Professional Documents

Culture Documents

(Woodworking Plans) Table Saw Cabinet

(Woodworking Plans) Table Saw Cabinet

Uploaded by

RizkiMohamadReza0 ratings0% found this document useful (0 votes)

10 views8 pagesOriginal Title

[Woodworking Plans] Table Saw Cabinet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views8 pages(Woodworking Plans) Table Saw Cabinet

(Woodworking Plans) Table Saw Cabinet

Uploaded by

RizkiMohamadRezaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

from

Woodsmith

MAGAZINE

Table Saw Cabinet

This cabinet is just what I’ve always are long, see grain direction in Fig.

wanted for my table saw. It adds 5.)

weight and stability, it rolls away DIVIDERS. Finally, cut the two

for storage, it has a sawdust col- dividers (D and E) to a length of

lection system in the cabinet, and it 1713/16" and to a width of 231/2", see

turns all the wasted space under Fig. 3. (Note: These dividers are

1

the saw into much-needed storage. /4" narrower than the other pieces

But before getting into the con- to allow for a 1/4" back.)

struction of the cabinet, something

RABBETS AND DADOES

should be said about its size. This

cabinet will comfortably support a Once the six major pieces were

Sears 10" table saw or a Delta cut to size, I laid out the positions

(Rockwell) 10" Contractor’s Saw. of the rabbets and dadoes used to

(The overall width of the cabinet is join them together.

sized to fit under the saw with It’s important to lay out these

extension wings.) cuts so there will be mirrored sets.

The height of the cabinet shown To keep things straight, I marked

here is 231/2" (with casters). This the front and back edges of each

puts the working height of both the piece, and also the face that will

Sears and Delta saws at 361/4" have all the cuts, see Fig. 5.

(which is the same as the Sears saw BACK RABBETS. Start by laying

on a Sears stand, but 2" higher than out and cutting rabbets for the 1/4"

the normal Delta setup.) Masonite back. These rabbets are

on the inside back edge of the top/bottom

CUT PIECES TO SIZE TOP/BOTTOM. First, cut the top/bottom pieces (A) and the inside back edge of both

I started work on the cabinet by cutting pieces (A) to a length of 39" and to a width ends (B and C), see Back Rabbet Detail in

the six main pieces (the top/bottom, ends, of 233/4", see Fig. 1. Fig. 4.

and dividers) to final size from a 4’x8’ sheet ENDS. Next cut two end pieces (B and C) Note: To keep things simple, all of the

of 3/4" birch plywood. (Birch is a little more to a length of 20" and to the same width as rabbets, dadoes, and grooves for the basic

expensive than CDX fir plywood, but the the top/bottom pieces (233/4"), see Fig. 2. cabinet are cut to a common depth of 1/4",

final appearance is worth it.) (Note: These pieces are wider than they only the width varies.

MATERIALS LIST CUTTING DIAGRAM

Overall Dimensions:231/2"h x 40"w x 241/4"d !/2” x 3!/2” - 72” !#/16” x 3!/2” - 72”

A Top/Bottom (2) 3/4" ply. x 233/4 - 39 M M M M M K K K K U

B Left End (1) 3/4" ply. x 233/4 - 20 !/2” x 3!/2” - 72” !#/16” x 5!/2” - 72”

C Right End (1) 3/4" ply. x 233/4 - 20 M M M O O L L L L H

D Left Divider (1) 3/4" ply. x 231/2 - 1713/16 !/2” x 5!/2” - 72”

!#/16” x 5!/2” - 72”

E Right Divider (1) 3/4" ply. x 231/2 - 1713/16 N N N N N S

R

F Drawer Runners (16) 1/2 x 3/4 - 13 !/2” x 5!/2” - 72”

3/4" ply. x 121/2 - 175/16

G Separators (2) N N N P P

H Shelf Cleats (4) 13/16 x 1 - 175/16

!/2” x 5!/2” - 72” NOTE: CUT !/4”-THICK TRIM

1/4" Mas. x 1713/16 - 39 STRIPS FROM WASTE

I Back Panel (1) P P O O W

J Shelves (2) 3/4" ply. x 73/4 - 121/2 V V ALSO REQUIRES

13/16 x 31/4 - 117/8

!/2” x 5!/2” - 48” !/8” PEGBOARD 12” x 24”

K Sm. Drwr. Fronts (4)

13/16 x 51/4 - 117/8 F F F

L Lrg. Drwr. Fronts (4)

1/2 x 31/4 - 133/4

M Sm. Drwr. Sides (8)

1/2 x 51/4 - 133/4 #/4” PLYWOOD 48” x 96” !/4” MASONITE 48” x 48”

N Lrg. Drwr. Sides (8)

1/2 x 23/4 - 111/4

O Sm. Drwr. Backs (4)

1/2 x 43/4 - 111/4 G

P Lrg. Drwr. Backs (4) I

Q Drawer Bottoms (8) 1/4 Mas. x 111/4 - 13 A B D

13/16 x 2 - 103/8

R Catcher Fr/Back (2)

13/16 x 2 - 181/8

G

S Catcher Sides (2)

1/4" Mas. x 11/4 - 185/8 Q Q Q Q

T Catcher Runners (2)

13/16 x 11/4 - 21 Y

U Catcher Cleats (2) J

V Door Stiles (2) 1/2 x 11/4 - 173/16

A C E Y

W Door Rails (2) 1/2 x 11/4 - 107/8 J Q Q Q Q

1/8" peg. x 107/8 - 153/16

X Door Panel (1) Y Y T T

3/4" ply. x 4 - 5

Y Caster Pads (4)

Plans NOW page 1 © 1998, August Home Publishing Co.

