Professional Documents

Culture Documents

Field Logging of Subsurface Explorations of Soil and Rock: Standard Guide For

Uploaded by

Luis Enrique Gutiérrez MoralesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Logging of Subsurface Explorations of Soil and Rock: Standard Guide For

Uploaded by

Luis Enrique Gutiérrez MoralesCopyright:

Available Formats

Designation: D5434 − 12

Standard Guide for

Field Logging of Subsurface Explorations of Soil and Rock1

This standard is issued under the fixed designation D5434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This guide describes the type of information that should 2.1 ASTM Standards:2

be recorded during field subsurface explorations in soil and D420 Guide to Site Characterization for Engineering Design

rock. and Construction Purposes (Withdrawn 2011)3

1.2 This guide is not intended to specify all of the informa- D653 Terminology Relating to Soil, Rock, and Contained

tion required for preparing field logs. Such requirements will Fluids

vary depending on the purpose of the investigation, the D1452 Practice for Soil Exploration and Sampling by Auger

intended use of the field log, and particular needs of the client Borings

or user. D1586 Test Method for Penetration Test (SPT) and Split-

Barrel Sampling of Soils

1.3 This guide is applicable to boreholes, auger holes, D1587 Practice for Thin-Walled Tube Sampling of Soils for

excavated pits, or other subsurface exposures such as road side Geotechnical Purposes

cuts or stream banks. This guide may serve as a supplement to D2113 Practice for Rock Core Drilling and Sampling of

Guide D420. Rock for Site Investigation

1.4 This guide may not be suited to all types of subsurface D2488 Practice for Description and Identification of Soils

exploration such as mining, agricultural, geologic hazardous (Visual-Manual Procedure)

waste, or other special types of exploration. D2573 Test Method for Field Vane Shear Test in Cohesive

Soil

1.5 This standard does not purport to address all of the

D3441 Test Method for Mechanical Cone Penetration Tests

safety concerns, if any, associated with its use. It is the

of Soil

responsibility of the user of this standard to establish appro-

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

priate safety and health practices and determine the applica-

Drive Sampling of Soils

bility of regulatory limitations prior to use.

D3740 Practice for Minimum Requirements for Agencies

1.6 This guide offers an organized collection of information Engaged in Testing and/or Inspection of Soil and Rock as

or a series of options and does not recommend a specific Used in Engineering Design and Construction

course of action. This document cannot replace education or D4083 Practice for Description of Frozen Soils (Visual-

experience and should be used in conjunction with professional Manual Procedure)

judgment. Not all aspects of this guide may be applicable in all D4220 Practices for Preserving and Transporting Soil

circumstances. This ASTM standard is not intended to repre- Samples

sent or replace the standard of care of which the adequacy of D4403 Practice for Extensometers Used in Rock

a given professional service must be judged, nor should this D4544 Practice for Estimating Peat Deposit Thickness

document be applied without consideration of a project’s many D4623 Test Method for Determination of In Situ Stress in

unique aspects. The word “Standard” in the title of this Rock Mass by Overcoring Method—USBM Borehole

document means only that the document has been approved Deformation Gauge

through the ASTM consensus process.

2

For referenced ASTM standard, visit the ASTM website, www.astm.org, or

1

This guide is under the jurisdiction of ASTM Committee D18 on Soil and Rock contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of D18.02 onIdentification and Classification of Soils. Standardsvolume information, refer to the standard’s Document Summary page of

Current edition approved Feb. 1, 2012. Published March 2012. Originally the ASTM website.

3

approved in 1993. Last previous edition approved in 2009 as D5434–09. DOI: The last approved version of this historical standard is referenced on

10.1520/D5434-12. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

D5434 − 12

D4633 Test Method for Energy Measurement for Dynamic 6.1.1.2 Name of personnel onsite during the exploration,

Penetrometers such as drilling crew, supervisor, geologist, engineer, and

D4645 Test Method for Determination of In-Situ Stress in technicians,

Rock Using Hydraulic Fracturing Method 6.1.1.3 Names and addresses of organizations involved,

D4719 Test Methods for Prebored Pressuremeter Testing in 6.1.1.4 Name of person(s) preparing log,

Soils 6.1.1.5 Reference datum for project if available and descrip-

D4750 Test Method for Determining Subsurface Liquid tion of datum, and

Levels in a Borehole or Monitoring Well (Observation 6.1.1.6 General remarks as appropriate.

