Professional Documents

Culture Documents

Fire Hydrant

Uploaded by

Mazin KC0 ratings0% found this document useful (0 votes)

28 views1 pageFire hydrants consist of a pipe connecting to the water main with a valve to control water flow and an outlet to connect fire hoses. They need to be accessible near buildings and spaced appropriately. Hydrants require periodic maintenance like lubrication and replacing broken parts to ensure reliable operation during fires.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFire hydrants consist of a pipe connecting to the water main with a valve to control water flow and an outlet to connect fire hoses. They need to be accessible near buildings and spaced appropriately. Hydrants require periodic maintenance like lubrication and replacing broken parts to ensure reliable operation during fires.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views1 pageFire Hydrant

Uploaded by

Mazin KCFire hydrants consist of a pipe connecting to the water main with a valve to control water flow and an outlet to connect fire hoses. They need to be accessible near buildings and spaced appropriately. Hydrants require periodic maintenance like lubrication and replacing broken parts to ensure reliable operation during fires.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

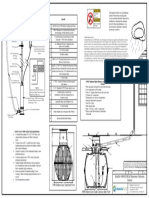

fitting which allows the fireman to

connect the hose or

stand pipe to the water main, thereby

making available the supply of water

for fire fighting

Fire hydrants essentially consists of

- A short length of flanged pipe

Periodical lubrication of head mechanism connecting to the water main

and restoration of head gaskets should be - A valve to control the flow of water

done - An outlet to which fire service

with flood grade, non-petroleum lubricant to

avoid contamination of the distributed connection are made

system.

Special seat wrenches may be used to

remove the seat or to replace the gasket or

broken

parts

Hydrant extensions may be used to raise a To Care

hydrant if the grade around the hydrant

changes.

Hydrant repair kits are also available to

repair sacrifice parts designed to break

when hit by a vehicle

IS 910 :1980(Reaffirmed 2000) – On basis of their position w.r.t ground level

Specification for combined key for hydrant, ∙ Ground Hydrant (below ground level)

hydrant cover ∙ Post/Pillar Hydrant (Above ground

and lower valve. level)

must be fitted with a detachable flanged

gunmetal 63 mm round thread

On the basis water always in the hydrant

outlet. all time

outlet cap should be attached by means of a

∙ Wet Hydrant (water within the hydrant

chain all the times)

important requirements for hydrants

e direction of opening of the spindle is to be

∙ Dry Hydrant (used in areas where

permanently marked freezing temperature could

Hydrant covers to be marked clearly as “

damage the hydrants.It uses a valve at

Fire Hydrant” or the initials “FH the base of the hydrant to control water

flow to all outlets. The base and this

on the premises at risk (type of occupancy) valve are below ground at the level of

supply of water water

possibility of damage to hydrant due to Spacing of ground hydrants main.

if possible, hydrants must be located near

structural

the points

)

collapse of building due to fire also is to

be considered of entry into buildings

-open the hydrant slowly to avoid

not placed above the main, but FIRE sudden jerk -close the hydrant

alongside it on a short branch. HYDRANT slowly ,particularly the last few turns to

avoid “water hammer” effect.

Water flows horizontally past the valve

-Ensure that hydrant are properly

inlet piece

three closed

sluice valve

duck-foot bend

components -never open the hydrant when the pit is

negligible loss of pressure filled with water to avoid contamination

of water in the main

. IS 909 :1992(Reaffirmed 2000) – “

Sluice valve type or Wedge-gate type -When no water is available in the

Specification

hydrants hydrant, or flow of water has failed,do

for underground hydrant, sluice valve

not

type”

remove the pipe from hydrant until the

valve is completely

Periodical inspection and maintenance

:-

1.Cleaning of hydrant pit;checking the

The common type of hydrants used brickwork of pit for damage.

combines ground hydrant and a stand pipe for fire fighting is 2.Ensuring proper functioning of frost

stands valve.

about 3 feet to 4 feet above the ground and 3.Ensuring that there is no leakage

has one or two outlets for water connection

through spindle gland.

fitted with an internal valve at the base, 4.Fittng the stand pipe and there by

which can be controlled by a key or a

wheel checking whether its fits correctly and

IS 908 :1975(Reaffirmed 2000) – “

easily.

