Professional Documents

Culture Documents

Sanoop V

Uploaded by

Aaryan K MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sanoop V

Uploaded by

Aaryan K MCopyright:

Available Formats

Project Report 2006 Dept.

of BBM

S.E.S

COLLEGE

SREEKANDAPURAM

PROJECT REPORT ON

An overall study on the Kanhirode Weavers Co-operative

Production And Sales Society Ltd.

kannur

DECLARATION

This is to certify that the project report entitled “An over all study about

the Kanhirode Weavers Co-operative P & S Society Ltd., Kannur”, submitted

Taliparamba Arts & Science College,Kanhirangad 1

Project Report 2006 Dept. of BBM

to Kannur University in partial fulfillment of the requirement for the award of the

Degree of Bachelor of Business Management (BBM) is a record of original

work done by me during my period of study in Taliparamba Arts & Science

College, Kanhirangad, under the guidance of Mr. Ajai Abraham Thomas,

MBA.

Place: KANHIRANGAD SANOOP . V

Date: Reg No: 78950

Taliparamba Arts & Science College,Kanhirangad 2

Project Report 2006 Dept. of BBM

ACKNOWLEDGEMENT

I am grateful to Mr. V.V. Kunhikrishnan, M.A, B.Ed, Ph.D, Principal

Taliparamba Arts & Science College, Kanhirangad, for permitting me to take up

this project work.

I wish to express my sincere thanks to Mr. P.V. Kamalakshan, M Com,

B.Ed, MBA, Head of the Department of Business Management for the help, co-

operation and advice extended to me throughout the study.

I wish to express to my sincere thanks to Mr. Ajai Abraham Thomas,

MBA, and faculty guide for the continuous and valuable information rendered to

me in completing my study with in the allotted time.

I thank Mr. Bhaskaran, the secretary of Kanhirode Weavers co-operative

P & S Society Ltd., for giving permission for conducting the project work in their

esteemed organization.

I express my deep sense of thank to Mr. Biju, Quality Handling officer and

Mr. Gireesh Kumar, Production Manger, for their continuous help and motivation

which help to me complete my study successfully.

Last but not least I thank my bellowed loving friends and all those helped

me in completing the study.

Taliparamba Arts & Science College,Kanhirangad 3

Project Report 2006 Dept. of BBM

CONTENTS

CHAPTER HEADING PAGE NO.

1 INTRODUCTION 5

2 AREA WISE ANALYSIS OF HANDLOOM IN 10

KERALA

3 RESEARCH METHODOLOGY 16

Objectives of the study

Research methodology

Limitations of the study

4 COMPANY PROFILE 18

5 DEPARTMENTS IN THE SOCIETY 37

6 PRODUCTION DEPARTMENT 40

7 MARKETING DEPARTMENT 43

8 PERSONNEL DEPARTMENT 62

9 FINANCE DEPARTMENT 72

10 PURCHASE DEPARTMENT 79

11 QUALITY CONTROL DEPARTMENT 86

12 FINDINGS AND SUGGESTIONS 93

13 CONCLUSION 96

Taliparamba Arts & Science College,Kanhirangad 4

Project Report 2006 Dept. of BBM

CHAPTER I

INTRODUCTION

Taliparamba Arts & Science College,Kanhirangad 5

Project Report 2006 Dept. of BBM

INTRODUCTION

The handloom was devised about 2000 Years ago and was brought to

England by the Romans. The process consisted of interlacing one set of threads

of yarn (the warp) with another (the weft). The warp threads are stretched

lengthwise in the weaving loom. The wefts, the cross-threads, are woven into the

warp to make the cloth.

Weaving remained unchanged for hundreds of years until John Kay

devised the flying shuttle. This enabled a weaves to knock the shuttle across the

loom and back again using one hand only. The speed of weaving was doubled,

and a single weaver could make cloths of any width, whereas previously two men

hand sat together at a loom to make broad cloth. By 1800 it was estimated that

there were 250000 handlooms in Britain.

Kerala, the greenish land lies between the western ghat and Arabian Sea,

about 15000 square miles with varying scenic beauty. Kerala is known as the

epitome of India. Historically Kerala has long been a land of racial mixture and

co-existence.

The milestone in Kerala’s history is that by first Christian church, First

Muslim mosque and first synagogue were established in Kerala. A number of

historically important Hindu Temples can be seen in Kerala.

Tolaracne and cosmopolitan out look are the characteristics of a “Keralite”.

This may be attributed to the religious and trade contract, which existed for

centuries with out side India. Handicraft handloom weaving, ivory works, Weaving

of coir are well known heritage of Kerala.Kerala handloom industry carries a vital

role in states economy as well as in the field of employment.

Taliparamba Arts & Science College,Kanhirangad 6

Project Report 2006 Dept. of BBM

A very large number of looms are located in rural areas. The rhythm of

handloom can be heard in almost every village in Kerala. There are men and

women weavers for whom weaving is a way of life. In early days majority of

handloom weavers followed the hereditary line. The main communities engaged

in weaving are saliyas and devangas. With the available information it is clear

that the saliyas and devangas migrated from the near by princely states.

Earlier they were producing cloth for their own consumption and for the

need of their village. Increase in production and improvement in transport

facilities removed the hindrances of time and easy the exchange of commodities.

The skill of weaving has been passed from parents to children.

During 15th century, British, French and Portuguese people visited Kerala.

The things like spices, ivory and beauty of handloom fabrics attracted them. They

began to purchase large quantities and exported to their countries.

Germany has established a mission called ‘Basal mission’ in 1829. This mission

paved the way of changing form home production to factory system. Apart from

this, French people started to give training in weaving. The imported versatile

loom and introduced principle designs from hooks.

After the British captured India they took up and nourished handloom

industries fro the purposes. At the end of 18 th century the monopoly came to an

end. Since 19th century with the advent of Industrial revolution, The English

people gave up all. They started mechanical production in their land during this

period of foreigners the weavers of Kerala learned al techniques and they

paralleled the way for the production of furnishing fabrics according to the new

style of demand.

During the dawn of 20th century, the Sree Narayana movement influenced

Kerala society by and large prompting the caste-based culture to change towards

Taliparamba Arts & Science College,Kanhirangad 7

Project Report 2006 Dept. of BBM

secular and modern industrious culture. So that many people from traditional

Thiyya/Ezhava community had take up their employment in handloom industry to

do away with the to day tapping to respond with the advice of Sree Narayana

Guru. These changes also have its own mark in making the present shape of

Kerala handloom industry. It has resulted in the production of various types for

artistic handloom goods in Kerala.

The women all over India for their fineness of count and natural colours,

texture and gold borders praise the ‘Kerala Kasavu Sarees’. Kerala is also known

for its unbleached cotton handloom crepe popularly known as ‘Kora’ cloth this

has entered in the foreign market and occupied a proud place in the garment

industry.

The secret of furnishing fabrics from Malabar is the excellent structure and

texture of the cloth, unique colour combination, wide width (98” - 120” ) and

craftsman ship. When we look back to the history of Kerala, it can be seen that in

1498 vascode Gama, the Portuguese navigator visited Calicut in Malabar. So it is

well known that 15th century handloom cloths of excellent qualities were exported

to Asian and European countries.

Balaramapuram, in Thiruvananthapuram district is the most historically

important place for handloom fabrics. The weavers belong to saliyas were

migrated from Nagar Coil and Thirunalveli in Tamil Nadu during the time of

Balarama Varma before 250 Years. Here they produced super fine ‘Mundum

Neriyathu’, for the need of royal family. Still they are existence and carry

important part of the total production. The technique of producing superfine

fabrics spreaded from them to the local weavers in Balaramapuram and

surrounding places. Initially they were producing ‘Mundu’ for men with 0.4cm of

width of “Kara” (cross border) with black yarn. Before 100 years the jeri from

Surat takes to Balaramapuram and “Kasavu Sarees” production was started.

