Professional Documents

Culture Documents

Manufacturing Technology - II (ME305) Quiz 1

Uploaded by

Gokul Singh0 ratings0% found this document useful (0 votes)

6 views2 pagesOriginal Title

quiz1 ME305

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesManufacturing Technology - II (ME305) Quiz 1

Uploaded by

Gokul SinghCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

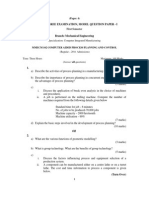

Manufacturing Technology – II (ME305)

Quiz 1

Course instructor: Prof. Harpreet Singh

Duration: 1hour (50min answering + 10min for scanning and uploading)

Total Marks: 30

1. What do you mean by cutter offset? (2 marks)

2. Suggest any three typical material handling equipment for “product type layout” (1mark)

3. Describe the principle of operation of self-guided vehicles? (2 marks)

4. In the context of NC positioning systems, how does ‘accuracy’ differ from ‘repeatability’?

Which factors effect accuracy and repeatability? (2.5 marks)

5. Explain the function of ‘position set’ feature of CNC system? (1mark)

6. How does an analog control differ from direct digital control? (3 marks)

7. Differentiate between a single-level interrupt system and a multi-level interrupt system? (2

marks)

8. When will you recommend use of adaptive control? (2 marks)

9. Illustrate the difference between process parameter and process variable with the help of an

example? (1mark)

10. Illustrate automation migration strategy with the help of a schematic diagram? (2marks)

11. One axis of an NC positioning system is driven by a stepping motor. The motor is connected

to a lead screw whose pitch is 4.0 mm, and the lead screw drives the table. Control resolution

for the table is specified as 0.025mm. Determine (a) the number of step angles required to

achieve the specified control resolution, (b) the size of each step angle in the motor, and (c)

the linear travel rate of the motor at a pulse frequency of 200 pulses per second. (4.5 marks)

12. Write an NC program to remove the material in the given diagram from points 2 to 7. You

just need to write the X and Y movement of the tool for every step. Use incremental

positioning system. (3.5marks)

13. Write the APT geometry statements to define the outline of the part in below figure. Use P0

as the origin in the x-y system. (3.5 marks)

----------------------------------------------------------------------------

You might also like

- MEC4108 CAT ONE 2022 Marking GuideDocument4 pagesMEC4108 CAT ONE 2022 Marking GuideMarvin kakindaNo ratings yet

- Computer Numerical ControlDocument28 pagesComputer Numerical ControlsaisenthNo ratings yet

- ExamMEC4108 15 16Document4 pagesExamMEC4108 15 16Marvin kakindaNo ratings yet

- UJ - MVS4 - Assessment#2 - 07 March 2022Document3 pagesUJ - MVS4 - Assessment#2 - 07 March 2022Dimakatso NgobeniNo ratings yet

- B.Tech.: NME-031/NPL-031 NME-031/NPL-031Document2 pagesB.Tech.: NME-031/NPL-031 NME-031/NPL-031Lakshita SharmaNo ratings yet

- Automation in ManufacturingDocument8 pagesAutomation in ManufacturingPradeepkumarKatgiNo ratings yet

- Mechatronics Question BankDocument9 pagesMechatronics Question BankVishwas ShettyNo ratings yet

- Answer All The Questions: From-To Data For The Parts Processed by The Machines Are Shown in The Table BelowDocument2 pagesAnswer All The Questions: From-To Data For The Parts Processed by The Machines Are Shown in The Table Belowbrahma2deen2chaudharNo ratings yet

- Sample Industry Internship ReportDocument3 pagesSample Industry Internship ReportKamarul NizamNo ratings yet

- Mmecm 102 Computer Aided Process Planning and ControlDocument4 pagesMmecm 102 Computer Aided Process Planning and ControlRaghu0% (1)

- Bài Tập Tiểu LuậnDocument5 pagesBài Tập Tiểu LuậnToy and MeNo ratings yet

- Model Examination: Hindusthan Institute of Technology, CoimbatoreDocument6 pagesModel Examination: Hindusthan Institute of Technology, CoimbatoreParama GuruNo ratings yet

