Professional Documents

Culture Documents

Powder Metallurgy of Tungsten Alloy

Uploaded by

Tanzil Zaidi0 ratings0% found this document useful (0 votes)

15 views2 pagesMet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesPowder Metallurgy of Tungsten Alloy

Uploaded by

Tanzil ZaidiMet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PC08-W-02

2006 POWDER METALLURGY

World Congress

Powder Metallurgy of Tungsten Alloy

Zhang Ke1,a, Ge Chang Chun2,b

1

Laboratory of Special Ceramic and Powder Metallurgy,

University of Science and Technology Beijing, Bejing 100083,China

2

Laboratory of Special Ceramic and Powder Metallurgy,

University of Science and Technology Beijing, Bejing 100083,China

a

zkdaz@163.com, bustbgcc@163.com

Abstract

Preparation of tungsten powder, sorts of tungsten alloys and their application in economy are made a summary

in this paper.

Keywords : tungsten, preparation, sorts, application, summary

1. Introduction expansion, and so on. So it is widely applied for aviation,

space flight, military and electronic industry. But high

Purity and size of raw material powder are very ductile-to-brittle transition temperature (DBTT) and poor

important to prepare high properties material. So it is oxidation resistance are great disadvantages to tungsten. To

critical to prepare superpure, superhomogeneous and increase strength and plasticity of tungsten and widen its

superfine powder. Now there are many methods to prepare application, tungsten alloy, such as W-Cu, W-Ni-Fe and

tungsten powder, such as Reduction method, Carbonyl W-Ni-Cu etc., is developed one after the other since 1930’.

process, Mechanical Alloying [1], Spray Drying, Chemical At the same time, a lot of researches in theory and

Vapor Deposition, Reaction Spray Process and Vacuum application are also carried out.

Plasma Spray Consolidation Process etc.

3.1 W-Cu alloy

WCu alloy is characteristic of both. So it is widely used

2. Preparation of tungsten powder for electrical contact materials and electrode materials.

However, melting points of W and Cu are quite difference

2.1 Carbonyl process and two kinds of elements don’t dissolve each other. WCu

Carbonyl process is a kind of chemical compound of alloy is a kind of classical pseudoalloy. Due to high melting

metal and CO. Its production mechanism as follows: some point of tungsten, preparation of WCu composites is usually

metal (Fe, Co or Ni etc.) could form carbonyl compound some ways of powder metallurgy.

under CO, while carbonyl compound could also dissociate

and become metal powder under some condition. Now 3.2 W/Cu functionally graded material (FGM)

carbonyl powder of Fe and Ni has been made. With the increase of power and harsher terms,

homogeneous WCu alloy is more difficult to meet the

2.2 Mechanical Alloying requirements. Functionally graded material (FGM) is

Benjamin et al invents Mechanical Alloying (MA) in considered to solve this problem very good.

1970’. It needs to put all kinds of metal powder of alloy into At present, FGM has become an effective method to

agitated ball mill, planetary-type mill or rotor high-energy increase material properties. Takahashi et al makes use of

mill to mill, and it needs argon to protect them in case of stratifying W powder of size differentness to press and

being oxygenized. sinter, and obtains porous body whose pore shows graded

2.3 Spray Drying distribution. Subsequently, Cu powder is melted and

Spray Drying is a kind of physical and chemical technique, infiltrates, then becomes W/Cu FGM. But due to different

which makes liquid atomize through physical methods to sintering shrinkage ratio, shape and size of material is

obtain superfine particles. It includes preparation of liquid and difficult to control.

mixture, atomization and dryness, and fluid-bed conversion. Professor Ge Changchun primarily puts forward making

use of FGM to prepare plasma facing material to fusion

3. Tungsten alloys device in China. His group develops a way of graded

sintering under ultrahigh pressure (GSUHP), of which they

Tungsten is characteristic of high melting point, good possess autonomous knowledge property right, to prepare

electrical conductivity, low coefficient of thermal W/Cu FGM [2] (SEM pattern is showed in Fig. 1).

