Professional Documents

Culture Documents

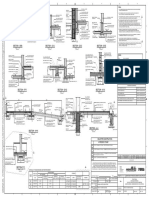

Cut Tee PB at Beam Junction Welded Gusset

Uploaded by

Rajveer SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cut Tee PB at Beam Junction Welded Gusset

Uploaded by

Rajveer SinghCopyright:

Available Formats

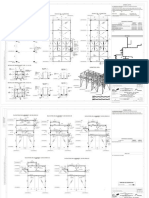

A B C D E F G H

NOTES:

TYP 1. ALL DIMENSIONS ARE IN FEETS AND INCHES.

a1

Lw

GUSSET PLATE 2. FOR ALL GENERAL NOTES, REFER TO DRAWING NO. XXXX.

TYP WP FOR STANDARD ABBERIVIATIONS, REFER TO ENGINEERING STANDARD NO.

(tp)

4CS05003A.

BEAM 3. MATERIAL, WORKMANSHIP AND PROTECTIVE COATING SHALL BE IN ACCORDANCE

WITH AIR PRODUCTS FABRICATION AND ERECTION SPECIFICATION 4ACS-640130

"FABRICATION OF STRUCTURAL STEEL".

GUSSET PLATE

(min.)

(TYP)

(tp) 4. BOLTS SHALL BE 3/4"Ø. ASTM A325-SC, TYPE 1.

1/2"

4 4

BRACE

5. BOLTS, NUTS AND WASHERS SHALL BE EITHER PLAIN (UNCOATED)

"N1" (FOR Nos. OF BOLTS OR GALVANIZED AS SPECIFIED IN SECTION 9 OF 4ACS-640130.

REFER TABLE)

6. HOLES SHALL BE 13/16" DIAMETER.

OVERSIZE AND SLOTTED HOLES (SHORT OR LONG SLOTS) ARE NOT PERMITTED.

E

AC

ga

A

BR

A 7. WELD ELECTRODES SHALL CONFORM TO FILLER METAL CLASSIFICATION

1

=

1

STRENGTH OF 70 ksi.

lh

=

1

sh

8. CONTACT SURFACES SHALL BE EITHER CLASS A (CLEAN MILL SCALE AND

BLAST-CLEANED SURFACES WITH CLASS A COATINGS) OR CLASS C (HOT DIP

GALVANIZED AND ROUGHENED SURFACES).

1

drawing is the property of Air Products and Chemicals, Inc. and/or subsidiaries, and must be accounted for and returned to the company upon request. Information on this drawing is confidential and proprietary information of Air Products and must not be used, copied, reproduced, or disclosed to others in

lh

9. THE ERECTION CONTRACTOR SHALL ROUGHEN ALL GALVANIZED CONTACT

SURFACES BY MEANS OF HAND WIRE BRUSHING PRIOR TO BOLTING UP.

BEAM POWER WIRE BRUSHING IS NOT PERMITTED.

10. "N" DENOTES NUMBER OF BOLTS. FOR "N" SEE PLANS.

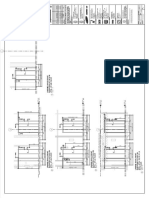

CUT TEE PLAN BRACE SECTION - A 11. PLATES SHALL BE 3/8" THICK (MINIMUM).

CONNECTION ON BEAM JUNCTION (NTS)

12. ALL ANGLE OF BRACE SHALL BE MORE THAN 30º AND LESS THAN 60º.

(NTS)

3 REFERENCE DRAWINGS 3

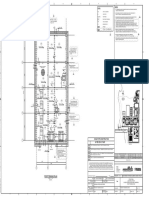

Allowable

Bolt details on Brace Flange Gusset Plate details DOC0000XXXXXX STRUCTURAL GENERAL NOTES

Capacity

Connection Brace Angle

Sr. No Brace Size Bolt Dia. N1 (No.

