Professional Documents

Culture Documents

Layout Planning Models and Design Algorithms: Chapter#06

Uploaded by

Discord Yt0 ratings0% found this document useful (0 votes)

9 views40 pagesThe document discusses facility layout planning models and design algorithms. It describes the two levels of facility layout as block layout and detailed layout. Block layout shows the location, shape, and size of departments, and is concerned with macro facility flows. Detailed layout shows the exact location of equipment within departments and focuses on micro flows. Effective layout procedures involve first developing a block layout and then a detailed departmental layout. Common layout methods include construction, improvement, and systematic layout planning approaches. Quantitative algorithms can be used to evaluate layout alternatives based on distance or adjacency objectives.

Original Description:

Original Title

ch.6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses facility layout planning models and design algorithms. It describes the two levels of facility layout as block layout and detailed layout. Block layout shows the location, shape, and size of departments, and is concerned with macro facility flows. Detailed layout shows the exact location of equipment within departments and focuses on micro flows. Effective layout procedures involve first developing a block layout and then a detailed departmental layout. Common layout methods include construction, improvement, and systematic layout planning approaches. Quantitative algorithms can be used to evaluate layout alternatives based on distance or adjacency objectives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views40 pagesLayout Planning Models and Design Algorithms: Chapter#06

Uploaded by

Discord YtThe document discusses facility layout planning models and design algorithms. It describes the two levels of facility layout as block layout and detailed layout. Block layout shows the location, shape, and size of departments, and is concerned with macro facility flows. Detailed layout shows the exact location of equipment within departments and focuses on micro flows. Effective layout procedures involve first developing a block layout and then a detailed departmental layout. Common layout methods include construction, improvement, and systematic layout planning approaches. Quantitative algorithms can be used to evaluate layout alternatives based on distance or adjacency objectives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 40

Chapter#06

Layout Planning Models and

Design Algorithms

Facility Layout

• Facility layout is simply the way a facility is

arranged in order to maximize processes that

are not only efficient but effective towards the

overall organizational goal.

• It consists of two levels:

– Block layout

– Detailed layout

Block Layout

• Block layout shows the location, shape, and

size of each planning department.

• Block layout is concerned primarily with

macro flows in the facility.

Detailed Layout

• Detailed layout shows the exact location of all

the equipment, work benches and storage areas

within each department.

• Detailed layout is concerned with micro flows

in the facility.

Which layout comes first!

• First, we must obtain the basic requirement of

each department (such as space requirement,

shape constraints, etc) and then develop a set

of alternative block layouts.

• Once the desirable block layout is identified,

the analyst can then develop a detailed layout

of each department.

Layout Procedures

• Many procedures are available

• Broadly classified:

– Construction layout method

• It involves developing a new layout “from scratch”

– Improvement layout method

• Generating layout alternatives by doing improvements

in an existing layout

Apple’s Plant Layout Procedure

Apple’s Plant Layout Procedure

Reed’s Plant Layout Procedure

Reed’s Plant Layout Procedure

• Most important

– Prepare layout planning chart

• Layout planning chart incorporates the following:

– Flow process, including operations, transportation,

storage and inspections

– Standard times for each operations

– Machine selection and balance

– Manpower selection and balance

– Material handling requirements

Layout Planning Chart

Systematic Layout Planning

• A well known procedural solution approach for

the layout problem is the Systematic Layout

Planning (SLP), which is developed in the early

1970s by Muther

• It consists of four phases:

– determining the location of the area where facilities

will be laid out

– establishing general overall layout

– establishing detailed layout plans

– installing the selected layout

Activity Relationship Chart

Relationship Diagram

• Relationship diagram position the activities

spatially.

• Proximities are typically used to reflect the

relationship between pair of activities

• Relationship diagram are usually two-

dimensional

Relationship Diagram

Space Requirement Diagram

• It involves the determination of the amount of

space to be assigned to each activity

• Once the space assignments have been made,

space templates are developed for each

planning department, and space is “hung on

the relationship diagram” to obtain the space

relationship diagram

Space Requirement Diagram

Alternative Block Layout

Algorithmic Approaches

• It helps the analyst to develop and improve the

layout.