- 1151 - © Korean Powder Metallurgy Institute

4. Applications [3]

Refractory metal W alloy is characteristic of a series of

good properties. So there are good prospects of it being

used to military industry, aerospace industry, nuclear

industry, electronic information, energy, metallurgy,

machining industry and so on. For example, W alloy is

substituted for plumbum as shielding material in nuclear

industry. And it is suitable for nuclear fuel container and

shielding material of radiation-resistant. W-Ni-Fe and

W-Ni-Cu high-density alloy are widely used for shielding

material in medical industry, communication industry and

electric industry. W-Cu alloy is used for electrical contact

material, micro-electronic packaging material and heat-sink

material. So tungsten alloy attaches importance to many

countries, now it becomes one of the most active fields in

material science community.

Fig. 1. SEM of W/Cu FGM.

5. References

3.3 Tungsten heavy alloy

1. Fan Jinglian, Huang Baiyun, Wang Denglong, Qu Xua

Tungsten heavy alloy is based on tungsten (90%~98%), nhui, Zhang Chuanfu. Preparation technology of Nan

and its bond is iron family element which is added into a ometer Size Refractory High Density Tungsten Base

little other elements. W heavy alloy is usually prepared by a d Alloy Composite Powder. Raremetal Materials and

way of powder metallurgy, including mixing, pressing, Engineering. 30(6), p. 401-405 (2001)(in Chinese)

sintering, post processor and so on. It is characteristic of 2. Ling Yunhan, Bai Xinde, Zhou Zhangjian, Li Jiangtao,

high density, high strength, good conductivity, low Ge Chuangchun. Thermal Shock Behavior of W/Cu

coefficient of thermal expansion, good erosion resistance, Functionally Gradient Material.Raremetal Materials and

good oxidation resistance, excellent weldability and so on. Engineering. 33(8), p.819-823 (2004) (in Chinese)

So it is widely used to military and civil industry. Now 3. Fan Jinglian, Huang Baiyun, Wang Denglong, Qu

input of tungstenheavy alloy R & D increases in order to Xuanhui.Nanometer Refractory High Density Tungsten

reduce its cost and develop its property. Based Alloy: Current Research Status and Its Prospec-

tive Application. Powder Metallrugy Materials Science

and Engineering. 6(3), p. 205-209 (2001) (in Chinese)

© Korean Powder Metallurgy Institute - 1152 -

You might also like

- Tata SteelDocument32 pagesTata Steelpatrik710No ratings yet

- Vapor Phase Corrosion Inhibitors: An OverviewDocument12 pagesVapor Phase Corrosion Inhibitors: An OverviewPrabath Nilan GunasekaraNo ratings yet

- Magnesium Casting Technology For Structural ApplicationsDocument21 pagesMagnesium Casting Technology For Structural ApplicationsJinsoo KimNo ratings yet

- Durgapur Steel PlantDocument33 pagesDurgapur Steel Plantpremsukh100% (1)

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Refractory Material Selection For Steelmaking: Emerging Ceramics & Glass TechnologyDocument52 pagesRefractory Material Selection For Steelmaking: Emerging Ceramics & Glass Technologyemregnes0% (1)

- Powder MetallurgyDocument96 pagesPowder Metallurgykhare_girishNo ratings yet

- Carbon Based Refractories Research PublicationDocument17 pagesCarbon Based Refractories Research PublicationSidra MasoodNo ratings yet

- A Comprehensive Review of Recent Advances in Magnesia Carbon RefractoryDocument9 pagesA Comprehensive Review of Recent Advances in Magnesia Carbon RefractorySoumya MukherjeeNo ratings yet

- Wear Phenomena of Refractory Linings in Cement Rotary Kilns: RefraDocument55 pagesWear Phenomena of Refractory Linings in Cement Rotary Kilns: ReframustafNo ratings yet