BOTTOM RABBETS. Next, lay out and cut FIGURE 1

the rabbets to join the bottom to the ends.

These rabbets are on the bottom edge of

both end pieces (B and C), see Bottom !/4” x !/4”

Rabbet Detail in Fig. 4. BACK RABBET

(SEE FIG. 4)

Note: The width of these rabbets should

equal the actual thickness of the plywood 23#/4”

which is usually a little shy of 3/4" for hard- !/4” x #/4”

A

wood plywood. But to keep things simple, DIVIDER DADO TOP/BOTTOM

(SEE FIG. 4)

all measurements are shown as 3/4".

TOP DADO. Now lay out the position of

FRONT

the dadoes that are used to join the top (A) EDGE

to the ends (B and C). To determine the

location of these dadoes I wanted to plan 12!/4” 12!/4”

ahead to allow enough space for the draw- 39”

ers below it. This requires an overall open-

ing of 175/16" for two 31/4"-high drawers and FIGURE 2 !/4” x #/4” SEPARATOR FIGURE 4

two 51/4"-high drawers with a 1/16" gap 1#/16” GROOVE (SEE FIG. 4)

ENDS

between each drawer and the cabinet.

When I had this measurement I worked 3” !/4” x !/4”

from the bottom edge up - allowing 3/4" for 6%/16”

BACK

RABBET

BACK

the bottom rabbet (refer to Fig. 2), plus RABBET

(SEE FIG. 4) DETAIL

9%/8” !/4”

175/16" for the drawers, plus 3/4" for the thick-

ness of the top (A). This left 13/16" as the 20” !/4”

measurement from the top edge to the top 14!%/16”

!/4” x #/4”

of the dado, see Fig. 2. (This position cre- BOTTOM

ates a raised edge to keep things from slid- RABBET

FRONT (SEE FIG. 4)

ing off the cabinet, refer to photo.) EDGE

DRAWER RUNNER DADOES. After the top

dadoes are cut, there are four more dadoes !/4” x #/4” 14”

DADO BOTTOM

for the drawer runners in the end pieces (B (SEE FIG. 4) 23#/4” RABBET

and C) and dividers (D and E), see Figs. 2 DETAIL

and 3. However, the problem with laying #/4”

FIGURE 3 !/4” x #/4” SEPARATOR

out these cuts is that you’re not working 1%/16” GROOVE (SEE FIG. 4)

DIVIDERS

with the same measurements on the ends !/4”

as on the dividers. The ends have to accom-

modate the top and raised edge that 4%/8”

extends above the top.

7!%/16”

To lay out the first (top) runner dado on !/4” x #/4”

the ends (B and C), measure down 3" from 13!/4”

DADO

(SEE FIG. 4)

the top edge. Then continue to work your

TYPICAL #/4”

way down laying out the remaining dadoes DADO/

as shown in Fig. 2. 17!#/16” GROOVE

DETAIL

Note: All of the measurements for the

!/4”

positions of the dadoes (shown in Figs. 2 14” FRONT

and 3) are taken from the top edge of the EDGE

23!/2”

workpiece to the top edge of the dado. This

is the same measurement needed when set- FIGURE 5

ting up the saw - it’s the measurement from

the fence to the dado blade.

RUNNER DADOES ON DIVIDERS. The top A

runner dado on the dividers (D and E) is TOP E

B RIGHT

only 15/16" from the top edge, see Fig. 3. LEFT DIVIDER

Note: For ease of construction on a table END

saw, we’ve shown all of the runner dadoes

going all the way to the back of the cabinet.

But the drawers only run part of the way

back. To get a slightly neater appearance,

you could use a router and stop the dadoes

14" from the front edge. D

SEPARATOR GROOVES. After the runner LEFT

dadoes are cut, lay out and cut the vertical DIVIDER C

grooves for the separators (G) that divide RIGHT

END

the drawer compartments from the shelf

compartments, refer to Figs. 7 and 8 on

page 3. Locate these grooves 14" from the A

front edge of the ends and dividers, see BOTTOM

Figs. 2 and 3.

Plans NOW page 2 © 1998, August Home Publishing Co.

FIGURE 6 DETAIL DRAWER RUNNERS

F !/2”

DRAWER !/16” After the rabbets, dadoes, and grooves are

13” RUNNER CHAMFER cut in the six main pieces, work can begin

on the drawer runners.

#/4”

Start by cutting 16 runners (F) 1/2"-thick

and to width to match the dadoes, see Fig.