• It provides the objective criteria to facilitate

the evaluation of various layout alternatives

that emerge in the process.

Algorithm Classification

• Layout algorithm can be classified on the type

of input data.

• Qualitative data (Relationship Chart)

• Quantitative data (To and From Chart)

• It can be classified w.r.t Objective Function.

a) Distance based objective

b) Adjacency based objective

Distance Based Objective

Adjacency Based Objective

Modeling Techniques for Algorithm

• There are many method/techniques which are

used in various layout Algorithms.

• Here we will discuss only two:

a) Pairwise Exchange Method

b) Graph Based Method

Department Shapes and Main

Aisles

• Attaining good department shapes is an

important consideration in finalizing block

layout

• Irregular department shapes leads to irregular

main aisles

• For efficient material handling, safety and

evacuation in emergency

Main aisle should connect all the departments in a

facility with

• Minimum travel

• Minimum number of turns

• Minimum jog overs

• Controlling department shapes is straight forward for

rectangular departments obtained with BLOCPLAN

and MIP

• It is straight-forward to define and measure shape of

rectangle

• It is ratio of longer side to its shorter side

• Non rectangular shapes those obtained with

CRAFT and MULTIPLE

• Shape measurement and control is not straight

forward for given two alternatives but “similar

shape” for the same department

• One alternative may be regarded as acceptable

while other regarded as poor

• First measure obtained by dividing the area of

the smallest enclosing rectangle (SER) by area

of department

• The second measure is obtained by dividing

the longer side of SER by its shortest side

• Third measure based on observation, given an

object with fixed area the perimeter of the

object generally increases as its shape become

more irregular

• Measure the shape of a department by dividing

its perimeter by its area

• It is difficult to predict reasonable value for it

• Above ratio is normalized as follow

• If ideal shape for a department is square, then

ideal shape factor

S*=(P/A)*=4√A/A=4/√A

• Normalized Shape Factor F is equal to

F=S/S*=P/A/4/√A=P/4√A

• If a department is square shape then we obtain

F=1.0 otherwise F>1.0

• Reasonable shapes are obtained if

1≤F ≤1.4

First measure Second measure

For figure a,b,c,d

a) =1 a) = 4

b) 25/16=1.5625 b) =1

c) =1.5625 c) =1

d) =1.5625 d) =1

Third measure perimeter

a) =1.25 a) =20

b)=1.25 b) =20

c) 1.5 c) =24

d) 1.625 d) =26

40

You might also like

- Tool Design - Chapter 1 (Part 1)Document20 pagesTool Design - Chapter 1 (Part 1)Fiq IFTNo ratings yet

- 9c - Geometric Dimension Ing & Tolerancing (Part 3)Document53 pages9c - Geometric Dimension Ing & Tolerancing (Part 3)api-3815216100% (2)

- Chapter 4 Storage SystemDocument42 pagesChapter 4 Storage SystemDiscord YtNo ratings yet

- City and Guilds 302 Students VersionDocument204 pagesCity and Guilds 302 Students VersionHatem Hussein100% (1)

- Faciility LayoutDocument64 pagesFaciility LayoutUmair AhmedNo ratings yet

- Section 5-Layout Planning Models and Design AlgorithmsDocument152 pagesSection 5-Layout Planning Models and Design AlgorithmsthamersaadNo ratings yet

- Monitoreo de Condiciones CaterpillarDocument181 pagesMonitoreo de Condiciones CaterpillarMauricio BallonNo ratings yet

- TEC - OPS - Supra MT - 750-1250 - 62-61921-20 - Rev - ENGDocument501 pagesTEC - OPS - Supra MT - 750-1250 - 62-61921-20 - Rev - ENGJennyJudithRuizSanchez100% (1)