- Refractory Demands On Inductive Melting of Cast Iron: E. DötschDocument8 pagesRefractory Demands On Inductive Melting of Cast Iron: E. DötschPrashant ParshivnikarNo ratings yet

- Magnesium AlloysDocument14 pagesMagnesium AlloysTamerNo ratings yet

- Powder MetallurgyDocument41 pagesPowder MetallurgyDhina CasungcadNo ratings yet

- Effect of Rare Earth Metals Y La and Refractory MeDocument20 pagesEffect of Rare Earth Metals Y La and Refractory MeAkhila AkkiNo ratings yet

- Copper P/M Composites Literature Review Focuses Mechanical PropertiesDocument20 pagesCopper P/M Composites Literature Review Focuses Mechanical PropertiesROSHANNo ratings yet

- 2019 - Comparative Investigation of The Ni and The Fe Effect On The Structure and Mechanical Response of A WC-W-Ni Hardmetal Obtained by InfiltrationDocument8 pages2019 - Comparative Investigation of The Ni and The Fe Effect On The Structure and Mechanical Response of A WC-W-Ni Hardmetal Obtained by Infiltrationcse crteNo ratings yet

- Titanium, Zirconium and Vanadium Conversion Coatings (TZVCCS) On Az91D Magnesium Alloy SheetsDocument10 pagesTitanium, Zirconium and Vanadium Conversion Coatings (TZVCCS) On Az91D Magnesium Alloy SheetsDr. AsthaNo ratings yet

- Design, Fabrication, and Properties of A Continuous Carbon-Fiber Reinforced Sm2O3 Polyimide Gamma Ray Neutron Shielding Material.Document8 pagesDesign, Fabrication, and Properties of A Continuous Carbon-Fiber Reinforced Sm2O3 Polyimide Gamma Ray Neutron Shielding Material.Fadhel HmoodNo ratings yet

- Review On Friction Stir Welding of Magne PDFDocument18 pagesReview On Friction Stir Welding of Magne PDFmurali_330No ratings yet

- Focused Review On Cu-Ni-Sn Spinodal Alloys: From Casting To Additive ManufacturingDocument26 pagesFocused Review On Cu-Ni-Sn Spinodal Alloys: From Casting To Additive Manufacturingชลธิชา โยชาลีNo ratings yet

- 1-s2.0-S0022311518300588-mainDocument8 pages1-s2.0-S0022311518300588-mainpela210No ratings yet

- Indian Activities on Developing Fusion Reactor MaterialsDocument8 pagesIndian Activities on Developing Fusion Reactor MaterialsArunNo ratings yet

- mmscience_2021-11_weldability-of-cobalt-alloys-by-hybrid-methodsDocument8 pagesmmscience_2021-11_weldability-of-cobalt-alloys-by-hybrid-methodsLUIS CARLOS ROMERO ALVAREZNo ratings yet

- Micro-Nano Dual-Scale Particle-Reinforced Tib / Cu-0.5Cr Composites Prepared by Vacuum Arc MeltingDocument8 pagesMicro-Nano Dual-Scale Particle-Reinforced Tib / Cu-0.5Cr Composites Prepared by Vacuum Arc MeltingShivansh MishraNo ratings yet

- Afe 2 16Document6 pagesAfe 2 16ชลธิชา โยชาลีNo ratings yet

- Bhattacharya 2022 J. Phys. Energy 4 034003Document52 pagesBhattacharya 2022 J. Phys. Energy 4 034003vikramNo ratings yet

- Mechanical Properties of 93% Tungsten Heavy AlloysDocument9 pagesMechanical Properties of 93% Tungsten Heavy AlloysSiddharthNo ratings yet

- Adobe Scan 09 Jul 2023Document20 pagesAdobe Scan 09 Jul 2023Roy patelNo ratings yet

- Hatel 2019 J. Phys. Conf. Ser. 1292 012014Document6 pagesHatel 2019 J. Phys. Conf. Ser. 1292 012014Thanh VuNo ratings yet