6. To help guide the drawers into place, I

14” sanded a slight chamfer on the front corner

NOTE: NOTE: of each runner, see Detail in Fig. 6.

NO RUNNER ALIGN DRAWER RUNNER After the runners are cut to size, glue

IN TOP DADO BOTTOM FLUSH WITH FRONT EDGE

FRONT RABBET them in so the front of each runner is flush

EDGE

with the front edge of the end or divider.

FIGURE 7 CUT FROM TOP VIEW SEPARATORS AND SHELF CLEATS

#/4” PLYWOOD 4/4 STOCK

2” There’s a separate compartment in the back

!/4” DIA. THROUGH H of the cabinet that has space for shelves, see

HOLES FOR 3!/2”

SHELF SUPPORTS SHELF SHELF DRAWER Top View in Fig. 7. The shelves are held up

SUPPORT COMPART- COMPARTMENT

CLEATS MENT with L-shaped pin-style shelf supports, see

(FOUR NEEDED) Detail in Fig. 12.

3!/2” SEPARATORS. To hold the shelf supports

RIGHT (and also give the cabinet rigidity), I cut 3/4"

G

DIVIDER plywood separators (G) to fit between the

17%/16” FRONT

SEPARATORS EDGE ends and dividers, see Figs. 7 and 8.

(TWO NEEDED) #/16” DIA. BACK SHELF SUPPORT CLEATS. Then to hold the

COUNTERSUNK RABBET

SHANK HOLES LEFT shelf supports at the back of the cabinet, cut

DIVIDER

3!/2”

FOR MOUNTING

CLEATS

four cleats (H) from 4/4 stock (13/16" actual

thickness) to a width of 1" and the same

length as the separators, see Fig. 7.

2” SHELF SUPPORT HOLES. After the separators

3!/2” SUPPORT

CLEATS SEPARATOR and cleats are cut to size, drill 1/4" holes for

the pin-style shelf supports, see Fig. 7. To

#/4” #/4” keep the holes aligned in all the pieces, I laid

12!/2” 1”

out the holes centered on one of the cleats

and then used that cleat as a drilling guide

FIGURE 8 for the other cleats and separators. (Note:

A

TOP Since the separators fit into 1/4"-deep

grooves, center the holes in the separators

3

/4" in from the edges.)

To make the pieces completely inter-

changeable (which makes assembly easi-

er), I drilled the holes completely through

the cleats and separators and kept the holes

C a uniform distance from each end.

RIGHT G D

END LEFT MOUNTING HOLES. Next, to mount the

SEPARATOR DIVIDER cleats to the cabinet, drill three counter-

sunk holes in each cleat, see Fig. 7.

ASSEMBLY

B Once the holes are drilled, assembly can

LEFT END begin. To check that everything fits as it

A

BOTTOM should, I started by dry assembling the

E entire cabinet with screws (counterboring

H RIGHT

DIVIDER the screw holes, see Screw Detail in Fig.

#8 x 1!/2” Fh SHELF

WOODSCREW SUPPORT BACK VIEW 10.) Once I was sure the cabinet was square,

CLEATS I took out the screws and then applied glue

before screwing it back together.

FIGURE 9 FIGURE 10 The procedure I used for assembly was

END to start by attaching the dividers (D and E)

H SCREW CLEAT

SHELF DETAIL to the top and bottom aligning the front

SUPPORT POSITION COUNTERBORE edges, see Fig. 8. Next, fit the separators

CLEAT CLEAT FLUSH

BOTTOM FOR !/2” DIA.

WITH INSIDE PLUG (G) into the grooves in the dividers and

EDGE OF

RABBETS glue and screw from the inside. Then attach

the ends (B and C) to the top, bottom, and

dividers. And finally, glue and screw in the

shelf support cleats (H), see Fig. 9.

#8 x 1!/2” Fh DRILL #/32” PILOT HOLE

WOODSCREW FOR #8 x 1!/2” DRILL #/16” DIA. Now plug all the counterbored screw

Fh WOODSCREW SHANK HOLE holes, see Fig. 10.

Plans NOW page 3 © 1998, August Home Publishing Co.

SHELF COMPARTMENT OPENING FIGURE 11 SABRE SAW DETAIL

When the basic cabinet is assembled, open- LEFT

END

ings can be cut in the ends so the shelf com- SEPARATOR

partments can be reached from the sides of DRILL

#/8” DIA.

the cabinet, refer to Fig. 12. To get a clean CORNER

opening in the plywood, there’s a nifty trick HOLES

using a sabre saw and a router. SHELF

FINISHED !/8” SUPPORT

Start by standing the cabinet up on end OPENING HOLE

LINE

and lay out the opening with a pencil. (The ROUTER DETAIL

opening corresponds to the inside edges of !/8” SABRE SAW

the cleat, top, bottom and separator.) CUT LINE FLUSH

SEPARATOR

TRIM

Next, drill 3/8" holes at each corner about BIT

1

/8" inside the penciled outline, see Fig. 11.

