesGKM H4000 StrainerbocahjeblogNo ratings yet

- ReinforcementDocument9 pagesReinforcementAnoop VgNo ratings yet

- Monocrystalline Silicon Solar Cells: 275Wp (6x10) 330Wp (6x 12)Document2 pagesMonocrystalline Silicon Solar Cells: 275Wp (6x10) 330Wp (6x 12)Foe AungNo ratings yet

- Copper Bussman FusesDocument9 pagesCopper Bussman FusesKhaled BellegdyNo ratings yet

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeDocument2 pages5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazNo ratings yet

- TMP - 20393 Barmex Ruland Oldham 07101550358290Document8 pagesTMP - 20393 Barmex Ruland Oldham 07101550358290Ramsay BoltNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- 9 - PneumaticsDocument44 pages9 - PneumaticsJOHNNo ratings yet

- Material For Stair at Uth Gas Plant - Rpo # 6510200305: SL# Description Length Bredth Qty Unit Total Grant Total 26.70Document1 pageMaterial For Stair at Uth Gas Plant - Rpo # 6510200305: SL# Description Length Bredth Qty Unit Total Grant Total 26.70Madhan KannanNo ratings yet

- Shoulder Plugs GasketsDocument1 pageShoulder Plugs GasketssergioteroNo ratings yet

- TC Statement 6Document1 pageTC Statement 6Amit Raj GuptaNo ratings yet

- Crimp DecalDocument1 pageCrimp DecalFernando Padilla0% (1)

- 7-12-0038 Rev 0 PDFDocument4 pages7-12-0038 Rev 0 PDFsuresh_vikiNo ratings yet

- Roughness Conversion Chart RampinelliDocument1 pageRoughness Conversion Chart RampinelliServesh KumarNo ratings yet

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarNo ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- Din 5402-2Document2 pagesDin 5402-2Dule JovanovicNo ratings yet

- EFI ResistanceDocument3 pagesEFI ResistanceMuni Muniyappan33% (3)

- K-511-V, FLW SWTDocument2 pagesK-511-V, FLW SWTamir shokrNo ratings yet

- Improvement and Widening To 2 Laning of Stretch From MANU TO LALCHERRADocument4 pagesImprovement and Widening To 2 Laning of Stretch From MANU TO LALCHERRAEr Biswajit SahaNo ratings yet

- RuukiDocument20 pagesRuukiproje01No ratings yet

- Hangsong - S ProDocument6 pagesHangsong - S ProcadcamtaiNo ratings yet

- SL No Description Unit 8mm 10mm 12mm 16mm 20mmDocument12 pagesSL No Description Unit 8mm 10mm 12mm 16mm 20mmSUCCESS VINOTHNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- Deep Groove Ball Bearings PDFDocument11 pagesDeep Groove Ball Bearings PDFArpit VermaNo ratings yet

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningDocument4 pagesFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaNo ratings yet

- L0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023Document25 pagesL0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023quality assuranceNo ratings yet

- TowerDocument4 pagesTowerPankaj SherwalNo ratings yet

- 6.1 BBS Pile Cap P1 - Block BDocument2 pages6.1 BBS Pile Cap P1 - Block BSURAJ SINHANo ratings yet

- Dorman HandbookDocument4 pagesDorman HandbooksharathkammarNo ratings yet

- Ejot Data Sheet jt2 5.50x 25Document2 pagesEjot Data Sheet jt2 5.50x 25Vengatesh HariNo ratings yet

- Footing and FB DesignDocument7 pagesFooting and FB Designrehan7421No ratings yet

- Polished Rod With Wrench Flats: Product DescriptionDocument3 pagesPolished Rod With Wrench Flats: Product DescriptionJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Tantalum Alloy Rev3 Tds en 3 v1Document1 pageTantalum Alloy Rev3 Tds en 3 v1Симеон АрабовNo ratings yet

- Area of Steel Calculation: (Limit State)Document16 pagesArea of Steel Calculation: (Limit State)RAVI PRAKASH SAININo ratings yet

- CS Bridge ApproachesDocument20 pagesCS Bridge ApproachesvenkyNo ratings yet

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. AguiarNo ratings yet

- Corrugated Hose DatasheetDocument1 pageCorrugated Hose DatasheetSam LarismaNo ratings yet

- 30 ACE AIR - Return Exhaust Fresh Air Grille (Model FL FB EG)Document2 pages30 ACE AIR - Return Exhaust Fresh Air Grille (Model FL FB EG)rndjafNo ratings yet

- D49502 REAR AXLE ## M-120DTC: Update Date: 2023/04/10 Printing Date: 2024/04/17Document2 pagesD49502 REAR AXLE ## M-120DTC: Update Date: 2023/04/10 Printing Date: 2024/04/17seppe.lambrechtNo ratings yet