Specification for hydrant stand-post type”

and IS Stand-post type hydrants

5714 : 1981 (Reaffirmed 2000) – “

Specification for hydrant stand pipe for fire

fighting”

Title FIRE HYDRANT Author Date 04-02-2022

File Company

04 February 2022

You might also like

- Technical Specification COOLING TOWERDocument5 pagesTechnical Specification COOLING TOWERfwzn_eeNo ratings yet

- Regent Dinflow BrochureDocument4 pagesRegent Dinflow Brochurebob marleyNo ratings yet

- Fire Fighting EquipmentsDocument1 pageFire Fighting EquipmentsMazin KCNo ratings yet

- Feba Brochure PDFDocument8 pagesFeba Brochure PDFFakhruddin KamsinNo ratings yet

- Ballast PumpDocument1 pageBallast PumpM YunusNo ratings yet

- Appendix 7 - RecommendationsDocument5 pagesAppendix 7 - Recommendationsdaoud12No ratings yet

- HPGR200: 60Hz/50Hz Submersible Sewage Grinder PumpDocument4 pagesHPGR200: 60Hz/50Hz Submersible Sewage Grinder Pumpallen_worstNo ratings yet

- Aeroquip FLOCSDocument20 pagesAeroquip FLOCSSetyohdWNo ratings yet

- Brochure Vibration Protection For Pumps ENDocument4 pagesBrochure Vibration Protection For Pumps ENAkshay KadiaNo ratings yet

- 0172 Private Fire Hydrants BrochureDocument4 pages0172 Private Fire Hydrants BrochureMousse MousseNo ratings yet

- DP 3127.180 Impcod471 - BrochureDocument10 pagesDP 3127.180 Impcod471 - BrochurehectorNo ratings yet

- Pts / PT: Bell Housings With Rigid/flexible Pump MountingDocument4 pagesPts / PT: Bell Housings With Rigid/flexible Pump Mountingmujeebahmed sayedNo ratings yet

- Fire Fighting VehiclesDocument1 pageFire Fighting VehiclesMazin KCNo ratings yet

- Fire Fighting VehiclesDocument1 pageFire Fighting VehiclesMazin KCNo ratings yet

- Conveyor Belt Motor en 82Document1 pageConveyor Belt Motor en 82plennyNo ratings yet

- Grundfos Hs Horisontal Split CaseDocument4 pagesGrundfos Hs Horisontal Split CaseHtuHnitNo ratings yet

- RainFlo 1000 IGDocument1 pageRainFlo 1000 IGRaux XarNo ratings yet

- Catalog Z SeriesDocument16 pagesCatalog Z SeriesTeuku Rizki Muda KeulanaNo ratings yet

- OBERDORFER S417 Spec SheetDocument2 pagesOBERDORFER S417 Spec SheetJavier GarciaNo ratings yet

- Installation: Installation and Laying of Kabelflex Cable ConduitDocument2 pagesInstallation: Installation and Laying of Kabelflex Cable ConduitTeodoro MendezNo ratings yet

- CDM PDFDocument3 pagesCDM PDFferas_elnggarNo ratings yet

- Enviro EquipmentDocument3 pagesEnviro Equipmentngueadoum100% (2)

- OBERDORFER S214 Spec SheetDocument2 pagesOBERDORFER S214 Spec SheetJavier GarciaNo ratings yet

- ManualDocument12 pagesManualelblinblinhotsauce100% (1)

- Portable Foam Inductor UNI 900 MDocument2 pagesPortable Foam Inductor UNI 900 MForum PompieriiNo ratings yet

- 2463248Document12 pages2463248Dexter Hawkins100% (1)

- TF100-53C 3900 Series QD CouplingsDocument8 pagesTF100-53C 3900 Series QD CouplingsAhmet SönmezNo ratings yet

- Cono RC CedarapidsDocument8 pagesCono RC CedarapidsJesus DugarteNo ratings yet

- Bladder TankDocument3 pagesBladder TankguruuptoNo ratings yet

- Blowdown Vessels Meeting The Requirements of HSE PM60 PDFDocument8 pagesBlowdown Vessels Meeting The Requirements of HSE PM60 PDFedgardiaz5519No ratings yet

- Innovation Through: Hammelmann Injection PumpsDocument8 pagesInnovation Through: Hammelmann Injection PumpsMin ZayarNo ratings yet

- Installation Data: Jointing Techniques Marley Pipe Support SystemDocument1 pageInstallation Data: Jointing Techniques Marley Pipe Support SystemBoraNo ratings yet