Then rough cut the opening with a sabre

saw staying about 1/8" inside the outline, BALL BEARING SHELF

see Sabre Saw Detail in Fig. 11. BOTTOM PILOT SUPPORT

HOLE

Now comes the trick. To clean up the

last 1/8", I used a flush trim router bit with

FIGURE 12 !/4” THICK

a ball bearing pilot. The pilot runs against TRIM STRIP

the inside of the cleat, top, bottom, and sep-

arator while the cutter trims up the last

1 FILLERS

/8" of plywood, see Router Detail in Fig. (SEE FIG. 14)

11. SHELF

J

BACK PANEL. Next, cut the back panel (I)

CUT TO FIT

from a piece of 1/4" Masonite to fit the back FROM #/4”

opening created by the rabbets, and nail it PLYWOOD

to the back edges of the dividers, see Fig.

12. BACK TRIM

SHELVES. Then cut the shelves (J) from PANEL STRIP

3 I

/4" plywood to fit in the shelf compart-

ments, see Fig. 12. SHELF

4d

TRIM AND FILL FINISHING

NAIL

To cover all the plywood edges on the cab-

inet and shelves, rip some 1/4"-thick trim

strips from 4/4 stock, see Step 1 in Fig. 13. BACK VIEW !/4” THICK

Then cut them to width to match the thick- TRIM STRIPS PIN STYLE

ness of the plywood, Step 2 in Fig. 13. SHELF SUPPORT

ADD THE STRIPS. Now glue and nail the

trim strips on with 1" brads and set the FIGURE 13 NOTE: USE THIN PUSH STICK FIGURE 15

heads, see Fig. 14. (Note: The trim strips RIP RIP

on the back edges of the cabinet hold in the FENCE FENCE CUT OUT

BACK SAWDUST FRONT

back panel.) Finally, round over the top CUT TRIM RIP TO WIDTH EDGE OPENING EDGE

STRIPS FROM TO MATCH

edges with a 1/8" round-over bit. 4/4 STOCK THICKNESS

FILL THE GAPS. After adding the trim !/4” OF PLYWOOD

strips, there are a couple gaps on the inside RIGHT

top of the ends that should be filled. (These DIVIDER

gaps were created when the grooves and

1!/2”

rabbets were cut.) To fill the gaps I cut a

couple pieces of scrap and glued them in

place, see Fig. 14.

FIGURE 14

!/8”

SAWDUST OPENING ROUNDOVER

2!/2” 13” 10”

There’s one more step to complete the basic

cabinet - cutting the sawdust opening in

the top. This opening allows the dust and

chips to collect in a plastic trash bag mount-

ed inside the cabinet. FILLERS CUT 1!/2”

Cut a 10" x 13" opening 21/2" from the TO FIT FROM

SCRAP

back edge of the top and centered between !/4”

LEFT

DIVIDER

the dividers (D and E), see Fig. 15. (Note: THICK

TRIM

This opening will fit both the 10" Sears and STRIPS

Delta/Rockwell saws. For other saws,

GLUE AND

check the opening on the saw and cut a cor- NAIL TRIM BACK

STRIPS ON PANEL

responding opening in the cabinet.) I

TOP VIEW

WITH

1” BRADS NOTE:

SET BRADS

AND FILL HOLES

Plans NOW page 4 © 1998, August Home Publishing Co.

FIGURE 16

THE DRAWERS

JOINT DETAIL #/16”

After the cabinet is complete, the eight

DRAWER CONSTRUCTION #/8” %/8” drawers can be built to fit the openings.

!/2” STOCK There are two drawer heights, but they’re

11!/4”

TACK !/4” MASONITE

both constructed the same way.

BOTTOM TO BACK DRAWER FRONTS. Begin by cutting the

WITH BRADS SIDE BACK

BACK SIDE fronts (K) for the four small drawers from

Q 4/4 stock to a width of 31/4" and the fronts

BOTTOM (L) for the four large drawers to a width of

!/4” MASONITE

51/4", see Fig. 16. To determine the length

!/2” of all the fronts, measure the cabinet open-

FRONT 11&/8” ing and subtract 1/8" to allow for a 1/16" gap

!/2” on each side.

CENTER PULL 1%/8” STOCK

FROM TOP EDGE DRAWER SIDES. Next, cut eight small

OF EACH DRAWER drawer sides (M) and eight large drawer

13#/4”

1&/8” sides (N) from 1/2" stock to match the width

DRAWER SMALL DRAWER

RUNNER HEIGHT = 3!/4” of the fronts, and cut them all to a common

4/4 STOCK !/2”

GROOVE LARGE DRAWER

HEIGHT = 5!/4”

length of 133/4", see Fig. 16.

#8 x 1” Fh

WOODSCREW The drawer sides have two grooves. Cut

FRONT !/4”

one groove 13/16" wide on the outside of each

FIGURE 17 FIGURE 18

drawer side for the drawer runners to slide

!/4” in. Also, cut a 1/4"-wide groove on the inside

of each drawer side and drawer front to

1” !/4” ROUNDOVER accept the 1/4" bottom, see Fig. 18.