Well) (Withdrawn 2010)3 6.1.2 Exploration information should include:

D4879 Guide for Geotechnical Mapping of Large Under- 6.1.2.1 Exploration number and location (station and coor-

ground Openings in Rock dinates if available and applicable, position relative to a local

D5079 Practices for Preserving and Transporting Rock Core permanent reference which is identified, or markings of explo-

Samples ration location),

D6032 Test Method for Determining Rock Quality Designa- 6.1.2.2 Type of exploration, such as drill hole, auger hole,

tion (RQD) of Rock Core test pit, or road cut,

6.1.2.3 Date and time of start and finish,

3. Terminology

6.1.2.4 Weather conditions including recent rain or other

3.1 Definitions—Except as listed below, all definitions are in events that could affect subsurface conditions,

accordance with Terminology D653. 6.1.2.5 Depth and size of completed exploration,

3.2 Definitions of Terms Specific to This Standard: 6.1.2.6 The condition of exploration prior to and after

3.2.1 field log—a record prepared during subsurface explo- backfilling or sealing, or both, and

rations of soil and rock to document procedures used, test data, 6.1.2.7 Method of backfilling or sealing exploration, or

descriptions of materials and depths where encountered, both.

ground water conditions, and other information. 6.1.3 Explorations by drill hole or auger hole should include

the following drilling information:

4. Summary of Guide 6.1.3.1 Type and make (manufacture and model if known)

4.1 This guide describes the type of information that should of drilling machine or description and name of contractor,

be recorded during the execution of field subsurface explora- 6.1.3.2 Method of drilling or advancing and cleaning the

tions in soil and rock. The information described relates to the borehole. State if air, water, or drilling fluid is used. Describe

project, personnel, methods of investigation and equipment type, source of water and additives, concentration, and tests

used, visual description of subsurface materials and ground performed on fluid,

water conditions, in-situ testing, installation of monitoring 6.1.3.3 Size, type, and section length of drilling rods (rod

equipment, and other data that may be appropriate. designations should conform with Table 3 of Method D2113)

and drilling bits used.

5. Significance and Use 6.1.3.4 Dates and times of each stage of operation and time

to complete intervals,

5.1 The preparation of field logs provides documentation of

field exploration procedures and findings for geotechnical, 6.1.3.5 Size of hole (diameter and depth),

geologic, hydrogeologic, and other investigations of subsurface 6.1.3.6 Ground elevation at top of borehole,

site conditions. This guide may be used for a broad range of 6.1.3.7 Orientation of drill hole, if not vertical (azimuth or

investigations. bearing and angle),

5.2 The recorded information in a field log will depend on NOTE 2—Even with careful drilling, the actual subsurface path of both

the specific purpose of the site investigation. All of the vertical and inclined drill holes may be different from the intended

direction of drilling. Deflection of the drill bit due to inclined bedding and

information given in this guide need not appear in all field logs. hard boulders are some of the many reasons a drill hole might deviate

NOTE 1—The quality of the result produced by this standard is from the intended direction. Drill holes that deviate from the intended

dependent on the competence of the personnel performing it, and the direction can give erroneous data if not corrected. This can lead to

suitability of the equipment and facilities used. Agencies that meet the significant interpretation errors of subsurface conditions and geologic

criteria of Practice D3740 are generally considered capable of competent structure. Depending on intended use of the data, it may be prudent to

and objective sampling. Users of this practice are cautioned that compli- perform a borehole survey so the borehole spatial data can be corrected.