- MTD AssignmentsDocument80 pagesMTD AssignmentsAdinath DhamdhereNo ratings yet

- Unit 1 Part 1.2Document6 pagesUnit 1 Part 1.2Abhishek KumarNo ratings yet

- CNC ManualDocument49 pagesCNC ManualThiagarajan VenugopalNo ratings yet

- NC, CNC & Robotics PDFDocument100 pagesNC, CNC & Robotics PDFSiddhrajsinh ZalaNo ratings yet

- B.Tech.: (Following Paper ID and Roll No. To Be Filled in Your Answer Book)Document3 pagesB.Tech.: (Following Paper ID and Roll No. To Be Filled in Your Answer Book)kapil kumarNo ratings yet

- Computer Aided Manufacturing (EME031)Document4 pagesComputer Aided Manufacturing (EME031)Hemant PalNo ratings yet

- CAM Question Paper AktuDocument2 pagesCAM Question Paper AktuAshutosh KumarNo ratings yet

- Closed-Loop Positioning SystemsDocument25 pagesClosed-Loop Positioning Systemsfarah nazNo ratings yet

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFHiru Purushothaman HirudayanathanNo ratings yet

- Mechatronics - UNIT1-FHDocument23 pagesMechatronics - UNIT1-FHsaba100% (3)

- Model Test Paper: ABES Institute of Technology, GhaziabadDocument2 pagesModel Test Paper: ABES Institute of Technology, GhaziabadYogesh Kumar GaurNo ratings yet

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFnagarajanceNo ratings yet

- CNC Report Bhel Haridwar Summer Training Report Electronic & CommunicationDocument29 pagesCNC Report Bhel Haridwar Summer Training Report Electronic & Communicationritika_arora19067% (3)

- Ch-11 NC CNC DNC FMS Automation and RoboticsDocument191 pagesCh-11 NC CNC DNC FMS Automation and RoboticsPrateek BayalNo ratings yet

- MCE 439 Assignment 3Document2 pagesMCE 439 Assignment 3Ammar1994No ratings yet

- Mechtronics QBDocument8 pagesMechtronics QBKarthik Perumal SwamyNo ratings yet

- Computer Numerical Control INDRADocument11 pagesComputer Numerical Control INDRAIndra Blue'DuatujuhNo ratings yet

- 07a81402 Flexible Manufacturing SystemsDocument4 pages07a81402 Flexible Manufacturing SystemsSharanya ThirichinapalliNo ratings yet

- Assignment o Tom at I OnDocument22 pagesAssignment o Tom at I OnphyrdowsNo ratings yet

- 254464.1 Car Mikac VezaDocument6 pages254464.1 Car Mikac VezaengrodeNo ratings yet

- SplitPDFFile 153 To 159Document7 pagesSplitPDFFile 153 To 159Sanjay DevNo ratings yet

- Department of Electronics & Instrumentation Engineering Continuous Internal Evaluation - 1 (Answer Key)Document8 pagesDepartment of Electronics & Instrumentation Engineering Continuous Internal Evaluation - 1 (Answer Key)Krushnasamy SuramaniyanNo ratings yet

- CNC NotesDocument21 pagesCNC NotesradhiostrokesNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document5 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Old Q.papers M.tech I SemDocument15 pagesOld Q.papers M.tech I SemallakagopichandNo ratings yet

- (3hours) : CompulsoryDocument7 pages(3hours) : CompulsorySaima ZainabNo ratings yet

- Act - Bank.newformat - Jan6 - 1230Document10 pagesAct - Bank.newformat - Jan6 - 1230Vijay RajuNo ratings yet

- Unit Wise Theory and Numerical Question BankDocument14 pagesUnit Wise Theory and Numerical Question BankVinayak GonelNo ratings yet

- Chapter-8: Advanced MachiningDocument7 pagesChapter-8: Advanced MachiningAniruddha Bartakke100% (1)

- Mechanism Final ProjectDocument14 pagesMechanism Final Projectsundari_murali100% (2)

- MecDocument5 pagesMecRajesh Kumar PNo ratings yet

- Speed Control Design For A Vehicle System Using Fuzzy LogicDocument8 pagesSpeed Control Design For A Vehicle System Using Fuzzy LogicMileNo ratings yet

- NR 422001 C Automation in ManufactureDocument8 pagesNR 422001 C Automation in ManufactureSrinivasa Rao GNo ratings yet

