Professional Documents

Culture Documents

South Bend Lathe Works - Shifting Cone Pulley and Adjusting Belt Tension

Uploaded by

trollforge0 ratings0% found this document useful (0 votes)

168 views1 pageShifting Cone Pulley and Adjusting Belt Tension, Document, and the drawing it refers to.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentShifting Cone Pulley and Adjusting Belt Tension, Document, and the drawing it refers to.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

168 views1 pageSouth Bend Lathe Works - Shifting Cone Pulley and Adjusting Belt Tension

Uploaded by

trollforgeShifting Cone Pulley and Adjusting Belt Tension, Document, and the drawing it refers to.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Shifting the Cone Pulley Belt and Adjusting

the Belt Tension

On the South Bend Underneath Belt Motor Driven Lathe

SHIFTING THE CONE PULLEY BELT

1. Raise the belt release crank up to position "B" as shown in Fig. 3 on Drawing No. 2500. Stop the

lathe so that neither motor nor spindle are rotating. The belt can now be shifted from step to step

on the cone pulley with one hand.

CONE PULLEY BELT TENSION IS IMPORTANT

1. The cone pulley belt should be fitted wiih the smooth side toward the cone pulley and just tight

enough to transmit the required power without slipping. Glued belts should be used, also rawhide

or gut laced belts operate satisfactorily. Tension on belt should not exceed ten to twenty pounds

which will permit the lathe tool to take a heavy cut. Too much tension on the belt will cause loss

of power, excessive wear on the bearings and shorten the life of the belt.

INCREASING CONE PULLEY BELT TENSION

1. Place belt release crank in position "C", Fig. 3. Adjust screw E", Fig. 1 outward, that is, by turn

ing to the left. This permits the cone pulley cradle to hang more heavily on the belt and increases

the tension. When screw "E" is set for proper belt tension, lock the screw in place with lock nut

"D", Fig. 1.

2. Adjust knob, "G" until belt release crank returns to position "C", Fig. 3, so that when the crank is

closed from "C" to "A" the entire motor drive unit is locked tightly against adjusting screw "E".

Do not adjust too tightly. About five pounds pressure should be necessary to push the crank from

position "D" to position "A” when correct adjustment has been made on knob "G".

3. Set screw "E" has been omitted on some sizes of lathes. The cradle assembly being spring bal

anced, otherwise adjustment of belt tension is the same as described above and the same care

should be exercised not to get the belt too tight.

DECREASING CONE PULLEY BELT TENSION

1. Set the belt release crank in position "C", Fig. 3. Adjust screw "E", Fig. 1 inward, that is, by turn

ing the screw to the right until the proper tension is obtained on the belt. Lock screw "E" with lock

nut "D". Adjust knob "G" until the belt release crank returns to position "G", Fig. 3, and so that

about five pounds pressure is required to close it from position "C" to position "A". Lock knob

"G" with lock nut "F".

2. If the cone pulley belt should be too loose so that adjustment provided by knob "G" is not suffi

cient, the belt should be shortened by cutting out a piece not more than 3/4" long and resplicing

the belt. Adjustments are then made the same as for a new belt.

FITTING A NEW CONE PULLEY BELT

1. Set the belt release crank at position "C", Fig. 3.

2. Raise the cone pulley cradle up to the limit with adjusting screw "G", Fig. 1. Be sure that belt re

lease crank will travel from "A" to "B" in Fig. 3 without binding. If necessary drop the cradle

slightly so that the crank will work free.

3. Cut new belt'of proper length to reach around upper and lower cone pulleys. See book "How to

Run a Lathe' for correct method of cutting, gluing or lacing new belt.

4. With the belt glued or laced and in position with corresponding steps of the cone pulleys make ad

justments for proper belt tension as outlined above.

5. The belt release crank should be up in position "B" when gluing or lacing a belt to provide suffi

cient slack for working.

ADJUSTING THE MOTOR "V" BELT TENSION

The "V" Belt which connects the motor with the lower cone pulley shaft is adjusted by moving

the lock nuts on the adjusting screw, "L", Fig. 2, until the proper tension is secured. The "V" belt

should be just tight enough to transmit the full power of the motor without slipping. Keep oil off of

flat leather belt and "V" motor belts. Oil takes the life out of rubber belts and also causes them

to slip.