- 200 MeV Ag15 Ion Beam Irradiation Induced Modificatio - 2019 - Nuclear EngineerDocument8 pages200 MeV Ag15 Ion Beam Irradiation Induced Modificatio - 2019 - Nuclear EngineerArnaud RomainNo ratings yet

- Xiao 2000Document7 pagesXiao 2000tehtnicaNo ratings yet

- Wear Characteristics of Heat Treated Hadfield Austenitic Manganese Steel For Engineering ApplicationDocument15 pagesWear Characteristics of Heat Treated Hadfield Austenitic Manganese Steel For Engineering Applicationshrikant mishraNo ratings yet

- Sintering Effect On The Performance of Tungsten-Copper Powder LinerDocument2 pagesSintering Effect On The Performance of Tungsten-Copper Powder LinermahsaNo ratings yet

- Microwave Sintering of W-18cu and W-7ni-3cu AlloysDocument5 pagesMicrowave Sintering of W-18cu and W-7ni-3cu AlloysAvijit MondalNo ratings yet

- Sintering Parameters Consequence On Microstructure and Hardness of Copper Alloy Prepared by Powder MetallurgyDocument6 pagesSintering Parameters Consequence On Microstructure and Hardness of Copper Alloy Prepared by Powder MetallurgytonyNo ratings yet

- Kay Ali 2015Document6 pagesKay Ali 2015João Paulo Moreira Santos BarbosaNo ratings yet

- Inclusions in Melting Process of Titanium and Titanium AlloysDocument9 pagesInclusions in Melting Process of Titanium and Titanium AlloyswidadNo ratings yet

- The Ferroelectric Properties of (Na0.5K0.5) NbO3Document7 pagesThe Ferroelectric Properties of (Na0.5K0.5) NbO3goldy243usNo ratings yet

- Kataria 2020Document4 pagesKataria 2020anandhunehNo ratings yet

- Minerals: A Review of Tungsten Resources and Potential Extraction From Mine WasteDocument18 pagesMinerals: A Review of Tungsten Resources and Potential Extraction From Mine WasteDai NguyenNo ratings yet

- Stainless Steel Bipolar Plates Deposited With Multilayer Films For PEMFC ApplicationsDocument7 pagesStainless Steel Bipolar Plates Deposited With Multilayer Films For PEMFC ApplicationsMurtaza ÇakaloğluNo ratings yet

- S Sutradhar Publication Feb 2021Document10 pagesS Sutradhar Publication Feb 2021Subham AdhikariNo ratings yet

- Development and Characterization of Nano - Flux - CompressedDocument10 pagesDevelopment and Characterization of Nano - Flux - CompressedSatyendra SinghNo ratings yet

- Thermal Conductivity of Copper Matrix Composites RDocument8 pagesThermal Conductivity of Copper Matrix Composites Rashutosh singhNo ratings yet

- Electroplating Review for Corrosion ProtectionDocument9 pagesElectroplating Review for Corrosion ProtectionHerda CahyaningrumNo ratings yet

- Copper (Cu) Nanoparticles Properties ApplicationsDocument2 pagesCopper (Cu) Nanoparticles Properties ApplicationswprongmaneeNo ratings yet

- Journal of Magnetism and Magnetic Materials: M.M. Rashad, D.A. Rayan, A.O. Turky, M.M. HessienDocument8 pagesJournal of Magnetism and Magnetic Materials: M.M. Rashad, D.A. Rayan, A.O. Turky, M.M. HessienSajjad HasanNo ratings yet

- Improving Al Coating Corrosion Resistance with Zn and Mg AlloysDocument13 pagesImproving Al Coating Corrosion Resistance with Zn and Mg AlloysMarlon Steven PerazaNo ratings yet

- A Review On Tribo-Mechanical Properties of Micro-And Nanoparticulate - Filled Nylon CompositesDocument17 pagesA Review On Tribo-Mechanical Properties of Micro-And Nanoparticulate - Filled Nylon CompositesAjay KanzariyaNo ratings yet