ance with Practice D3740 does not in itself assure reliable results. Reliable

results depend on many factors; Practice D3740 provides a means of 6.1.3.8 Size and description of casing, if appropriate,

evaluating some of those factors. method of casing installation (driven, drilled, or pushed) and

depth of cased portion of boring (casing size designations

6. Summary of Work should conform with Table 2 of Method D2113), hollow-stem

6.1 Soil and rock field logs should include the following augers,

written information: 6.1.3.9 Methods used for cleaning equipment or drilling

6.1.1 Project information should include: tools, or both, when required, and

6.1.1.1 Name and location of the project or project number, 6.1.3.10 Describe and state depth of any drilling problems

or both, such as borehole instability (cave in, squeezing hole, flowing

Copyright by ASTM Int'l (all rights reserved); 2

D5434 − 12

sands), cobbles, lost drilling fluid, lost ground, obstruction, 6.1.6.11 Destination or recipient of samples and method of

fluid return color changes, and equipment problems. transportation.

6.1.4 Exploration by test pit, road cut, stream cut, etc., 6.1.7 Ground water information should include:

should include: 6.1.7.1 Depths and times at which ground water is

6.1.4.1 Method of exploration, encountered, including seepage zones, if appropriate,

6.1.4.2 Equipment used for excavation, 6.1.7.2 In the case of drilling using drilling fluid, depth of

6.1.4.3 Type of shoring used, and fluid surface in boring and drilling depth at the time of a noted

6.1.4.4 Excavation problems: instability of cut (sloughing, loss or gain in drilling fluid,

caving, etc.), depth of refusal, difficulty of excavating, etc. 6.1.7.3 Depth to ground water level at the completion of

6.1.5 Subsurface information should include: drilling and removal of drill steel and description of datum

6.1.5.1 Depth of changes and discontinuities in geologic (note condition of borehole, for example, cased or uncased).

material and method used to establish change (such as Practice Date and time measured,

D4544). 6.1.7.4 Depth to ground water level at some reported time

6.1.5.2 Description of material encountered with origin or period following completion of drilling and description of

formation name, if possible, and type of samples used for datum, when possible.

description. The system or method of soil (such as Practices 6.1.7.5 Method or equipment used to determine depth of

D2488 and D4083) or rock description should be referenced. ground water level, such as Test Method D4750,

6.1.5.3 Description of nature of boundary between strata 6.1.7.6 Method and depth of ground water samples

(gradual or abrupt, as appropriate) and other relevant structural obtained, including size of samples taken and description of

features such as breccia, slickensides, solution zones, discol- sampler, and

orations by weathering or hydrothermal fluids, and other 6.1.7.7 Description of any field tests conducted on ground

stratigraphic information. water samples such as pH, temperature, conductivity, turbidity,

6.1.6 Soil or rock sampling and testing information should or odor.

include: 6.1.8 Information regarding installation of instrumentation

6.1.6.1 Depth of each sample and number (if used), or monitoring equipment should include:

6.1.6.2 Method of sampling (reference to appropriate 6.1.8.1 Type of equipment installed, for example,

ASTM standard, for example, Practice D1452, Test Method piezometers, monitoring well screens, inclinometer, including

D1586, Method D1587, Practice D3550, or other method). sizes and types of materials,

6.1.6.3 Description of sampler: inside and outside 6.1.8.2 Depth and description of equipment installed (refer-

dimensions, length, type of metal, type of coating, and type of ence to applicable ASTM standard, for example, Practice

liner, D4403, or other standards or procedures),

6.1.6.4 Method of sampler insertion: pushed, cored, or 6.1.8.3 Methods used for installation of equipment and

driven, method used for sealing annular space, and

6.1.6.5 Sampler penetration and recovery length of sample. 6.1.8.4 Methods used to protect equipment (casing cap or

For each rock sample (core run), record the rock quality locks).

designation (RQD) in accordance with Test Method D6032, 6.2 Soil and rock field logs should include the following

and the rate of coring, pictorial information:

6.1.6.6 Method of sample extrusion. Mark direction of 6.2.1 Maps, drawings, or sketches of area of exploration and

extrusion, subsurface surfaces observed. Include pertinent surface infor-

6.1.6.7 Method of preserving samples and preparing for mation such as neighboring outcrops, as appropriate. Describe

transport (refer to Practices D4220 or D5079), system of mapping, such as Guide D4879 for rock, or legend

6.1.6.8 Mark top and bottom of samples and orientation, if for symbols of materials. Include dimensions, directions, and

possible, slopes, and

6.1.6.9 Depth and description of any in-situ test performed 6.2.2 Photographs of activities, surfaces, or core. Describe

(reference to applicable ASTM standard, for example, Test sequence, dates and time, direction, objects used for scale, and

Methods D1586, D2573, D3441, D4623, D4633, D4645, subject.

D4719, or other tests if applicable),

6.1.6.10 Description of any other field tests conducted on 7. Keywords

soil and rock during the exploration such as pH, hydraulic 7.1 drilling; explorations; geologic investigations; ground

conductivity, pressuremeter geophysical, pocket penetrometer, water; logging; preliminary investigations; sampling; soil in-

soil gas/vapor analysis, or other tests, and vestigations; subsurface investigations

Copyright by ASTM Int'l (all rights reserved); 3

D5434 − 12

SUMMARY OF CHANGES

Committee D18 has identified the location of selected changes to this guide since the last issue, D5434–09,

that may impact the use of this guide. (Approved February 1, 2012)

(1) Revised 6.1.6.5.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 4

You might also like

- 1600 Scientists' Signatures On This Paper - There Is No Climate EmergencyDocument53 pages1600 Scientists' Signatures On This Paper - There Is No Climate EmergencyMichael Smith20% (5)

- Updated Ten Year Ecological Solid Waste Management PlanDocument142 pagesUpdated Ten Year Ecological Solid Waste Management PlanTrisha DamianNo ratings yet

- D5434 Field LoggingDocument4 pagesD5434 Field LoggingSamuel BurgaNo ratings yet

- 05 Mazier Retractable Core Barrels PDFDocument1 page05 Mazier Retractable Core Barrels PDFCut MutiaNo ratings yet

- D3441 Mechanical Cone Penetration Testing of Soils PDFDocument8 pagesD3441 Mechanical Cone Penetration Testing of Soils PDFjayshri bamneNo ratings yet

- Photosynthesis and Carbon CycleDocument7 pagesPhotosynthesis and Carbon Cyclerandhirsaha2000No ratings yet

- Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersDocument14 pagesField Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersJohnCarlosGilNo ratings yet

- Using The Frequency Domain Electromagnetic Method For Subsurface InvestigationsDocument14 pagesUsing The Frequency Domain Electromagnetic Method For Subsurface Investigationsmohammed karasnehNo ratings yet

- Field Quality Assurance in A Groundwater Sampling Event: Standard Guide ForDocument3 pagesField Quality Assurance in A Groundwater Sampling Event: Standard Guide Forrobert gridleyNo ratings yet

- Anexo 4 - Astm D-4695Document6 pagesAnexo 4 - Astm D-4695Ronald CarahuatayNo ratings yet

- Calibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForDocument6 pagesCalibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForAbid HussainNo ratings yet

- D5434.14 (Logeo)Document4 pagesD5434.14 (Logeo)Jony Gutiérrez AbantoNo ratings yet

- Field Logging of Subsurface Explorations of Soil and Rock: Standard Guide ForDocument4 pagesField Logging of Subsurface Explorations of Soil and Rock: Standard Guide ForLuis Enrique Gutiérrez MoralesNo ratings yet

- Field Logging of Subsurface Explorations of Soil and Rock: Standard Guide ForDocument4 pagesField Logging of Subsurface Explorations of Soil and Rock: Standard Guide ForLuis Enrique Gutiérrez MoralesNo ratings yet

- ASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFDocument9 pagesASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFMarcos67% (3)