- AnnaDocument2 pagesAnnakannan_kcetNo ratings yet

- Nmam Institute of Technology: Department of Computer Science and EngineeringDocument8 pagesNmam Institute of Technology: Department of Computer Science and Engineeringsmitha shettyNo ratings yet

- Paper UksimDocument6 pagesPaper Uksimsattanic666No ratings yet

- Dcdrives2 QPDocument1 pageDcdrives2 QPKamaraj VijayarajanNo ratings yet

- MechatronicsDocument7 pagesMechatronicsmuralmohanNo ratings yet

- Hari Om Summer Training PPT CNCDocument44 pagesHari Om Summer Training PPT CNCAbhay TiwariNo ratings yet

- Design and Implementation of Large-Range Compliant Micropositioning SystemsFrom EverandDesign and Implementation of Large-Range Compliant Micropositioning SystemsNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- Advanced Techniques and Technology of Computer-Aided Feedback ControlFrom EverandAdvanced Techniques and Technology of Computer-Aided Feedback ControlNo ratings yet

- Nonlinear Control Feedback Linearization Sliding Mode ControlFrom EverandNonlinear Control Feedback Linearization Sliding Mode ControlNo ratings yet

- HS301 Assignment-2: Supervised By: Dr. AmriteshDocument15 pagesHS301 Assignment-2: Supervised By: Dr. AmriteshGokul SinghNo ratings yet

- HS301 Assignment-1Document11 pagesHS301 Assignment-1Gokul SinghNo ratings yet

- AppliDocument2 pagesAppliGokul SinghNo ratings yet

- Suryansh's Lecture-4 LogDocument1 pageSuryansh's Lecture-4 LogGokul SinghNo ratings yet

- Chemical Reaction Engineering First Semester of Academic Year 2021 - 2022 End-Semester ExaminationDocument3 pagesChemical Reaction Engineering First Semester of Academic Year 2021 - 2022 End-Semester ExaminationGokul SinghNo ratings yet

- AppliDocument2 pagesAppliGokul SinghNo ratings yet

- Nuclear Power Plant I: Chernobyl Reactor Meltdown: CH320 - Seminar IIIDocument47 pagesNuclear Power Plant I: Chernobyl Reactor Meltdown: CH320 - Seminar IIIGokul SinghNo ratings yet

- Instructions To The Candidate: Examination Centre: Centre Code: 5023 ID Number: Photo IDDocument1 pageInstructions To The Candidate: Examination Centre: Centre Code: 5023 ID Number: Photo IDNeeleshNo ratings yet

- CH331 - Process Control Lab Temperature Control in A Heat ExchangerDocument23 pagesCH331 - Process Control Lab Temperature Control in A Heat ExchangerGokul SinghNo ratings yet

- Log Report 2Document2 pagesLog Report 2Gokul SinghNo ratings yet

- Instructions To The Candidate: Examination Centre: Centre Code: 3015 ID Number: Photo IDDocument1 pageInstructions To The Candidate: Examination Centre: Centre Code: 3015 ID Number: Photo IDGokul SinghNo ratings yet

- The Protective Barriers. Immediately: The Core Cooling Systems Fine. They Put LargeDocument2 pagesThe Protective Barriers. Immediately: The Core Cooling Systems Fine. They Put LargeGokul SinghNo ratings yet

- Manufacturing Technology - II (ME305) Quiz 1Document2 pagesManufacturing Technology - II (ME305) Quiz 1Gokul SinghNo ratings yet

- Log Report 3Document1 pageLog Report 3Gokul SinghNo ratings yet

- Production of Biogas From Cow and Buffalo Dung Problem-In Villages Most of The Villagers Burn Woods After Cutting The Trees To Use Them ForDocument2 pagesProduction of Biogas From Cow and Buffalo Dung Problem-In Villages Most of The Villagers Burn Woods After Cutting The Trees To Use Them ForGokul SinghNo ratings yet

- Log Report 3Document1 pageLog Report 3Gokul SinghNo ratings yet

- Temperature Control in Heat ExchangerDocument26 pagesTemperature Control in Heat ExchangerGokul SinghNo ratings yet

- JKT Esa Vu Finm+K Oxz Esa 'Kkfey Tkfr@Oxz DH LWPH: State List of ObcDocument2 pagesJKT Esa Vu Finm+K Oxz Esa 'Kkfey Tkfr@Oxz DH LWPH: State List of ObcAnand KirtiNo ratings yet