- 30Cr2Ni4MoV MaterialDocument12 pages30Cr2Ni4MoV Materiallacoste11111No ratings yet

- Naterial Karakterisas9iDocument11 pagesNaterial Karakterisas9iHusen TaufiqNo ratings yet

- Emg 2201 Engineerinr Materials Lecture NotesDocument18 pagesEmg 2201 Engineerinr Materials Lecture NotesAbdul jeleelNo ratings yet

- Weldability of Tungsten and Its AlloysDocument8 pagesWeldability of Tungsten and Its Alloyss_m_taheriNo ratings yet

- Microwave and Conventional Sintering of Premixed and Prealloyed Tungsten Heavy AlloysDocument14 pagesMicrowave and Conventional Sintering of Premixed and Prealloyed Tungsten Heavy AlloysPhung Tuan AnhNo ratings yet

- Thermal Conductivity of Beryllium Oxide CeramicDocument4 pagesThermal Conductivity of Beryllium Oxide CeramicSagirul IslamNo ratings yet

- Evaluation of the electrical properties of carbon electrodes developed with bio-material additions as a sacrificial anode in cathodic protectionDocument12 pagesEvaluation of the electrical properties of carbon electrodes developed with bio-material additions as a sacrificial anode in cathodic protectionFrancisco Javier Dominguez De Los SantosNo ratings yet

- 多元添加劑對高磁導率Mn Zn鐵氧體組織和磁性能的影響Document5 pages多元添加劑對高磁導率Mn Zn鐵氧體組織和磁性能的影響吳尚謙No ratings yet

- An Investigation Into Microstructure and MechanicaDocument10 pagesAn Investigation Into Microstructure and MechanicaGowri Shankar WuritiNo ratings yet

- 1 s2.0 S2238785421009960 MainDocument12 pages1 s2.0 S2238785421009960 MainAlagar SamyNo ratings yet

- Zaitsev 2020Document6 pagesZaitsev 2020Р ЧNo ratings yet

- Enhanced Electromagnetic Interference Shielding Effectiveness of An Eco Friendly Cenosphere Filled Aluminum Matrix Syntactic FoamDocument13 pagesEnhanced Electromagnetic Interference Shielding Effectiveness of An Eco Friendly Cenosphere Filled Aluminum Matrix Syntactic Foamkt rajaNo ratings yet

- Ravi Kiran 2013Document8 pagesRavi Kiran 2013Bilal AhmedNo ratings yet

- Usman Et Al Second PaperDocument10 pagesUsman Et Al Second PaperFerry JiwandhonoNo ratings yet

- EME Module 2Document31 pagesEME Module 2Yashaswini AnandNo ratings yet

- Earth Science OutputsDocument7 pagesEarth Science OutputsRangerbackNo ratings yet

- Tungsten Extractive Metallurgy - A Review of Processes and Their Challenges For SustainabilityDocument14 pagesTungsten Extractive Metallurgy - A Review of Processes and Their Challenges For SustainabilityJuan Diego Lopez AlvarezNo ratings yet

- Microstructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsDocument8 pagesMicrostructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsMangesh LingampalleNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- Engineering Considerations For Anodizing AluminumDocument1 pageEngineering Considerations For Anodizing AluminumTanzil ZaidiNo ratings yet

- Viton FtirDocument53 pagesViton FtirTanzil ZaidiNo ratings yet

- Type II Vs Type III Anodizing of 2024 AluminumDocument7 pagesType II Vs Type III Anodizing of 2024 AluminumTanzil ZaidiNo ratings yet

- CHP - 10.1007 - 978 3 030 49882 5 - 4Document12 pagesCHP - 10.1007 - 978 3 030 49882 5 - 4Tanzil ZaidiNo ratings yet

- E Tin Bismuth SLOTOLOY SNB 30 1Document1 pageE Tin Bismuth SLOTOLOY SNB 30 1Tanzil ZaidiNo ratings yet