- Selection of Purging and Sampling Devices For Groundwater Monitoring WellsDocument15 pagesSelection of Purging and Sampling Devices For Groundwater Monitoring Wellsmohammed karasnehNo ratings yet

- Astm F 679-03Document6 pagesAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- Assessment of Liquefaction Susceptibility of Fine Grained Soils Bray - SancioDocument187 pagesAssessment of Liquefaction Susceptibility of Fine Grained Soils Bray - SancioFernando ChiribogaNo ratings yet

- Effects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Document7 pagesEffects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Kev SantiagoNo ratings yet

- Selection of Passive Techniques For Sampling Groundwater Monitoring WellsDocument14 pagesSelection of Passive Techniques For Sampling Groundwater Monitoring WellsasmaNo ratings yet

- Lap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedDocument2 pagesLap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedMohammad YaseenNo ratings yet

- Preparation of Test Specimens of Asphalt-Stabilized Soils: Standard Practice ForDocument5 pagesPreparation of Test Specimens of Asphalt-Stabilized Soils: Standard Practice Forโก อู๋No ratings yet

- Using Rock-Mass Classification Systems For Engineering PurposesDocument30 pagesUsing Rock-Mass Classification Systems For Engineering PurposesSFC ABHA 1100% (1)

- Standard D5299D5299M.liry4178Document18 pagesStandard D5299D5299M.liry4178Mihai MunteanuNo ratings yet

- Coastal Processes and HazardsDocument26 pagesCoastal Processes and Hazardslex marantal100% (1)

- D 5783 - 95 R00 - Rdu3odmDocument7 pagesD 5783 - 95 R00 - Rdu3odmEmiliano AgostiniNo ratings yet

- Permeability of Granular Soils (Constant Head) : Standard Test Method ForDocument5 pagesPermeability of Granular Soils (Constant Head) : Standard Test Method ForbudiNo ratings yet

- RILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodDocument17 pagesRILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodAlvaro Pazmiño RomanNo ratings yet

- D 4015 - 15e1 - Resonant ColumnDocument22 pagesD 4015 - 15e1 - Resonant ColumnDalimNo ratings yet

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsDocument7 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsHandyNo ratings yet

- Planning and Preparing For A Groundwater Sampling EventDocument4 pagesPlanning and Preparing For A Groundwater Sampling EventsamerNo ratings yet

- Astm D2573 D2573M 15Document8 pagesAstm D2573 D2573M 15Wilson KoNo ratings yet

- D5918Document12 pagesD5918grats_singcoNo ratings yet

- D653 27514 PDFDocument50 pagesD653 27514 PDFJUAN CAMILO VIVARES GÓMEZNo ratings yet

- Density of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsDocument7 pagesDensity of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsIonut VasilescuNo ratings yet

- Astm D2573 D2573M 15Document8 pagesAstm D2573 D2573M 15Wilson KoNo ratings yet

- Anexo 5.4 Astm d5092Document16 pagesAnexo 5.4 Astm d5092marvin060517No ratings yet

- Contents of Geostatistical Site Investigation Report: Standard Guide ForDocument5 pagesContents of Geostatistical Site Investigation Report: Standard Guide ForSFC ABHA 1100% (1)

- Consolidación Con Deformación Controlada (D4186-D4186M-12)Document18 pagesConsolidación Con Deformación Controlada (D4186-D4186M-12)joake spasNo ratings yet

- C637-14 Standard Specification For Aggregates For Radiation-Shielding ConcreteDocument4 pagesC637-14 Standard Specification For Aggregates For Radiation-Shielding ConcreteFahad RedaNo ratings yet

- D4043-17 - Selection Aquifer TestsDocument6 pagesD4043-17 - Selection Aquifer TestsJessikaNo ratings yet

- D 4767 Test Method For Consolidated Undrained Triaxial Compression Test For Cohesive Soils PDFDocument13 pagesD 4767 Test Method For Consolidated Undrained Triaxial Compression Test For Cohesive Soils PDFjairoNo ratings yet

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 pagesDirect Shear Test of Soils Under Consolidated Drained ConditionsFaten Abou ShakraNo ratings yet