Taliparamba Arts & Science College,Kanhirangad 8

Project Report 2006 Dept. of BBM

Koothampalli in Thrissur district is also well known for handloom fabric.

Here Devangas immigrated from Karnataka are engaged in weaving. The

‘Kasavu Sarees’, which are being produced here, is mostly with half fine jeri. The

middle class people would like to purchase this sarees because of its cheapness.

The price of a saree can be reduced from 5000 to 1000 by using half fine jeri

instead of pure jeri.

Chendamangalam, in the Eranakulam district is also an important

handloom center in Kerala. Here they have been producing the double and

‘Mudnu’ and ‘Neriyathu’. The distinction of these fabrics is in its structure in the

plain structure, they have producing a special effect in weft direction.

Taliparamba Arts & Science College,Kanhirangad 9

Project Report 2006 Dept. of BBM

CHAPTER II

AREA WISE ANALYSIS OF

HANDLOOM IN KERALA

Taliparamba Arts & Science College,Kanhirangad 10

Project Report 2006 Dept. of BBM

AREA WISE ANALYSIS OF

HANDLOOM IN KERALA

Kerala has 14 districts from Thiruvananthapruam to Kasargod. The

handloom industry is spread allover the state. But the handloom industry is

concentrated in certain places. The southern Kerala is famous for its superfine

products, like sarees, dhothies and ‘Set Mundu’ etc. The middle Kerala also

engaged with such products. Btu while going to northern side called Malabar the

main production changed to coarser verities like furnishing items, spreads, towels

etc. The common production in Kerala is ‘Thorthu’ (bathing towel) and ‘Lungies’.

Almost two lakhs of weavers are earning their livelihood from handloom 75% of

the mare in the co-operative line. Almost five lakhs families are depending upon

handloom industry.

A district wise analysis gives us a clear out idea about the places where

handlooms are concentrated and the places, which are important for traditional

verities.

1. THIRUVANANTHAPURAM:

The capital city has its own historical importance. And in the map of

handloom also it has an important place. There are 349 societies and 44700

weavers are working with their looms. The main products of district are fine

cotton textures; during with special design Balaramapuram is very famous for its

fine grey sarees with Kasavu (Jeri). The other products here are set mundu

‘mundum neriyathum’- (Traditional dress for a malayalee lady) ‘Mundu’ (dhothi for

men), Earezha thorthu (bathing towel) ‘Melmundu’ etc. Other places where

handloom concentrations are Parassala the south most of Kerala where weavers

are involved in weaving of sarees, dhothis, etc. Cheravinkeezhu, Kulathur are the

other places where handloom density places. Here also the productions are as

explained above be range of counts is 60s – 120s. The jeri used here is superfine

one.

Taliparamba Arts & Science College,Kanhirangad 11

Project Report 2006 Dept. of BBM

2. KOLLAM:

The very old city has few handloom production places. Her almost 80 co-

operative societies with 10271 registered weavers with their looms. In this district

almost all varieties produced in Kerala are produced in small scale. In olden days

the Kollam was an important port in south India. So the effect of exporting items

are effected the weaves in Kollam district Lungies, Furnishing items, Erazha

Thorthu, Sarees, Dhothies are the main products. Terry towels, Jacquard durries

we also produced.

Kollam, Karunagappally, chathannur, are the main places related to

handloom in the district. The products from these places are mainly for domestic

market. Therefore colours, fashions etc of these products suit the domestic

market.

3. PATHANAMTHITTA:

There are seven co-operative societies and 165 registered looms are here.

With these 281 weavers are earning their livelihood. In this district the main

products are lungies and dhothies.

4. ALAPPUZHA:

Alappuzha is very famous for its coir products. Coir weaving also done

with the hands only. But its is considering as another wing. The main products in

these centers are mainly dhoties, sarees, lungies, erazha thorthu, etc. There are

25 co-operative societies with looms and 2309 weavers in this district.

5. KOTTAYAM:

In Kottayam district the main products are Earezha Thorthu, Panimundu,

and Lungies. They are also producing bed sheets and sarees. There are 16

societies with looms and 1853 weaves are here. Kidangoor, Karingannoor, are

main centers.

Taliparamba Arts & Science College,Kanhirangad 12

Project Report 2006 Dept. of BBM

6. IDUKKI:

In this district there are 11 societies and 414 weavers with their looms. The

main products are sarees, lungies etc.

7. ERANAKULAM:

‘Chennamangalam Sarees’ is famous in Kerala. This fine grey sarees are

the product of Eranakulam District. The main products are super fine double

dhothies, synthetic and silk sarees, matching set etc. In Paravoor 120s fine

double dhothies are produced. In east Eranakulam, earzha thorthu, and cheaper

variety bed sheets are produced. There are 30 societies and 8494 weavers with

their looms.

8. THRISSUR:

The cultural capital of Kerala has an important role in the tradition of

Kerala. Here a traditional variety named ‘Koothampally Saree’ is produced.

Koothampally is a place situated in Thrissur. The productions are set mundu,

woven with half fine jeri., Dhothies, Lungies are also produced in this district.

There are 30 societies in Thrissur and 6052 weavers.

9. PALAKKAD:

In this district is handloom weaving is very popular Chittur, Pudunagaram,

Kollengode, Peruvemba, Karimpuzha are some of the handloom concentrated

place situated in the district. Here main products are sarees, dhothies, lungies

etc. here silk sarees production also started recently. There are 45 societies and

11236 weavers depending on the handloom weavers with their looms.

Taliparamba Arts & Science College,Kanhirangad 13

Project Report 2006 Dept. of BBM

10. MALAPURAM:

A number of Muslim weavers are here. The main places are Tiroor, etc.

The main products are furnishing items, which influenced from Calicut and

sarees, lungie. There are 13 societies and 2774 weavers.

11. KOZHIKODE:

The district from Malapuram to Kasaragod known as Malabar. The

famous “Malabar loom” came from this place only. The other famous of this place

is, in olden days famous “calico cloth” came from Calicut only. In olden days

foreigners established some companies. Some of them remaining now also.

“Common wealth Trust” which is situated in Calicut is one such company. The

main products are mainly meant for export. Furnishing, Jacquard products, Bed

sheet, Tablemats, coarser varieties etc. The products are mainly coming from

Malabar loom.

The products from Kozhikode have an excellent value in domestic market

also. The main centers are Kozhikode, Qualandi, Vatakara, Chombal, and

Maniyur etc. There are 41 societies (most of them are industrial societies) are in

this district.

12. WYANAD:

There is not that much important in this high range. There are only four

societies in this district and 136 weavers. The products will be a part of Calicut

and Kannur.

13. KANNUR:

Kannur is called as “the Manchester of Kerala”. The famous Kannur sports

shirting, varieties like crepe is the donation of this district. The weavers are

mainly working industrial societies.

Taliparamba Arts & Science College,Kanhirangad 14

Project Report 2006 Dept. of BBM

For export of handloom products Kerala mainly depending upon the products

from Kannur. The main products are shirting, made-ups, Jacquard, Furnishing,

Turkish towels, Sateen sheets, Crepe such export oriented and Lungies, Earzha

thorthu etc for domestic purpose. The products are coaser varieties Kannur

Mundu are a popular variety.

The main centers are Kannur, Azhikode, Chirakkal, Kanhirode, Irinav,

Morazha, Mayyil, Panoor, Kuthuparambu, Kalyassery, and Pappinissery etc.

There are 73 societies established in this district and with about 50 exporters in

private sector together have, 13667 weavers working this field.

14. KASARAGOD:

Kasaragod is the north most district in Kerala. Here sarees are produced

and export varieties also produced here. Kasaragod, Mancheswaram are main

centers. 11 societies are here and 3401 weavers working in there societies.