SOUTH BEND LATHE WORKS

You might also like

- 1936 - How To Cut Screw Threads in The Lathe - Bulletin 36ADocument24 pages1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AJason Bowman100% (1)

- Oneida Eagle BowDocument12 pagesOneida Eagle Bowbbireland80% (5)

- SingerDocument26 pagesSingerOmar Burgos MercadoNo ratings yet

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine PartsDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Partszakki ahmadNo ratings yet

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang SetiawanNo ratings yet

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFArnold Mhlanga50% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Woodworking For BeginnersDocument569 pagesWoodworking For BeginnersSaul Mejia60% (5)

- ShopNotes Issue 41 PDFDocument32 pagesShopNotes Issue 41 PDFbenignoNo ratings yet

- 66 - Series Singer 66 Sewing Machine ManualDocument16 pages66 - Series Singer 66 Sewing Machine ManualCynthia PorterNo ratings yet

- Construction - Bicycles, Dicycles Or Otto Type Machines And TricyclesFrom EverandConstruction - Bicycles, Dicycles Or Otto Type Machines And TricyclesNo ratings yet

- How To Make A Tool Post GrinderDocument5 pagesHow To Make A Tool Post Grinderozland9No ratings yet

- Manual 148.12071Document34 pagesManual 148.12071Kathleen Erland Kennedy100% (1)

- Instruction Manual: Singer Sewing Machine No. 66Document29 pagesInstruction Manual: Singer Sewing Machine No. 66Andy100% (5)

- White 664 Sewing Machine ManualDocument22 pagesWhite 664 Sewing Machine Manualgr8gee50% (4)

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaDocument7 pagesProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanNo ratings yet

- WheelHorse Side Mounted Sickle Mower Owners Manual 7-1311 - 375Document4 pagesWheelHorse Side Mounted Sickle Mower Owners Manual 7-1311 - 375Kevins Small Engine and Tractor ServiceNo ratings yet

- What To Consider When Digging Your Own Well - Water Well Drilling, Water Well, WellnessDocument2 pagesWhat To Consider When Digging Your Own Well - Water Well Drilling, Water Well, WellnessCyril Jean-BaptisteNo ratings yet

- White 628 XDocument27 pagesWhite 628 Xbmurray68100% (2)

- Sheet Metal Stamping 101 - Art HedrickDocument18 pagesSheet Metal Stamping 101 - Art Hedricktrollforge100% (1)

- 13 Ford Stake Bed 1929 PlanDocument45 pages13 Ford Stake Bed 1929 PlanJoseane Dias50% (4)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- The Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesFrom EverandThe Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesNo ratings yet

- VW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMDocument12 pagesVW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMAnonymous WzR5h9g8VNo ratings yet

- XQ28-2 6Y英文说明书Document26 pagesXQ28-2 6Y英文说明书ADM MTCNo ratings yet

- South Bend Taper AttachmentDocument6 pagesSouth Bend Taper AttachmentMikeNo ratings yet

- PlanetCNC TNGDocument421 pagesPlanetCNC TNGJavier JhamalNo ratings yet

- Potential Failure Mode and Effect Analysis: (Process Fmea)Document9 pagesPotential Failure Mode and Effect Analysis: (Process Fmea)SACHIN KUMARNo ratings yet

- C11 Valves and InjDocument7 pagesC11 Valves and Injraymon1191No ratings yet

- Viking Automatic 21Document11 pagesViking Automatic 21knulla din mammaNo ratings yet

- 945 - White S 2400 Dressmaker XDocument34 pages945 - White S 2400 Dressmaker XDarby Scott100% (1)

- AHS EHG Technical Paper No 22 - SynchronomeDocument6 pagesAHS EHG Technical Paper No 22 - SynchronomeMichelNo ratings yet

- Lifesport's Free Bike Repair GuideDocument7 pagesLifesport's Free Bike Repair GuideLifesport ShopsNo ratings yet

- 8-54 Lower U N It: AdjustmentDocument1 page8-54 Lower U N It: AdjustmentBranko FerenčakNo ratings yet

- Circular Machine Practical TrainingDocument70 pagesCircular Machine Practical TrainingLiyew WorkieNo ratings yet

- American Beauty Zig Zag 1300 Deluxe - ManualDocument32 pagesAmerican Beauty Zig Zag 1300 Deluxe - ManualJust4Him0% (1)

- FTW Weav 5Document59 pagesFTW Weav 5Kannan KumarNo ratings yet

- Fig GTR1: Aug-10 Gtrigb3 DsDocument3 pagesFig GTR1: Aug-10 Gtrigb3 DsmamatnamakuNo ratings yet

- Chapter ThreeDocument1 pageChapter ThreeStefan JakovljevicNo ratings yet

- Saurer Let Off Pawan NemadeDocument5 pagesSaurer Let Off Pawan NemadePavan NemadeNo ratings yet

- Zoje ZJ0628Document32 pagesZoje ZJ0628celadaNo ratings yet

- Bolens Models 1969 1972Document3 pagesBolens Models 1969 1972Paul MartinNo ratings yet

- 13) Rear Derailleur InstallationDocument4 pages13) Rear Derailleur InstallationKyrul NizamNo ratings yet

- Adjustable Pitch Propeller Taper-Lock HubDocument2 pagesAdjustable Pitch Propeller Taper-Lock HubhaosfNo ratings yet