- ENERGY STAR Guide Petroleum Refineries 20150330Document7 pagesENERGY STAR Guide Petroleum Refineries 20150330rameshkarthik810No ratings yet

- 350p Mig GunDocument4 pages350p Mig Gunmike kNo ratings yet

- Hammelmann Injection PumpsDocument8 pagesHammelmann Injection Pumpsgk218No ratings yet

- FBV Series Full-Flow Seacocks: Installation, Operation, and MaintenanceDocument1 pageFBV Series Full-Flow Seacocks: Installation, Operation, and MaintenanceStathis MoumousisNo ratings yet

- Steam Dump SystemDocument8 pagesSteam Dump Systemphil philaNo ratings yet

- KVT High Pressure Large Bore Valves PDFDocument16 pagesKVT High Pressure Large Bore Valves PDFkamal arabNo ratings yet

- GALAPESCA Ga - SuctiondischargeDocument1 pageGALAPESCA Ga - SuctiondischargeFrancisco AlarconNo ratings yet

- Cooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorDocument5 pagesCooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorAleksander RzeczyckiNo ratings yet

- 26 Vortex PDFDocument10 pages26 Vortex PDFKittipong RueankhamNo ratings yet

- Complete PVDF Jp180Document2 pagesComplete PVDF Jp180bivomixNo ratings yet

- Key Components: Pvcu Soil - Push-Fit or Solvent WeldDocument1 pageKey Components: Pvcu Soil - Push-Fit or Solvent WeldBoraNo ratings yet

- DIN20066 Masa Pakai Dan PenggantianDocument2 pagesDIN20066 Masa Pakai Dan Penggantianeko handoyoNo ratings yet

- 8639GBDocument34 pages8639GBWai Ee YapNo ratings yet

- Private Fire HydrantDocument4 pagesPrivate Fire HydrantAkilaJosephNo ratings yet

- Geafol Transformers Dry TypeDocument10 pagesGeafol Transformers Dry Typesunil_031100% (3)

- Catalo Martin Rosca 3 PDFDocument16 pagesCatalo Martin Rosca 3 PDFEzequiel CastroNo ratings yet

- Ps 10 6 Ea4 PDFDocument4 pagesPs 10 6 Ea4 PDFYeisson Beltran AquinoNo ratings yet

- Francis Urbines Litostroj Power Product SheetDocument2 pagesFrancis Urbines Litostroj Power Product SheetНенад АритоновиќNo ratings yet

- Condenser Level Protection - Functional DescriptionDocument2 pagesCondenser Level Protection - Functional DescriptiondnbinhNo ratings yet

- VM FRL FlyerDocument4 pagesVM FRL FlyeralmacenNo ratings yet

- Hydraulic Dampers: 1. Description 2. ApplicationDocument20 pagesHydraulic Dampers: 1. Description 2. ApplicationJean DuboisNo ratings yet

- Compact C Range BrochureDocument6 pagesCompact C Range BrochurePeter RobinsonNo ratings yet

- SCHWRTG: Portable Concrete PumpDocument4 pagesSCHWRTG: Portable Concrete PumpVipulNo ratings yet

- AlexanderDocument4 pagesAlexanderMazin KCNo ratings yet

- Probability Analysis and Prevention of Offshore Oil and Gas Accidents: Fire As A Cause and A ConsequenceDocument23 pagesProbability Analysis and Prevention of Offshore Oil and Gas Accidents: Fire As A Cause and A ConsequenceMazin KCNo ratings yet

- Stand PipeDocument1 pageStand PipeMazin KCNo ratings yet

- Ladders Ladders: Turntable LadderDocument1 pageLadders Ladders: Turntable LadderMazin KCNo ratings yet

- Small GearDocument1 pageSmall GearMazin KCNo ratings yet

- Fire Fighting VehiclesDocument1 pageFire Fighting VehiclesMazin KCNo ratings yet

- HosesDocument1 pageHosesMazin KCNo ratings yet

- PumpsDocument1 pagePumpsMazin KCNo ratings yet

- MonitorDocument1 pageMonitorMazin KCNo ratings yet

- Fire Fighting VehiclesDocument1 pageFire Fighting VehiclesMazin KCNo ratings yet