- ASTM D6938 (Densidad Método Nuclear)Document10 pagesASTM D6938 (Densidad Método Nuclear)Gerardo ChahuaNo ratings yet

- D4403 - 05Document10 pagesD4403 - 05Jesus Luis Arce GuillermoNo ratings yet

- Consolidated Drained Triaxial Compression Test For SoilsDocument12 pagesConsolidated Drained Triaxial Compression Test For SoilsRaul Vilcherrez Mendieta100% (1)

- Standards Content 17892 10Document12 pagesStandards Content 17892 10Tbaya Tbaya0% (1)

- Making and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryDocument7 pagesMaking and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryCarlos CmbbNo ratings yet

- Astm D4829Document4 pagesAstm D4829Felipe Ignacio Córdoba rebolledoNo ratings yet

- d5255 (Personal)Document3 pagesd5255 (Personal)Victor HernandezNo ratings yet

- ASTM - D4253 16E01 - en USDocument16 pagesASTM - D4253 16E01 - en USMatias Leiva FloresNo ratings yet

- Astm d5873 Esclerometro PDFDocument4 pagesAstm d5873 Esclerometro PDFJulio Oyola Salvador100% (1)

- D3551-08 Standard Practice For Laboratory Preparation of Soil-Lime Mixtures Using Mechanical MixerDocument2 pagesD3551-08 Standard Practice For Laboratory Preparation of Soil-Lime Mixtures Using Mechanical MixerFaten Abou ShakraNo ratings yet

- D3213-13 Standard Practices For Handling, Storing, and Preparing Soft Intact Marine SoilDocument5 pagesD3213-13 Standard Practices For Handling, Storing, and Preparing Soft Intact Marine SoilFaten Abou ShakraNo ratings yet

- D5922-96 (2010) Standard Guide For Analysis of Spatial Variation in Geostatistical Site InvestigationsDocument4 pagesD5922-96 (2010) Standard Guide For Analysis of Spatial Variation in Geostatistical Site InvestigationsVag KatsikopoulosNo ratings yet

- D427Document4 pagesD427Nouman KhalidNo ratings yet

- D2172D2172M 17Document10 pagesD2172D2172M 17mehdiNo ratings yet

- Memo 097.7 - 102319 - Item 450 Tunnel ExcavationDocument9 pagesMemo 097.7 - 102319 - Item 450 Tunnel ExcavationBai Alleha MusaNo ratings yet

- D 692 - 00 Rdy5mi0wmaDocument2 pagesD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- Astm C 642-21Document3 pagesAstm C 642-21GEOENSAYOS sasNo ratings yet

- Expansion Index of Soils: Standard Test Method ForDocument5 pagesExpansion Index of Soils: Standard Test Method ForOmar Encalada MejiaNo ratings yet

- Thermal Integrity Profiling of Concrete Deep Foundations: Standard Test Methods ForDocument7 pagesThermal Integrity Profiling of Concrete Deep Foundations: Standard Test Methods ForasmaNo ratings yet

- Evaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingDocument6 pagesEvaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingAhmedJardakNo ratings yet

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 pagesDirect Shear Test of Soils Under Consolidated Drained ConditionsKoppolu SrinivasuluNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- Astm D 4220 PDFDocument11 pagesAstm D 4220 PDFstellaraydanNo ratings yet

- D1587 Muestreo Con Tubo de Pared DelgadaDocument4 pagesD1587 Muestreo Con Tubo de Pared DelgadaLuis Enrique Gutiérrez MoralesNo ratings yet

- Report Geotechnical R 000267 0081 4Document74 pagesReport Geotechnical R 000267 0081 4MohamedNo ratings yet

- The Environmental Impact of Shrimp Aquaculture PDFDocument10 pagesThe Environmental Impact of Shrimp Aquaculture PDFAlexander TeixeiraNo ratings yet

- Groundwater Recharge EstimationDocument207 pagesGroundwater Recharge EstimationValen RamiirezNo ratings yet

