Professional Documents

Culture Documents

Locomotives

Uploaded by

suvo das0 ratings0% found this document useful (0 votes)

81 views15 pagesThe document discusses the classification and components of electric locomotives and multiple units (EMUs) used in Indian railways. It describes how locomotives and EMUs are classified based on gauge, power supply type, and service handled. The key components of the power circuit include the pantograph, circuit breaker, tap changer, traction transformer, rectifier, smoothing reactor, and traction motors. The auxiliary circuit provides power for lighting, horns, and operating components like blowers, compressors, and exhausters using equipment such as batteries, converters, and motors.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the classification and components of electric locomotives and multiple units (EMUs) used in Indian railways. It describes how locomotives and EMUs are classified based on gauge, power supply type, and service handled. The key components of the power circuit include the pantograph, circuit breaker, tap changer, traction transformer, rectifier, smoothing reactor, and traction motors. The auxiliary circuit provides power for lighting, horns, and operating components like blowers, compressors, and exhausters using equipment such as batteries, converters, and motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

81 views15 pagesLocomotives

Uploaded by

suvo dasThe document discusses the classification and components of electric locomotives and multiple units (EMUs) used in Indian railways. It describes how locomotives and EMUs are classified based on gauge, power supply type, and service handled. The key components of the power circuit include the pantograph, circuit breaker, tap changer, traction transformer, rectifier, smoothing reactor, and traction motors. The auxiliary circuit provides power for lighting, horns, and operating components like blowers, compressors, and exhausters using equipment such as batteries, converters, and motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

• Classification of Locomotive and Electric Multiple Unit (EMU)

On Indian railways, locomotives and EMU are classified according to the:

(i) Type of services handled - Goods carrier services, Passenger service, and Mixed

traffic services.

(ii) Gauge of the railway - Broad or Meter Gauge.

(iii) Type of supply used - Alternating Current (AC) or Direct Current (DC).

Electric rolling stock is designated by three letters:

(i) First letter indicates the gauge; W is used for broad gauge and Y for meter gauge

and Z for narrow gauge.

(ii) Second letter indicates the type of supply. A is used for AC, and C is used for DC

supply.

(iii) Third letter indicates the types of service handle, 'M' is used for mixed traffic of

goods and passenger, 'G' is used for goods carrier services and, 'U' is used for EMU.

(iv) Fourth is a number which indicates the individual designs in the class.

Indian railways having been following type of rolling stocks:

(i) AC locos: WAM,, WAM, WAM,, WAG,, WAG, WAG,, WAG, and YAM.

(ii) AC EMU stock: WAU, WAU, WAU, WAU, YAU.

• Power Circuit

Power Circuit in an electric locomotive is the circuit which carries

current for the traction motors.

Power Circuit Diagram of AC Locomotive

1. OHE or Contact wire: It provides power supply to the electric

locomotives.

2. Pantograph: It collects the power from contact wire.

3. C.B. : Its main function is to disconnect the locomotive

equipment from the supply in the event of fault in the

equipment.

4. On load tap changer: It is used to change the input voltage to

the rectifier section as required by traction circuit to change

the speed /torque generated by motors.

5. Traction transformer: It is used in combination with the tap

changer to supply voltage in the high range of 15 to 25 kV. But

the normal utilization voltages are low.

6. Rectifier: It is used to convert ac input voltage to DC suitable

for traction motor.

7. Smoothing reactor: It is used to filter the rectifier output to

give smooth v/f of the dc supply for the operation of traction

motors.

8. Traction motors: It Generates mechanical power required

according to the dc supply given, for the requirement of

speed and torque.

• Equipments in Power Circuit and their Function:

(a) Circuit Breaker:

• When supply to a vehicle is given from H.V. then it is necessaryto provide a Circuit Breaker (CB).

• In 25 kV, 50 Hz, supply system, CB is provided in between pantograph and transformer.

• Its main function is to disconnect the locomotive equipmentfrom the supply in the event of fault in the

equipment.

• Its additional function is to isolate the locomotive equipment at a phase-change point in the Overhead

Equipments (OHE) such as before entry into the neutral section.

• Air blast type CB is normally used.

(b) Earthing Switch:

• Earthing switch is provided to every traction power circuit.

• The earthing switch is to be closed whenever the line maintenance is to be done on the system.

• For the maintenance of the lines, the CB is to be opened first, and then the earthing switch is closed. If by

any reason the charge is still present in the line, then it will discharge upon the ground with the help of

earthing switch.