- Hose FittingsDocument1 pageHose FittingsMazin KCNo ratings yet

- KnotDocument1 pageKnotMazin KCNo ratings yet

- Demag Drives: Keeping Things On The MoveDocument28 pagesDemag Drives: Keeping Things On The MoveAbdulah TaufikNo ratings yet

- LM1877Document9 pagesLM1877Carl Eric Davó BourhenneNo ratings yet

- 3D Sound Field Recording With Higher Order Ambisonics - Objective Measurements and Validation of Spherical Microphone PDFDocument24 pages3D Sound Field Recording With Higher Order Ambisonics - Objective Measurements and Validation of Spherical Microphone PDF郭俊麟No ratings yet

- Tension Test ReportDocument7 pagesTension Test ReportTomy GeorgeNo ratings yet

- Business PlanDocument14 pagesBusiness PlanEnusah AbdulaiNo ratings yet

- Riser DesgnDocument13 pagesRiser Desgnplatipus_8575% (4)

- BDM Series: Explosion Proof Cable Glands (IIC, E, TD)Document7 pagesBDM Series: Explosion Proof Cable Glands (IIC, E, TD)Irvan FauziNo ratings yet

- 3G Causes Suggestions - 19mayDocument4 pages3G Causes Suggestions - 19mayUttam RusiaNo ratings yet

- Technical Data: Model NumberDocument5 pagesTechnical Data: Model NumberThais PontesNo ratings yet

- 367 - Etisalat Metro Station To International City Dubai Bus Service TimetableDocument5 pages367 - Etisalat Metro Station To International City Dubai Bus Service TimetableDubai Q&ANo ratings yet

- ABL Deposit SlipDocument1 pageABL Deposit Slipraja.hamzafarooq786No ratings yet

- Series 307Document4 pagesSeries 307Prathamesh GangalNo ratings yet

- DMS & DW-HC MS-700 Wellhead Presentation (Bien Dong)Document140 pagesDMS & DW-HC MS-700 Wellhead Presentation (Bien Dong)New Auto TVNo ratings yet

- System Hardware Overview LectureDocument45 pagesSystem Hardware Overview LectureHéctor RodríguezNo ratings yet

- 7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantDocument9 pages7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantAra SanirapNo ratings yet

- 10 Total Mark: 10 X 1 10: NPTEL Online Certification Courses Indian Institute of Technology KharagpurDocument7 pages10 Total Mark: 10 X 1 10: NPTEL Online Certification Courses Indian Institute of Technology KharagpurvitNo ratings yet

- C++ FQ PrelimsDocument3 pagesC++ FQ PrelimsRhexel ReyesNo ratings yet

- Item Analysis With: Most Learned and Least LearnedDocument9 pagesItem Analysis With: Most Learned and Least LearnedBern Mariveles-JavanaNo ratings yet

- Status of Sponge Iron Units in Orissa PDFDocument14 pagesStatus of Sponge Iron Units in Orissa PDFPriyanka TiwariNo ratings yet

- Visvesvaraya Technological University: "Moflin Ai Robot"Document16 pagesVisvesvaraya Technological University: "Moflin Ai Robot"Noornabi HussainNo ratings yet

- Aoyue 936a 936Document12 pagesAoyue 936a 936rabas_No ratings yet

- Register Formats: Customer Complaint Register Register No.Document3 pagesRegister Formats: Customer Complaint Register Register No.nareshNo ratings yet

- Photography and Digital ArtDocument7 pagesPhotography and Digital ArtJohn Bricks CarsolaNo ratings yet

- Cassandra: Wa'el Belkasim Arash Akhlaghi Badrinath JayakumarDocument37 pagesCassandra: Wa'el Belkasim Arash Akhlaghi Badrinath JayakumarrickitNo ratings yet

- 4 Hydrates & Hydrate PreventionDocument26 pages4 Hydrates & Hydrate PreventionWael Badri100% (1)

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- Oracle Primavera P6 EPPMDocument2 pagesOracle Primavera P6 EPPMsakkhanNo ratings yet

- Unitwise Objective Question With AnswerDocument19 pagesUnitwise Objective Question With AnswerKutty ShivaNo ratings yet

- Copenhagen SchemaDocument56 pagesCopenhagen Schemaraaj9850100% (1)

- Datos Técnicos Robot Industrial IRB 6600 03Document2 pagesDatos Técnicos Robot Industrial IRB 6600 03gussyNo ratings yet