Professional Documents

Culture Documents

Data Sheet - Railcar Unloader

Uploaded by

carlawtCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet - Railcar Unloader

Uploaded by

carlawtCopyright:

Available Formats

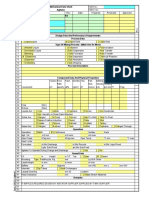

GRINDING MILL DATA SHEET DATA SHEET No.

Rev

TANDEM ROTARY RAILCAR DUMPER Date

By

Client: Chkd

Project: Project No. Appd

44 VENDOR DATA (Vendor to complete or modify)

45 BALL MILL DETAIL Car Details

46 Manufacturer Car Types

47 Supplier Car Types

48 Mill Type Weight of Car Gross (Maximum)

49 Model No. Weight of Car Tare

50 Ball Mill Motor Size (kW) Length of Car over Coupler

51 Ball Mill Nominal Power Draw (kW) Car Height

52 Ball Mill Maximum Power Draw (kW) Car Width

53 Estimated Ball Mill Size (diameter and length in feet) Discharge End Bearing Fixed or Floating

54 Effective Grinding Legth (mm) Quantity of Seals

55 Working Mill Volume (m3) Seal Type

56 Maximum Volumetric Load (%) Oil Cooler Manufacturer

57 Maximum Volumetric Ball Load (% ) Oil Cooler Size

58 Bearing Lubrication System Type Oil Cooler Cooling Capacity

59 Bearing Lubrication Oil Reservoir Size Number of Oil Heaters

60 High Pressure Lubrication Oil Flow (m3/h) Heating Capacity (kW)

61 High Pressure Lubrication Oil Pressure (kPa) Number of Cradles

62 High Pressure Lubrication Oil Pump Type Ring Gear Manufacturer

63 Number of High Pressure Oil Pumps Ring Gear Type (Cast/Forged)

64 Low Pressure Lubrication Oil Flow (m3/h) Ring Gear Mounting Method

65 Low Pressure Lubrication Oil Pressure (kPa) Pinion Manufacturer

66 Low Pressure Lubrication Oil Pump Type Gear Reducer Manufacturer

67 Number of Low Pressure Oil Pumps Gear Reducer Model Number and Type

68 Gear Spray System Manufacturer

69 Gear Spray System Type

70 Feed End Support Bearing Description

71 Feed End Bearing Type

72 MATERIALS CONSTRUCTION

73 Shell Number of Pinions

74 Feed End Type of Pinion

75 Discharge End Number of Pinion Teeth

76 Feed End Trunnion Face Width (mm)

77 Discharge End Trunnion Durability Factor

78 Shell Liner Strength Factor

79 Feed End Trunnion Liner BHN of Pinion teeth

80 Discharge End Trunnion Liner Shell Liner Plate Thickness (mm)

81 Feed End Bearing Shell Lifter Thickness (mm)

82 Discharge End Bearing Feed End Liner Plate Thickness (mm)

83 Cradle Feed End Lifter Thickness (mm)

84 Liner Bolts Discharge End Liner Thickness (mm)

85 Feed Chute Discharge End Liner Lifter Thickness (mm)

86 Feed Chute Liners Feed End Trunnion Manufacturer

87 Discharge Screen Feed End Trunnion Thickness (mm)

88 Feed End Liners Feed End Trunnion Inside Diameter (mm)

89 Liner Backing Material Weight of Feed End Trunnion (kg)

90 Corner Filling Ring Discharge End Trunnion Manufacturer

91 Trommel Screen Panels Discharge End Trunnion Thickness (mm)

92 Ring Gear Material Discharge End Trunnion Inside Diameter (mm)

93 Pinion Material Weight of Discharge End Trunnion (kg)

94 Gear Guard Material Discharge End Trunnion Liner Manufacturer

95 CONSTRUCTION Discharge End Trunnion Liner Thickness (mm)

96 Shell Manufacturer Corner Filling Ring Max. Thickness (mm)

97 Number of Shell Sections Total Weight of Liners (kg)

98 Shell Thickness (mm) Liner Backing Thickness (mm)

99 Weight of Shell (kg) Liner Backing Thickness (mm)

100 Feed End Manufacturer Feed End Bearing Size (mm, DIA x Length)

101 Number of Feed End Sections Discharge End Bearing Size (mm, DIA x Length)

102 Feed End Thickness (mm) Number of Bolt Holes on Shell

103 Weight of Feed End (kg) Number of Bolt Holes on Feed End

104 Discharge End Manufacturer Number of Bolt Holes on Discharge End

105 Number of Discharge End Sections Lifting Lugs on All Sections (yes/no)

106 Discharge End Thickness (mm) Trommel Screen Size (mm, DIA x Length)

107 Weight of Discharge End (kg) Size of Removable Panels

108 Number of Ring Gear Sections Size of Screen Opening (mm)

109 Type Gear Structure Screen Open Area (%)

110 Pitch of Teeth Weight of Trommel Screen (kg)

111 Number of Gear Teeth Lubrication System Manufacturer

112 Face Width Gear Reducer Size (mm)

113 Durability Factor Gear reducer Weight (kg)

114 Strength Factor Total Weight of Mill with Liners (kg)

115 BNH of Gear Teeth

116 Location of Gear on Mill

117 Gear Guide Location

118

579881321.xlsxBall mill 2 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cat 307D Main Pump OperationDocument3 pagesCat 307D Main Pump Operationkahandawala100% (1)