- ASM Subject Guide - FailureAnalysisDocument4 pagesASM Subject Guide - FailureAnalysisVinh Do ThanhNo ratings yet

- Basics of Pyrometry, Industry Specifications and Temperature Uniformity SurveysDocument5 pagesBasics of Pyrometry, Industry Specifications and Temperature Uniformity SurveysTanzil ZaidiNo ratings yet

- Preparation and Properties of Lightweight CarboncaDocument9 pagesPreparation and Properties of Lightweight CarboncaTanzil ZaidiNo ratings yet

- Proceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeDocument9 pagesProceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeTanzil ZaidiNo ratings yet

- Armco Pure Iron PDB Euro Final Secured 92Document24 pagesArmco Pure Iron PDB Euro Final Secured 92Tanzil ZaidiNo ratings yet

- 1J76 、1J77 、1J79 、1J80 、1J85 、1J86: Shanghai Xinxi Alloy Material Co.,LtdDocument4 pages1J76 、1J77 、1J79 、1J80 、1J85 、1J86: Shanghai Xinxi Alloy Material Co.,LtdTanzil ZaidiNo ratings yet

- Structural Ceramic Nanocomposites: A Review of Properties and Powders' Synthesis MethodsDocument42 pagesStructural Ceramic Nanocomposites: A Review of Properties and Powders' Synthesis MethodsTanzil ZaidiNo ratings yet

- 1j95 Research PaperDocument8 pages1j95 Research PaperTanzil ZaidiNo ratings yet

- Nanomaterials 10 01077Document14 pagesNanomaterials 10 01077Tanzil ZaidiNo ratings yet

- ASM Subject Guide - FailureAnalysisDocument4 pagesASM Subject Guide - FailureAnalysisVinh Do ThanhNo ratings yet

- InTech-Introduction of Fibre Reinforced Polymers Polymers and Composites Concepts Properties and ProcessesDocument39 pagesInTech-Introduction of Fibre Reinforced Polymers Polymers and Composites Concepts Properties and ProcessesTanzil ZaidiNo ratings yet

- Study The Microstructure and Mechanical PropertiesDocument7 pagesStudy The Microstructure and Mechanical PropertiesTanzil ZaidiNo ratings yet

- Nanocomposites For Structural ApplicationsDocument9 pagesNanocomposites For Structural ApplicationsTanzil ZaidiNo ratings yet

- ResearchGate publication on nanocomposites and applicationsDocument15 pagesResearchGate publication on nanocomposites and applicationsTanzil ZaidiNo ratings yet

- 11.glassfiber Reinforcedpolymercomposite Areview OriginalDocument20 pages11.glassfiber Reinforcedpolymercomposite Areview OriginalŜṟéẻ Ṛąṁ ChowdaryNo ratings yet

- Wear Behavior of Graphene-Reinforced Alumina-Silicon Carbide Whisker NanocompositeDocument11 pagesWear Behavior of Graphene-Reinforced Alumina-Silicon Carbide Whisker NanocompositeTanzil ZaidiNo ratings yet

- Metals: Advanced Metal Matrix NanocompositesDocument39 pagesMetals: Advanced Metal Matrix NanocompositesTanzil ZaidiNo ratings yet

- In-Situ Measurement of Sic/Si Interfacial Tensile Strength of Reaction Bonded Sic/Si CompositeDocument8 pagesIn-Situ Measurement of Sic/Si Interfacial Tensile Strength of Reaction Bonded Sic/Si CompositeTanzil ZaidiNo ratings yet

- Calculation of Carbon Diffusion Forcementation of Gear WheelsDocument10 pagesCalculation of Carbon Diffusion Forcementation of Gear WheelsTanzil ZaidiNo ratings yet

- Zard Mohabbat by Mawra TalhaDocument21 pagesZard Mohabbat by Mawra TalhaTanzil ZaidiNo ratings yet