Kasaragod sarees are very famous in Kerala. Now a days there is a very

good demand for the silk sarees woven with different colours pattern and

ornamented sarees.

Taliparamba Arts & Science College,Kanhirangad 15

Project Report 2006 Dept. of BBM

CHAPTER III

RESEARCH METHODOLOGY

Taliparamba Arts & Science College,Kanhirangad 16

Project Report 2006 Dept. of BBM

RESEARCH METHODOLOGY

OBJECTIVE OF THE STUDY:

To know about the administration and management of KWCS.

To know about the production processes carried out in the KWCS.

To know about the personnel policies of the KWCS.

To known about the marketing strategies of the KWCS.

To know about the quality control measures used by KWCS.

To known about the financial policy of the KWCS.

RESEARCH METHODOLOGY:

Primary data is collected through personal interview with manager,

secretary, and other staff of the society.

Interactions with various departmental heads and supervisors.

Secondary data is collected from company’s annual reports and other

published materials.

LIMITATION OF THE STUDY:

A detailed study could not be made due to time constraints.

A comparative study with a similar concern was not made.

Taliparamba Arts & Science College,Kanhirangad 17

Project Report 2006 Dept. of BBM

CHAPTER IV

COMPANY PROFILE

Taliparamba Arts & Science College,Kanhirangad 18

Project Report 2006 Dept. of BBM

COMPANY PROFILE

The Kanhirode weavers co-operative P & S society is one of the main

handloom manufacturing unit in Kerala. This society is registered as a co-

operative society under the Act of VI of 1932 (Madras) on 16-9-1952 and started

its function on 05-10-1952. At that item it’s paid up share capital was only 10,130

Rupees. It is also known as “weaveco”.

The main object of the society is to provide regular employment to poor

workers at a reasonable wages and there by improving the standard of living and

economic conditions of the weavers.

In the initial period, the company ahs only 200 members and they

produced “Thorth” and “Pudava”. They sold these products in their locality by the

weavers. Later bullock cart have used to carry these goods.

The society is engaged for manufacturing various kinds of cotton fabrics.

Which is suitable for export market as well as local market. The 1964-65’s was

the period, which gave the society a hope to shine in the textile world and they

started to produce shirting, lower count lungies. Which were sold different parts of

the country through agents.

During 1973-74, the society started to producing crepe fabrics which

attached orders of merchant exporters. Then again started production of

furnishing fabrics suitable for export market and the products to merchant

exporters.

The Kanhirode weavers co-operative society is an ISO 9001-2000 certified

company. It is the first ISO certified handloom co-operative society in the state.

The society has very good market for its products.

Taliparamba Arts & Science College,Kanhirangad 19

Project Report 2006 Dept. of BBM

The society’s address shall be Kanhirode village, Kanhirode post in the

Taluk of Taliparamba, in the cannanore district. Its operation shall be confined to

Kanhirode and Kuttiatoor Amsam in Taliparamba Taluk, Munderi and

Anjarakandy Amsams in Kannur and Koodali in Tellichery Taluk.

The company having workforce of 500 workers and 300 working looms

with various width capacity from 48-90 inches. It includes five looms for silk. They

are also having 30 stitching machines and two dehumidification rooms to keep

the geniuses of fabrics.

Majority of the society employees are females. There by ensuring the

economic freedom of the major households in around the locality.

The company mainly producing different items like lungies, shirting, saten

and printed bed sheet, bed spread, Dhothies, Towels, Thorth etc. for local market

and furnishing fabrics, jacquard items, shritings, crepe, bed sheet, table cover,

Napkin, Cushion covers etc for export markets. For the last 8 years the company

engaged in direct exporting. The earn 75% of profit from international markets.

They produced goods on the basis for customers requirement.

For the diversification of products, the company had established a silk

weaving centre, and a jute development center, quality dyeing unit etc. the

society had availed financial assistance from central and state government for the

following purposes.

1. Working capital for handloom development centre.

2. Silk weaving unit.

3. Quality draining unit.

4. Project package scheme.

5. Jute development centre.

Taliparamba Arts & Science College,Kanhirangad 20

Project Report 2006 Dept. of BBM

The important requirements for any business activities are land, labour,

capital and organization. This company ahs permanent building and adequate

workforce, storage places and other working environment requirements as per

the factory act of Land. The company also has adequate equipments for

manufacturing as well as other documentation requirements like computer and

other accessories. Al these facilities are very helpful in the success of this

society.

The society has a better working environment. The workers enjoy the best

working atmosphere. Like space, machinery, wages etc. fabrics and made-ups

manufacturing is not hazardous to the personnel involved in it. How ever the

company strictly supported to all mandatory requirements of safety like fire

extinguishers, first aid facilities.

LOCATION OF KWCS.

Kannur, “city of Looms and lores” lies in northern part of Kerala. The

kanhirode weavers co-operative P & S society Ltd. is located at Kudukkimotta.

This place is 15KM away from Kannur and it is near to the Mattannur.

VARIOUS FECILITIES AVAILABLE IN THE KWCS.

Cabinet dyeing machine with capacity of 250 Kg.

Dyeing chamber with capacity of 500 Kg.

300 working looms with up to 90 inches.

10 numbers silk weaving loom width up to 90 inches.

Dehumidification rooms for moisture control of fabrics.

In house stitching unit with 30 numbers juki machines.

Taliparamba Arts & Science College,Kanhirangad 21

Project Report 2006 Dept. of BBM

VISION OF KWCS

A complete range of handloom fabrics inheriting age-old tradition of classic

warp weft combinations importing modern chrematistics of convenience without

compromising up on the core values of quality.

The fabric range has been created through adequate research and

expertise that will enable Indian textile to acquire a competitive edge in global

market.

AWARDS GOT BY KWCS:

1. The first ISO 9001-2000 certified primary handloom co-operative society in

the state.

2. The contribution of the society in the field of craftsmanship was well

appreciated and awarded with GOLD MEDAL for the BEST

PERFORMACNE by the ministry of textiles, Govt. of India during 1993-94.

3. The Govt. of India had selected this society for participation in international

Trade Fair at Frankfurt, Germany during 1995 and 2004.

Taliparamba Arts & Science College,Kanhirangad 22

Project Report 2006 Dept. of BBM

MEMBERSHIP

The liability of the members of the society shall be limited to the share

capital subscribed by them.

The capital of the society shall for the present be Rs 4000000/- made up of

40000 shares of Rs 100/- each. The value of each share shall be paid either in

one lumsum on allotment, or installment, when paid in installment Rs 25/- shall

be paid at the time of taking share and the balance in five months commencing

from the months subsequent to that in which share was taken. In the case of

weaver members, installment maybe collected, as stipulated in bylaw 16 CA. The

monthly installments shall be paid on before 15 th day of the months to which it

relates.

Application for admission as members and for allotment of shares shall be

made to the secretary in the form, if any, prescribed by the society for the

purpose. The Board of Directors who shall be disposed of by the Board of

Directors who shall have power to grant admission or to refuse it without

assigning reasons shall dispose of every such application.

Every member shall take at least one share, but no member shall take

more than 50 shares. But this application is not applicable for the share

participation by the Government of Kerala. In very member except govt. of Kerala

shall pay on entrance fee or Rs 5/- for each share taken by him, at the time of

taking the share, provided that the total payment of entrance fee by any member

of all the shares held by him shall not exceed Rs. 5/-.

No member shall be permitted to withdraw any of the shares held by him

in the society with in three years after the date when he took such shares. But a

member may with draw shares with the consent of the board of directors after

such period, provided, firstly that he has given at least six months notice of

Taliparamba Arts & Science College,Kanhirangad 23

Project Report 2006 Dept. of BBM

withdrawal, secondly that the total amount of share capital that is permitted to be

withdrawn in any one year does not exceed 10 percentage of the aggregate paid

up share capital of the society, as it was on June 30 th proceeding, thirdly that

there are no debits due to the society and fourthly, that there are no debts due to

the society in regard to which he has stood surety. When a member withdraws

shares under this bylaw, he shall be paid back the share capital actually paid by

him with the dividend declared if any.