- Ibanez Edge III ManualDocument27 pagesIbanez Edge III ManualIamNAlmasihinNo ratings yet

- FIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive ManualDocument8 pagesFIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive Manualnangkarak8201No ratings yet

- Service Manual Tandberg Td20aDocument41 pagesService Manual Tandberg Td20aangelescuo100% (1)

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p054Document1 pageToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p054sơn forkliftNo ratings yet

- Adjust ValveDocument3 pagesAdjust ValveAwanNo ratings yet

- EN Pilot-XPDocument6 pagesEN Pilot-XProssandcoNo ratings yet

- Installation Instructions: Balance BarsDocument2 pagesInstallation Instructions: Balance BarsTan Gin HuiNo ratings yet

- Edge Zero II TremoloDocument3 pagesEdge Zero II TremoloFikri Maulana AzhariNo ratings yet

- DPK 5 3 EnglishDocument4 pagesDPK 5 3 EnglishSooin LeeNo ratings yet

- Adjusting Hydraulic Conversion Brake-Park BrakeDocument2 pagesAdjusting Hydraulic Conversion Brake-Park Brakev53No ratings yet

- Ca M249Document13 pagesCa M249viqsenNo ratings yet

- 7 CP 06Document12 pages7 CP 06JackNo ratings yet

- SUN Grate Height Adjustment 01-23-20 BTDocument8 pagesSUN Grate Height Adjustment 01-23-20 BTPablo Gasca RmzNo ratings yet

- Ski Bee 1969 1970Document3 pagesSki Bee 1969 1970Paul MartinNo ratings yet

- Singer 20 U ManualDocument40 pagesSinger 20 U Manualjapa_ps67% (6)

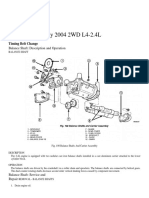

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- GS-X Sweep Release Assembly AdjustmentDocument2 pagesGS-X Sweep Release Assembly Adjustmentdick headNo ratings yet

- Pivot Bolt Pivot Bushing Lever Stop Adjustment: Installation InstructionsDocument1 pagePivot Bolt Pivot Bushing Lever Stop Adjustment: Installation InstructionsPaulo CostaNo ratings yet

- JD 2030 Kvačilo PDFDocument7 pagesJD 2030 Kvačilo PDFBranko Mikulinjak100% (1)

- Merlin Motorsport OBPDocument3 pagesMerlin Motorsport OBPMayur PatelNo ratings yet

- TappetDocument10 pagesTappetoronno5No ratings yet

- American Beauty 175 Zig Zag Automatic Sewing Machine InstructionsDocument27 pagesAmerican Beauty 175 Zig Zag Automatic Sewing Machine InstructionsiliiexpugnansNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Scottish TamDocument4 pagesScottish TamtrollforgeNo ratings yet

- Scurvy and Canadian ExplorationDocument7 pagesScurvy and Canadian ExplorationtrollforgeNo ratings yet

- Styrofoam Forced Air Egg Incubator V 2Document21 pagesStyrofoam Forced Air Egg Incubator V 2trollforgeNo ratings yet

- Ontario's Tree Atlas: What Trees Grow Best Where You Live?Document21 pagesOntario's Tree Atlas: What Trees Grow Best Where You Live?Zdravko VidakovicNo ratings yet

- Machining Fundamentals Instructor's Resource 05 Layout WorkDocument8 pagesMachining Fundamentals Instructor's Resource 05 Layout WorktrollforgeNo ratings yet

- Dye Penetrant InspectionDocument6 pagesDye Penetrant InspectionHabib ur RehmanNo ratings yet

- Esquemas de Medicion Con Pie de Rey y MicrometroDocument22 pagesEsquemas de Medicion Con Pie de Rey y MicrometroGiovanny muñozNo ratings yet

- South Bend Lathe Works - Shifting Cone Pulley and Adjusting Belt Tension + Drawing No 2500 - 1933 (Booklet Format)Document1 pageSouth Bend Lathe Works - Shifting Cone Pulley and Adjusting Belt Tension + Drawing No 2500 - 1933 (Booklet Format)trollforgeNo ratings yet

- 4129DraftControlGuide PDFDocument12 pages4129DraftControlGuide PDFtrollforgeNo ratings yet

- Pull-Engineering Workshop ManualDocument104 pagesPull-Engineering Workshop ManualtrollforgeNo ratings yet

- Medieval Combat, A 15th C Illustrated Manual of Sword Fighting and Close-Quarter Combat - Hans TalhofferDocument161 pagesMedieval Combat, A 15th C Illustrated Manual of Sword Fighting and Close-Quarter Combat - Hans TalhoffertrollforgeNo ratings yet