DRAWER AFTER ASSEMBLY

RUNNER !#/16” JOINTS. The drawer sides are joined to

SMALL DRAWER

3!/4” the fronts with rabbet joints that are

!/16” GAPS !/4”

secured with screws. Cut the rabbets on the

3!/4” drawer fronts to match the thickness of

#/16” the drawer sides (1/2"), see Detail in Fig.

16.

1” !/4” ROUNDOVER

AFTER ASSEMBLY Then to accept the drawer back, cut a

5!/4” 1/2"-wide dado on the inside of the drawer

!#/16”

sides 3/8" from the back edge.

LARGE DRAWER

DRAWER BACKS. Now cut the drawer

5!/4” !/4”

1%/8” TYPICAL backs (O and P) from 1/2" stock to fit

between the dadoes in the sides and wide

!/16” GAPS

!/4” enough to rest on top of the drawer bottoms

(right at the top of the grooves).

Now clamp the drawer together and drill

#/16” countersunk screw holes through the sides

FIGURE 19 CUT ALL PIECES FIGURE 20 and into the front and back, see Fig. 16.

R FROM 4/4 STOCK SIDE !/2” DRAWER BOTTOMS. Temporarily screw

BACK !/4”

FRONT the drawer together, and measure and cut

4/4

eight drawer bottoms (Q) from 1/4" Masonite

S STOCK to fit in the grooves and under the back.

SIDE 2” Now assemble each drawer with glue and

#8 x 1!/2” Fh

WOOD screws. Then slide in the bottom, and nail

10#/8” CORNER 4/4 SCREW it to the drawer back.

DETAIL STOCK When the drawer is dry, round over the

18!/8” R

FIGURE 21 ROUTER

inside top edges. Then mount a pull on the

FRONT front of each drawer, see Fig. 16.

CHIP CATCHER TABLE

CONSTRUCTION #8 x 1!/2” Fh 1” FENCE

WOODSCREW CHIP CATCHER

CHIP

CATCHER The chips and sawdust that fall through

FIGURE 22 #8 x 1” Fh ON EDGE

WOODSCREW the opening in the top of the cabinet are

caught in a plastic trash bag. To hold the

!/2” CORE !/4” bag (and make it easier to pull out for emp-

BOX BIT tying), I built a chip catcher frame.

FRAME. Start by cutting the front/back

FIGURE 23 pieces (R) from 4/4 stock to a width of 2" and

1!/4”

ALIGN WITH

INSIDE EDGE

a length of 103/8", see Fig. 19. Then cut two

18%/8” sides (S) 2" wide and 181/8" long.

Now cut rabbets on the front and back

MASONITE

T CHIP RUNNER pieces, and screw the frame together, see

CHIP CATCHER Fig. 20.

CATCHER SIDE

RUNNER KEEPER GROOVE. The trash bag is held

!/4” THICK x 1!/4” WIDE to the frame with a large rubber band or

MASONITE SIDE FRONT

“bungee” tie-down cord that fits in a cove

Plans NOW page 5 © 1998, August Home Publishing Co.

around the frame. To cut the cove, use a FIGURE 24

1/2" core box bit on the router table and rout FIGURE 25 CHIP

CROSS SECTION CATCHER

all four sides of the frame, see Fig. 21. CLEATS

RUNNERS. The frame is held in the cabi- #8 x 1!/2” Fh TOP

WOODSCREW

net with 1/4" Masonite runners (T) that ride

on top of a couple cleats, refer to Fig. 25.

Screw the runners down to the top edge of

the frame so the inside edge is flush with

the inside of the frame, see Figs. 22 and %/16

23.

CLEATS. Next, cut two cleats (U) from U

4/4 stock to a width of 11/4" and a length of CLEAT

21". To help guide the frame into place, CLEAT

DETAIL

chamfer the top front corner of the cleats,

see Cleat Detail in Fig. 25. BUNGEE CHAMFER

CORD 1!/4”

Now screw the cleats to the dividers 21/4"

from the front of the cabinet and down from

TRASH

the top, see Figs. 24 and 27. BAG

!#/16” 21”

DOOR

After I was sure the chip catcher would FIGURE 26

10&/8” !/8” GROOVE, !/4” LONG STUB TENON

slide easily into the opening, I began work 10#/8” !/4” DEEP CUT TO FIT GROOVE

on the door that covers the chip catcher CENTERED ON

W RAIL THICKNESS

opening. The door is made with a pegboard OF STOCK

panel that provides additional space to hang 1!/4”

tools and saw blades. 2” RAIL

5”

STILES AND RAILS. I built the door using

stub tenon and groove joinery (see DRILL HOLES

Woodsmith No. 29 for more on making this X

TO MATCH STILE

joint). First, cut the stiles (V) from 1/2" stock HANDLE

DOOR PANEL

to a width of 11/4" and 1/8" less in length than V !/8” PEGBOARD

the height of the opening, see Fig. 26. Then STILE

measure the width of the opening and cut 15#/16” 17#/8”

the rails (W) to length, subtracting the

V

width of both stiles and a 1/16" gap on both 10&/8” MORTISE

sides of the door, and adding an allowance SLIGHTLY

LESS THAN

for the 1/4"-long stub tenons on each end. THICKNESS

(In my case, this made the rails 107/8" long.) OF HINGE

KNUCKLE

GROOVES AND TENONS. Now cut 1/8"-wide

grooves (to accept the 1/8" pegboard panel)

on the inside edge of each stile and rail. 1!/4” W

Then cut stub tenons on the ends of the 1!/4”

rails to match the grooves.