The Govt. of Kerala shall have the right to withdraw the share participation

in the society at any time with out assigning any reason thereof.

A past member shall be liable as provided in bylaw 3 for the debts due by

the society, as they existed on the date when he ceased to be member, for a

period of two years from such date.

The estate of a deceased member shall be liable as provided in the bylaw

3 for the debts due by the society, as they existed on the date of his decease for

a period of two yeas after his decease.

No member shall be permitted to transfer his share or shares or create a

charge in respect of the same in favour of another member or person except with

the previous sanction of the Board of Directors.

Taliparamba Arts & Science College,Kanhirangad 24

Project Report 2006 Dept. of BBM

MANAGEMENT OF THE SOCIETY

Subject to such resolutions as the general body may from time to time

pass the Executive Management of the affairs of the society shall vest in a Board

of Directors. The Board of Directors shall consists of not more than a members of

whom 7 members shall be elected as stipulated in bylaw No. 20 and the two

members shall be nominated by the District industries officer from his staff and

their term of office shall be subject to the direction of the District Industries

Officer.

The members of the board of directors shall be elected as per the rule 35

of Kerala co-operative rules for a period of five years from among the members

for the period of the members of the Board the year shall begins from the date of

assumption of the office. A retiring member of the Board shall be eligible for re-

election. After the member of the Board of Director are elected they shall elected

from among themselves a president and a vice-president.

All the members of the Board of Directors shall vacate their offices on

completion on their term of five years unless the period is extended by the

Registrar under sub-rule (2) of Rule 39 of the Kerala Co-operative Rules. All the

members of the board of directors shall be elected at one and the same time for

the specified period of five years. Any interim vacancy or vacancies, which has

not been filled, may be filled up by the election as per rule 35 of Kerala co-

operative rules for the unexpired portion of the original period. The proceedings

of the board of directors shall not be invalidated on account of any vacancy or

vacancies of the board that remain unfilled.

Any member of the board of directors may at any time resign from his

office by sending a letter of resignation to the secretary of the society but such

resignation shall take effect only from the date of the society but such resignation

Taliparamba Arts & Science College,Kanhirangad 25

Project Report 2006 Dept. of BBM

shall take effect only from the date on which it is accepted by the board of

directors. The board shall appoint a full time paid secretary from among suitable

qualified persons approved by the general manager. District industries officer,

Kannur. The secretary shall not have a seat in the board.

The board of directors shall meet once a fortnight or oftener, if necessary

to conduct the affairs of the society. The president or in his absent. Vice-

president shall preside over the meeting of the board. In the absence of the both

a chairman shall be elected from among the members present. The quorum for

the directors meeting is four. All the questions before the board of directors shall

be decided by a majority of votes. Should there be an equality of votes the

president or other presiding members shall have a casting vote. No member of

the board of directors shall be present at any meeting of the board of directors

shall be present at a meeting of the board when any matter in which he is

personally interested 15 being discussed. In case of urgency where there may

not be sufficient time to convene a meeting of the Board of Directors and in all

case in which such a procedure may from time the secretary may obtain the

orders of the Board of Directors by circulation of papers among members present

at the headquarters of the society such division arrived at by circulation shall be

placed before the next meting of the board of directors for their rectification. It

should a difference of opinion arise in the course of such circulation the member

shall not be decided by the circulation but shall be placed before a meeting of the

Board of Directors.

Any member of the Board of Directors who commits default in respect of a

loan taken by him from the society shall ipso facto be considered disqualified to

continue as an office bearer. But if the default has been for a period of 3 months

or less, the defaulter may reinstated by the General body on his showing good

cause for the default. In no circumstances a defaulter continue to hold office as a

member of the board of directors if his default has continued for more than three

months.

Taliparamba Arts & Science College,Kanhirangad 26

Project Report 2006 Dept. of BBM

Receipt shall be issued for all moneys paid to the society. For moneys

paid by members the receipts shall be signed by the president or the secretary,

or the manager who ever is selected by the board of directors to discharge his

function. In the case of borrowing from non-members or from other society the

receipt of the bond shall be executed by at least four members of the board of

directors of whom the president shall be one.

The board of Directors shall have power to prescribe from time to time the

scale of office establishment and to inure such expenditure as may be necessary

for the management of the society with reference to the scale and with in budget

allotment sanctioned by the general body for each year which will be subjected to

the approval of the Dy. Registrar. It shall be competent to the secretary to insure

the peti contingent expenditure subject to a maximum of Re. 1/- for any time. The

board of directors shall be competent to fix the amount and nature of the security

if any, to be given by the office establishment, as prescribed by the Registrar.

The services of the members of the Board of Directors shall be gratuitous

except as provided under bylaw 50. They shall be eligible for sitting fee for

attending the board, sub-committee meeting and the president shall be eligible

for a daily allowance for attending the office. The board of directors shall also

eligible for Traveling allowance for the journey performed in connection with the

affairs of the society. The rate of sitting fees, daily allowances and Traveling

allowances should be fixed by the committee and approved by the registrar.

Taliparamba Arts & Science College,Kanhirangad 27

Project Report 2006 Dept. of BBM

BOARD OF DIRECTORS OF KWCS

1. Sri. Kala Balan : President

2. Sri. K. K. Narayanan : Vice-President

3. Sri. K. Rameshan : Director

4. Sri. M. Pavithran : Director

5. Sri. V. M. Rajan : Director

6. Sri. P.P. Kumaran : Director

7. Sri. P. P. Kumaran : Director

8. Smt. P. Sumithra : Director

Taliparamba Arts & Science College,Kanhirangad 28

Project Report 2006 Dept. of BBM

COMPANY ADDRESS

Name of the Company: The Kanhirode Weavers co-operative

P & S Society Ltd., No. L.L.44

Registered Office: Kanhirode (P.O),

Koodali (Via)

Kannur Dist.,

Kerala – 670592

India

Telephone: 0497-2857259

0497-2857865

Fax: 0497-2858546

E-Mail: weavecoknr@sancharnet.In

weaveco@rediffmail.com

weavecoknr@hotmail.com

Website: www.weaveco.com

Bankers: Kannur Dist. Co-operative Bank.

SBI

SBT

Auditors: Dept. Co-operative society,

Asst. Registrar office, Kannur.

Taliparamba Arts & Science College,Kanhirangad 29

Project Report 2006 Dept. of BBM

PRODUCT PROFILE

The Kanhirode Weavers co-operative P&S society Ltd. produced different

types of handloom products for local market and international market. They are

as follows.

For Local Market:

Lungies

Shirtings

Satin and printed bed sheet

Dhothies

Towels

Thorth

Saree

International Market:

Furnishing Fabrics

Jacquard items.

Shirtings.

Crepe

Bed sheet

Bed spreads

Table cloth

Napkins

Cushion covers

Curtains

Sofa cases

Sofa covers

Floor mats

Bolster

Taliparamba Arts & Science College,Kanhirangad 30

Project Report 2006 Dept. of BBM

ACTIVITY CHART OF KWCS

Buyers order Yarn Purchasing Boiling

Inspection

Vertical warping Bobbin winding Dyeing

Beaming Drawing & Denting Pirn winding

Sewing Cutting Weaving

Inspection

Button holing & Finishing &

buttoning Pressing Packing

Inspection

Billing Stock entry Pricing

Dispatch

Taliparamba Arts & Science College,Kanhirangad 31

Project Report 2006 Dept. of BBM

ORGANISATION STRUCTURE

Board of Directors

President

Secretary /CE

Management

Representative

Manager Export & Weaving Dyeing Business

Administration Master Master Manager

Production Manager Q.A Supervisor

Quality controller

Store Keeper

finishing works

Accountant Accounts

Assistant

Taliparamba Arts & Science College,Kanhirangad 32

Project Report 2006 Dept. of BBM

AUTHORITY AND RESPONSIBILITY

1. President:

He is responsible to:

To take policy divisions of the company.

