Professional Documents

Culture Documents

Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator Training

Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator Training

Uploaded by

GUESSOUMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator Training

Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator Training

Uploaded by

GUESSOUMACopyright:

Available Formats

CX501KB7

TRAINING GAS TURBINES

CUSTOMER MAINTENANCE

AND DAILY LOG

MLN BLOCK 405, ALGERIA

OPERATOR TRAINING

CX501KB7

TRAINING GAS TURBINES

Comprehensive Maintenance Contract (Optional)

Customer Responsibilities:

1. Operation and running of equipment in accordance

with the Centrax Manuals;

2. Maintenance

- lube oil levels

- compressor washing

- replacement of filters;

3. Record keeping, logging of performance and

reporting;

4. Supply of fuels, fluids, extinguishant, filters, lamps;

5. Fluid analysis - oil and fuel.

MAINTENANCE SECTION 14 PAGE 1-2

CX501KB7

TRAINING GAS TURBINES

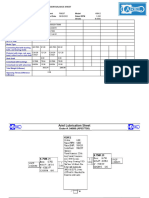

DAILY LOG

Monitoring and Logging the Generator's performance is an

essential part of daily maintenance.

The Daily Log will show performance trends and may be used for

the early fault identification.

The Log is also essential for ascertaining the optimum timing for

compressor washing.

The Log Sheets should be compiled from the following and placed

in the most logical order for convenience - this depends on the

relative positions of the control panels and instruments in the

control room.

0.8

0.6

0.4

0.2

0

1

CX501KB7

TRAINING GAS TURBINES

DAILY LOG SHEET (TYPICAL)

TURBINE OIL PRESSURE DATE

LUBE OIL PRESSURE TIME

LUBE OIL TEMP HOURS RUN

LUBE OIL DIFF. PRESSURE PEAK HOURS

GAS FUEL PRESSURE STARTS

COMP. DISCHARGE PRES. TIT

AMBIENT PRESSURE TOT1

GENERATOR POWER TOT2

GENERATOR FREQUENCY CIT

GEN. REACTIVE POWER GP SPEED

GEN. CURRENT 1,2,3 AIR INTAKE TEMP.

GEN. VOLTS 1,2,3 TURBINE VIBRATION

GEN. STATOR TEMP. L1,2,3 PTO VIBRATION

GEN. OUTLET AIR TEMP. G/BOX AXIAL VIBRATION

AIR FILTER DIFF. PRES. GEN DE VIBRATION

BATTERY CHARGER GEN NDE VIBRATION

GAS DETECTORS GEN DE TEMP.

U.V. DETECTOR GEN NDE TEMP.

MAINTENANCE SECTION 14 PAGE 3-4

CX501KB7

TRAINING GAS TURBINES

DAILY INSPECTION

Complete daily Log Sheet - this will include looking inside the

unit through the windows provided to check pipework for

security and leaks (air, oil and water)

Check lube oil level

Check all air intakes are free from debris

Carry out a compressor wash - frequency dictated by local

conditions and rate of power loss over time

CX501KB7

TRAINING GAS TURBINES

COMPRESSOR CLEANING

Running Wash - normally carried out at least twice a week.

Motoring Washing is usually carried out on a weekly or fortnightly

basis - the turbine has to be shutdown.

Whilst the set is shutdown:

ISOLATE FIRE SYSTEM BEFORE ENTERING THE ENCLOSURE

Check inside and outside the turbine enclosure for security of

components and plumbing;

Top up the oil level as necessary;

Clean up any spillages or leaks ;

Take the opportunity to clean the machine.

MAINTENANCE SECTION 14 PAGE 5-6

CX501KB7

TRAINING GAS TURBINES

FILTER CHANGING

Oil, Air and Gas Filters are routinely changed under the Centrax

Service Policy however;

If a high differential pressure is indicated on the HMI, the filter

in question is becoming clogged and should be changed - a

sudden increase in differential pressure should be

investigated - and Centrax informed immediately.

The duplex oil filter can be switched over manually when the

differential pressure reaches the alarm level (2 to 3.0 bar g)

The duplex fuel filter can be switched over manually when the

differential pressure reaches the alarm level (2 to 3.0 bar g)

CX501KB7

TRAINING GAS TURBINES

OIL CONDITION

The synthetic lubricating oil used in this generating set has an

extremely long life. In order to detect long-term degradation of the

oil, samples should be analysed regularly. The first sample should

be taken at commissioning and analysed for Total Acid Number

(TAN) and viscosity. The TAN should not increase by more that

1.0mg KOH per gm over that of new oil. Viscosity should not

increase by more than 15% to 25% over that of new oil. Samples

should subsequently be taken every 6 months. In the event that

these levels are reached or exceeded the oil should be changed at

the earliest opportunity.