• It is provided on additional protection to the person who is performing maintenance of the line.

• (c) Tap changer:

• Tap changers are of two types such as "on load" tap changer and "off load" tap changer.

• In the traction power circuit, mainly on-load tap changer is used. Tap changers are used to change the input

voltage to the rectifier's section as required by traction circuit to change the speed or torque generated by

motors.

• There are two methods of tap changer adopted:

(i) Keeping primary turns of the transformer unchanged but changing secondary turns by tap changer in

secondary. This is the "low voltage tap changing method".

(ii) The second way of tap changer is that by applying variable voltage to the primary. This method is

known as "high voltages tap changing".

(d) Traction Transformer:

• Traction transformer is the main equipment to the traction system. They are mounted on the locomotive as

well as mounted on the traction substation.

• They are used to step-down the high voltage of 220/132/110 kV to 25 kV operating voltage. This is done at

traction substation.

• 25 kV voltages are again step-down to working voltage levels required by the traction motors. This is done

with the help of the transformer which is mounted in the locomotive itself.

• Normally, the traction transformer is oil immersed, air cooled with forced oil circulation.

(e) Rectifier:

• The rectifier is used to convert AC supply into DC supply.

This DC supply is given to traction motors.

• For converting AC into DC, diode and thyristors use as a

rectifiers.

• Modern electric locomotives usually have at least two

rectifiers, one for power circuit called as "main" rectifiers

and other one are used for the auxiliary circuit's to the

power circuit, DC traction motors are connected and to

auxiliary circuit other necessary electrical systems are

connected.

(f) Smoothing Reactor:

• The output of the rectifiers is not a purely DC it consists of

some AC ripples (pulsating DC).

• Smoothing reactor is used to remove the AC ripples and

making rectifiers output purely DC.

• Smoothing reactor is nothing but a pair of choke coils.

• The output of the rectifiers is fed to the smoothing reactor

before feeding it to the DC traction motors.

• Equipments in Auxiliary Circuit and Their

Function:

(a) Head Light:

• The head light is provided at centre position of the locomotive. It is at the

roof level or mid-level.

• The main function as the head light is to light up the track andalso to warn

the people on the track.

• The intensity as the head light can be adjusted.

• 24V, 100/90W twin filament halogen lamp is used for a headlight.

(b) Flasher Light:

• This is used in case of emergency or special circumstance.

• It is arranged at the right side to the head light.

• Nowadays, the conventional flashers light unit is replaced by Light Emitting

Diode (LED) based flasher light unit.

(c) Horn:

• The train horn is an air horn, which serves as an audible warning device on electric locomotives.

• Its main purpose is to alert people and animal about the presence of a train, so they can clear the tracks. The

horn is also used for communication purpose.

• These horns are operated by compressed air. The air pressure is about 125 to 140 psi and it is fed from the

locomotive main air tank.

(d) Marker Light:

• In electric locomotive the head lights are always referred as "Marker light.“

• These are provided at the both ends, and are arranged above the buffers.

• The marker's light has two colors such as yellow or white and red.

• When the train is traveling, the rear side marker light is lit red and the front-side marker is lit white or yellow.

• In case of critical condition, obstructions ahead, etc. The front marker's lights are lit red.

(e) Batteries:

• Batteries are used for lighting the train, when it is in standstill condition.

• Nowadays, Lead acid and Nickel-Iron batteries are replaced by the light weight Nickel-Metal Hydride and

lithium batteries.

• Batteries should have low cost, long life and low maintenance.

• Traction batteries must be capable of withstanding wide temperature ranges from -31° to + 65⁰.

(f) Arno Convertor:

• Its main function is to convert 1 phase AC supply into 3 phases AC Basically; it is on Induction Motor (IM).

• This Three phase supply is needed for the IM used at various places such as blowers and exhausters.

• The Arno convertor is supplied by the main traction transformer.

• To start the Arno convertor, 1 phase AC supply is given to two leads of the induction motor direct while 3rd lead is

connected to supply through starting resistance and starting contactor.

• The motor start up as split phase IM and when its speed riches 90% of synchronous speed, starting resistance is

opened out by means of relay.

• The machine then pulls into synchronism and gives 3 phase output.

• Currents in the 3 phase windings are not equal; this gives unbalance voltage in the 3 phase supply obtained from Arno

convertor.

• Output voltage of Arno convertor fluctuates between 290 volts to 460 volts.