To make investment division, long term financial commitments and

diversification plan of the company in consultation with board of directors.

2. Chief Executive/Secretary:

He is responsible to:

Define and document the company’s quality policy and objectives.

Provide adequate resources for implementing QM.

Discharge the duties of purchase manager.

Over all operations of the company.

Allocation of various resources to the different departments.

Assessing the training needs of the HOD’s and initiates training programs.

New customer development.

Attend the fair ad develop new markets and new customers.

Procure orders for the company.

Handling customers complaint.

Define company’s long-term business plans.

3. Management Representative:

Establish, implement, maintain and monitor quality system.

Control the distribution of QM, SOP, WI and TAD.

Plan and arrange internal quality audit.

Co-ordinate the activities concerned with the external agencies.

Responsible to reporting to the top mgt on the performance quality

management.

Taliparamba Arts & Science College,Kanhirangad 33

Project Report 2006 Dept. of BBM

4. Manager-Raw material purchase:

Establish and document specification for raw materials and accessories.

Assess the availability of raw materials and accessories as per the

requirements.

Purchase the raw material through purchase orders.

Development the new raw-material suppliers.

Acts as a factory manager.

Maintain inspection status of raw materials and accessories in the store.

Production, planning and control activities.

Responsibility for issues of materials, stock updating, and material

reconciliation for yam, dyes and chemicals.

5. Weaving Master:

Plan and execute the production activities at the weaving production units.

Allocation of work to various workmen.

Ensure the product characteristics during production.

Assess the training needs of the work force in weaving dept.

Initiate the corrective action in the dyeing and weaving dept.

Preserve the approved samples/customer samples with proper

identification.

Acts as custodian of grey and dyed yarns.

Maintenance of weaving machines.

6. Quality Assurance supervisor (QAS):

Ensure inspection of yarn, dyes and chemicals accessories, and fabrics,

made up and garments at all stages.

Maintain inspection status of raw materials in process and finished goods.

Taliparamba Arts & Science College,Kanhirangad 34

Project Report 2006 Dept. of BBM

Arrange proper handling, storage and presentation of raw materials and

accessories.

Prepare suppliers evaluation record.

7. Production Manager:

Develop new samples as per the requirements communicated by CE.

Develop designs from the existing samples.

Prepare costing details of samples.

Ensure the all required accessories are available in the unit before made-

ups the production started.

Initiate the corrective action and preventive action as necessary.

Help the CE in the mater of matter of marketing activities.

Responsible for verification of yarn, dyes and chemicals.

8. Dyeing Master:

Production, planning and control in the dyeing dept.

Maintenance of the dyeing machines.

Prepare the recipe as per the shades required.

Maintain the master shade card.

Approve dyed yarn before issued to further processing.

Safe keeping of dyes and chemicals in procurements.

9. Manager Export & Administration:

Handle all export/import and banking formalities.

Liaise with clearing agents regarding the shipments of merchandise.

Communicate with customers.

General administration of the company.

Carry out stock verification activities.

Taliparamba Arts & Science College,Kanhirangad 35

Project Report 2006 Dept. of BBM

10. Business Manager:

Assist secretary to procure orders.

Assist the secretary to co-ordinate with buying houses and buying

agents.

Assist the secretary to handle customers complaints.

Taliparamba Arts & Science College,Kanhirangad 36

Project Report 2006 Dept. of BBM

CHAPTER V

DEPARTMENTS IN THE SOCIETY

Taliparamba Arts & Science College,Kanhirangad 37

Project Report 2006 Dept. of BBM

DEPARTMENTS IN THE SOCIETY

The Kanhirode weavers co-operative society is one of the famous

handloom products manufacturing society in Kerala. This society working under

the co-operative societies act. The overall control of the society is the secretary of

the society controls came under the board of directors and all day-to-day

activities.

This society has different departments for functioning different specialized

activities. The main departments in this society are production department,

Finance departments, Marketing departments, Personnel department, Quality

control department and purchasing department.

Weaving and dyeing are the main production process in the society. They

produce different types of handloom products for local market and international

markets. The foreign countries have heavy demand in handloom products so

they mainly concentrated in export marketing.

Production is the main activity in the society. The production department

functioning very well in this society. They are designing and producing quality

products as per the requirements of the parties for local market and international

market. They utilise the equipments, labours and other facilities in the society in a

maximum manner and to make uninterrupted production of goods.

The finance department of in the society, prepare various financial

statements like trading ale, P & L ale, Balance sheet etc. This society has its own

finance department under a financial manager.

The marketing department concerned with the marketing of the goods

produced by the society. It is one of the important functions in an organization.

The efficient marketing department helps to achieve the organizational

objectives. It is very important in handloom manufacturing

Taliparamba Arts & Science College,Kanhirangad 38

Project Report 2006 Dept. of BBM

Industries. The problem of marketing is greatly affecting the industries in India,

especially in Kerala. Many cotton mills and cotton textile industries are closed

due to the inefficient management of the marketing area.

Personnel department is concerned with the obtaining and maintaining of

a satisfied and satisfactory work force in an organization. It is an extension of

general management. The primary objective of this department is to satisfying

employees and achieving organizational objectives. This society provides various

welfare measures to its employees for motivating them.

The quality control department plays an important role in an organization.

This society has an efficient quality control department headed by the quality

assurance supervision (QAS). This department checking raw materials, work-in-

progress and finished goods and to ensure the quality. It conducts various tests

for ensuring quality.

The main raw materials used in the production like yarns, dyes, and the

purchasing department purchases chemical. This department purchase material

on the basis of quantity of production. They mainly purchased materials from

National Handloom Development Corporation (NHDC). It may be either on cash

or on credit basis.

Taliparamba Arts & Science College,Kanhirangad 39

Project Report 2006 Dept. of BBM

CHAPTER VI

PRODUCTION DEPARTMENT

Taliparamba Arts & Science College,Kanhirangad 40

Project Report 2006 Dept. of BBM

PRODUCTION DEPARTMENT

Among all the functional areas at management, production is considered

to be crucial in any industrial organization. Production is the process by which

raw materials and other inputs are converted into finished goods. It means

generation of goods or services to satisfy customer’s needs. The other word

synonymously used with production is manufacturing. Manufacturing is

understood to refers to the process of producing only tangible goods. Where as

production include creation of both tangible goods as well as intangible service.

Production management refers to the application of management

principles to the production function in a factory. In other words production

management involves application of planning, organizing, directing and

controlling of to the production process.

The application of management to the field of production has been the

result of at least three developments. First is the development of factory system

of production. Until the emergence of the concept of manufacturing, there was no

such thing as management as we know it. It is true that people operated business

of one type or another, but for the most part these people were owners of the

business and did not regard themselves as managers as well. The second

essentially stems form the first, viz, the development of the large-scale

organization with many owners and the necessity to hire people to operate the

business. The third reason stems from the work of many of the pioneers of

scientific management who were able to demonstrate the value from a

performance and profit point of view, of some of the techniques they were

developing.

The production department is normally under a production manager. He

assists the production functions. The production manager is the co-ordination link

between production department and the society.Production department must

work in coordination with planning as that both of the production target and as

estimated by the objectives are achieved.