- Unmarked Cast Iron Cookware Identification - The Cast Iron Collector Information For The Vintage Cookware EnthusiastDocument18 pagesUnmarked Cast Iron Cookware Identification - The Cast Iron Collector Information For The Vintage Cookware EnthusiasttrollforgeNo ratings yet

- Rust Blue Multi SDS GHS Rev 2Document10 pagesRust Blue Multi SDS GHS Rev 2trollforgeNo ratings yet

- Rust Check Rust Converter - 11005 236ml - Eng NewDocument2 pagesRust Check Rust Converter - 11005 236ml - Eng NewtrollforgeNo ratings yet

- Care and Cleaning of Iron - CCI Notes 9-6Document4 pagesCare and Cleaning of Iron - CCI Notes 9-6Dan Octavian PaulNo ratings yet

- Chicago Electric Inverter Plasma Cutter - 35A Model 45949Document12 pagesChicago Electric Inverter Plasma Cutter - 35A Model 45949trollforgeNo ratings yet

- Root-Knot Nematodes in Your GardenDocument4 pagesRoot-Knot Nematodes in Your GardentrollforgeNo ratings yet

- Your Seed PacketDocument1 pageYour Seed PackettrollforgeNo ratings yet

- JerryCan LabelsDocument6 pagesJerryCan LabelstrollforgeNo ratings yet

- Spring Tempering SteelDocument1 pageSpring Tempering SteeltrollforgeNo ratings yet

- Kinetic Diamond Impregnated Drill BitsDocument4 pagesKinetic Diamond Impregnated Drill BitsLoganBohannonNo ratings yet

- 2 Chapter 2 Design of LocatorDocument39 pages2 Chapter 2 Design of LocatorKhaled HamdyNo ratings yet

- NZ Wood Design GuidesDocument48 pagesNZ Wood Design GuidesHiệp Nguyễn VănNo ratings yet

- How To Make A Skateboard (With Pictures) - WikiHowDocument10 pagesHow To Make A Skateboard (With Pictures) - WikiHowNelastaBandeiraNo ratings yet

- Workshop Practice DE-42 Mechatronics: SyndicateDocument6 pagesWorkshop Practice DE-42 Mechatronics: SyndicateibrahimNo ratings yet

- Sculpfun ParametersDocument2 pagesSculpfun ParametersShisharo CMNo ratings yet

- MB46 T-SlotDocument2 pagesMB46 T-Slotdarkarmy100No ratings yet

- "Nothing Too Strong Ever Broke": 5C Spindexer IndexerDocument13 pages"Nothing Too Strong Ever Broke": 5C Spindexer IndexerSushilkumar RajageNo ratings yet

- 2x4 BenchDocument11 pages2x4 BenchDan MatincaNo ratings yet

- Sr. KG Concept 1st Week AprilDocument8 pagesSr. KG Concept 1st Week AprilAdvocate JaniNo ratings yet

- Bandsaw Machine 8inDocument1 pageBandsaw Machine 8inManufaktur Sinar JoyoboyoNo ratings yet

- Workshop Technology Lab Viva Questions and AnswersDocument5 pagesWorkshop Technology Lab Viva Questions and AnswersDe vil100% (3)

- 金属车床说明书1835A (3) (1) (2) 1687946779071Document56 pages金属车床说明书1835A (3) (1) (2) 1687946779071philip coquelinNo ratings yet

- Jurassic Parts RulesDocument16 pagesJurassic Parts RulesSunnyNo ratings yet

- Owais Iqbal 1203-2021 QUIZ 1 WTDocument3 pagesOwais Iqbal 1203-2021 QUIZ 1 WTOwais IqbalNo ratings yet

- Electrical Hand Tools and Equipment's: Module in TLE 8Document4 pagesElectrical Hand Tools and Equipment's: Module in TLE 8Israel Marquez100% (2)

- The Putter ShedDocument4 pagesThe Putter ShedRonney GuerraNo ratings yet

- NIPL Stock ListDocument27 pagesNIPL Stock ListJaisheel DhandargiNo ratings yet

- Miyano Model Bnd-51Sy2 4-Axis Turning Center, Sub Spindle, Revolving Tool Attachment, & Y - AxisDocument20 pagesMiyano Model Bnd-51Sy2 4-Axis Turning Center, Sub Spindle, Revolving Tool Attachment, & Y - AxisViet LeNo ratings yet

- Cutting Tools in Industrial AutomationDocument22 pagesCutting Tools in Industrial AutomationShazeenNo ratings yet

- cm351 PartsDocument202 pagescm351 PartsRoger Lopez Gonzalez100% (1)

- N384518, DW616 RouterDocument7 pagesN384518, DW616 RouterOswaldo Diaz NievesNo ratings yet

- Build 137 27 Build Right Cantilevered DecksDocument2 pagesBuild 137 27 Build Right Cantilevered Deckssuejack2020No ratings yet