(g) Blowers:

• Blower is used for cooling various equipments such as transformer oil, cooling radiator, rectifier, smoothing

reactors, traction motors, etc.

• Nowadays, locomotive are having a complex air managements system which monitors the temperatures of

the various rotating machines in the locomotives and accordingly adjusts the flow rate through the air. This is

done with the help of blowers.

• 3 Phase motors are used for blowers supplied from Arno convertor.

(h) Exhausters:

• Exhausters are nothing but a two-speed rotary machine fittedon a locomotive to evacuate the atmospheric

pressure from the break pipe, reservoirs and break cylinders to affect the brake release.

• There are two types of exhausters: (i) Reciprocating type, (ii) Rotary type.

• It is controlled by the locomotive operator with the help of brake valve.

• Exhausters are operated by the electric motors or directly by the diesel engines.

• It is also called as ejectors.

• It is used for electric traction for vacuum braking system in the operation of vacuum brakes, Exhauster is

needed to produce vacuum.

(i) Compressors:

• These are used to provide the compressed air supply on the locomotive for various applications like operation

of breakers, Horn, Air blast, CB pantograph contractors etc.

• The compressed air is produced by the air compressor about 1000 liters per minute. At 9kg/cm2 pressure.

• There are various types of compressors such as direct power driven compressors, Belt driven compressors

and mechanically driven compressors.

(j) Selsyn Transformer:

• Selsyn is an electro-mechanical device used for the easy transmission of angular data between two or

remoter points.

• Its construction is much more like, electric motor primary winding. It is fixed in the motor and is excited by

alternating current.

• Electromagnetic induction current flows in the three star connected secondary winding. Which are fixed at

120° to each other on the stator.

• The selsyn transformer supplies 115 VAC supply to the system which transmits the position of the tap changer

to the control desk for indication after stepping down 230V AC supply.

You might also like

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Project Report On Static Converter For RailwayDocument20 pagesProject Report On Static Converter For RailwayScampy RamNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- EmuDocument18 pagesEmuKundan KumarNo ratings yet

- Interview QuestionDocument49 pagesInterview Questionshubha christopherNo ratings yet

- Engineering QuestionsDocument31 pagesEngineering QuestionsRizwan ShahidNo ratings yet

- Intenship in Traction Motor ShedDocument16 pagesIntenship in Traction Motor ShedPallav PantNo ratings yet

- Electric Traction SystemDocument42 pagesElectric Traction SystemBabu YadavNo ratings yet

- MotorDocument32 pagesMotorDeke Elektronik IndustriNo ratings yet

- CCCCCCC: C C C C CCCC CDocument18 pagesCCCCCCC: C C C C CCCC ChumrahulNo ratings yet

- Electric Traction System: Presented byDocument42 pagesElectric Traction System: Presented byrajelec100% (11)

- Train Lighting System and Power Generation .Document24 pagesTrain Lighting System and Power Generation .sushmaNo ratings yet

- UtcDocument8 pagesUtcمحمدضيأ الدينNo ratings yet

- Electric Traction SystemDocument23 pagesElectric Traction SystemAniket LikharNo ratings yet

- Introduction To Electric Power System and A. C. SupplyDocument141 pagesIntroduction To Electric Power System and A. C. Supplyteza maruNo ratings yet

- Lecture No 5Document27 pagesLecture No 5Walid salamaNo ratings yet

- EpgtDocument43 pagesEpgtdarshan arkasaliNo ratings yet

- Mechatronics MotorsDocument39 pagesMechatronics MotorsSanskar AgrawalNo ratings yet

- PM (Dr. S.N.Saxena)Document45 pagesPM (Dr. S.N.Saxena)Rk SkNo ratings yet

- DC Power DistributionDocument24 pagesDC Power DistributionZay YarNo ratings yet

- Electric Traction RailwaysDocument34 pagesElectric Traction Railwayssaurabh8435100% (1)

- TractionsDocument6 pagesTractionsShashidhar KarravulaNo ratings yet

- IntroductionDocument29 pagesIntroductionmanishachouhan8319No ratings yet

- Presentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarDocument70 pagesPresentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarAnonymous ExWAN2xjFJ100% (1)

- Energy Efficiency in Electrical UtilitiesDocument82 pagesEnergy Efficiency in Electrical Utilitiesmanorajcv100% (1)

- Electrical Engineering Interview Guide BookDocument8 pagesElectrical Engineering Interview Guide BookshubhampattiNo ratings yet