- A3 Comb-10 A4 Comb-10 B1 Comb-10 C1 Comb-10 C3 Comb-10 C4 Comb-10 D1 Comb-10 D3 Comb-10 D4 Comb-10 A2 Comb-10Document10 pagesA3 Comb-10 A4 Comb-10 B1 Comb-10 C1 Comb-10 C3 Comb-10 C4 Comb-10 D1 Comb-10 D3 Comb-10 D4 Comb-10 A2 Comb-10saubhagya majhiNo ratings yet

- CCF 000163Document1 pageCCF 000163Erik Jhonattan Jara YpanaqueNo ratings yet

- RCC Ladder Qty1Document25 pagesRCC Ladder Qty1Kannan GnanaprakasamNo ratings yet

- Data Sheet: Steam Condenser Protection Type HOV-SCDocument2 pagesData Sheet: Steam Condenser Protection Type HOV-SCRonak PatelNo ratings yet

- Drive Shaft CalculationDocument106 pagesDrive Shaft CalculationMustu AkolawalaNo ratings yet

- Ai Cylinders - Heavyduty PDFDocument15 pagesAi Cylinders - Heavyduty PDFGM HerbalsNo ratings yet

- Ambion: Wearnes CambionDocument2 pagesAmbion: Wearnes CambionalexanderNo ratings yet

- ECG-Calculation Sheets: Design of Concrete StructuresDocument5 pagesECG-Calculation Sheets: Design of Concrete StructuresBahaa Gaber100% (1)

- Wire Rod ENDocument2 pagesWire Rod ENEltjon PumiNo ratings yet

- Tolerance For Press Work PDFDocument1 pageTolerance For Press Work PDFmr.nguyenkNo ratings yet

- From Design To Inspection: The Use of GDT For Predictable AssemblyDocument19 pagesFrom Design To Inspection: The Use of GDT For Predictable Assemblyag cnc & wedm machining shopNo ratings yet

- Understanding The Operation Process in Wire EdmDocument1 pageUnderstanding The Operation Process in Wire Edmag cnc & wedm machining shopNo ratings yet

- 3 - Cutter Speeds and FeedsDocument23 pages3 - Cutter Speeds and FeedsAirlangga GoonersNo ratings yet

- Part Design Specification: Spring 2011 Dr. R. A. WyskDocument52 pagesPart Design Specification: Spring 2011 Dr. R. A. Wyskag cnc & wedm machining shopNo ratings yet

- VM1 PLWD r02x2-304Document241 pagesVM1 PLWD r02x2-304ag cnc & wedm machining shopNo ratings yet

- A Series Software Loading Instruction ManualDocument12 pagesA Series Software Loading Instruction Manualag cnc & wedm machining shopNo ratings yet

- Online Fa Series Machine Manual Main Menu PageDocument1 pageOnline Fa Series Machine Manual Main Menu Pageag cnc & wedm machining shopNo ratings yet

- MD ProDocument38 pagesMD Proag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training Manual Main Menu PageDocument1 pageRa Qa Fa Series Training Manual Main Menu Pageag cnc & wedm machining shopNo ratings yet

- A Series Software Loading Instruction ManualDocument12 pagesA Series Software Loading Instruction Manualag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 12 - ApplicationsDocument33 pagesRa Qa Fa Series Training - Chap 12 - Applicationsag cnc & wedm machining shopNo ratings yet

- A Series Level 1 Workbook V2-Machine FundementalsDocument123 pagesA Series Level 1 Workbook V2-Machine Fundementalsag cnc & wedm machining shopNo ratings yet

- MD+PRO SeriesDocument3 pagesMD+PRO Seriesag cnc & wedm machining shopNo ratings yet

- The Best Time You'Ve Ever SpentDocument41 pagesThe Best Time You'Ve Ever Spentag cnc & wedm machining shopNo ratings yet

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 10 - TaperDocument35 pagesRa Qa Fa Series Training - Chap 10 - Taperag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 9 - PositionDocument3 pagesRa Qa Fa Series Training - Chap 9 - Positionag cnc & wedm machining shopNo ratings yet

- Qa Ra Fa Auxiliary and Training Manual Back CoverDocument1 pageQa Ra Fa Auxiliary and Training Manual Back Coverag cnc & wedm machining shopNo ratings yet

- MD+PRO SeriesDocument3 pagesMD+PRO Seriesag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 8 - Input OutputDocument18 pagesRa Qa Fa Series Training - Chap 8 - Input Outputag cnc & wedm machining shopNo ratings yet