PEGBOARD PANEL. After the tenons are

cut, dry assemble the frame, and cut the FIGURE 27 CHIP TOP VIEW

pegboard panel (X) to size to fit in the CATCHER MAGNETIC

CLEAT CATCH

grooves, see Fig. 26. Then glue the frame DOOR

together with the panel in the grooves. CATCH PLATE

HINGE MORTISES. Once the door is glued

together, cut 2"-long hinge mortises in the LEFT RIGHT

DIVIDER 2!/4” DIVIDER

left stile, see Fig. 26. (Note: Mortise to a 2” BUTT

CENTER DOOR

1!/4” HANDLE ON STILE

depth slightly less than the thickness of HINGE

the hinge knuckle.) Then mount the hinges

in the mortises, and mount the door to the TRIM STRIP

inside of the opening so that the face sets

back 11/4" from the front edge of the cabi- FIGURE 28 FIGURE 29

net, see Fig. 27. WASHER

!/4” x 1!/2” WASHER !/4” x 1”

HANDLE AND CATCH. To complete the door LAG SCREW LAG SCREW TABLE SAW

add a handle (pull), and mount a magnetic !/4” x 1” MOUNTING

SQUARE FLANGE

catch to the divider and catch plate on the MASONITE

back of the door, see Fig. 27. SPACER

CASTER PADS. To hold casters to the bot- !/2”

!/2”

tom of the cabinet, I glued caster pads (Y)

on each of the corners. Then I screwed the

casters to the pads, see Fig. 28.

FINISHING. I finished the cabinet with 4”

three coats of Deft Clear Wood Finish, and 5” CHIP CLEAT

CASTER CATCHER

then screwed the saw to the top with lag Y PAD

screws and Masonite spacers, see Fig. 29. #/4” PLYWOOD

Plans NOW page 6 © 1998, August Home Publishing Co.

Outfeed Table

After building the table saw cabinet, I

decided to add an outfeed table. I wanted

this table to be permanently attached to

the saw (not a separate unit that has to be

set up each time you use it - like a roller

stand).

I also wanted to be able to fold the out-

feed table down so the saw could be rolled

against a wall. This design does just that.

(And it can be built to fit any saw, with or

without the cabinet.)

ARMS

The outfeed table is supported by two arms

(A) that are attached to the extension wings

of the table saw, see Fig. 1. Begin by cut-

ting these arms from 4/4 stock (13/16" actu-

al thickness) to a width of 31/2" and a length

of 40".

Note: This length assumes the table saw

top is 27" deep - that’s typical for most 10"

Sears and Delta/Rockwell saws - so the

arms project 13" behind the saw.

LAG SCREW SLOT. The outfeed table is

held to the arms and pivots to the “down”

position on two lag screws. These screws

slide in 1/4"-wide slots routed into the arms.

To make these slots, first drill two 1/4"-dia. the arms to the saw with 1/4" bolts, see cut it to a length of 24". (Note grain direc-

end holes centered on the width of each Detail in Fig. 1. (The holes are drilled over- tion in Fig. 2.)

arm and 81/2" apart, see Fig. 1. Now clean size to allow for final adjustment.) MITER GAUGE SLOTS. Since the saw’s

out the area between the holes with a 1/4" miter gauge often gets pushed beyond the

THE TABLE back of the saw, miter gauge slots have to

straight bit on the router table (or with a

hand-held router and edge guide). Rout in After the arms are securely mounted, work be cut into the outfeed table. To determine

a series of passes increasing the depth until can begin on the outfeed table. The table the location of these slots, I clamped the

the bit cuts through the workpiece. is made out of a piece of 3/4" plywood fas- plywood top into place between the arms.

NOTCH FOR RAIL. After the slot is routed, tened to the top of a support frame, see Then I transferred the location of the

cut a notch in the right arm to fit around Fig. 2. slots to the plywood and routed the slots

the saw’s rear rip fence rail, see Fig. 1. (I PLYWOOD TOP. To determine the width of slightly wider than the existing saw slots.

cut a 2"-deep by 21/4"-wide notch. This fits the plywood top (B), measure the distance FRAME SIDES. Next, the support frame

around the rails on most saws.) between the arms, and cut the top about can be built. Start by cutting two frame

1/16" less than this measurement so it won’t sides (C) to a width of 11/2" and to the same

TRIM OFF CORNERS. Next, to break the

sharp corners, I trimmed a 45° angle off bind between the arms, see Fig. 1. Then length as the plywood top (24").

the bottom corners of the arms and rout- FIGURE 1

40”

ed a 1/8" chamfer on the outside edges, see 10#/4” 2!/4”

Bolt Detail in Fig. 1.