- Chapter 3 - DC Chopper (Part A)Document20 pagesChapter 3 - DC Chopper (Part A)andersonNo ratings yet

- Power Electronics: P.Karthikeyan, BE (EEE), SmecDocument19 pagesPower Electronics: P.Karthikeyan, BE (EEE), SmecKrishnamoorthy AyyasamiNo ratings yet

- LECTURE 4 Transformers 02Document156 pagesLECTURE 4 Transformers 02MINH Nguyễn TuấnNo ratings yet

- Answer QB 2Document22 pagesAnswer QB 2Goud SannyNo ratings yet

- Advance Sub-Station DesignDocument42 pagesAdvance Sub-Station Designedward agbanlogIINo ratings yet

- TOPIK1 - 27.9.2021 Versi 2 BARUDocument45 pagesTOPIK1 - 27.9.2021 Versi 2 BARUtiagoNo ratings yet

- Expt No.6 Electric TractionDocument7 pagesExpt No.6 Electric TractionPriyanka MauryaNo ratings yet

- Project Documentation For Multilevel InvertersDocument89 pagesProject Documentation For Multilevel InvertersAnonymous hm7nSy1ebNo ratings yet

- Jaipur National University, JaipurDocument30 pagesJaipur National University, JaipurPatel DipenNo ratings yet

- Utilization of Electrical Energy: CHAPTER 4: Electric Traction L-4-2Document25 pagesUtilization of Electrical Energy: CHAPTER 4: Electric Traction L-4-2Frozen BoyNo ratings yet

- Electromechanical Systems CH 5Document46 pagesElectromechanical Systems CH 5fabrice mellantNo ratings yet

- Electric Locomotive, Diesel Electric and Hybrid LocomotiveDocument9 pagesElectric Locomotive, Diesel Electric and Hybrid LocomotiveKeerthie Hewavithana100% (1)

- Electric EngineDocument4 pagesElectric EngineDiwakar PayasiNo ratings yet

- Presentation On North Western Railway Ajmer (Rajasthan)Document38 pagesPresentation On North Western Railway Ajmer (Rajasthan)hariom77777No ratings yet

- Electrical - Module 3 - Part 66 - DAY 24Document32 pagesElectrical - Module 3 - Part 66 - DAY 24irene pafraNo ratings yet

- Electrical Energy Utilisation and Management - Electric TractionDocument42 pagesElectrical Energy Utilisation and Management - Electric Tractionmadhu balanNo ratings yet

- KronDocument4 pagesKronDeepak Singh100% (1)

- CH - 5 Synchronous MachinesDocument28 pagesCH - 5 Synchronous MachinesNAHOM ANTENEHNo ratings yet

- 1.3 Block DiagramDocument29 pages1.3 Block DiagramAlphaBravoNo ratings yet

- Ece Vii Power Electronics (06ec73) SolutionDocument77 pagesEce Vii Power Electronics (06ec73) SolutionVijay SaiNo ratings yet

- Train LightingDocument5 pagesTrain Lightingsanket100% (1)

- Electric Traction - 1 PDFDocument46 pagesElectric Traction - 1 PDFbbbbbbbNo ratings yet

- Traction With Speed Time GraphDocument5 pagesTraction With Speed Time GraphJack Ansari100% (2)

- Electric Drives Part 2Document18 pagesElectric Drives Part 2Srujana TallaNo ratings yet

- Module 1 Notes 2Document36 pagesModule 1 Notes 2canusha820No ratings yet

- Chapter 2Document46 pagesChapter 2Syazwan HafidziNo ratings yet

- GasDocument29 pagesGasKedar patilNo ratings yet

- Vocational Training WbsetclDocument55 pagesVocational Training WbsetclAbhishek Jain100% (2)

- Actuation SystemsDocument52 pagesActuation SystemsJkl MahanthNo ratings yet

- SubstationsDocument33 pagesSubstationsTabi4every1100% (1)

- EE6009 PERES Unit IIIDocument301 pagesEE6009 PERES Unit IIIrivehappy1996No ratings yet

- Mesin Arus SearahDocument23 pagesMesin Arus SearahboypardedeNo ratings yet

- DC & AcDocument2 pagesDC & AcVedanta NairNo ratings yet

- Baderia Global Group of Institutions, Jabalpur: "Wdp4 Locomotive"Document40 pagesBaderia Global Group of Institutions, Jabalpur: "Wdp4 Locomotive"James StephenNo ratings yet