Taliparamba Arts & Science College,Kanhirangad 41

Project Report 2006 Dept. of BBM

The production department maintenance the progress of different departments in

the society. The production manager has to the responsibility to the co-ordinate

the availability of raw-materials, machines, labours etc. and also fore cast any

possible delays which could affect the production. The efficient working of the

production department can prevent delays before they arise and there by

ensuring maximum utilization of production capacity.

The inspection department in factory has a major responsibility in as much

as it has to estimate loses due to low quality material purchasing, control in time

all detective production and ensure quality of raw materials, work in progress and

finished goods. A good inspection department is very helpful for achieving

production quality.

PRODUCTION SYSTEM IN KWCS LTD.

The kanhirode weavers co-operative P & S society produces different

types of handloom products for local market and international market. They

produce products on the basis of orders. This society has its own production

factory with inches looms. There are 345 workers are engaged in production

process. They produce pure cotton products with different colours and designs on

the basis of order received from parties.

The main raw materials used in the production are;

Yarns

Dyes

Chemicals

Accessories

Taliparamba Arts & Science College,Kanhirangad 42

Project Report 2006 Dept. of BBM

They purchase these raw materials from Government agencies, National

Handloom Development corporation (NHDC) and also purchase materials from

private firms. At the time of purchase materials from NHDC, they provide different

subsidies. The purchase of raw materials either on cash or on credit basis. The

purchase department does this.

Taliparamba Arts & Science College,Kanhirangad 43

Project Report 2006 Dept. of BBM

PRODUCTION CAPACITY

SCOURING

IN HOUSE 6000 Bundles/Month

BLEACHING & DYEING

IN HOUSE 6000 Bundles/Month

WEAVING

Width Monthly In house capacity Monthly outsource

100 Inches 500 Mts 2000 Mts

90 Inches 500 Mts 2000 Mts

72 Inches 1000 Mts 2000 Mts

60 Inches 3000 Mts 3000 Mts

54 Inches 1000 Mts 2000 Mts

48 Inches 2000 Mts 2000 Mts

36 to 42 Inches 2000 Mts 2000 Mts

JACQUARD

60 Inches 1000 Mts 3000 Mts

STITCHING

IN HOUSE 4 machines

OUT SOURCE 25 machines

Taliparamba Arts & Science College,Kanhirangad 44

Project Report 2006 Dept. of BBM

PRODUCTION PROCESS CHART

BOILING

DYEING

WINDING

WARPING

WEAVING

QUALITY INSPECTION

CUTTING & SWEING

Taliparamba Arts & Science College,Kanhirangad 45

Project Report 2006 Dept. of BBM

PRODUCTION PROCESSES IN KWCS

The main production processes in Kanhirode Weavers Co-operative

society Ltd. are as given below.

Boiling

Dyeing

Winding

Warping

Weaving

Quality inspection

Cutting & Sewing

1. Boiling

Boiling is the first step in the production process. It is done for removing

the impurities present in the yarn used for bleaching and dyeing. Fro the boiling

process they use wood as fuel. The processed yarn is bleached using bleaching

powder/and hydrogen peroxide according to the requirements.

2. Dyeing

Dyeing is the process of impregnating the fiber, yarn or fabric with the

dyestuff. Dyeing can be done on the yarn, fiber or fabric. It is the method by

which colour is applied to the fabric. Usually they are dyeing the material on the

yarn stage.

3. Winding

Winding converts the package of the yarn the hank yarn is wounded on

the pirn (small bobbin used in handloom weaving) for preparing the weft. It is

done manually, especially of ladies are engaged in this work.

Taliparamba Arts & Science College,Kanhirangad 46

Project Report 2006 Dept. of BBM

4. Warping

Warping is the preparatory stage for weaving. Which prepares the yarn for

weaving. Cones of yarn are created on to a machine and winding about 500 to

700 threads produce a sheet of yarn on beam together.

5. Weaving

Weaving is interlacing of vertical yarn (warp) and horizontal yarn (weft).

Depending on the type of the weave, warp yarn sheet is divided and lifted. Weft

yarn is carried across in a pirm held in a shuttle. This is the basis weaving

process. The shuttle is thrown from one end of the warp sheet to another end by

hand.

6. Quality Inspection

Quality of the products is thoroughly checked by trained and qualified

employees. The inspection is carried out various stages such as purchase of raw

materials, during manufacturing process and final stage to assess the status of

the product for acceptance or other wise.

7. Cutting & Sweing

The made-ups are then stitched at the society. Styles are followed in

precision with great care given to detailing in each and made-ups items. This unit

has a workforce of 45 workers.

Taliparamba Arts & Science College,Kanhirangad 47

Project Report 2006 Dept. of BBM

CHAPTER VII

MARKETING DEPARTMENT

Taliparamba Arts & Science College,Kanhirangad 48

Project Report 2006 Dept. of BBM

MARKETING DEPARTMENT

The success of every business organization depends on providing right

product at right time in right quantity to the customers. Marketing deals with all

activities, which create, promote and distribute products in accordance with the

customers demand.

Marketing management is another important functional department in the

society. It is concerned with decisions and policies relating to the marketing

activities in the business. The concept to market has three inter related aspects

place; which pre supposes a convenient meeting place for the buyers and sellers.

Area aspect; which limits the market to a convenient area, the demand aspects

which implies customer demand. Marketing is the process of discovering and

translating the consumer needs and wants into products and services. And they

in turn making it possible for more and more consumers to enjoy more and more

of those products and services.

This society produced products mainly for exporting. In the society more

than 75% of the products are exported.

The KWCS Ltd produces different types of handloom products for local

market and international market.

For Local Market

Lungies

Shirting

Satin & Printed bed sheets

Dhothies

Towels

Thorth

Saree etc.

Taliparamba Arts & Science College,Kanhirangad 49

Project Report 2006 Dept. of BBM

For International Market

Furnishing Fabrics

Jacquard Items

Shirtings

Crepe

Apron

Bed sheet

Bed spreads

Table cloth

Napkins

Cushion covers

Curtains

Sofa cases

Sofa covers

Floor mats

Balster

Terry towels

Other made-ups etc.

This society mainly exported to UK and USA. And other countries are

Australia, France, Germany, Italy, Dubai, Hong Kong, Europe etc. They produce

and export these. Products on the basis of orders from foreigners. After receiving

the orders from parties and produced with high quality and then exported.

They started exporting in 1960 to 1970. At that item they exported in small

quantities. Later the major portion of productions is selling through exporting.

They export more than 75% of the total production and earn more profit.

For catching foreign customers they conduct exhibitions in foreign

countries.

Taliparamba Arts & Science College,Kanhirangad 50

Project Report 2006 Dept. of BBM

They export their products through ships and airways. Mostly they use

ship because of less transportation cost. They adopt two types of marketing in

exporting. They are,

1. Merchant Exporters

2. Direct Exporting

1. Merchant Exporters.

These are the middlemen for party and the company. The collect orders

from parties and the society receive orders from these merchant exporters.

According to these orders the society produced products.

2. Direct Exporting

In this type of export, the society directly conducts with the foreign

customers and collects orders from these parties. Then produce products on the

requirements of customers and export these products directly. This company

started direct exporting in the year 1998 on wards. Now a day they gave more

importance to direct exporting.

They earn 75% of profit in international market and earn 25% profit in

domestic market.

The 25% of products are sold in local market through dealers (deports)

and exhibitions etc. During the festival season they conduct exhibitions in various

places. They have six depots; they are in Kudukkimotta, Kanhirode, Taliparamba,

Kuttiyattoor, Kambil and Iritty.

The prices of the products are fixed on the basis of cost of production and

certain percentage of profit. They also provide 20% discounts or rebate for its

products.

Taliparamba Arts & Science College,Kanhirangad 51

Project Report 2006 Dept. of BBM

MARKETING CHANNELS

For International Market:

Company Merchant Exporters

Customers

For Local Market:

Company Dealer (Deport) Customers

Following are main products for local market.