Name Axial sh1 lh1 ga1 Lw (min) tp a1

(db) of Bolts

(degrees) (kips) (in) (Nos) (in) (in) (in) (in) (in) (in) LEGENDS:

1 HB2 W-01 CT146x127x16 30o to 60o 55 3/4" 4 3 1" 1/2 2" 3/4 7" 1/2 7/16" 1/4" WP = WORKING POINT

o o

2 HB2 W-02 CT146x127x16 30 to 60 65 3/4" 6 3 1" 1/2 2" 3/4 9 3/8" 1/4" NTS = NOT TO SCALE

3 HB2 W-03 CT146x127x16 30o to 60o 80 3/4" 6 3 1" 1/2 2" 3/4 11 3/8" 1/4"

4 HB2 W-04 CT146x127x19 30o to 60o 65 3/4" 4 3 1" 1/2 2" 3/4 9 7/16" 1/4"

5 HB2 W-05 CT146x127x19 30o to 60o 80 3/4" 6 3 1" 1/2 2" 3/4 11 3/8" 1/4"

6 HB2 W-06 CT146x127x19 30o to 60o 95 3/4" 6 3 1" 1/2 2" 3/4 12" 1/2 7/16" 1/4"

7 HB2 W-07 CT152x76x15 30o to 60o 50 3/4" 4 3 1" 1/2 3 7 3/8" 1/4"

8 HB2 W-08 CT152x76x15 30o to 60o 65 3/4" 4 3 1" 1/2 3 9 7/16" 1/4"

9 HB2 W-09 CT152x76x15 30o to 60o 75 3/4" 6 3 1" 1/2 3 10 3/8" 1/4"

10 HB2 W-10 CT165x152x20 30o to 60o 70 3/4" 6 3 1" 1/2 3" 7/16 9" 1/2 3/8" 1/4"

11 HB2 W-11 CT165x152x20 30o to 60o 85 3/4" 6 3 1" 1/2 3" 7/16 11" 1/2 3/8" 1/4"

or in part, without proper authorization. This drawing may not be reproduced or used for purposes other than that for which it was supplied.