- Brown (1994) The Generation, Segregation, Ascent and Emplacement of Granite Magma The Migmatite To Crustally Derived Granite Connection in Thickened Orogens PDFDocument48 pagesBrown (1994) The Generation, Segregation, Ascent and Emplacement of Granite Magma The Migmatite To Crustally Derived Granite Connection in Thickened Orogens PDFAmitava SahaNo ratings yet

- Jacinto Et Al. 2011 - Hypoxia in Manila Bay, Philippines During The Northeast MonsoonDocument6 pagesJacinto Et Al. 2011 - Hypoxia in Manila Bay, Philippines During The Northeast MonsoonjohnwcaragNo ratings yet

- What Does The Fossil Record Tell UsDocument6 pagesWhat Does The Fossil Record Tell UsSamuel Venilde SimoqueNo ratings yet

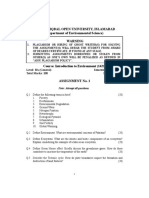

- Allama Iqbal Open University, Islamabad (Department of Environmental Science) WarningDocument3 pagesAllama Iqbal Open University, Islamabad (Department of Environmental Science) WarningIftikhar AhmadNo ratings yet

- Questor Training Example 1Document2 pagesQuestor Training Example 1Gary NgNo ratings yet

- Review of Environmental Studies by Namrata VermaDocument2 pagesReview of Environmental Studies by Namrata VermaDineshNo ratings yet

- Course Specifications Navigation 101Document6 pagesCourse Specifications Navigation 101glockenspiel997150% (2)

- SoilDocument26 pagesSoilJatin GuptaNo ratings yet

- Effects - of - Cotton - Ginning - Mill - Effluents20161204 24828 8cfgmp With Cover Page v2Document12 pagesEffects - of - Cotton - Ginning - Mill - Effluents20161204 24828 8cfgmp With Cover Page v2Nessre ZeineNo ratings yet

- Fact About India GeograpyDocument13 pagesFact About India GeograpyVeera Shekar GNo ratings yet

- What Location Is 60 Degrees North and 30 Degrees West 7 4thDocument2 pagesWhat Location Is 60 Degrees North and 30 Degrees West 7 4thDiane Rafer NageraNo ratings yet

- Adopt A Plant ReportDocument10 pagesAdopt A Plant Reportprapti WamreNo ratings yet

- Request Letter of InterviewDocument7 pagesRequest Letter of InterviewGrace Marie CervantesNo ratings yet

- Morning Forecast: ArgentinaDocument3 pagesMorning Forecast: Argentinaapi-111127973No ratings yet

- Introducing Flooding Presentation NewDocument17 pagesIntroducing Flooding Presentation NewGulzar AhmedNo ratings yet

- Hydrochemical Assessment of SW and GW Quality Along Uyyakondan ChannelDocument13 pagesHydrochemical Assessment of SW and GW Quality Along Uyyakondan ChannelbrindhaNo ratings yet

- Mantle Convection Pamhplet For Ghianne ErfeDocument2 pagesMantle Convection Pamhplet For Ghianne ErfePATRICIA ANGELICA VINUYA100% (1)

- Field Density Test by Sand Replacement Method. (As Per IS 2720, (Part - 28) ) Road NameDocument7 pagesField Density Test by Sand Replacement Method. (As Per IS 2720, (Part - 28) ) Road NameAnmol PatelNo ratings yet

- Atmospheric CirculationDocument6 pagesAtmospheric CirculationWinard WantogNo ratings yet

- Nav 1b Session 1Document32 pagesNav 1b Session 1Robert M. Maluya100% (1)

- Anh 11 HK 2 Ma de 246Document4 pagesAnh 11 HK 2 Ma de 246Lò TùngNo ratings yet

- Global WarmingDocument28 pagesGlobal Warmingapi-264756260No ratings yet

- 9.4 Geohazard PhenomenonDocument27 pages9.4 Geohazard PhenomenonEmily Ti Er ChiNo ratings yet