- Catálogo ACE 6000Document4 pagesCatálogo ACE 6000Luis NovaisNo ratings yet

- E 550 ManualDocument99 pagesE 550 ManualOnkolio73% (11)

- Task 1 - Power Source Unit Implementation You Are A...Document3 pagesTask 1 - Power Source Unit Implementation You Are A...Zulqarnain KhanNo ratings yet

- HV9120Document11 pagesHV9120dra6anNo ratings yet

- Alfatronix - AD MT-DMDocument2 pagesAlfatronix - AD MT-DMcarlosf_6No ratings yet

- 63230-216-244 MCS025 InstallSheetDocument8 pages63230-216-244 MCS025 InstallSheetDony SaputraNo ratings yet

- Analogue Gas Controller (GA-300.E01/2/3/4) : DescriptionDocument2 pagesAnalogue Gas Controller (GA-300.E01/2/3/4) : DescriptionmotaNo ratings yet

- Tsx17 TSX t407 Telemecanique User ManualDocument72 pagesTsx17 TSX t407 Telemecanique User ManualJose Eduardo Briceño0% (1)

- IN Maritime: Guidelines FOR EarthingDocument36 pagesIN Maritime: Guidelines FOR EarthingKunalan AhthilhitanNo ratings yet

- GRD200 (6F2S1927 G2a) 0.18 PDFDocument1,529 pagesGRD200 (6F2S1927 G2a) 0.18 PDFlong100% (1)

- Hand Book For Dual Cab (WDP4D) Locomotives Siemens MakeDocument82 pagesHand Book For Dual Cab (WDP4D) Locomotives Siemens MakeSumit dharaNo ratings yet

- Control Ningbo NBSL nsfc01 01 Control System 4swDocument10 pagesControl Ningbo NBSL nsfc01 01 Control System 4swShadi MattarNo ratings yet

- AGA-9 Revision Draft 082403Document49 pagesAGA-9 Revision Draft 082403mathijn75No ratings yet

- Parts List For Schneider Electric Electromagnetic Flow ProductsDocument34 pagesParts List For Schneider Electric Electromagnetic Flow Productspablo emilio peronaNo ratings yet

- Onkyo TX-SR600/E SERVICE MANUALDocument63 pagesOnkyo TX-SR600/E SERVICE MANUALkuko61100% (2)

- Atlas 210 XDocument67 pagesAtlas 210 Xdgerson1No ratings yet

- "Standard"Self-contained-Hopper-Loader - SAL-330-360 SHINIDocument40 pages"Standard"Self-contained-Hopper-Loader - SAL-330-360 SHINIthành trung phạmNo ratings yet

- PCS-985B/AW: Generator-Transformer Unit RelayDocument5 pagesPCS-985B/AW: Generator-Transformer Unit RelayNur ImanNo ratings yet

- Beckwith M 3425 ADocument229 pagesBeckwith M 3425 ASueli E FranciscoNo ratings yet

- FOX61x Electrical Cables - pc1Document44 pagesFOX61x Electrical Cables - pc1René San Martín PérezNo ratings yet

- Proprietary Electronics For Reactor Safety and ControlsDocument13 pagesProprietary Electronics For Reactor Safety and ControlsVarshaNo ratings yet

- A Simple LED Lamp Circuit From ScrapDocument9 pagesA Simple LED Lamp Circuit From ScrapNachiket D SakinalNo ratings yet

- (V5812G) DataSheet ENDocument18 pages(V5812G) DataSheet ENVien Thong OnecomNo ratings yet

- M-167.1-MA8000-EN-Installation Version 06-2022 - 07-07-22Document54 pagesM-167.1-MA8000-EN-Installation Version 06-2022 - 07-07-22Breixo HarguindeyNo ratings yet

- Techniczna - 1.4 - 1381.20 100 102 ENDocument318 pagesTechniczna - 1.4 - 1381.20 100 102 ENJacek KuśmierskiNo ratings yet

- CDX C4900 - CDX C5000Document76 pagesCDX C4900 - CDX C5000Bila Nicola Florin SorinNo ratings yet

- The Parameters of The Borehole Camera FLX-PT2000REC (Ø90mm Pan & Tilt Camera With Focus Adjustment)Document23 pagesThe Parameters of The Borehole Camera FLX-PT2000REC (Ø90mm Pan & Tilt Camera With Focus Adjustment)PSC RFQNo ratings yet

- DEVKIT-MPC5744P QSG v6 PDFDocument24 pagesDEVKIT-MPC5744P QSG v6 PDFPhuRioNo ratings yet

- X60 Wiring Diagram 20120707Document114 pagesX60 Wiring Diagram 20120707lartsim115100% (4)