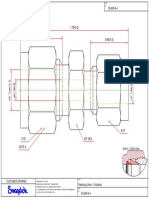

- SS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022Document1 pageSS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022TaQuangDucNo ratings yet

- Alloy-20 DS US ENDocument2 pagesAlloy-20 DS US ENmimouniNo ratings yet

- How To Become A Peaceful Parenting CoachDocument53 pagesHow To Become A Peaceful Parenting CoachcarlawtNo ratings yet

- VENDOR DATA (Vendor To Complete or Modify) : Ball MillDocument1 pageVENDOR DATA (Vendor To Complete or Modify) : Ball MillcarlawtNo ratings yet

- Data Sheet - AgitatorDocument4 pagesData Sheet - AgitatorcarlawtNo ratings yet

- Steps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1Document1 pageSteps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1carlawtNo ratings yet

- Steps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1Document1 pageSteps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1carlawtNo ratings yet

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Document59 pagesAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)vuchinhNo ratings yet

- Welding PositionDocument6 pagesWelding Positionenels77No ratings yet

- Steps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1Document1 pageSteps To Convert Autoplant Piping To Caepipe / Caesar Ii: Step 1carlawtNo ratings yet

- Ce353 CH7 PDFDocument19 pagesCe353 CH7 PDFDarlene Mae ZaraNo ratings yet

- TMA2 12 09 2021 UploadDocument3 pagesTMA2 12 09 2021 UploadG.G. PRABHATH CHINTHAKANo ratings yet

- Chittagong University of Engineering & Technology Chittagong - 4349, BangladeshDocument8 pagesChittagong University of Engineering & Technology Chittagong - 4349, BangladeshAL-AMIN AHMED MOBIN 1801015No ratings yet

- Flow Serve PDFDocument26 pagesFlow Serve PDFTushar LanjekarNo ratings yet

- Calculation Report On Bearing-Aashto-2012Document12 pagesCalculation Report On Bearing-Aashto-2012Tawfiqul IslamNo ratings yet

- FRR 500 - 500S Igm0087 - 6-CylDocument4 pagesFRR 500 - 500S Igm0087 - 6-CylMarvin White0% (1)

- Flower Duet in G Voices OnlyDocument80 pagesFlower Duet in G Voices Onlym1d0r1No ratings yet

- Signum-Technical-Guide LO SAMPLING GUIDEDocument30 pagesSignum-Technical-Guide LO SAMPLING GUIDEshirishkv100% (1)

- Modification and Development in Air CoolerDocument6 pagesModification and Development in Air CoolerSONUNo ratings yet

- CH 5 Kerja Dan EnergiDocument21 pagesCH 5 Kerja Dan EnergiDey TandirerungNo ratings yet

- Chapter 2Document27 pagesChapter 2hailegebreselassie24No ratings yet

- Lift Arm & BOB-TACH - S530 PDFDocument4 pagesLift Arm & BOB-TACH - S530 PDFeduardo chavezNo ratings yet

- Scheda Tecnica: IT-T1S Itb-T1SDocument1 pageScheda Tecnica: IT-T1S Itb-T1SITALFIL S.p.A.No ratings yet

- Is.2951.2.1965 Head Loss in Flow Through PipesDocument19 pagesIs.2951.2.1965 Head Loss in Flow Through PipeskdpgrahiNo ratings yet

- KTA19-G3A: Engine Model: Reference InformationDocument3 pagesKTA19-G3A: Engine Model: Reference InformationTeodoro Cornelius AltuveNo ratings yet

- Wafflemat Design WhitepaperDocument13 pagesWafflemat Design WhitepaperantiacidoNo ratings yet

- CondenserDocument5 pagesCondensersandeshNo ratings yet

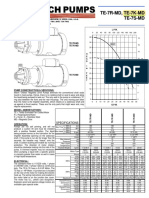

- Manual March Te-7k-MdDocument2 pagesManual March Te-7k-MdjoseNo ratings yet

- Penawaran Overhoul Engine Acera 6.4Document1 pagePenawaran Overhoul Engine Acera 6.4Aneh Bin AjaibNo ratings yet

- 1 SMDocument18 pages1 SMYogi Kawar Ganga NathNo ratings yet

- Entropy of Mixing PDFDocument16 pagesEntropy of Mixing PDFrupaliroyNo ratings yet

- Exp-7 Fatigue TestDocument5 pagesExp-7 Fatigue TestdeathesNo ratings yet

- Regolatore Aspirazione Rh38EDocument2 pagesRegolatore Aspirazione Rh38EДжон ДиллинджерNo ratings yet

- Ignition SystemDocument51 pagesIgnition SystemEyob TeklemariamNo ratings yet

- BPT 13 Balanced Pressure Thermostatic Steam TrapDocument2 pagesBPT 13 Balanced Pressure Thermostatic Steam Trapmember1000No ratings yet

- Metal Seated Ball ValveDocument12 pagesMetal Seated Ball ValvezazamoteurNo ratings yet

- Listino Velox 2011 Inglese (30-03-2011)Document39 pagesListino Velox 2011 Inglese (30-03-2011)panos320No ratings yet

- Theoretical Model of Buoyancy-Induced Heat Transfer in Closed Compressor RotorsDocument7 pagesTheoretical Model of Buoyancy-Induced Heat Transfer in Closed Compressor RotorsmhjianNo ratings yet

- Iso 2503 2009 en PDFDocument11 pagesIso 2503 2009 en PDFВикторNo ratings yet