ATTACHING THE ARMS. The arms are bolt- 1#/4” 2” NOTE:

3!/2” A NOTCH ONLY ONE ARM

ed to the outside edges of the saw exten- FOR REAR RIP FENCE RAIL 1!/4”

sion wings (or the table itself if it doesn’t

1#/4” 8!/2” !/4”

have extensions), see Bolt Detail in Fig. 1. WIDE

(Note: If the table top or extensions don’t SLOT

RIP FENCE BOLT DETAIL

have holes in the edges, drill two 1/4"-dia. RAIL ALIGN ARM FLUSH WITH

TOP OF TABLE SAW

holes near each end.)

Then to locate the bolt holes in the arms,

clamp the arms to the edge of the table

with the top edge of the arm aligned flush %/16”

DIA.

with the table saw top. Reach under the HOLE

table and mark through the bolt holes. !/4” x 1!/2”

BOLT

Once the holes are marked, remove the !/8”

PLYWOOD TOP EQUALS !/16” LESS

arms from the saw, and drill a 5/16"-dia. THAN DISTANCE BETWEEN ARMS CHAMFER

(oversized) hole at each mark. Then bolt

Plans NOW page 7 © 1998, August Home Publishing Co.

Now clamp these pieces under the ply- FIGURE 2 CHAMFER OUTSIDE FIGURE 3

wood top flush with the edges, and drill 24” EDGES !/8” CROSS SECTION

counterbored screw holes, see Fig. 3.

SCREW

STRETCHERS. After the top is screwed B HOLE

down to the sides, measure the distance PLUGS #/8”

NOTCH IS CUT SO

between the sides. In my case this was TABLE SAW GUARD

CAN BE TIPPED TO

385/16". Then cut two stretchers (D) to this A FULL 45° STRETCHER #/4”

length. D

Now screw one stretcher under the far C

#8 x 1!/4”

end of the table and another 101/2" from the C

WOOD-

SCREWS

near end, see Fig. 2. Finally, drill and screw DETAIL 1!/2”

through the side frames into the ends of SUPPORT

1!/2”

BLOCK

the stretchers and plug all the screw holes, E

see Fig. 3. #/8”

10!/2”

E

SUPPORT BLOCKS. To add a little more #/16” DEEP

1!/2”

strength to the pivot point on the arms, I !/2” 3”

CUT ALL FRAME PIECES NOTE: COUNTERBORE

glued a support block (E) to the front (open) RADIUS FROM 4/4 STOCK SCREW HOLES #/16” DEEP

end of each arm and rounded over the bot-

FIGURE 4 FIGURE 5

tom to a 1/2" radius, see Detail in Fig. 2. CROSS SECTION

CUT GLIDE

GLIDE RAILS RAILS FROM

4/4 STOCK

To support the table, I added glide rails A

TABLE TOP

(F) to the arms (A). To determine the width AND ARM 2!/4”

of these glide rails, clamp the table between SHOULD C

BE FLUSH !/2”

the arms so the top is flush with the top

edge of the arms. Then measure the dis- #8 x 1!/4” 12”

tance from the bottom of the frame side WOODSCREW !/2”

1!/4”

(C) to the bottom of the arm, see Fig. 4. %/8”

F

Now cut the glide rails to a length of 12" and GLIDE 2!/4”

mount them to the arms, see Fig. 5. RAIL

GUARD NOTCH. You will have to cut out a

FIGURE 6 FIGURE 7 CROSS SECTION

notch in the front of the table for the safe-

ty guard. The notch has to be wide enough 1 2

so the guard can tip to a full 45°. For a

Sears saw this means a notch about 21/4"

wide and 31/2" deep, see Fig. 2.

CHAMFER EDGES. After the notch is cut,

rout a 1/8" chamfer around all the outside CLAMP FRONT EDGE

OF OUTFEED TABLE

edges of the table top and frame. FLUSH WITH NOTCH

USE !/4” BRAD POINT DRILL A #/16” PILOT HOLE,

ASSEMBLY BIT TO MARK CENTER 2” DEEP CENTERED ON

FIRST HOLE

OF HOLE

The table is connected to the arms with lag

screws used as pivot pins. To locate them, 3

clamp the table in place so the front edge

is aligned with the notch in the right arm,

see Fig. 6. Then drill through the front end

NOTE:

of the slot into the frame side in two steps. DON’T

First, use a 1/4" brad point bit in the 1/4" DRILL INTO FRAME SIDE OVERTIGHTEN

LAG SCREWS !/4” x 2”

slot to drill in just enough to make a cen- WITH BIT CENTERED AGAINST LAG SCREW

END OF SLOT

tering hole, see Step 1 in Fig. 7. Then drill

a pilot hole with a 3/16" bit, see Step 2.