Testing is carried out by the oil company or its local supplier

MAINTENANCE SECTION 14 PAGE 7-8

You might also like

- Altronic V Installation Manual (FORM AV II)Document12 pagesAltronic V Installation Manual (FORM AV II)francis_mouille_iiNo ratings yet

- Lube Oil System: MLN Block 405, Algeria Operator TrainingDocument10 pagesLube Oil System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Lube Oil System: MLN Block 405, Algeria Operator TrainingDocument10 pagesLube Oil System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- 1978 RCA Power DevicesDocument624 pages1978 RCA Power Devicesasccorrea100% (3)

- Stopping Procedure: MLN Block 405 Algeria Operator TrainingDocument10 pagesStopping Procedure: MLN Block 405 Algeria Operator TrainingGUESSOUMA100% (1)

- Stopping Procedure: MLN Block 405 Algeria Operator TrainingDocument10 pagesStopping Procedure: MLN Block 405 Algeria Operator TrainingGUESSOUMA100% (1)

- C10550138Document1 pageC10550138foro100% (1)

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- Developing Guide Lines Related To Structural Design and Thermal Aspects of EV Motors and Battery SystemDocument11 pagesDeveloping Guide Lines Related To Structural Design and Thermal Aspects of EV Motors and Battery SystemvaishnaviNo ratings yet

- Ariel Is Pleased To Announce The Production Release of The All New KBK:TDocument2 pagesAriel Is Pleased To Announce The Production Release of The All New KBK:TMUHAMMAD AFNANNo ratings yet

- Ariel Compressor Balance SheetDocument130 pagesAriel Compressor Balance Sheetariel.garayNo ratings yet

- 13.8kV Bus Duct Sizing For Arar Dated 23.03.2005Document9 pages13.8kV Bus Duct Sizing For Arar Dated 23.03.2005srigirisetty208No ratings yet

- Nigeria Gas Specification - GACNDocument1 pageNigeria Gas Specification - GACNOlusegun OyebanjiNo ratings yet

- Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingDocument18 pagesRolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingDocument18 pagesRolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingDocument18 pagesRolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- 04alt PDFDocument9 pages04alt PDFGUESSOUMANo ratings yet

- 04alt PDFDocument9 pages04alt PDFGUESSOUMANo ratings yet

- Vorecon Applications PDFDocument46 pagesVorecon Applications PDFlancasaNo ratings yet

- m1 - 8 Version 6.0x IntegratedDocument104 pagesm1 - 8 Version 6.0x Integratednianyounian50% (2)

- Compressor Wash System: MLN Block 405, Algeria Operator TrainingDocument19 pagesCompressor Wash System: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Compressor Wash System: MLN Block 405, Algeria Operator TrainingDocument19 pagesCompressor Wash System: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Enclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaDocument7 pagesEnclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaGUESSOUMANo ratings yet

- Enclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaDocument7 pagesEnclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaGUESSOUMANo ratings yet

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Solar Photovoltaic Water Pumping System For Irrigation PDFDocument7 pagesSolar Photovoltaic Water Pumping System For Irrigation PDFGUESSOUMA100% (1)

- Guidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryDocument48 pagesGuidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryFabbrox100% (2)

- LM6000 DatasheetDocument2 pagesLM6000 DatasheetpatrialvamelNo ratings yet

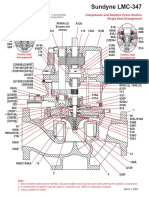

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal Arrangementmasoud67aNo ratings yet

- P O N M L K J I H G F E D C B A: Howden Solyvent (India) Pvt. LTDDocument1 pageP O N M L K J I H G F E D C B A: Howden Solyvent (India) Pvt. LTDNagendraNo ratings yet

- AIB XRHS 836 CD ENDocument27 pagesAIB XRHS 836 CD ENcristianrblr100% (1)

- 6 Testing and Qualification of Two-Stage Turbocharging SystemsDocument16 pages6 Testing and Qualification of Two-Stage Turbocharging SystemsMuzaffar Ali QuaziNo ratings yet

- Scheduled Maintenance Program Turbocharged F, GP, &SD Model Locomotives (645E3 Thru 645E3C Engines)Document16 pagesScheduled Maintenance Program Turbocharged F, GP, &SD Model Locomotives (645E3 Thru 645E3C Engines)amir barekatiNo ratings yet