12 HB2 W-12 CT165x152x20 30o to 60o 105 3/4" 8 3 1" 1/2 3" 7/16 14 3/8" 1/4"

2 2

13 HB2 W-13 CT171x178x26 30o to 60o 90 3/4" 6 3 1" 1/2 3" 3/4 12 3/8" 1/4"

14 HB2 W-14 CT171x178x26 30o to 60o 110 3/4" 8 3 1" 1/2 3" 3/4 14" 1/2 3/8" 1/4"

15 HB2 W-15 CT171x178x26 30o to 60o 135 3/4" 8 3 1" 1/2 3" 3/4 17" 1/2 7/16" 1/4"

16 HB2 W-16 CT171x178x29 30o to 60o 100 3/4" 6 3 1" 1/2 3" 3/4 13" 1/2 7/16" 1/4"

17 HB2 W-17 CT171x178x29 30o to 60o 125 3/4" 8 3 1" 1/2 3" 3/4 16" 1/2 7/16" 1/4"

18 HB2 W-18 CT171x178x29 30o to 60o 150 3/4" 10 3 1" 1/2 3" 3/4 19" 1/2 3/8" 1/4"

19 HB2 W-19 CT178x203x30 30o to 60o 105 3/4" 8 3 1" 1/2 4 14 3/8" 1/4"

20 HB2 W-20 CT178x203x30 30o to 60o 130 3/4" 8 3 1" 1/2 4 17 7/16" 1/4"

21 HB2 W-21 CT178x203x30 30o to 60o 160 3/4" 10 3 1" 1/2 4 21 7/16" 1/4"

22 HB2 W-22 CT203x102x23 30o to 60o 80 3/4" 6 3 1" 1/2 5 11 3/8" 1/4"

23 HB2 W-23 CT203x102x23 30o to 60o 100 3/4" 6 3 1" 1/2 5 13" 1/2 3/8" 1/4"

24 HB2 W-24 CT203x102x23 30o to 60o 120 3/4" 8 3 1" 1/2 5 16 3/8" 1/4"

25 HB2 W-25 CT203x102x30 30o to 60o 105 3/4" 8 3 1" 1/2 5" 1/16 14 3/8" 1/4"

26 HB2 W-26 CT203x102x30 30o to 60o 130 3/4" 8 3 1" 1/2 5" 1/16 17 3/8" 1/4"

27 HB2 W-27 CT203x102x30 30o to 60o 155 3/4" 10 3 1" 1/2 5" 1/16 20 3/8" 1/4"

28 HB2 W-28 CT254x127x37 30o to 60o 125 3/4" 8 3 1" 1/2 7 16" 1/2 3/8" 1/4"

29 HB2 W-29 CT254x127x37 30o to 60o 160 3/4" 10 3 1" 1/2 7 21 3/8" 1/4"

30 HB2 W-30 CT254x127x37 30o to 60o 190 3/4" 12 3 1" 1/2 7 24" 1/2 3/8" 1/4"

1 31 HB2 W-31 CT254x127x45 30o to 60o 155 3/4" 10 3 1" 1/2 7" 1/16 20 3/8" 1/4" 1

32 HB2 W-32 CT254x127x45 30o to 60o 195 3/4" 12 3 1" 1/2 7" 1/16 25 3/8" 1/4"

33 HB2 W-33 CT254x127x45 30o to 60o 235 3/4" 14 3 1" 1/2 7" 1/16 30 3/8" 1/4"

CONFIDENTIAL AND This

USED ON

TITLE

XXXXXXXX

PROPRIETARY DATA:

STRUCTURAL OWNER GROUP

HORIZONTAL BRACING CIVIL/STRUCTURAL

RELEASE PURPOSE

c Air Products and Chemicals, Inc. TYPICAL DETAILS DESIGN

REFERENCE

DEPARTMENT STANDARD XXXXXXXX

VADODARA, GUJARAT, INDIA DOC No

0 - ISSUED FOR REVIEW 21Sep20 KDS JG JS As of Dates in REVISIONS list XXXXXXXXXXXXX

All rights reserved

REV CN No REVISION DESCRIPTION DATE BY CHK'D APP'D SCALE SHEET

AS SHOWN 01 OF 01

A B C D E F G H

You might also like

- Smart Winner New SchematicDocument5 pagesSmart Winner New Schematicscales100% (1)

- Yamaha p-150 SchematicsDocument2 pagesYamaha p-150 SchematicsMichael KageorgeNo ratings yet

- Design Report of Lifting Spreader BeamDocument70 pagesDesign Report of Lifting Spreader BeamRajveer SinghNo ratings yet

- Automatic Drainage Cleaning SystemDocument42 pagesAutomatic Drainage Cleaning SystemAnonymous j0aO95fg100% (2)

- Trace Elliot 715 ManualDocument35 pagesTrace Elliot 715 ManualOrvelNo ratings yet

- Cut Tee Plan Brace Connection On Beam JunctionDocument1 pageCut Tee Plan Brace Connection On Beam JunctionRajveer SinghNo ratings yet

- Pm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...Document1 pagePm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...MOHAMMAD JAKARIA HASANNo ratings yet

- 9 Sketch Shear ConnectionDocument1 page9 Sketch Shear ConnectionER Deepak SutharNo ratings yet

- Pm210011-Nui900-Rl5-00016 - 02 - Roof Framing Plan - (261-B203) Operators Bu...Document1 pagePm210011-Nui900-Rl5-00016 - 02 - Roof Framing Plan - (261-B203) Operators Bu...MOHAMMAD JAKARIA HASANNo ratings yet

- Double Cut Tee Plan Brace Connection On Beam WebDocument1 pageDouble Cut Tee Plan Brace Connection On Beam WebRajveer SinghNo ratings yet

- Obtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderDocument1 pageObtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderProfessor PuppiesNo ratings yet

- N 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdateDocument2 pagesN 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdatephanikrishnabNo ratings yet

- LOTIZACION QUISPE - FEBRRERO - 2019-ModelDocument1 pageLOTIZACION QUISPE - FEBRRERO - 2019-ModelRomp PevilNo ratings yet

- S303 76-10526-Detail Design: Wall ScheduleDocument1 pageS303 76-10526-Detail Design: Wall ScheduleMazen IsmailNo ratings yet

- Jak1 Aur El DWG C 1 4001 (D)Document1 pageJak1 Aur El DWG C 1 4001 (D)Budi HahnNo ratings yet

- General Arrangement Plan - Podium Level 00: NotesDocument1 pageGeneral Arrangement Plan - Podium Level 00: Notesprasahnthrk07No ratings yet

- Isolation Package For 25-T-01: Remove SpoolDocument2 pagesIsolation Package For 25-T-01: Remove SpoolAdel Moustafa NafrawyNo ratings yet

- Ec1-02a Second Floor Fdas LayoutDocument1 pageEc1-02a Second Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Water Supply PHDocument1 pageWater Supply PHMohammed Javid HassanNo ratings yet

- Vermer PipeDocument4 pagesVermer PipeVermer FabregasNo ratings yet

- Lor 03127Document1 pageLor 03127HighSpeedRailNo ratings yet

- Notes: Process Flow Diagram Waste Water Treatment (Section 70)Document1 pageNotes: Process Flow Diagram Waste Water Treatment (Section 70)rajindo1No ratings yet

- K Detail: Jba Design, Build & ConstructionDocument1 pageK Detail: Jba Design, Build & ConstructionArch. John Bernard AbadNo ratings yet

- 1 - FF Plan Ic5 (As Built) SinageDocument1 page1 - FF Plan Ic5 (As Built) Sinageabdulazizarab1992No ratings yet

- PLMB 400Document20 pagesPLMB 400Khalid AlotaibiNo ratings yet

- Tender Documents: U W C D A S M E P I L XDocument1 pageTender Documents: U W C D A S M E P I L XaalqaisiNo ratings yet

- Fire Pump Room @basement: Zone 3Document1 pageFire Pump Room @basement: Zone 3MØhãmmed ØwięsNo ratings yet

- HW Nic Allam DD Ge 002Document1 pageHW Nic Allam DD Ge 002ehab.m.saad88No ratings yet

- Elevation of Tower - 1 (Facing North) Part 3 of 3: Section F-FDocument1 pageElevation of Tower - 1 (Facing North) Part 3 of 3: Section F-FHozien OnofreNo ratings yet

- Power Supply TNP8EPL90 Panasonic GLP23Document3 pagesPower Supply TNP8EPL90 Panasonic GLP23Анатоли АнгеловNo ratings yet

- Grand - L07-L19 Scut Roa 20201129Document1 pageGrand - L07-L19 Scut Roa 20201129Ricardo Alejandro Oyarce ArmijoNo ratings yet

- RB A225 Approval Rev 1 - 10 10Document1 pageRB A225 Approval Rev 1 - 10 10TariqMahmoodNo ratings yet

- 2 - 2+3 Plan Ic5 (As Built) SinageDocument1 page2 - 2+3 Plan Ic5 (As Built) Sinageabdulazizarab1992No ratings yet

- Structural Engineering DrawingsDocument7 pagesStructural Engineering DrawingsObaidullah ObaidNo ratings yet

- Instalación Eléctrica 3Document4 pagesInstalación Eléctrica 3Alda MarínNo ratings yet

- Conjunto Residencial Las Hiedras: LOSA N+2.70Document1 pageConjunto Residencial Las Hiedras: LOSA N+2.70Daniel AtiNo ratings yet