- TM-1861 AVEVA Administration (1.4) System Administration Rev 1.0Document106 pagesTM-1861 AVEVA Administration (1.4) System Administration Rev 1.0praveen jangir100% (2)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Amit - Optimizing Oracle Essbase Formulas & Calc ScriptsDocument100 pagesAmit - Optimizing Oracle Essbase Formulas & Calc ScriptsAraz AbbaszadehNo ratings yet

- Calibre Fundamentals Performing DRC Lvs - 063568Document18 pagesCalibre Fundamentals Performing DRC Lvs - 063568Kumar KumarNo ratings yet

- VO10 - Parts - 2016Document63 pagesVO10 - Parts - 2016Centrifugal Separator100% (1)

- BS en 13501-6-2018 - (2020-09-14 - 05-44-34 Am)Document34 pagesBS en 13501-6-2018 - (2020-09-14 - 05-44-34 Am)luke hainesNo ratings yet

- Layout Planning (Operations Management)Document14 pagesLayout Planning (Operations Management)Jean Carla Lim MerinoNo ratings yet

- Naga Harish Renduchintala: Profile - About MeDocument5 pagesNaga Harish Renduchintala: Profile - About MeNaga HarishNo ratings yet

- Product Design MorphologyDocument15 pagesProduct Design Morphologybalaganesh50% (2)

- Facilities and Design Chapter 4Document11 pagesFacilities and Design Chapter 4Louie Guese ManguneNo ratings yet

- Facility LayoutDocument63 pagesFacility LayoutBharti KumariNo ratings yet

- MDP408a Lecture13Document39 pagesMDP408a Lecture13Hisham Ahmed FouadNo ratings yet

- CSG Brep Solid ModelingDocument64 pagesCSG Brep Solid ModelingHariNo ratings yet

- Facility LayoutDocument64 pagesFacility Layoutabdelghani cherkaouiNo ratings yet

- Facility LayoutDocument63 pagesFacility Layoutsiyoum negashNo ratings yet

- Facilities: Dr. J. R. Sharma @imt, NagpurDocument30 pagesFacilities: Dr. J. R. Sharma @imt, NagpuraluranaNo ratings yet

- Design Step 3: Evaluation of Alternatives and Selection of A ConceptDocument34 pagesDesign Step 3: Evaluation of Alternatives and Selection of A ConceptTophe EscarezNo ratings yet

- Ch05 Facilities LayoutDocument45 pagesCh05 Facilities LayoutPhương UyênNo ratings yet

- Algoritma Untuk Tataletak FasilitasDocument53 pagesAlgoritma Untuk Tataletak FasilitasgadoNo ratings yet

- EngineeringDrawing Lecture1 Rev 180822Document68 pagesEngineeringDrawing Lecture1 Rev 180822helenNo ratings yet

- Mod 4Document88 pagesMod 4Sudheesh SNo ratings yet

- Operations Management-14: Process Layout IBS Campus CaseDocument34 pagesOperations Management-14: Process Layout IBS Campus Casesaikiran38No ratings yet

- Layout - Definition: - Layout: The Physical Arrangement ofDocument32 pagesLayout - Definition: - Layout: The Physical Arrangement ofRichar Contreras BejarNo ratings yet

- Production Plant Layout (1) : - Facility Layout Problem: Design ProblemDocument64 pagesProduction Plant Layout (1) : - Facility Layout Problem: Design ProblemPraveen CoolNo ratings yet

- Chapter 04 - Layout Planning ProceduresDocument34 pagesChapter 04 - Layout Planning Proceduresimran_chaudhryNo ratings yet

- 5 - Mathematical Models For Plant Layout IIDocument27 pages5 - Mathematical Models For Plant Layout IIhandsomefa22No ratings yet

- FP Lec 6 (Compatibility Mode)Document47 pagesFP Lec 6 (Compatibility Mode)yehyaNo ratings yet

- Line BalancingDocument46 pagesLine BalancingxyzNo ratings yet

- Facility Planning and DesignDocument9 pagesFacility Planning and DesignVinay KorekarNo ratings yet