- Seleccion de SoplantesDocument69 pagesSeleccion de Soplantesmartin.rubenNo ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air Systemmilad100% (1)

- Renault With Can234Document19 pagesRenault With Can234carsoNo ratings yet

- Section7 - Service Information and Maintenance ECM 585Document26 pagesSection7 - Service Information and Maintenance ECM 585Michael A Fourie100% (1)

- GT2019 90177Document11 pagesGT2019 90177Hiwa Khaledi100% (1)

- Hitachi zw95 Operator's ManualDocument278 pagesHitachi zw95 Operator's ManualanuelNo ratings yet

- General Electric Model 9E Gas Turbine: 9E Advanced Gas Path (AGP) Standard Curves: DLN - Natural GasDocument43 pagesGeneral Electric Model 9E Gas Turbine: 9E Advanced Gas Path (AGP) Standard Curves: DLN - Natural GasRob RhNo ratings yet

- Performance of Industrial GasturbinesDocument28 pagesPerformance of Industrial Gasturbinessomporn duangbuntaoNo ratings yet

- Axial Comp On OffDocument4 pagesAxial Comp On OffMohamed OmarNo ratings yet

- Brochure BHGEDocument44 pagesBrochure BHGEbederinadmlNo ratings yet

- B600 PDFDocument4 pagesB600 PDFzsmithNo ratings yet

- 4396-13.0-01-04 - 0 Operation & Maintenance InstructionDocument56 pages4396-13.0-01-04 - 0 Operation & Maintenance InstructionJAIME100% (1)

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- Estudos de Casos - Revamps & Upgrades HOERBIGERDocument11 pagesEstudos de Casos - Revamps & Upgrades HOERBIGERJoseNo ratings yet

- GL600Document3 pagesGL600Cristian LeizzaNo ratings yet

- Base de Datos, Motores, Compresores.Document69 pagesBase de Datos, Motores, Compresores.Argenis JimenezNo ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- Data Sheet - Superior 12 SGTDDocument2 pagesData Sheet - Superior 12 SGTDmauricio cañonNo ratings yet

- 306 Final PaperDocument14 pages306 Final PaperThanapaet RittirutNo ratings yet

- General Electric Model PG9171 (E) Gas Turbine: Estim A Ted Performance - Configuration: DLN CombustorDocument1 pageGeneral Electric Model PG9171 (E) Gas Turbine: Estim A Ted Performance - Configuration: DLN Combustorkarim karimNo ratings yet

- Ss Mobilith SHCDocument2 pagesSs Mobilith SHCFarrukh JamalNo ratings yet

- Actuador Limitorque MX y QXDocument6 pagesActuador Limitorque MX y QXManuel FernizaNo ratings yet

- Kei-Rsos Maritime Limited MachineryDocument28 pagesKei-Rsos Maritime Limited MachineryTabitha MorinNo ratings yet

- Lubrimist Model Ivt PDFDocument2 pagesLubrimist Model Ivt PDFLluhiNo ratings yet

- Don GTS BrochureDocument8 pagesDon GTS BrochuresanigzlNo ratings yet

- Waukesha Gas Engines: Service BulletinDocument1 pageWaukesha Gas Engines: Service BulletindfmolinaNo ratings yet

- Efficient & Economical Risk Assessment: Health CheckDocument12 pagesEfficient & Economical Risk Assessment: Health Checkleonardo LunaNo ratings yet

- Ajax Integral Engine-Compressor DPC-2201: 148 BHP 440 RPMDocument2 pagesAjax Integral Engine-Compressor DPC-2201: 148 BHP 440 RPMAlexNo ratings yet

- IOPTC PLC4TurbineDocument4 pagesIOPTC PLC4TurbineStarlightbrightNo ratings yet

- Start Sequence: MLN Block 405, Algeria Operator TrainingDocument13 pagesStart Sequence: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- Manual Mto 1203 - 5,6 MWDocument98 pagesManual Mto 1203 - 5,6 MWAgustin BaratcabalNo ratings yet

- Gas Turbine System & PropulsionDocument35 pagesGas Turbine System & PropulsionnaveedsidhuNo ratings yet

- 275GL Series 12V 275GL+: Gas Engine With ESM 2Document2 pages275GL Series 12V 275GL+: Gas Engine With ESM 2Jaadi 786100% (1)

- Aerzen High Vaccum Blower HVseries CatalogDocument12 pagesAerzen High Vaccum Blower HVseries CatalogСергей КолесниковNo ratings yet