- Cam Tech Hitachi TM El Locoeng 05Document58 pagesCam Tech Hitachi TM El Locoeng 05santhosh kumarNo ratings yet

- A Project Report On AC DC DRIVE AND SPEE PDFDocument33 pagesA Project Report On AC DC DRIVE AND SPEE PDFkarpal singhNo ratings yet

- Uee Unit 4Document17 pagesUee Unit 4narendra kumarNo ratings yet

- Selection of The Optimal Gearbox Layout For An Electric VehicleDocument14 pagesSelection of The Optimal Gearbox Layout For An Electric VehicleSwati NikamNo ratings yet

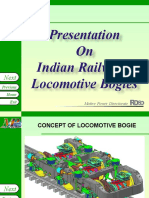

- PRESENTATION of IR LOCOMOTIVE BOGIESDocument38 pagesPRESENTATION of IR LOCOMOTIVE BOGIESAMAN GUPTANo ratings yet

- FICHA TECNICA HYSTER E80-120xn-Tech-GuideDocument8 pagesFICHA TECNICA HYSTER E80-120xn-Tech-Guideblurhe2023No ratings yet

- Repert On Bhel JagdishpurDocument36 pagesRepert On Bhel JagdishpurAnkitGargNo ratings yet

- Training ManualDocument258 pagesTraining ManualMike Finazzi83% (6)

- FINAL BLACK BOOK Latest PDFDocument106 pagesFINAL BLACK BOOK Latest PDFRavi NagNo ratings yet

- Regenerative Braking in Trains MinorDocument25 pagesRegenerative Braking in Trains Minormanish guptaNo ratings yet

- DLW Training Report, VaranasiDocument93 pagesDLW Training Report, VaranasiDigvijay Singh40% (5)

- Address Details For UploadingDocument93 pagesAddress Details For UploadingJigisha VasaNo ratings yet

- Overview of Hybrid Excitation Synchronous Machines TechnologyDocument10 pagesOverview of Hybrid Excitation Synchronous Machines TechnologyMurat Erhan BalciNo ratings yet

- Utilization of Electrical EnergyDocument4 pagesUtilization of Electrical Energykartheek4270% (1)

- A Seminar On Electric CarDocument17 pagesA Seminar On Electric CarHimanshu YadavNo ratings yet

- TC 142Document48 pagesTC 142anuj singhNo ratings yet

- EV100-200LX Controller and Handset TroubleshootingDocument70 pagesEV100-200LX Controller and Handset TroubleshootingTan Jai100% (2)

- Traction Power System Study For Metro-North RailroadDocument20 pagesTraction Power System Study For Metro-North Railroad曾乙申100% (1)

- TractionDocument26 pagesTractionYogesh GurjarNo ratings yet

- Mini Project PDFDocument25 pagesMini Project PDFKarim Faisal0% (1)

- Wp2300 SeriesDocument146 pagesWp2300 Serieskhin jaa Alipar100% (4)

- Chapter 1 - General Requirements: Part - Iv Lifts PagesDocument56 pagesChapter 1 - General Requirements: Part - Iv Lifts PagesNidas SameeraNo ratings yet

- Financial Ratio Analysis of B.H.E.L: Project Submitted On Completion of Summer InternshipDocument66 pagesFinancial Ratio Analysis of B.H.E.L: Project Submitted On Completion of Summer Internshipjoshhere14150% (2)

- Powerpak SEM Manual Rev N4Document62 pagesPowerpak SEM Manual Rev N4Renzo De PisisNo ratings yet

- Under The Guidance Of: Prof. Ajoya Ku Pradhan HOD Dept. of Electrical EngineeringDocument27 pagesUnder The Guidance Of: Prof. Ajoya Ku Pradhan HOD Dept. of Electrical Engineeringishfaq222100% (1)

- Fully Electric Stacker Brochure.Document6 pagesFully Electric Stacker Brochure.gopinadhNo ratings yet

- Industrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationDocument47 pagesIndustrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationAkash KumarNo ratings yet

- Drive SystemsDocument17 pagesDrive SystemstchepssilveiraNo ratings yet

- 9852 1696 01 Maintenance Schedules ROC F7Document53 pages9852 1696 01 Maintenance Schedules ROC F7eko sunaryo100% (2)

- TIP Assignment 2Document16 pagesTIP Assignment 2HARSH MATHURNo ratings yet