- 7 Old and 7 New Tools For Quality AssuranceDocument46 pages7 Old and 7 New Tools For Quality AssuranceIshaan RajNo ratings yet

- Systems Analysis and DesignDocument4 pagesSystems Analysis and DesignJOANNECHUNo ratings yet

- System Analysis & Design: Unit - IIDocument33 pagesSystem Analysis & Design: Unit - IIArun MishraNo ratings yet

- Facility LayoutDocument30 pagesFacility Layoutayushichaudhary72No ratings yet

- Module 4 - Approach To System DevelopmentDocument48 pagesModule 4 - Approach To System DevelopmentLadyDiane Muñoz BeltranNo ratings yet

- Section A (I)Document69 pagesSection A (I)Tashmeet SinghNo ratings yet

- Designing AlgorithmsDocument22 pagesDesigning AlgorithmsLulu TojeenNo ratings yet

- Design For AsssemblyDocument28 pagesDesign For AsssemblyGowtham JayaramanNo ratings yet

- 5.2 - System Analysis and DesignDocument19 pages5.2 - System Analysis and DesignPiyush SinghNo ratings yet

- Quantitative & Qualitative Formulation of Facility Layout ProblemsDocument39 pagesQuantitative & Qualitative Formulation of Facility Layout ProblemsSudheesh SNo ratings yet

- Chapter 1: Introduction To Manufacturing Facilities Design and Material HandlingDocument33 pagesChapter 1: Introduction To Manufacturing Facilities Design and Material HandlingPeter GeorgesNo ratings yet

- 4 Layout Planning Models1 PDFDocument52 pages4 Layout Planning Models1 PDFVirojana TantibadaroNo ratings yet

- Production and Operations Management: Unit 6-Facility or Layout Planning and AnalysisDocument29 pagesProduction and Operations Management: Unit 6-Facility or Layout Planning and AnalysisJuha PropertiesNo ratings yet

- Developing Information System Solutions Week 3Document29 pagesDeveloping Information System Solutions Week 3Zain alviNo ratings yet

- Lecture 7 (SE)Document18 pagesLecture 7 (SE)Meskelo ShumaNo ratings yet

- System DesignDocument25 pagesSystem DesignazsadiqNo ratings yet

- Itec 4010 1 - IntroDocument42 pagesItec 4010 1 - Introneelayp11No ratings yet

- Prerequisites: Work Study and Methods Engineering, ObjectiveDocument21 pagesPrerequisites: Work Study and Methods Engineering, ObjectiveAchraf AourikNo ratings yet

- Construction Methods and Project ManagementDocument24 pagesConstruction Methods and Project ManagementLouise LuyNo ratings yet

- Abstract Oriented Design ProcessDocument11 pagesAbstract Oriented Design Processaayena123No ratings yet

- Project Activities: Generating The Work Breakdown Structure (WBS)Document12 pagesProject Activities: Generating The Work Breakdown Structure (WBS)Abdul BasitNo ratings yet

- Facility Design-Week 9-Computerized Layout PlanningDocument40 pagesFacility Design-Week 9-Computerized Layout PlanningNithyapriya VeeraraghavanNo ratings yet

- Analysis and Design: of E-Commerce SystemsDocument50 pagesAnalysis and Design: of E-Commerce Systemshamedsky100% (1)

- J2EENET ProcessDocument17 pagesJ2EENET Processveeru9No ratings yet

- New W2 - 3D Modeling PDFDocument44 pagesNew W2 - 3D Modeling PDFMohammad Rizal RamlyNo ratings yet

- Industrial Engineering ServicesDocument27 pagesIndustrial Engineering ServicesPrabakaran ManickamNo ratings yet

- Chapter13 PlanningDocument48 pagesChapter13 PlanningUddalak Banerjee100% (1)

- Analisa Spasial Data Vektor Sederhana: Pertemuan 7Document60 pagesAnalisa Spasial Data Vektor Sederhana: Pertemuan 7ratihokebgtNo ratings yet