- CSD 100Document1 pageCSD 100murugesanNo ratings yet

- GMR10-07203 Current Frame T10 Rev02Document7 pagesGMR10-07203 Current Frame T10 Rev02Mladen NinkovicNo ratings yet

- Ricoh MP3010-Point-to-Point DiagramDocument16 pagesRicoh MP3010-Point-to-Point DiagramPeter xuNo ratings yet

- Mwihoko 3DDocument1 pageMwihoko 3DNewtonNo ratings yet

- Floor PlanDocument1 pageFloor PlanShweta SainiNo ratings yet

- 87ae5500 Cyr - Uty%Document1 page87ae5500 Cyr - Uty%Narendra GadeNo ratings yet

- Grand l21 Scut Roa 20201209Document1 pageGrand l21 Scut Roa 20201209Ricardo Alejandro Oyarce ArmijoNo ratings yet

- Duty Corrector: Schematic Diagram (DSP)Document11 pagesDuty Corrector: Schematic Diagram (DSP)Robertas PutinasNo ratings yet

- Ashok: First Angle ProjectionDocument1 pageAshok: First Angle ProjectionNitesh JangirNo ratings yet

- Lor 03109Document1 pageLor 03109HighSpeedRailNo ratings yet

- Electrical Equipment LayoutDocument1 pageElectrical Equipment Layoutmohdtakrimi100% (1)

- CITIIS - NGGOs COLONY - School - ARCHDocument34 pagesCITIIS - NGGOs COLONY - School - ARCHKingSantoshNo ratings yet

- Thanamalvila Hospital Layout1Document1 pageThanamalvila Hospital Layout1buildings departmentNo ratings yet

- 19BL VSH LFT SCT S5S6 0038Document1 page19BL VSH LFT SCT S5S6 0038Rajiv NagarathinamNo ratings yet

- 15-Bed-Hospital PH B1Document10 pages15-Bed-Hospital PH B1Sunil Kumar BhagatNo ratings yet

- 4300 AI DU 126100001 - Q Combined PDFDocument5 pages4300 AI DU 126100001 - Q Combined PDFSaid AlzamarehNo ratings yet

- Pm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...Document1 pagePm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...MOHAMMAD JAKARIA HASANNo ratings yet

- UntitledDocument1 pageUntitledCDFNo ratings yet

- BEAM 5 (9"x17")Document1 pageBEAM 5 (9"x17")Rooking Ewondo SfuutNo ratings yet

- LD-Board TNP4G549 Panasonic KM21EDocument2 pagesLD-Board TNP4G549 Panasonic KM21Emsg2000No ratings yet

- Lor 03113Document1 pageLor 03113HighSpeedRailNo ratings yet

- Pm210011-Nui900-Rl5-00015 - 02 - Slab On Grade Plan - (261-B203) Operators B...Document1 pagePm210011-Nui900-Rl5-00015 - 02 - Slab On Grade Plan - (261-B203) Operators B...MOHAMMAD JAKARIA HASANNo ratings yet

- A219 P 2 PDocument2 pagesA219 P 2 PElr MagnificoNo ratings yet

- M-01-001-AC Typical Details - 05-SHEET-4Document1 pageM-01-001-AC Typical Details - 05-SHEET-4nomanNo ratings yet

- Lor 03106Document1 pageLor 03106HighSpeedRailNo ratings yet

- Lor 03122Document1 pageLor 03122HighSpeedRailNo ratings yet

- B) 21 - 06 - 142B - SM - R0-OEx - CommentsDocument2 pagesB) 21 - 06 - 142B - SM - R0-OEx - CommentsRajveer SinghNo ratings yet

- 2140 - Transportation Support - 01Document23 pages2140 - Transportation Support - 01Rajveer SinghNo ratings yet

- Mat Foundation Reinforcement DesignDocument1,094 pagesMat Foundation Reinforcement DesignRajveer SinghNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- Isometric View Lifting Detail: NotesDocument2 pagesIsometric View Lifting Detail: NotesRajveer SinghNo ratings yet