- 210 X2103491E B Nominal PerformanceDocument4 pages210 X2103491E B Nominal PerformanceJaroslav KurucNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Mi 1743B TDocument18 pagesMi 1743B Tamir barekatiNo ratings yet

- Dual Fuel System: MLN Block 405, Algeria Operator TrainingDocument19 pagesDual Fuel System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Advantech HMI User Guide: CX501-KB7Document23 pagesAdvantech HMI User Guide: CX501-KB7GUESSOUMANo ratings yet

- Start Sequence: MLN Block 405, Algeria Operator TrainingDocument13 pagesStart Sequence: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Control System: MLN Block 405 Algeria Operator TrainingDocument14 pagesControl System: MLN Block 405 Algeria Operator TrainingGUESSOUMANo ratings yet

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Epicyclic Speed Reduction Gears: MLN Block 405, Algeria Operator TrainingDocument8 pagesEpicyclic Speed Reduction Gears: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Compressed Air System: MLN Block 405, Algeria Operator TrainingDocument6 pagesCompressed Air System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Improve An Engine Cooling Fan Using Design For Six Sigma Techniques PDFDocument7 pagesImprove An Engine Cooling Fan Using Design For Six Sigma Techniques PDFGUESSOUMANo ratings yet

- JJM DG Set CalculationDocument2 pagesJJM DG Set CalculationVivek Kumar YadavNo ratings yet

- Manual Huawei SUN2000-20KTLDocument126 pagesManual Huawei SUN2000-20KTLRoberto GallardoNo ratings yet

- Model B, C, CHD Tubing Spider Cut SheetDocument2 pagesModel B, C, CHD Tubing Spider Cut SheetEdgar Moreira Fernandez100% (1)

- SCANIA Crane CatalougeDocument574 pagesSCANIA Crane Catalougeahmed elsanabary100% (1)

- វចនានុក្រម អេឡិចត្រូនិចDocument50 pagesវចនានុក្រម អេឡិចត្រូនិចVannak ChenNo ratings yet

- Report Break Down RigDocument4 pagesReport Break Down RigFortuna HunilaNo ratings yet

- Post Pyro Ip01Document56 pagesPost Pyro Ip01Durga PrasadNo ratings yet

- Products For Industrial FanDocument8 pagesProducts For Industrial FanLLNo ratings yet

- Hood - Panels, SideDocument3 pagesHood - Panels, SideLUIS FERNANDO JOAQUINNo ratings yet

- Cable Wire Catalogue PDFDocument47 pagesCable Wire Catalogue PDFyoupick10No ratings yet

- Department of Mechanical Engineering. Mce315 Design Studies 1 Report On ExperimentDocument9 pagesDepartment of Mechanical Engineering. Mce315 Design Studies 1 Report On ExperimentBukky EmmanuelNo ratings yet

- Closing Findings Weekly Safety Patrol On 13 Dec 2019.Document3 pagesClosing Findings Weekly Safety Patrol On 13 Dec 2019.InsanNo ratings yet

- Frozen Carbonated Beverage Freezer: Four Flavor FeaturesDocument2 pagesFrozen Carbonated Beverage Freezer: Four Flavor FeaturesAndrewNo ratings yet

- 1794 In107 - en PDocument6 pages1794 In107 - en PSaga_10No ratings yet

- Wb146 5 Partes PDFDocument131 pagesWb146 5 Partes PDFMARCO ANTONIONo ratings yet

- Kode Eror WCPUDocument2 pagesKode Eror WCPUbagus wicaksonNo ratings yet

- DANASEA Technical ProposalDocument4 pagesDANASEA Technical ProposalBadrul 'boxer' HishamNo ratings yet

- Fully Hydraulic Crawler Crane: Lifting Capacity 250 Metric TonsDocument12 pagesFully Hydraulic Crawler Crane: Lifting Capacity 250 Metric Tons이현기No ratings yet

- OSCA Exam QPDocument8 pagesOSCA Exam QPNishan Raj Shrestha Pandit100% (1)

- AQUATECHDocument3 pagesAQUATECHAmit BidlanNo ratings yet

- 2220 - Mosfet PDFDocument4 pages2220 - Mosfet PDFEdmundBlackadderIVNo ratings yet

- Rockit: User ManualDocument33 pagesRockit: User ManualAnthonyNo ratings yet

- HP w1907 DisassemblyDocument30 pagesHP w1907 DisassemblyGary FabricanteNo ratings yet

- General Aircraft InformationDocument7 pagesGeneral Aircraft InformationromixrayzenNo ratings yet