- Guidelines To Spreadsheet EngineeringDocument37 pagesGuidelines To Spreadsheet Engineeringtwinkle JoyNo ratings yet

- Caper HCI2014Document7 pagesCaper HCI2014Discord YtNo ratings yet

- IE 6560 Deterministic Optimization Project Abstract-1Document3 pagesIE 6560 Deterministic Optimization Project Abstract-1Discord YtNo ratings yet

- Ethical Frameworks Student ExampleDocument6 pagesEthical Frameworks Student ExampleDiscord YtNo ratings yet

- 15626518501year AdvanceDiplomaInClinicalPsychologyDocument1 page15626518501year AdvanceDiplomaInClinicalPsychologyDiscord YtNo ratings yet

- CIM Lab 8Document8 pagesCIM Lab 8Discord YtNo ratings yet

- Formula SheetDocument1 pageFormula SheetDiscord YtNo ratings yet

- Disappearing Packages Problem Solving TemplateDocument2 pagesDisappearing Packages Problem Solving TemplateDiscord YtNo ratings yet

- Sustainable Supply Chain Management and Multi-Criteria Decision-Making Methods: A Systematic ReviewDocument28 pagesSustainable Supply Chain Management and Multi-Criteria Decision-Making Methods: A Systematic ReviewDiscord YtNo ratings yet

- Parametric Analyses On CompressiveDocument6 pagesParametric Analyses On CompressiveDiscord YtNo ratings yet

- Supply Chain Management Project: The Case of Nike IncDocument13 pagesSupply Chain Management Project: The Case of Nike IncDiscord YtNo ratings yet

- 1562653112MPhil 2years EducationDocument4 pages1562653112MPhil 2years EducationDiscord YtNo ratings yet

- 1562653326MPhil 2years PsychologyDocument2 pages1562653326MPhil 2years PsychologyDiscord YtNo ratings yet

- Optimizing The Value Chain Advanced Supply Chain Optimization Traditional & State-Of-The-Art ModelsDocument18 pagesOptimizing The Value Chain Advanced Supply Chain Optimization Traditional & State-Of-The-Art ModelsDiscord YtNo ratings yet

- Chapter 14 Simple Linear RegressionDocument45 pagesChapter 14 Simple Linear RegressionDiscord YtNo ratings yet

- International Management Systems & Standards: Auditing Techniques (ISO 9001:2015)Document15 pagesInternational Management Systems & Standards: Auditing Techniques (ISO 9001:2015)Discord YtNo ratings yet

- University of Engineering & Technology, Taxila Department of Industrial EngineeringDocument2 pagesUniversity of Engineering & Technology, Taxila Department of Industrial EngineeringDiscord YtNo ratings yet

- Sustainable Supply Chain in Pulp and Paper Industry: A ReviewDocument13 pagesSustainable Supply Chain in Pulp and Paper Industry: A ReviewDiscord YtNo ratings yet

- Notes For Isye 6413 Design and Analysis of Experiments: Instructor: C. F. Jeff WuDocument49 pagesNotes For Isye 6413 Design and Analysis of Experiments: Instructor: C. F. Jeff WuDiscord YtNo ratings yet

- Supply Chain Optimisation in The Paper IndustryDocument11 pagesSupply Chain Optimisation in The Paper IndustryDiscord YtNo ratings yet

- Design and Manufacture of Casting Pattern Plates by Rapid ToolingDocument5 pagesDesign and Manufacture of Casting Pattern Plates by Rapid ToolingDiscord YtNo ratings yet

- Negotiation Can Be Defined AsDocument3 pagesNegotiation Can Be Defined AsDiscord YtNo ratings yet

- Optimization of Cutting Parameters To Minimize The Surface Roughness in The End Milling Process Using The Taguchi MethodDocument7 pagesOptimization of Cutting Parameters To Minimize The Surface Roughness in The End Milling Process Using The Taguchi MethodDiscord YtNo ratings yet

- 894-Article Text-13257-1-10-20210622Document13 pages894-Article Text-13257-1-10-20210622Discord YtNo ratings yet