FIGURE 8 CLAMP TABLE

Finally, screw in a 1/4" x 2" lag screw with TO GLIDE RAIL

a washer (but not too tight), see Step 3. CROSS SECTION

STOP PIN. The last step is to prevent the

1 LIFT UP STOP PIN DETAIL

outfeed table from sliding out of position. STOP PIN

Clamp the table into place with the lag

screw tight against the front end of the

slot. Then drill a 1/4"-dia. hole up from the

bottom through the glide rail and 3/8" into

each of the frame sides, see Fig. 8. 2 PULL OUT

1” STOP PIN

Then lift up the table and glue a 1/2"-long HOLE

dowel into the hole in the frame side, see

Detail in Fig. 8. STOP PIN

(!/4” DOWEL)

Now the table is ready to use. To put it !/ 2”

into the “down” position, lift up slightly !/4” !/8”

HOLE SLIGHTLY

(enough to lift the pin out of the hole), slide CENTERED STOP PIN CHAMFER

ON GLIDE HOLE BOTTOM

the table forward, and pivot it down. RAIL

Plans NOW page 8 © 1998, August Home Publishing Co.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 1 - Final - SMAW - Module1Grade9-lrmds-new FOR STUDENTDocument24 pages1 - Final - SMAW - Module1Grade9-lrmds-new FOR STUDENTMarz AgwantaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ceramic Tile Manufacturing ProcesssDocument20 pagesCeramic Tile Manufacturing ProcesssMike Cajes AsiadoNo ratings yet

- Prepare and Operate Equipment, Tools and Machinery - Power ToolsDocument48 pagesPrepare and Operate Equipment, Tools and Machinery - Power ToolsdokumenkabidNo ratings yet

- F&S - Harvery 270deg LollipopDocument2 pagesF&S - Harvery 270deg LollipopRobotNo ratings yet

- Side Table: Woodworks: Intermediate ProjectDocument8 pagesSide Table: Woodworks: Intermediate Projecttheresa0derek0frostNo ratings yet

- KD-213 TDSDocument3 pagesKD-213 TDSalpesh.samruddhigroupNo ratings yet

- ChemicalDocument2 pagesChemicaldalton2004No ratings yet

- Steel MakingDocument38 pagesSteel Makings.samNo ratings yet

- Machining Process - Definition, Types, Advantages, Disadvantages & Applications (PDF)Document6 pagesMachining Process - Definition, Types, Advantages, Disadvantages & Applications (PDF)Azeez AdebayoNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- Nondestrucive Testing Reference Standards PHToolDocument47 pagesNondestrucive Testing Reference Standards PHToolmarcos crisostoNo ratings yet

- ERDEMIR General Product BrochureDocument32 pagesERDEMIR General Product BrochureTC Mehmet Danış Eryılmaz100% (1)

- Starkraft Presentation 2019Document37 pagesStarkraft Presentation 2019Liestia NoorNo ratings yet

- Advancements in Sulfur Recovery ProcessesDocument21 pagesAdvancements in Sulfur Recovery Processesprateek kumarNo ratings yet

- Drilling AccessoriesDocument38 pagesDrilling Accessoriesbagus100% (1)

- Over Toilet Storage ShelvesDocument13 pagesOver Toilet Storage ShelvesSergio OrellanoNo ratings yet

- Checklist For Sleeves & Puddle Flang InstallationDocument1 pageChecklist For Sleeves & Puddle Flang InstallationBelal Alrwadieh0% (1)

- Catalog Cobit SCULEGERODocument49 pagesCatalog Cobit SCULEGEROSculegeroNo ratings yet

- The History of Investment Foundry ProcessDocument11 pagesThe History of Investment Foundry ProcessVrinda NilotpalNo ratings yet

- Lecture 18 - Powder MetallurgyDocument13 pagesLecture 18 - Powder MetallurgyKonark PatelNo ratings yet

- Metal Working ProcessesDocument191 pagesMetal Working Processesss2mrattriNo ratings yet

- Knuth Lathe V-Turn 410 - 1000Document5 pagesKnuth Lathe V-Turn 410 - 1000martin_jaitmanNo ratings yet

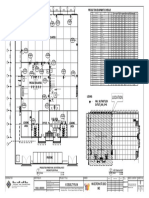

- A020a020m PDFDocument31 pagesA020a020m PDFDaniel LodiNo ratings yet

- Mat Sci Group 3Document5 pagesMat Sci Group 3Future HazeNo ratings yet

- ChE 3202 - Conventional and Non Conventional MethodsDocument8 pagesChE 3202 - Conventional and Non Conventional MethodsWingel LullabyNo ratings yet

- Division of Cebu Province District of Balamban Ii: TLE - IAAW9WM-Ie-3)Document5 pagesDivision of Cebu Province District of Balamban Ii: TLE - IAAW9WM-Ie-3)Felix MilanNo ratings yet

- White SpiritDocument6 pagesWhite Spiritandrewwilliampalileo@yahoocomNo ratings yet

- BMP - DrawingDocument22 pagesBMP - Drawingmantra2010No ratings yet

- E-11 FinalDocument1 pageE-11 FinalRyan RNo ratings yet

- Böhler Fox Skwam: Classifi CationsDocument1 pageBöhler Fox Skwam: Classifi CationsBranko FerenčakNo ratings yet