- Transportation Plan 12-01-2022Document4 pagesTransportation Plan 12-01-2022Rajveer SinghNo ratings yet

- C) Deviations and Clarifications-Hazardous Non-Hazardous Cranes - CommentsDocument2 pagesC) Deviations and Clarifications-Hazardous Non-Hazardous Cranes - CommentsRajveer SinghNo ratings yet

- 40 Ton Capacity Motor DataDocument2 pages40 Ton Capacity Motor DataRajveer SinghNo ratings yet

- 40 Ton Capacity CRANE WHEEL LOAD DATADocument1 page40 Ton Capacity CRANE WHEEL LOAD DATARajveer SinghNo ratings yet

- 40 Ton Capacity COMPONENTS AND ADDITIONAL FEATURES DATADocument1 page40 Ton Capacity COMPONENTS AND ADDITIONAL FEATURES DATARajveer SinghNo ratings yet

- Singh, Rajveer: From: Sent: To: Subject: AttachmentsDocument5 pagesSingh, Rajveer: From: Sent: To: Subject: AttachmentsRajveer SinghNo ratings yet

- Lifting MethodologyDocument5 pagesLifting MethodologyRajveer SinghNo ratings yet

- Virtu: Virtual IT Drop inDocument22 pagesVirtu: Virtual IT Drop inRajveer SinghNo ratings yet

- Introduction To MS Edge: Presentation By: Tech Support Client - Infrastructure OperationsDocument9 pagesIntroduction To MS Edge: Presentation By: Tech Support Client - Infrastructure OperationsRajveer SinghNo ratings yet

- Introduction To MS Team: Presentation By: Tech Support Client - InfrastructureDocument11 pagesIntroduction To MS Team: Presentation By: Tech Support Client - InfrastructureRajveer SinghNo ratings yet

- Visag - Part - 1 of 2Document25 pagesVisag - Part - 1 of 2Rajveer SinghNo ratings yet

- Visag - Part - 2 of 2Document26 pagesVisag - Part - 2 of 2Rajveer SinghNo ratings yet

- Jubail Industrial Gases Hub: Thursday, February 3, 2022 Air Products Internal Use OnlyDocument9 pagesJubail Industrial Gases Hub: Thursday, February 3, 2022 Air Products Internal Use OnlyRajveer SinghNo ratings yet

- Zoom For Government: Tech Support Client TeamDocument17 pagesZoom For Government: Tech Support Client TeamRajveer SinghNo ratings yet

- Load Combinations For Shelters - 0001Document104 pagesLoad Combinations For Shelters - 0001Rajveer SinghNo ratings yet

- Mobile Bill Receipts - RajveerDocument6 pagesMobile Bill Receipts - RajveerRajveer SinghNo ratings yet

- Service Car - PDFDocument1 pageService Car - PDFRajveer SinghNo ratings yet

- Specification For Plant Access Platforms, Stairs and Ladders Materials and FabricationDocument41 pagesSpecification For Plant Access Platforms, Stairs and Ladders Materials and FabricationRajveer SinghNo ratings yet

- Safety Moment: Five Major Safety Tips To Avoid Fire Mishaps at Industrial SitesDocument3 pagesSafety Moment: Five Major Safety Tips To Avoid Fire Mishaps at Industrial SitesRajveer SinghNo ratings yet

- Covid Cases Rise With Delta Variant, But Deaths Don't Thanks To Vaccine - VoxDocument6 pagesCovid Cases Rise With Delta Variant, But Deaths Don't Thanks To Vaccine - VoxRajveer SinghNo ratings yet

- Lecture 1 TF BiomechanicsDocument63 pagesLecture 1 TF BiomechanicsAlfred JacksonNo ratings yet

- Tut 1Document5 pagesTut 1foranangelqwertyNo ratings yet

- ASC - General - Purpose - Capacitor For HallsensorDocument19 pagesASC - General - Purpose - Capacitor For HallsensorLusiNo ratings yet