1. Bed Sheet

The Bed sheet is one of the main products in local market. There are three

types of bed sheet are manufactured by the society. They are plane, printed and

check. From these printed bed sheet is of more demand in the market compared

to other two’s. The cost of printed bed sheet is high because printing charge will

be insured in it.

2. Lungies

It is of high demand in the local market the read in lungies are 60, 72, 80

and 100.

3. Shirtings

Taliparamba Arts & Science College,Kanhirangad 52

Project Report 2006 Dept. of BBM

The demand for shirting is very high because it is made pure cotton. The

brand name used by the society in selling the shirting items are a “weaveco”. The

company is planning to concentrate on the market of ready-made shirts.

4. Dhothies

Dhothies are two types; they are double dhothi and Kavi dhothi.

In Marketing, they function of buying implies buying raw materials by

manufacturers for use in production of buying goods by middlemen or sale to

consumers and not buying of goods by consumers for final consumption. Buying

refers to the purchase of the right type of goods in right quantity, at the right time

from the right source at the right place.

Selling is another important function of marketing. Selling include,

1. Product planning and development, forecasting consumer needs etc.

2. Searching for new uses of the product.

3. Creation, maintenance, and extension demand for goods through such

means as advertising, personal selling, sales promotion etc.

4. Negotiation with the buyers as to the terms of sale made of delivery, terms

of payment etc.

5. Entering into final contract with buyers and effecting transfer of ownership

and possession of goods to the buyers.

This company sells its products through local market and international

market. The sales turnover and export sales turnover of the company are given

below;

Taliparamba Arts & Science College,Kanhirangad 53

Project Report 2006 Dept. of BBM

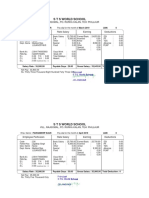

SALES TURNOVER FOR THE LAST 4 YEARS.

2001-2002 Rs. 39672917

2002-2003 Rs. 37981807

2003-2004 Rs. 47115928

2004-2005 Rs. 42524980

Taliparamba Arts & Science College,Kanhirangad 54

Project Report 2006 Dept. of BBM

SALES TURNOVER CHART FOR THE LAST 4 YEARS

EXPORT SALES TURNOVER FOR THE LAST 5 YEARS.

Taliparamba Arts & Science College,Kanhirangad 55

Project Report 2006 Dept. of BBM

2000-2001 Rs. 25502166

2001-2002 Rs. 32557209

2002-2003 Rs. 26660562

2003-2004 Rs. 34262702

2004-2005 Rs. 28502695

Taliparamba Arts & Science College,Kanhirangad 56

Project Report 2006 Dept. of BBM

EXPORT SALES TURNOVER CHART FOR THE LAST 5

YEARS

Taliparamba Arts & Science College,Kanhirangad 57

Project Report 2006 Dept. of BBM

Production and consumption are linked through transportation.

Transportation is an important function of marketing. The speed and reliability of

transportation encourages the function of storage. The manufactures need

transportation for carrying machinery and raw materials to the factory. Then

finished goods have to be transported to the middlemen and finally delivered to

the consumers, at all these stages transportation is very essential. The

transportation for marketing involves the selection a particular model of transport

depending upon the speed and economy.

They mainly use road transport for carrying raw materials. For exporting

they use airways and waterways. They exported mainly through ships be cause

of less transportation cost.

Storage is an essential function at marketing. Warehousing facilitates

storage. Storage refers to the holding and preservation of gods between the time

of their production and consumption. Warehouses are large storage hours

contracted for the purpose of storing and preserving goods.

This society has its own warehouse for storing materials and finished

goods. The yarn bales received area stored off the floor count wise. The dyes

and chemicals are stored in a separate room to avoid exposure to air and

probable deterioration. It is issued on a “First-in-First out” basis. The yarn during

the wet procession is stored off the floor using bamboo stick or polythene rodes.

The processed yarn is stored safely in the designated area. The trims and

accessories are stored in the bin or racks. Packing materials are stored size wise

in a separate place. The weaving supervisor ensures proper storage of

intermediate products such as ball warp, bobbins, warp beam, and pirns at the

proper storage of pattern, cut components and finished made-ups or garments.

The export in charge ensures proper storage of final pack ages with clear

identification such as order number, package number, buyer’s name, destination

etc. The items are stored for more than one year, and it is re-Inspected to find out

the probable deterioration and to ascertaining the usability in future.

Taliparamba Arts & Science College,Kanhirangad 58

Project Report 2006 Dept. of BBM

Standardization and grading of products is essential function in marketing.

Natural raw materials require standardizations and grading in the process of

selling. Manufactured goods are standardized and graded in the process of

production itself. Standardizations refer to the establishment of certain standards

for commodity on the basis of its physical properties or quality. Standardized

goods have some quality from who ever they are bought. Standardization and

grading facilitates selling by description and sample. Cost of advertising and

sales promoting will be less standardized goods.

Package

Packaging is the out of designing and creating proper packages for

different products. A package is wrapper or container in which a product is

concluding for the purpose of sale. The main advantages of packaging are;

1. Packaging protects the goods from deterioration, expose etc during

transport, storage and use.

2. It helps to identify the product by the brand name and re collect the name

while purchasing.

3. Packaging indicates nature, weight, content etc of the product. This

provides an assurance to the customer about quality, weight etc.

4. Packaging attracts the attention of the buyers and acts as an advertisement.

5. Packaging facilities handling and use of product. This method o fusing the

product is sometimes indicated on the package.

6. Packaging helps branding as the brand name can be printed.

Taliparamba Arts & Science College,Kanhirangad 59

Project Report 2006 Dept. of BBM

STANDARD PACKING INSTRUCTIONS OF KWCS

Fabrics:

1. Roll the fabrics in paper width 61’ length and 1’ diameter.

2. Cover the fabrics in polyethylene sheet.

3. Cover the fabrics in far paper (Craft paper).

4. Pack each roll in polyethylene bags.

5. Strap two rolls tightened.

6. Cover the rolls with water paper and far paper and gunny fabrics.

7. Mark bale number. Party Name, address etc.

8. Add silica gel into bale pieces while packing.

Made-ups/cushion covers:

1. Put each pieces in polyethylene bags.

2. 10 pieces into master bags.

3. 4 Master bags into 7 ply cartons.

4. Make the cartons with number and party’s name.

5. Ad silica gel in master bags and in cartons.

Sofa case and other made-ups:

1. Bundle 5 or 10 pieces required together to one polyethylene bag.

2. 2 master bags into 7 ply cartons.

3. Mark the carton with number and party’s name.

4. Add silica gel in each master bag.

Brand Name

Branding is a marketing technique. In the society the brand name is used

in all products. Their brand name is “WEAVECO”. The products of the society

are very familiar and attractive in local market and international market.

Taliparamba Arts & Science College,Kanhirangad 60

Project Report 2006 Dept. of BBM

Advertisement

Advertising is one of the major promotional tool in marketing. Advertising is

the any paid form of non-personal presentation and promotion of ideas, goods

and services by an identified sponsor. The advertising increases the demand of

the products.

They mainly used advertisement medias are newspapers, magazines and

other published materials. The publications of co-operative and other

organizations, souvenir published during festival seasons and other cultural

events are the main media of advertisement of the society. They are selling

products directly or through middlemen.

Taliparamba Arts & Science College,Kanhirangad 61

Project Report 2006 Dept. of BBM

CHAPTER VIII

PERSONNEL DEPARTMENT

Taliparamba Arts & Science College,Kanhirangad 62

Project Report 2006 Dept. of BBM

PERSONNEL DEPARTMENT

The success of modern business organization is heavily dependent upon

the contribution made by employees as they perform the various tasks to which

they are assigned. Organizations tend to be successful when employees are

satisfied and productive in performing their tasks.