- Coatings 07 00122Document27 pagesCoatings 07 00122dimNo ratings yet

- Experimental Investigation of Material Removal Rate in CNC TC Using Taguchi ApproachDocument9 pagesExperimental Investigation of Material Removal Rate in CNC TC Using Taguchi ApproachTanzil ZaidiNo ratings yet

- Journal: Spark-Plasma Sintering of Silicon Carbide Whiskers (Sic) Reinforced Nanocrystalline AluminaDocument4 pagesJournal: Spark-Plasma Sintering of Silicon Carbide Whiskers (Sic) Reinforced Nanocrystalline AluminaTanzil ZaidiNo ratings yet

- Optimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachDocument4 pagesOptimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachTanzil ZaidiNo ratings yet

- Recovery of Alumina and Ferric Oxide From Bayer Red Mud Rich inDocument6 pagesRecovery of Alumina and Ferric Oxide From Bayer Red Mud Rich inPRACHIPRAVA PRADHANNo ratings yet

- A New Sintering Additive For Silicon Carbide CeramicDocument5 pagesA New Sintering Additive For Silicon Carbide CeramicyinxinshixianNo ratings yet

- CNSK OiliteDocument36 pagesCNSK Oiliteaataylor83No ratings yet

- Value-Added Products of Rice Husk in Various DisciplinesDocument17 pagesValue-Added Products of Rice Husk in Various DisciplinesIJRASETPublicationsNo ratings yet

- A Review On Nano Hydroxyapatite Fabrication TechniquesDocument8 pagesA Review On Nano Hydroxyapatite Fabrication TechniquesEditor IJTSRDNo ratings yet

- Nexion Marble GalleryDocument91 pagesNexion Marble Gallerymahesh navaghaneNo ratings yet

- Synthesis of Thermal Spray Grade Yttrium Oxide Powder and Its Application For Plasma Spray DepositionDocument6 pagesSynthesis of Thermal Spray Grade Yttrium Oxide Powder and Its Application For Plasma Spray DepositionSutanwi LahiriNo ratings yet

- Stir Casting Squeeze CastingDocument25 pagesStir Casting Squeeze CastingPethuraj50% (2)

- 1.11 Ceramic MembranesDocument28 pages1.11 Ceramic Membranesfzl123007No ratings yet

- Graduation ProjectDocument18 pagesGraduation Projectmohamed moradNo ratings yet

- Journal of The European Ceramic SocietyDocument14 pagesJournal of The European Ceramic SocietyAntonio SilvaNo ratings yet

- Advanced Powder TechnologyDocument4 pagesAdvanced Powder TechnologyHARIMETLYNo ratings yet

- Creep of MaterialsDocument67 pagesCreep of MaterialsAnilNo ratings yet

- NFCDocument46 pagesNFCLuptongaNo ratings yet

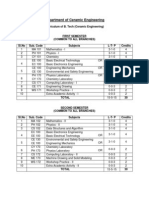

- Anna University Ceramic Technology CurriculumDocument62 pagesAnna University Ceramic Technology CurriculumselvanmsNo ratings yet

- Bujes GarlockDocument60 pagesBujes GarlockEstrada Martinez Manuel VictorNo ratings yet

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Document13 pagesSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNo ratings yet

- Powder Metallurgy: Hasrul Farhan Harun Safety, Health and Environment EngineerDocument17 pagesPowder Metallurgy: Hasrul Farhan Harun Safety, Health and Environment EngineerpharhuntrunNo ratings yet

- Atac 113 Pfmea R10 IatfDocument50 pagesAtac 113 Pfmea R10 IatfAzlan MustaphaNo ratings yet

- Syllabus 4Document33 pagesSyllabus 4microsoftkarthiNo ratings yet

- 10.1016/j.powtec.2017.06.053: Powder TechnologyDocument46 pages10.1016/j.powtec.2017.06.053: Powder TechnologychandiniNo ratings yet

- Hot Isostatic Pressing CeramicsDocument4 pagesHot Isostatic Pressing CeramicsamirsuryahidayahNo ratings yet