- Genicular Nerves BlockDocument14 pagesGenicular Nerves BlocknsatriotomoNo ratings yet

- 2.SLTC Proposals For Bridges - Booklet 01.08.2022Document9 pages2.SLTC Proposals For Bridges - Booklet 01.08.2022harsha vardhanNo ratings yet

- Assignment On Neurological AssessmentDocument20 pagesAssignment On Neurological AssessmentSumandeep KaurNo ratings yet

- Basic - Digital - Circuits v7Document64 pagesBasic - Digital - Circuits v7Marco LopezNo ratings yet

- Manalaysay JPT Thesis With Approval PDFDocument103 pagesManalaysay JPT Thesis With Approval PDFTheresa Marie PrestoNo ratings yet

- RS PRO Digital, Bench Power Supply, 217W, 3 Output, 0 32V 3 A, 5 ADocument5 pagesRS PRO Digital, Bench Power Supply, 217W, 3 Output, 0 32V 3 A, 5 AGuillaume FoubertNo ratings yet

- LG 47ld450-Ua Chassis La01bDocument71 pagesLG 47ld450-Ua Chassis La01belrudo11100% (1)

- Board of Technical Education: "Design & Analysis of Highway Pavement"Document43 pagesBoard of Technical Education: "Design & Analysis of Highway Pavement"Bharath SrinivasreddyNo ratings yet

- Compound Plamar GanglionDocument4 pagesCompound Plamar Ganglionchinmayghaisas100% (2)

- GAT - Subject (Electronics)Document14 pagesGAT - Subject (Electronics)Muhammad Sarmad Hafeez100% (3)

- Gandolfi - L'Eclissi e L'orbe Magno Del LeoneDocument24 pagesGandolfi - L'Eclissi e L'orbe Magno Del LeoneberixNo ratings yet

- Electrical DrivesDocument1 pageElectrical DriveschaitanayNo ratings yet

- Line of Fire D&D 5e AdventureDocument10 pagesLine of Fire D&D 5e Adventurebob Raymond100% (5)

- Templar BuildsDocument18 pagesTemplar Buildsel_beardfaceNo ratings yet

- In Praise of LongchenpaDocument3 pagesIn Praise of LongchenpaJigdrel77No ratings yet

- HFWB - 170224 - Floor StandingDocument2 pagesHFWB - 170224 - Floor StandingAkilaJosephNo ratings yet

- Et3491 Esiot LabDocument95 pagesEt3491 Esiot LabfreefireyomaNo ratings yet

- Spa 20008080VDocument1 pageSpa 20008080Vmichele DSNo ratings yet

- Service Tool Screens: JS1 PVE JoystickDocument20 pagesService Tool Screens: JS1 PVE JoystickPitupyNo ratings yet

- A Project Work Submitted in Partial Fulfilment of The Requirement For The Degree of B.SC (Honours) in M.J.P. Rohilkhand University, BareillyDocument4 pagesA Project Work Submitted in Partial Fulfilment of The Requirement For The Degree of B.SC (Honours) in M.J.P. Rohilkhand University, Bareillymohd ameerNo ratings yet

- Traverse SurveyingDocument2 pagesTraverse Surveyingchaudharylucky1818.sNo ratings yet

- Laughlin - A Comparison of Turbine Pulley Design Philosophies With Historical PerspectiveDocument3 pagesLaughlin - A Comparison of Turbine Pulley Design Philosophies With Historical Perspectivedarkwing888No ratings yet

- BuffersDocument3 pagesBuffersIshak Ika Kovac100% (1)

- Whitaker Test PDFDocument4 pagesWhitaker Test PDFKahn GenghisNo ratings yet

- Civilization S Quotations Life S IdealDocument342 pagesCivilization S Quotations Life S Idealsamuel thomasNo ratings yet