- Design of Experiments: Hongyan ZhangDocument14 pagesDesign of Experiments: Hongyan ZhangDiscord YtNo ratings yet

- Lab 3 Surface RoughnessDocument13 pagesLab 3 Surface RoughnessDiscord YtNo ratings yet

- Gating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesDocument12 pagesGating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesDiscord YtNo ratings yet

- Module2-Signals and SystemsDocument21 pagesModule2-Signals and SystemsAkul PaiNo ratings yet

- Setup Local Mail Server Using Postfix, Dovecot and Squirrelmail On OpenSUSE 13Document17 pagesSetup Local Mail Server Using Postfix, Dovecot and Squirrelmail On OpenSUSE 13JohnVonNeumannNo ratings yet

- E-Sh Series: Erp 2009/125/ceDocument124 pagesE-Sh Series: Erp 2009/125/ceabedzNo ratings yet

- Health Research Poster ContestDocument15 pagesHealth Research Poster ContestJed BellenNo ratings yet

- Manual de Usuario Ecografo DC40 PDFDocument291 pagesManual de Usuario Ecografo DC40 PDFFederico Rodriguez MonsalveNo ratings yet

- Normal Probability Distribution and Z TableDocument4 pagesNormal Probability Distribution and Z TableAnimeliciousNo ratings yet

- Cmd. 00427991823303 Cmd. 00427991823303 Cmd. 00427991823303 Cmd. 00427991823303Document1 pageCmd. 00427991823303 Cmd. 00427991823303 Cmd. 00427991823303 Cmd. 00427991823303Niaz HussainNo ratings yet

- 7124b168cc7e0c6a11120728ad5b9ea9Document4,413 pages7124b168cc7e0c6a11120728ad5b9ea9Jaisal FrancisNo ratings yet

- DR - Sri.Sri - Sri.Shivakumara Mahaswamy College of Engineering Department of Civil Engineering I InternalDocument2 pagesDR - Sri.Sri - Sri.Shivakumara Mahaswamy College of Engineering Department of Civil Engineering I InternalCivil EngineeringNo ratings yet

- Oracle Process ExecutionDocument552 pagesOracle Process ExecutionVineethNo ratings yet

- User Guide For Kathrein Rfid Uhf Readers - v1.10Document153 pagesUser Guide For Kathrein Rfid Uhf Readers - v1.10Técnica 02 Zumm-LtdaNo ratings yet

- Manual Sony Z7U InglesDocument20 pagesManual Sony Z7U InglesSusana EsNo ratings yet

- Paper 9007Document11 pagesPaper 9007IJARSCT JournalNo ratings yet

- Test Questions m7 q2Document3 pagesTest Questions m7 q2Jake Lester DafangNo ratings yet

- Eaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsDocument20 pagesEaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsRicardo ArzolaNo ratings yet

- 06-STM32 Security WS STM32 Trust IntroductionDocument27 pages06-STM32 Security WS STM32 Trust IntroductionsolokingNo ratings yet

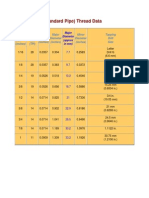

- BSP Pipe ThreadDocument1 pageBSP Pipe ThreadgvmindiaNo ratings yet

- XMLServices5.0 CapabilityAndQuoteServiceDocument78 pagesXMLServices5.0 CapabilityAndQuoteServicewilson ndongoNo ratings yet

- Socmed ReportDocument45 pagesSocmed ReportFarhah SyahiraNo ratings yet

- Telkom Brosur Siemens Connection Master LaunchedDocument2 pagesTelkom Brosur Siemens Connection Master LaunchedPontasNo ratings yet

- Isopropil MiristatDocument1 pageIsopropil MiristatnofaNo ratings yet

- Datasheet Valvulas ps1Document5 pagesDatasheet Valvulas ps1jose luis guzman gonzalezNo ratings yet

- Hydraulic Lab ReportDocument2 pagesHydraulic Lab ReportAllaFonteNo ratings yet