The term ‘personnel’ refers to body of persons employed in an

organization, factory, office etc. personnel management, therefore means

management of people employed in an organization. In this sense, personnel

management is related to the staffing function of management.

The basic objectives of a personnel department is to assist the

management to produce and distribute goods and service by creating, retaining a

workforce with the ability and motivation to accomplish the objectives of the

organization.

The importance of personnel management is increasingly realized in these

days, especially, in business and industry. The problems in spite of increasing

automation, the future of mankind depends on the effective utilization of human

resources. That is whey in modern industry a separate department is developed

for managing the human resources.

The personnel department is responsible for the execution of policies

regarding selection, employment, transfer and discharge of workers and payment

of wages to them. Different departments to the personnel department send

requisitions for placement of workers. The personnel department then initiates

actions in selecting personnel either locally or advertisement in newspapers.

Personnel management is an extension of general management that

promotes and stimulates every employee to make all contribution to the purpose

Taliparamba Arts & Science College,Kanhirangad 63

Project Report 2006 Dept. of BBM

of the business. The main object of human resource department is the

accomplishment of the objectives of an enterprise. It is making an uninterrupted

supply of labour force in the organization & motivates the workforce of the

organization.

In Kanhirode Weavers co-operative society, there is a separate

specialized department for managing human resources. This department is co-

coordinated by the chief executive/secretary.

The over all control of the society is carried by board of directors. The

shareholders elect the board of directors. The boards of directors are selecting

one of the directors as a president or a vice-president.

The board of directors recruits all the office and administrative staffs. The

board of directors shall consists of not more than a members of whom 7

members are elected and at least five shall be weavers members and the

remaining two shall be nominated by the district industries officer from his staff.

The secretary shall be responsible for the executive administration of the

society Subject to the control of the president. The secretary shall be the ex-

officio treasurer and shall have the custody of all the properties of the society.

The president has a general control over all the affairs of the society.

No person shall be eligible for the post mentioned below unless he

possesses the qualifications noted against him or her.

1. Secretary or manager : SSLC (Eligible for college course and a course of

training undergone in any of the co-operative industries)

2. Clerk A: Pass in IV form

3. Attenders A: Pass in II form

4. Peons : Literate knowing read and write.

Taliparamba Arts & Science College,Kanhirangad 64

Project Report 2006 Dept. of BBM

At the present 370 employees are working in the society. Which include

office staff, dyeing workers, weavers, winding workers, packing, sales, designing

and stitching workers. Majority of the society employees are womens. There by

ensuring the economic freedom of major household in around the locality.

Number of Employees in KWCS

Working Area No. of Workers

Office 15

Dyeing 16

Weaving 230

Winding 79

Packing 9

Sales 7

Designing 2

Stitching 12

All the employees working in the organization to undertake the specified

duties are competent to undertake the job on the basis of education, training,

skills and experience.

This society provides appropriate training to the employees as per the

requirements. The Chief Executive or Secretary maintains the records of

employees.

The head of the department conduct periodical meeting to create

awareness, relevance and importance of their activities towards the achievement

of quality objectives.

Wage Structure:

For staff : Salary + D A

For workers : Piece rate + D A

Taliparamba Arts & Science College,Kanhirangad 65

Project Report 2006 Dept. of BBM

Benefits to Workers

Apart from the actual wages, the society provides the following benefits to

its workers.

Contributory provident Fund 12%

Bonus 8.33-20%

Casual leave wages 5%

Medical Allowances 5% (Approximate slab system-

Maximum 6%)

Loom maintenance/Allowances 3%

Gratuity 5%

Festival Holidays wages 5% (13 days Avg. wags)

And the society also provides maternity benefits.

Incentive schemes

Apart from the above benefits, the society had implemented its own

welfare fund scheme and Employee State Insurance (ESI) scheme for the

benefits of the workers and employees.

Towards the fund, the society shall collect from workers @ Rs 4/- per

month and society shall be paying Rs 16/- per month per worker. Both these

contributions were deposited in the bank A/c. The interest accrued are also

credited in the same A/c. 10% of the Net profit of the society are also credited to

this A/c. Out of these, the society provide 6% production incentives to

workers.Out of these benefits, the society provides various financial assistance to

its workers. They are as follows.

1) Financial assistance to meet the educational expenses of workers

children.

Taliparamba Arts & Science College,Kanhirangad 66

Project Report 2006 Dept. of BBM

Pre Degree/Diploma - Rs. 500/ Year

Graduation - Rs 750/ Year

Post Graduation - Rs 1000/ Year

Medical/Engineering - Rs 2000/ Year

2) Financial assistance to meet the funeral, when the workers, or their family

members die.

3) Retirement Benefits:

When a worker retire from service, after, completing 20 years of ser vice

and after attaining the age of 55 years, then the workers are entitled to get

a lump sum amount of Rs. 5000/- from the fund.

4) The society also provides medical assistance to its employees.

Bonus

The society gives bonus to its workers and employees in festival time. The

management in a discussion determines the rate of bonus payable with trade

union representatives. In the last year, the society provide 20% bonus to its

employees.

Leaves

Every employee of the society shall be entitled to casual leave not

exceeding 15 days in a year. Every employee of the society shall be entitled to

sick leave on any reasonable ground up to 18 days of every 12 months of his

service.

The secretary shall be authority competent section casual leave to other

employee of the society and the president shall be the authority competent to

sanction of causal leave to the secretary and privilege leave to all the employees

including the secretary. No employee of the society shall canvassing or otherwise

use his influence in any way in the election of office bearers of the institution in

which they are employed.

Taliparamba Arts & Science College,Kanhirangad 67

Project Report 2006 Dept. of BBM

Promotion

Promotion is the upward reassignment in an organizational hierarchy

accompanied by increased responsibility, enhanced status and usually with

increased income.

In Kanhirode Weavers Co-operative Society, the promotion of the

employees is base don seniority.

Time Schedule

Office Time : 9 AM to 5.30 PM

Working Time : 8.30 AM to 6 PM

In this schedule includes one-hour lunch break and half hour tea break.

Trade Union

Trade union is a continuous association of wage earners for the purpose

of maintaining and improving the conditions of their working life. In the company,

employee-employer relationship is very cordial. The trade union influence

industrial democracy, morale and productivity. The workers and staff of the

company formed their own unions to protect their interest.

In this society there are mainly two trade unions. They are;

1. Kerala Co-operative Employees union (KCEU)

2. Handloom Workers Union (HWU)

These two trade unions are affiliated to CITU. Since there is only one trade

union. So there is no scope for interunion revelry.

Taliparamba Arts & Science College,Kanhirangad 68

Project Report 2006 Dept. of BBM

FUNCTIONS OF PERSONNEL DEPARTMENT

The personnel department performs various functions in an organization.

The personnel function is concerned with the procurement, development,

compensation, integration and maintenance of the personnel of an organization

towards the accomplishment of the organizations major goals and policies.

The important functions of personnel department are as follows.

1) Procurement of personnel

This includes manpower planning, recruitment, selection, vocational

guidance, and placement of the right people for various jobs in the organization.

2) Development of personnel.

This is concerned with the increase of workers skill through education and

training, necessary for efficient job performance, it is concerned with forming

sound promotion policy, determination of the basis of promotion and making

performance appraisal also came under the personnel department function.

3) Compensation

Compensation to the employees in the form of wages, salaries, and bonus

assumes great significance, as remuneration is probably the best motivation for

workers to perform the jobs assigned to them. Implementation of incentive and

premium bonus plans and policies.

4) Integration

The personnel department has to reconcile or integrate individual and

organizational objectives through sound industrial relations. The measures for

Taliparamba Arts & Science College,Kanhirangad 69

Project Report 2006 Dept. of BBM

promoting industrial relations include industrial discipline, maintenance of